Method for eliminating unevenness of LED friction grooves

A uniform and grooved technology, applied in the LCD field, can solve the problems of uneven friction grooves, unguaranteed yield rate, low production efficiency, etc., to ensure product yield and quality, improve production efficiency, and be easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

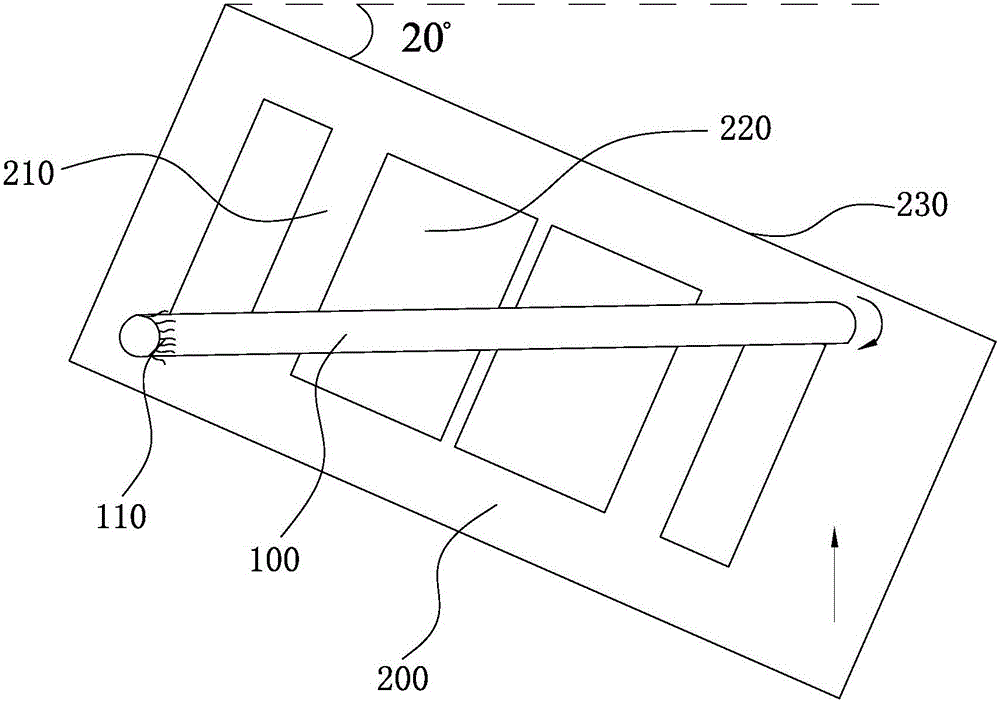

[0022] Such as figure 1 As shown, it is a scheme diagram of a method for eliminating uneven friction grooves of an LCD according to an embodiment of the present invention.

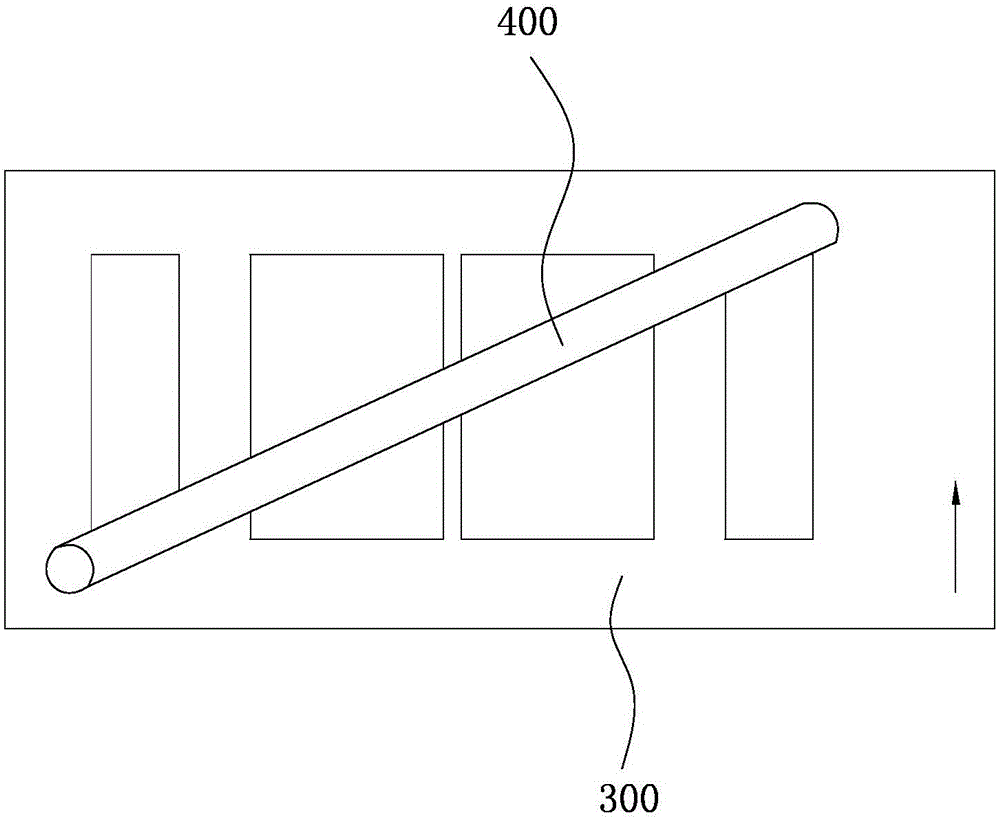

[0023] A method for eliminating the unevenness of LCD friction grooves. The ITO glass substrate 200 coated with a PI layer is rubbed and oriented by a friction roller 100. The ITO glass substrate 200 has a PIN pin (stitch) area 210, an electrode pattern area 220 and a side 230, including the steps of:

[0024] Step S10, attaching the friction roller 100 to the surface of the ITO glass substrate 200, the axis of the friction roller 100 is parallel to the side 230;

[0025] Step S20, rotating the friction roller 100 along the surface of the ITO glass substrate 200, so that the axis of the friction ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com