Patents

Literature

36results about How to "High luminous output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

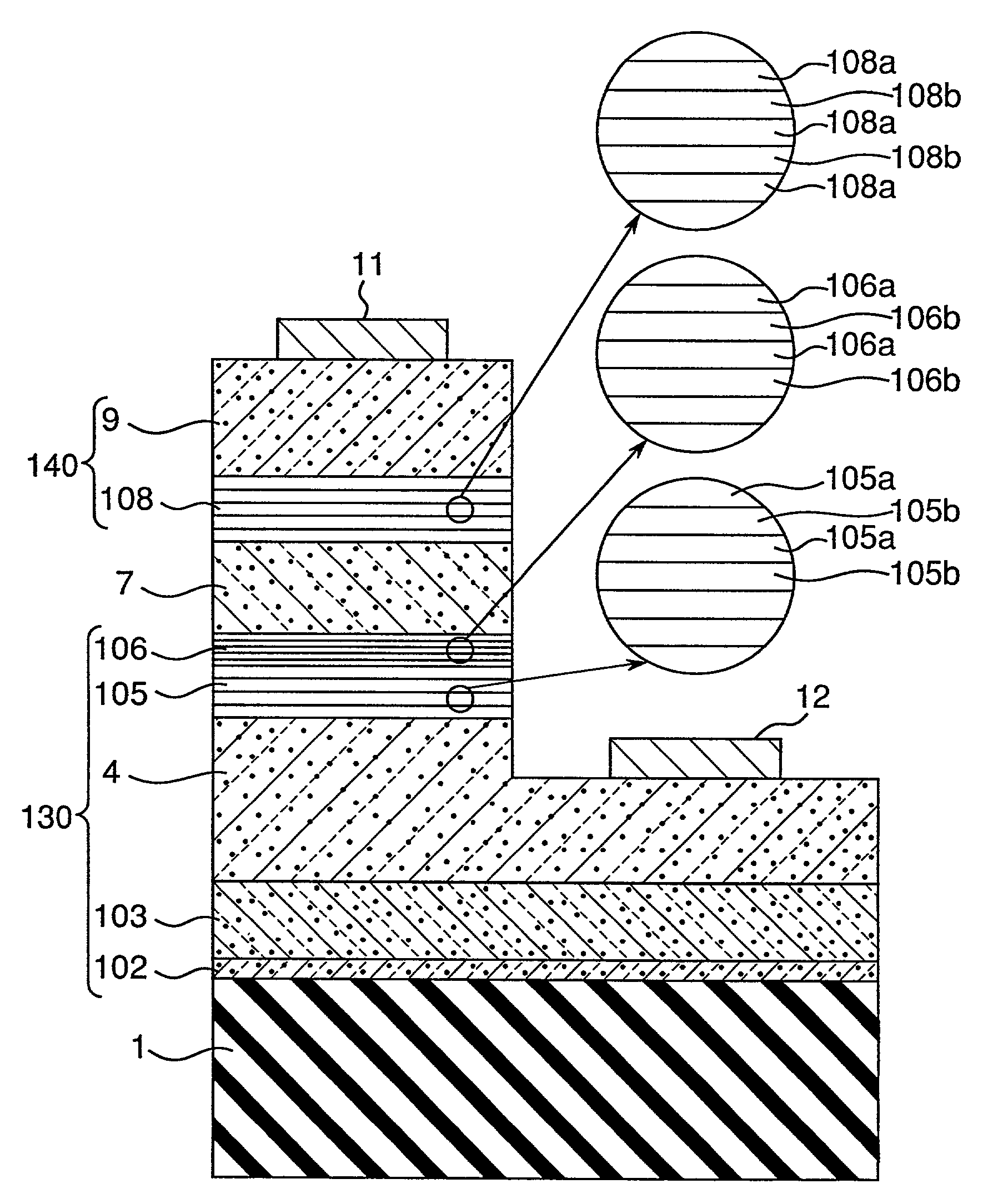

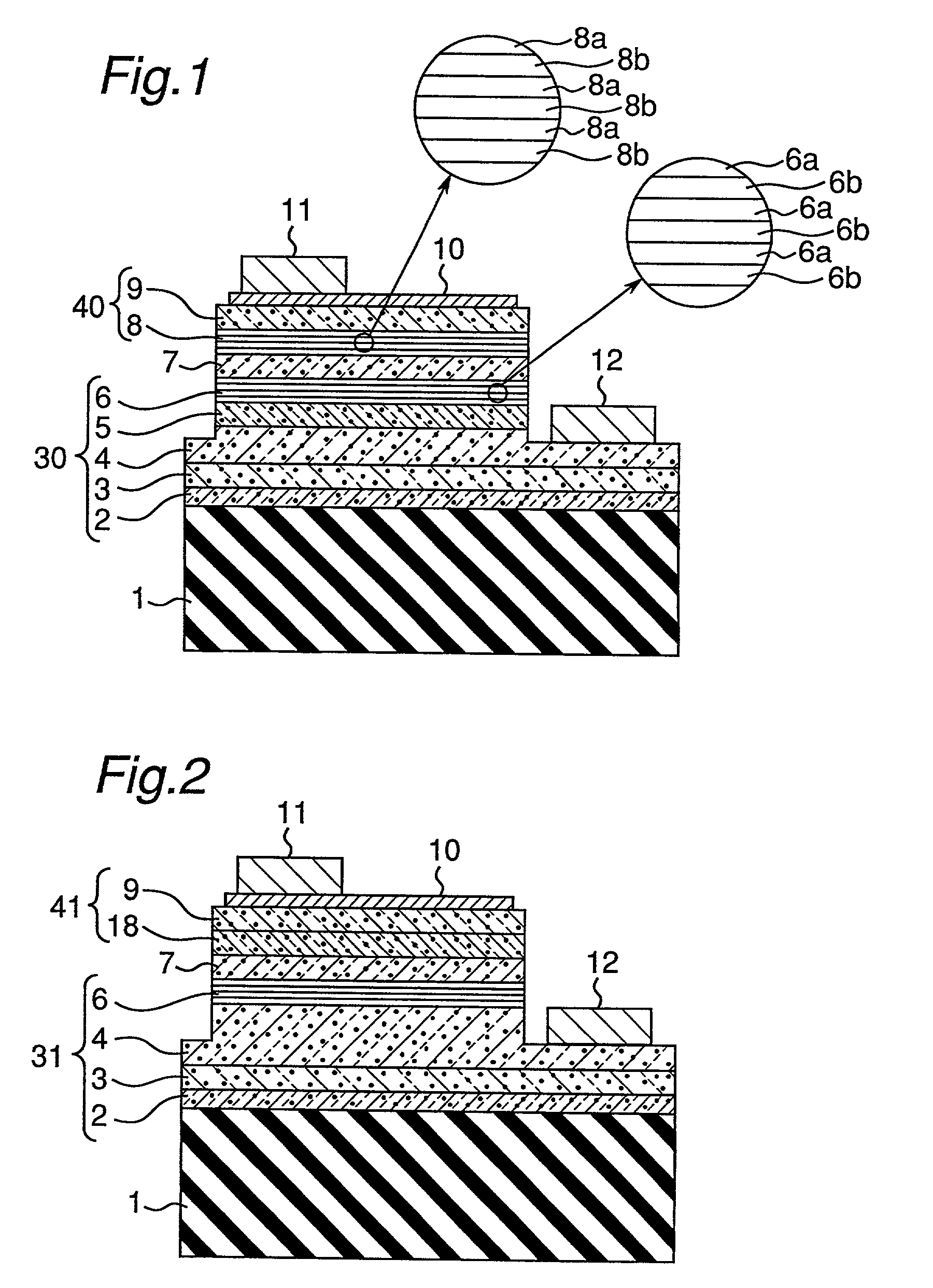

Nitride semiconductor device

InactiveUS7193246B1Light emission efficiencyHigh luminous outputOptical wave guidanceLaser detailsMultiple quantumNitride semiconductors

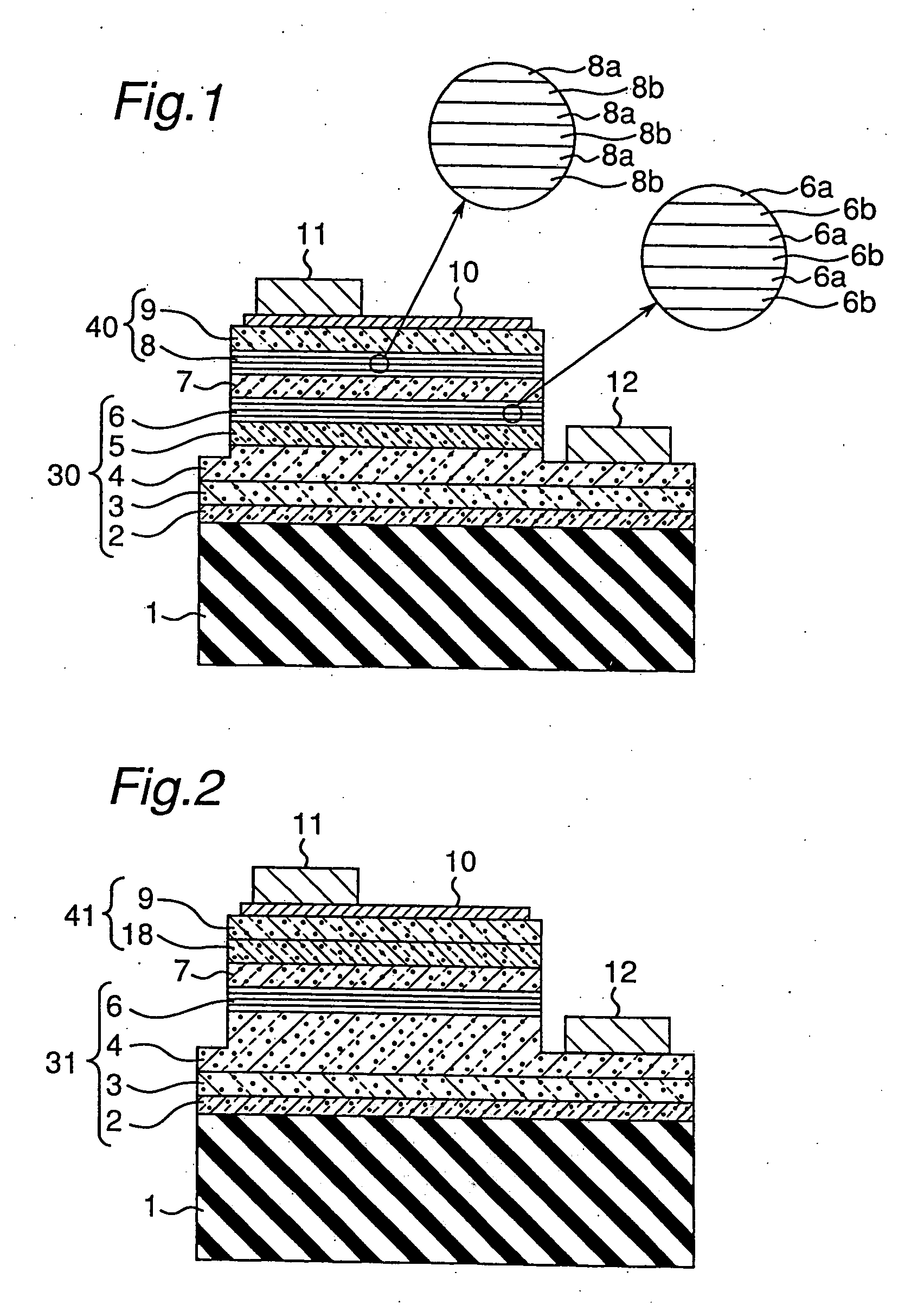

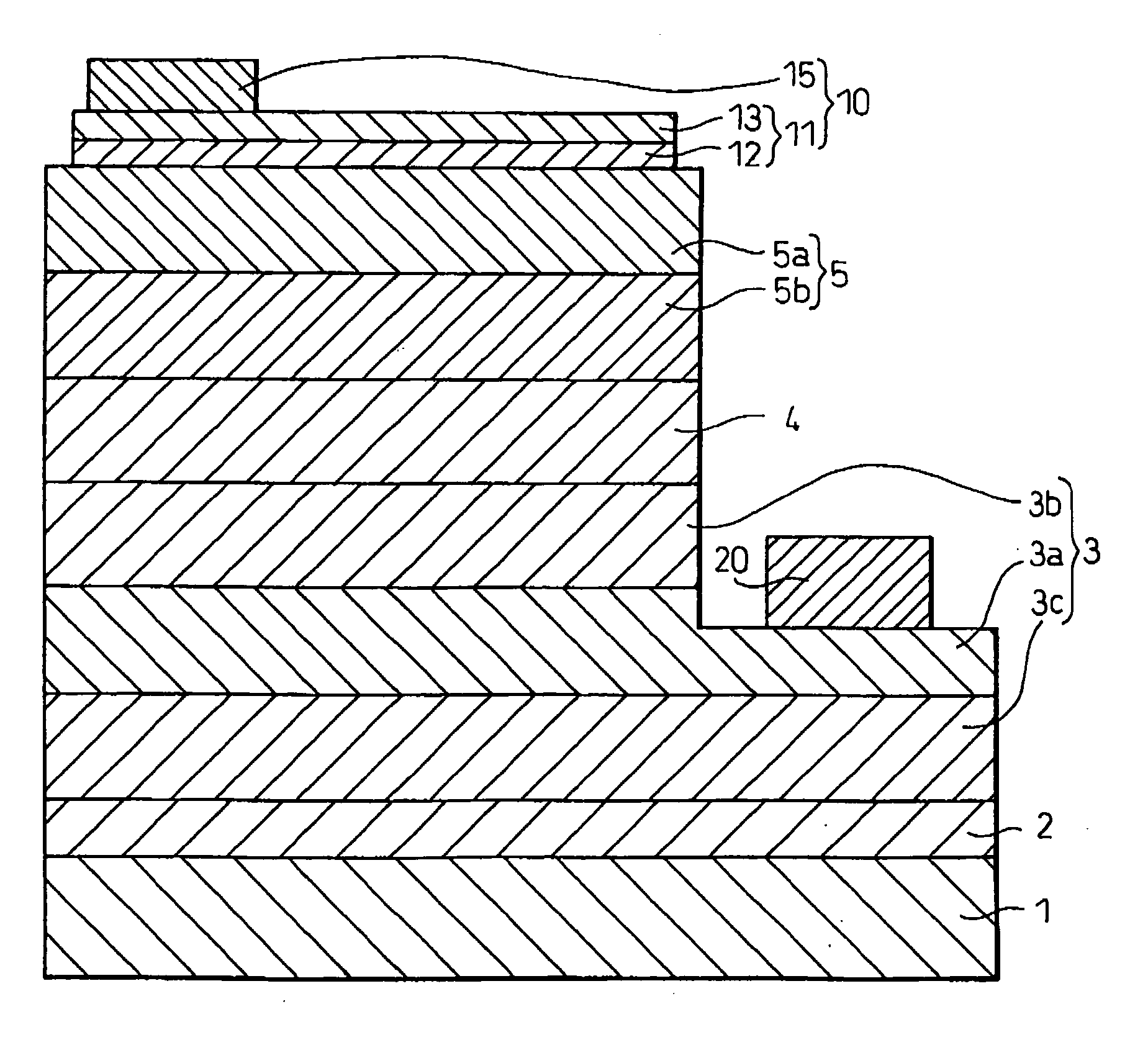

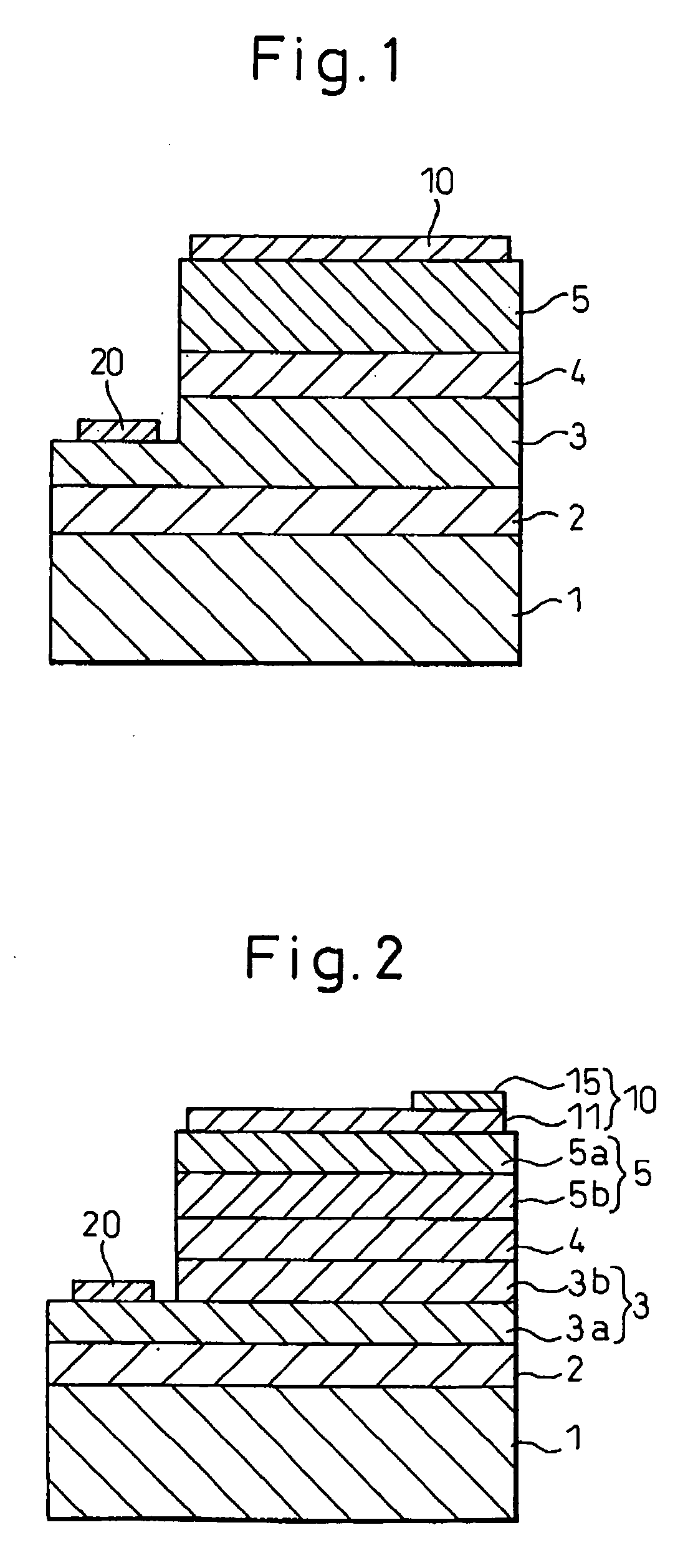

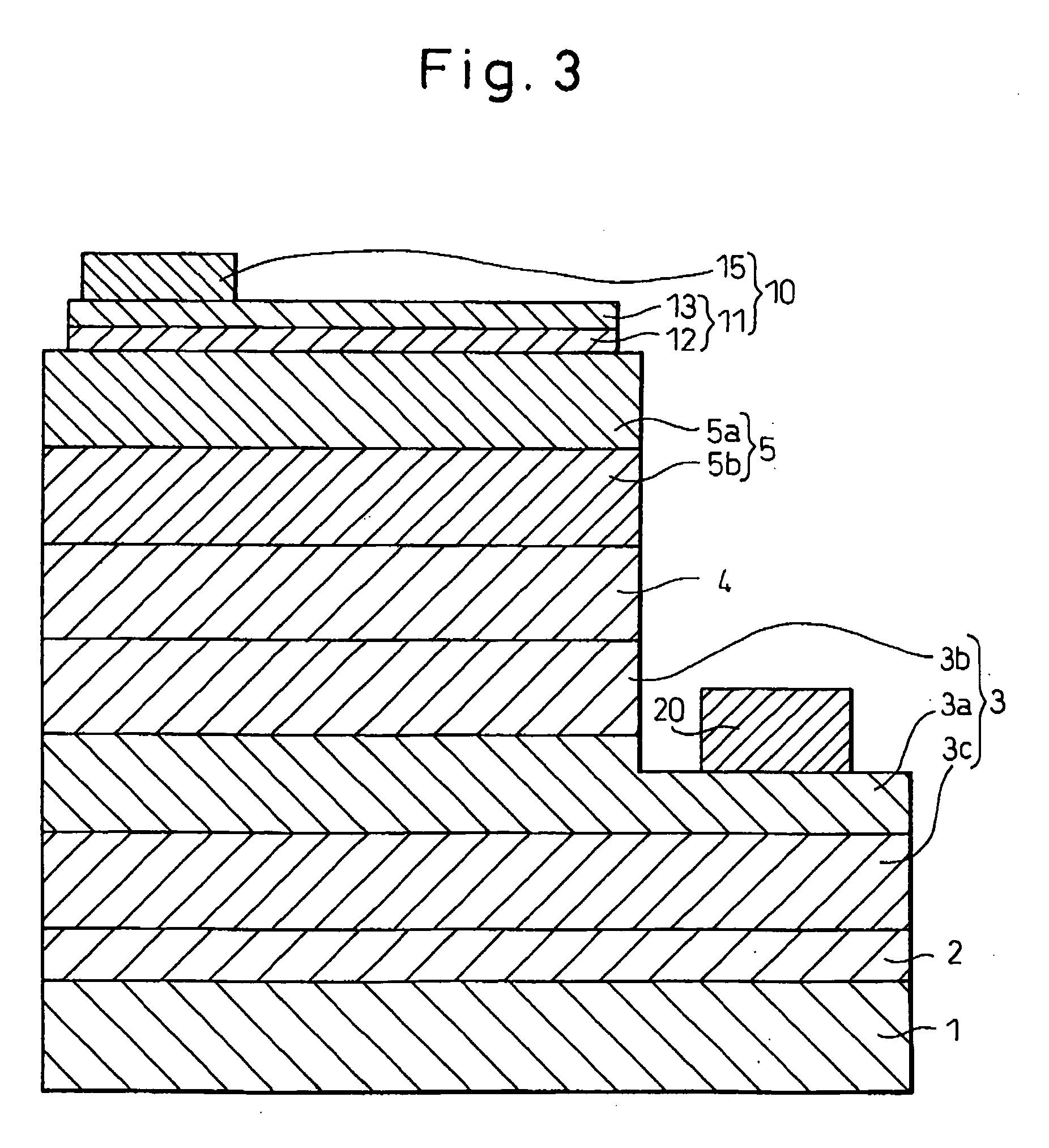

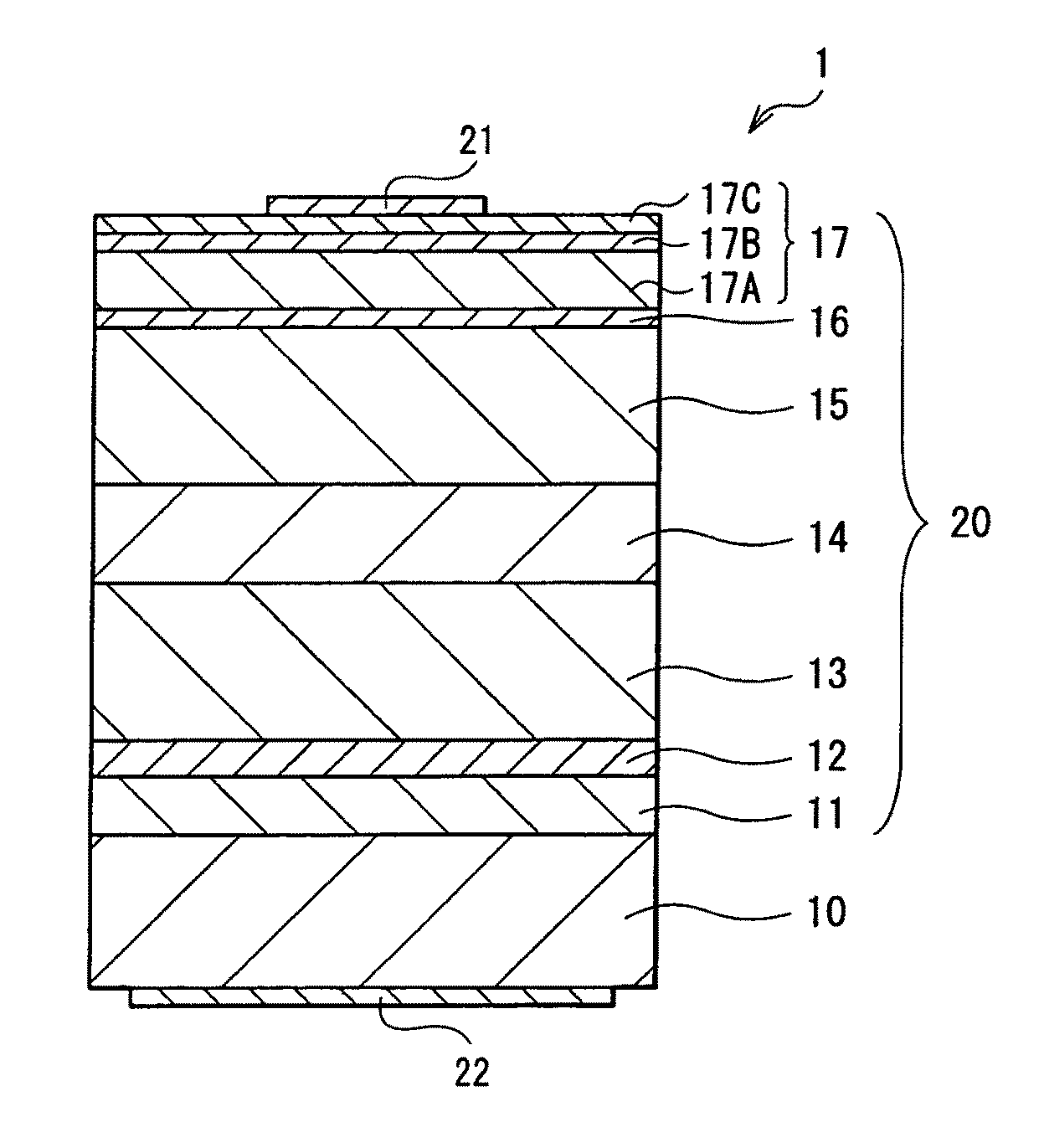

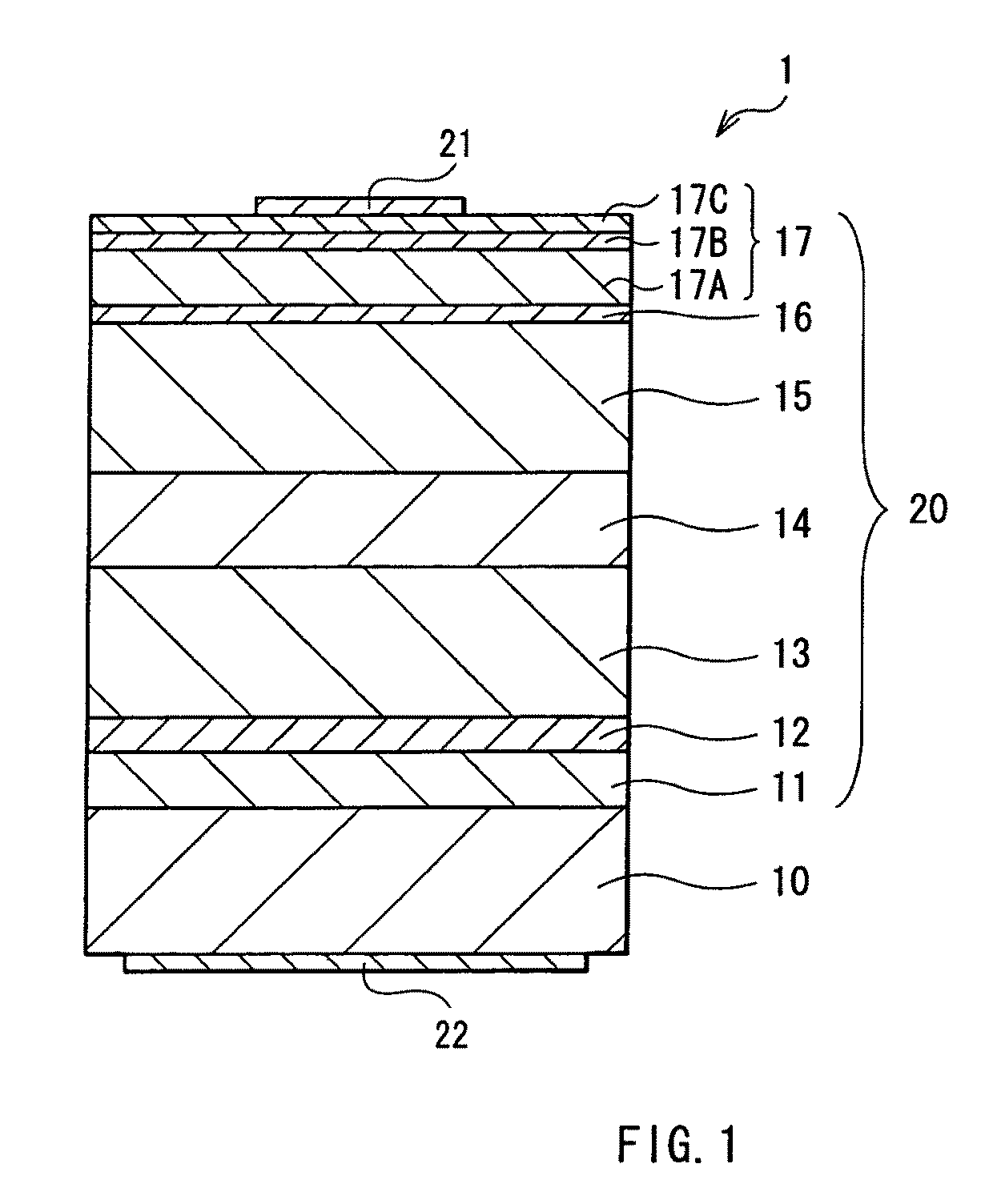

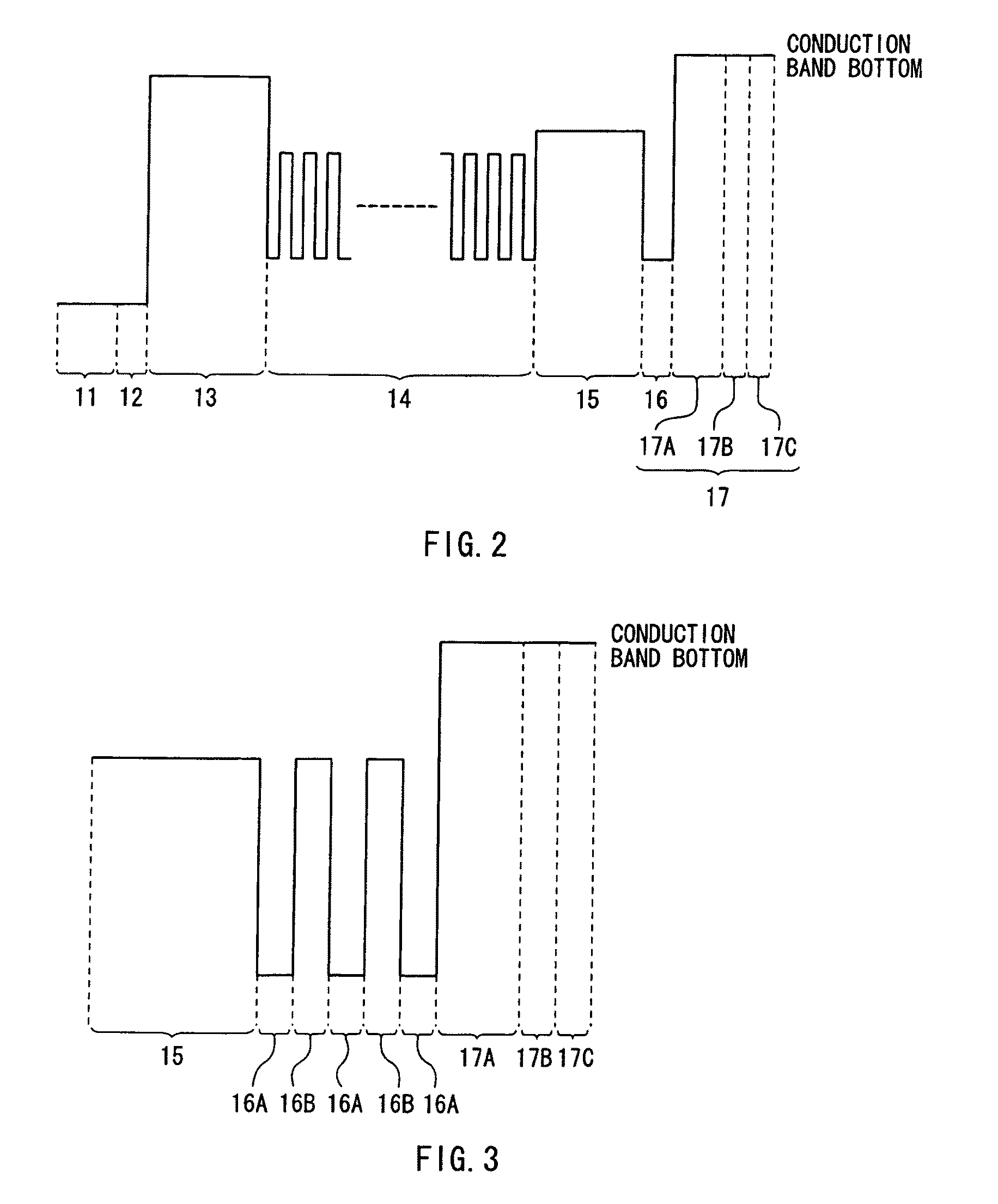

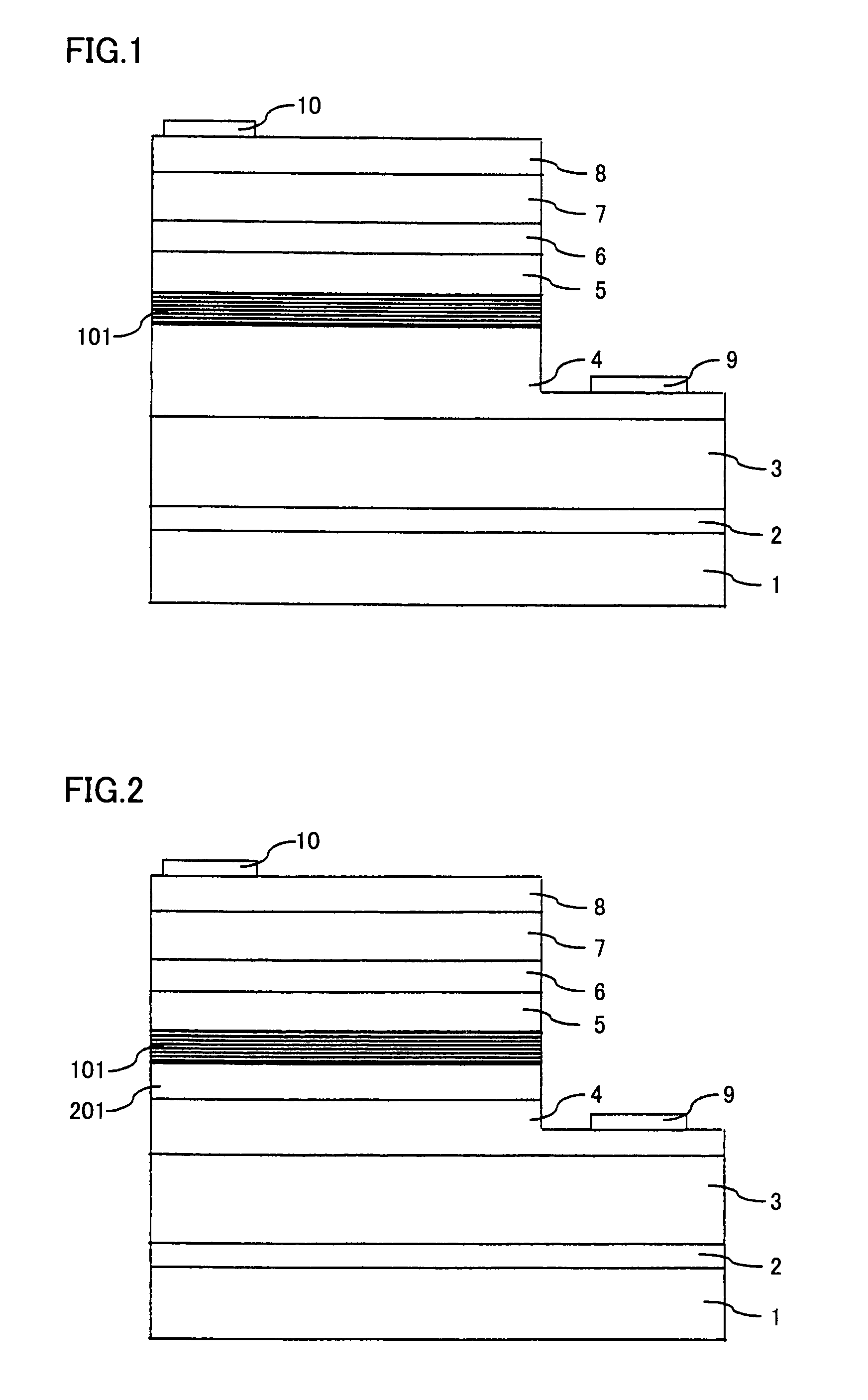

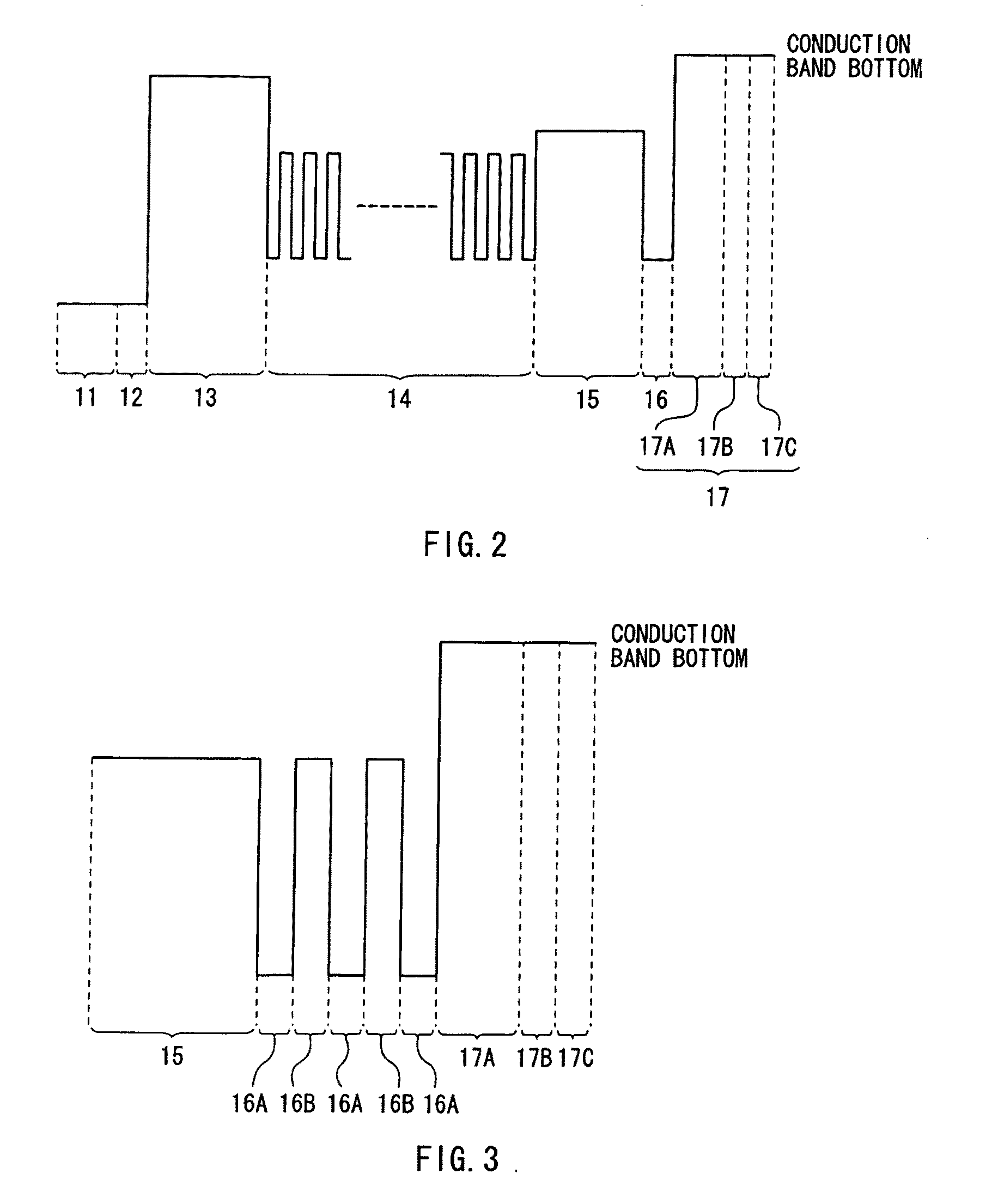

According to the nitride semiconductor device with the active layer made of the multiple quantum well structure of the present invention, the performance of the multiple quantum well structure can be brought out to intensify the luminous output thereof thereby contributing an expanded application of the nitride semiconductor device. In the nitride semiconductor device comprises an n-region having a plurality of nitride semiconductor films, a p-region having a plurality of nitride semiconductor films, and an active layer interposed therebetween, a multi-film layer with two kinds of the nitride semiconductor films is formed in at least one of the n-region or the p-region.

Owner:NICHIA CORP

Nitride semiconductor device

InactiveUS20070063207A1Light emission efficiencyHigh luminous outputOptical wave guidanceLaser detailsActive layerNitride semiconductors

According to the nitride semiconductor device with the active layer made of the multiple quantum well structure of the present invention, the performance of the multiple quantum well structure can be brought out to intensify the luminous output thereof thereby contributing an expanded application of the nitride semiconductor device. In the nitride semiconductor device comprises an n-region having a plurality of nitride semiconductor films, a p-region having a plurality of nitride semiconductor films, and an active layer interposed therebetween, a multi-film layer with two kinds of the nitride semiconductor films is formed in at least one of the n-region or the p-region,

Owner:NICHIA CORP

Group-iii nitride semiconductor light-emitting device, method for manufacturing the same, and lamp

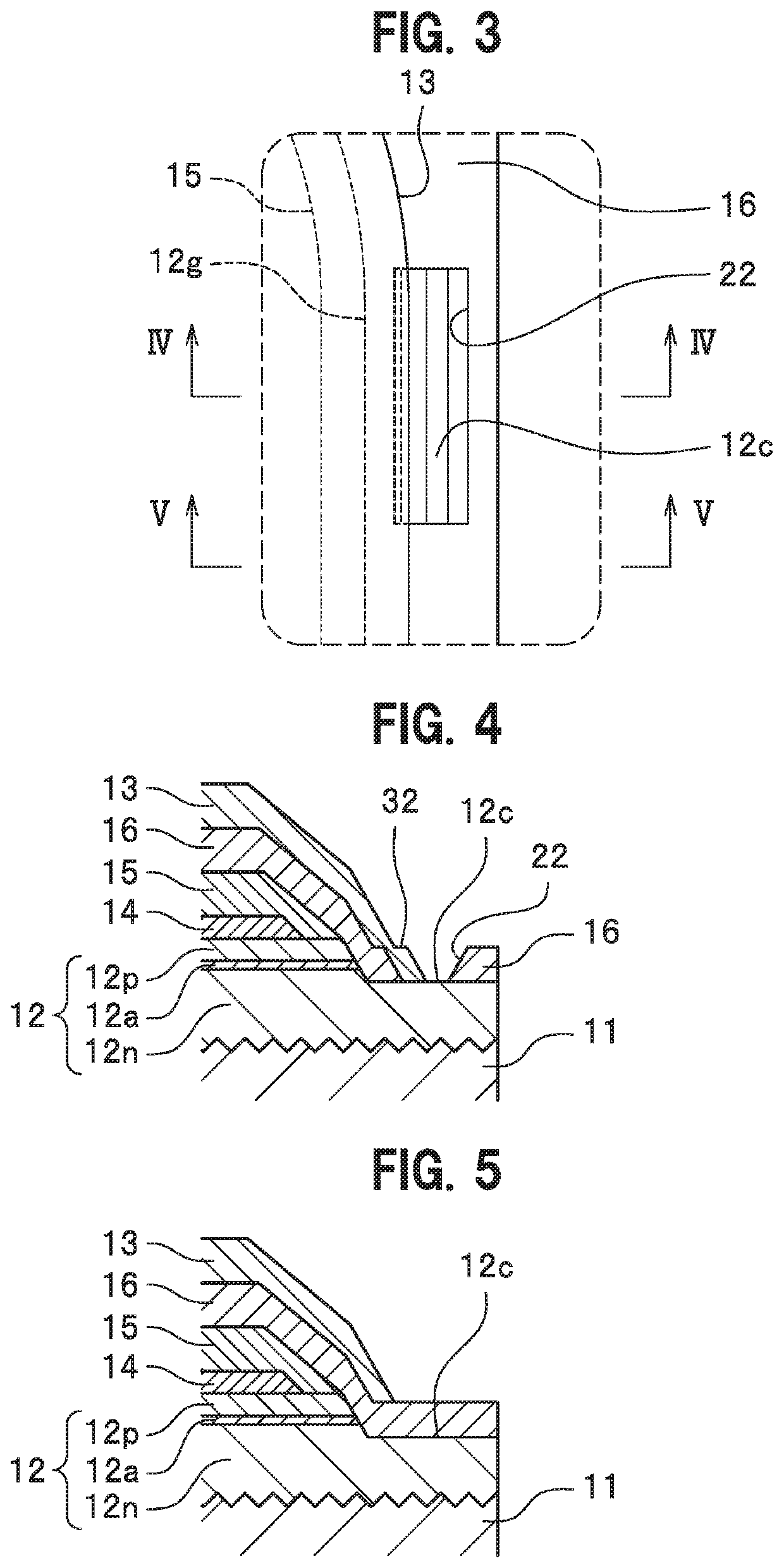

ActiveUS20110095331A1High crystallinityHigh level light emission outputNanoinformaticsSolid-state devicesQuantum efficiencyEngineering

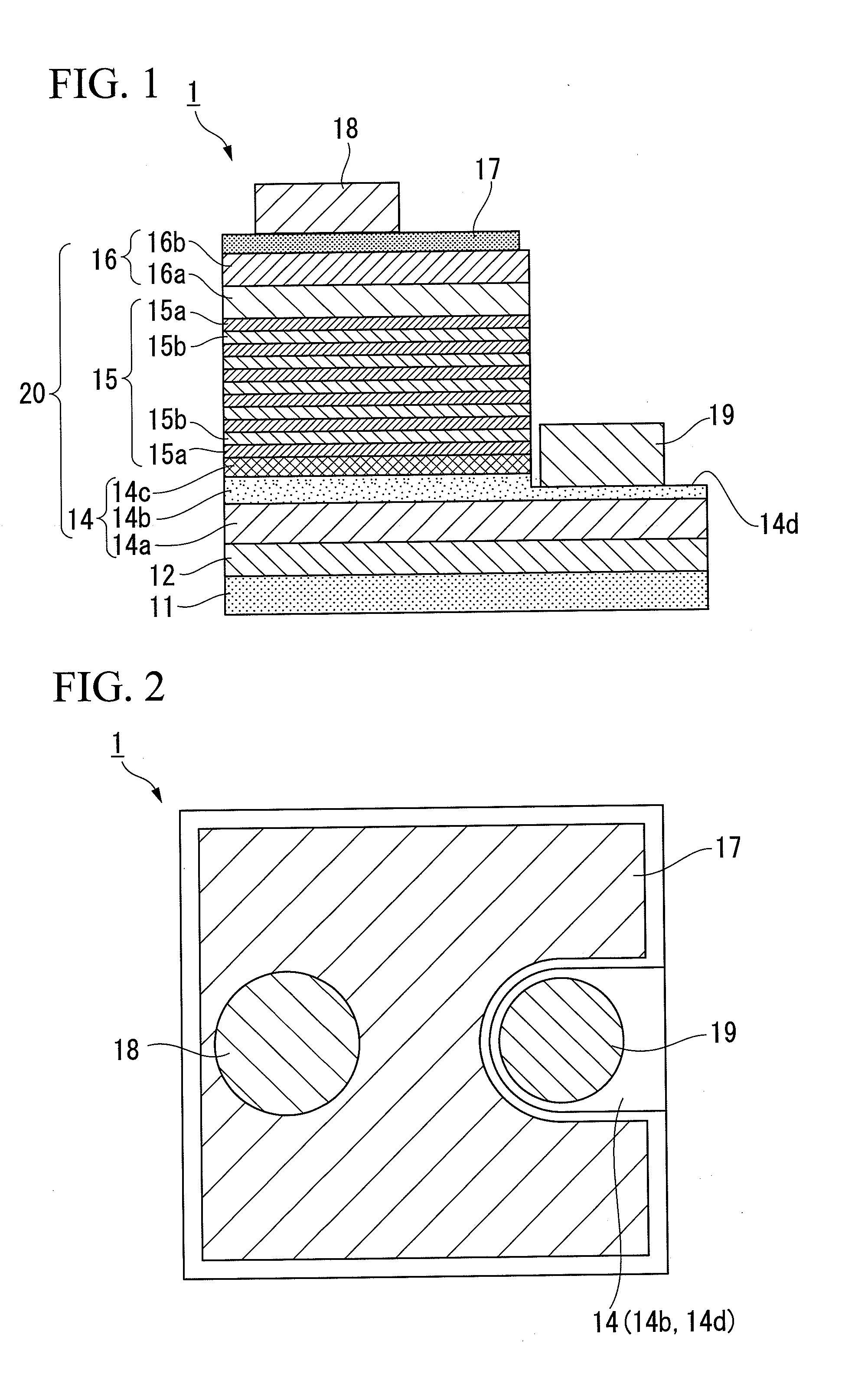

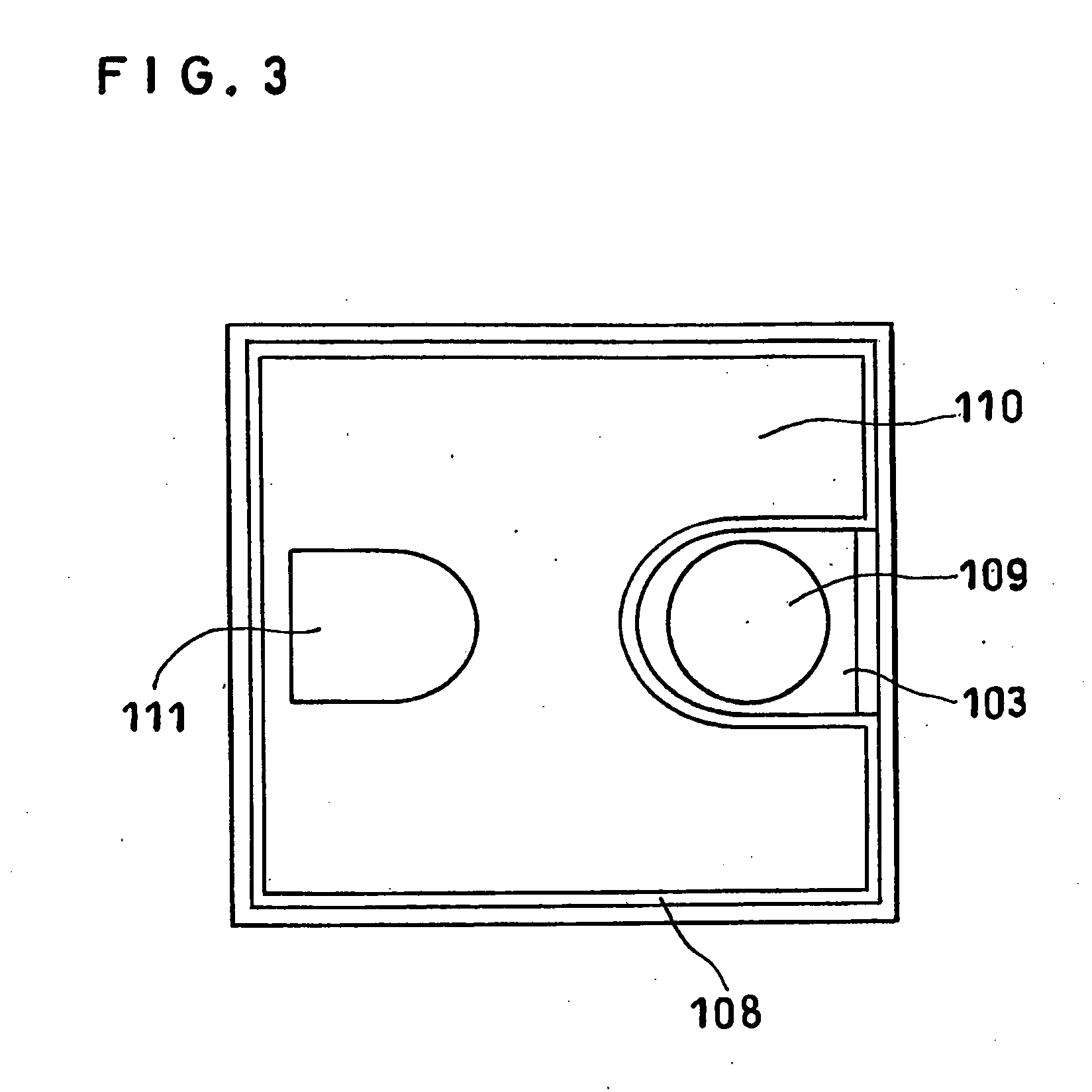

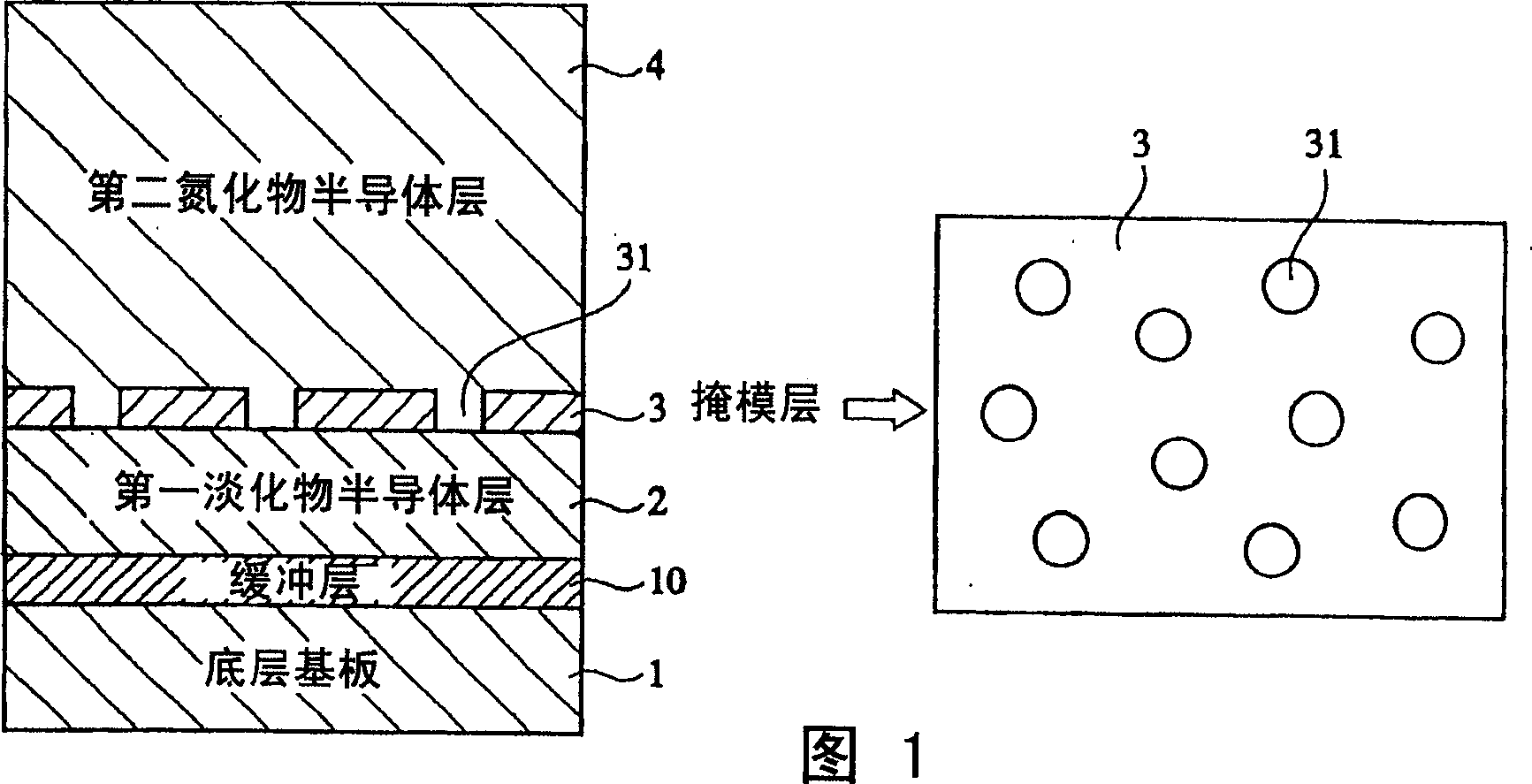

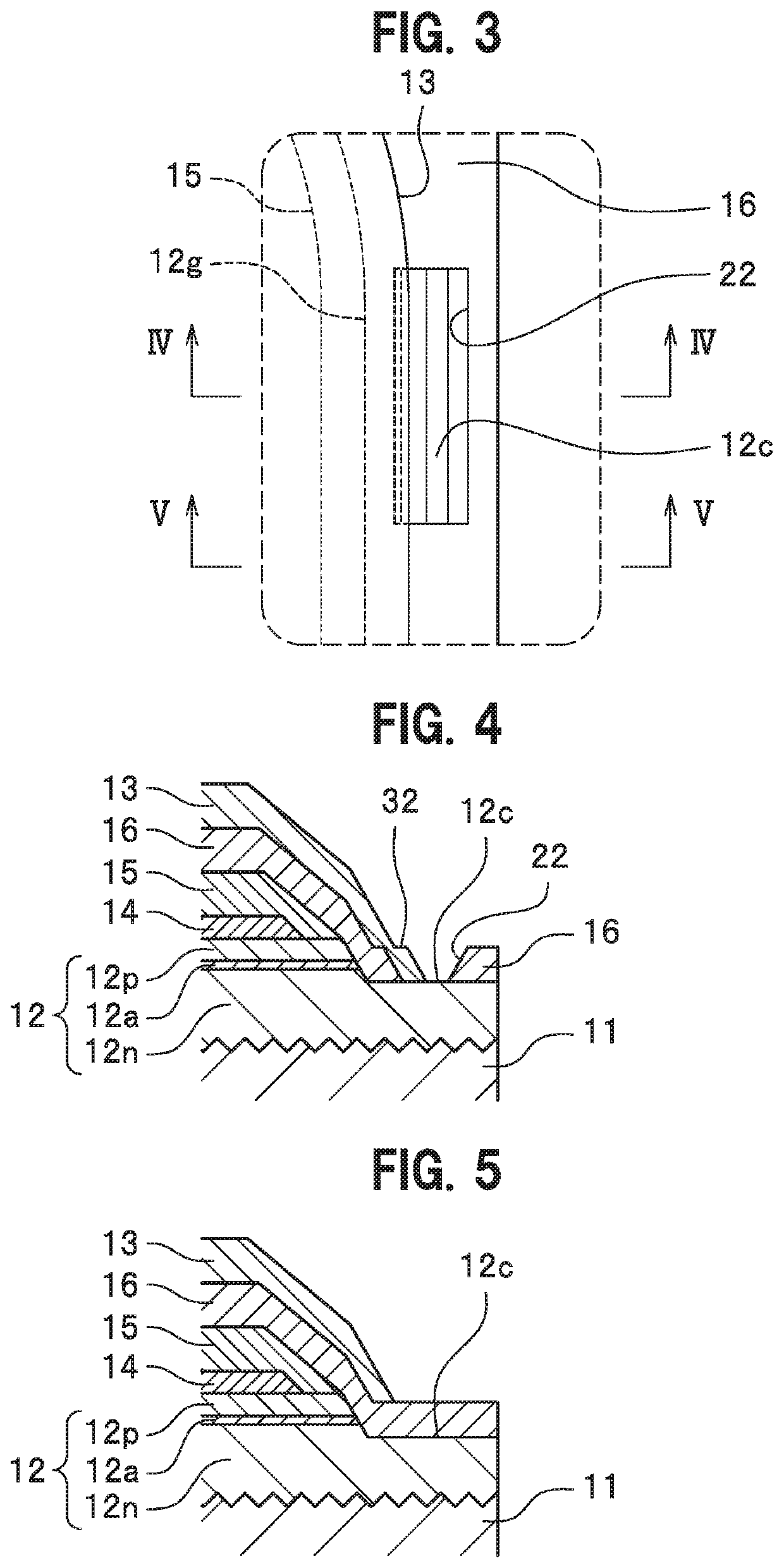

Provided is a group-III nitride semiconductor light-emitting device which has a high level of crystallinity and superior internal quantum efficiency and which is capable of enabling acquisition of high level light emission output, and a manufacturing method thereof, and a lamp. An AlN seed layer composed of a group-III nitride based compound is laminated on a substrate 11, and on this AlN seed layer, there are sequentially laminated each layer of an n-type semiconductor layer, a light-emitting layer, and a p-type semiconductor layer respectively composed of a group-III nitride semiconductor, wherein the full width at half-maximum of the X-ray rocking curve of the (0002) plane of the p-type semiconductor layer 16 is 60 arcsec or less, and the full width at half-maximum of the X-ray rocking curve of the (10-10) plane is 250 arcsec or less.

Owner:TOYODA GOSEI CO LTD

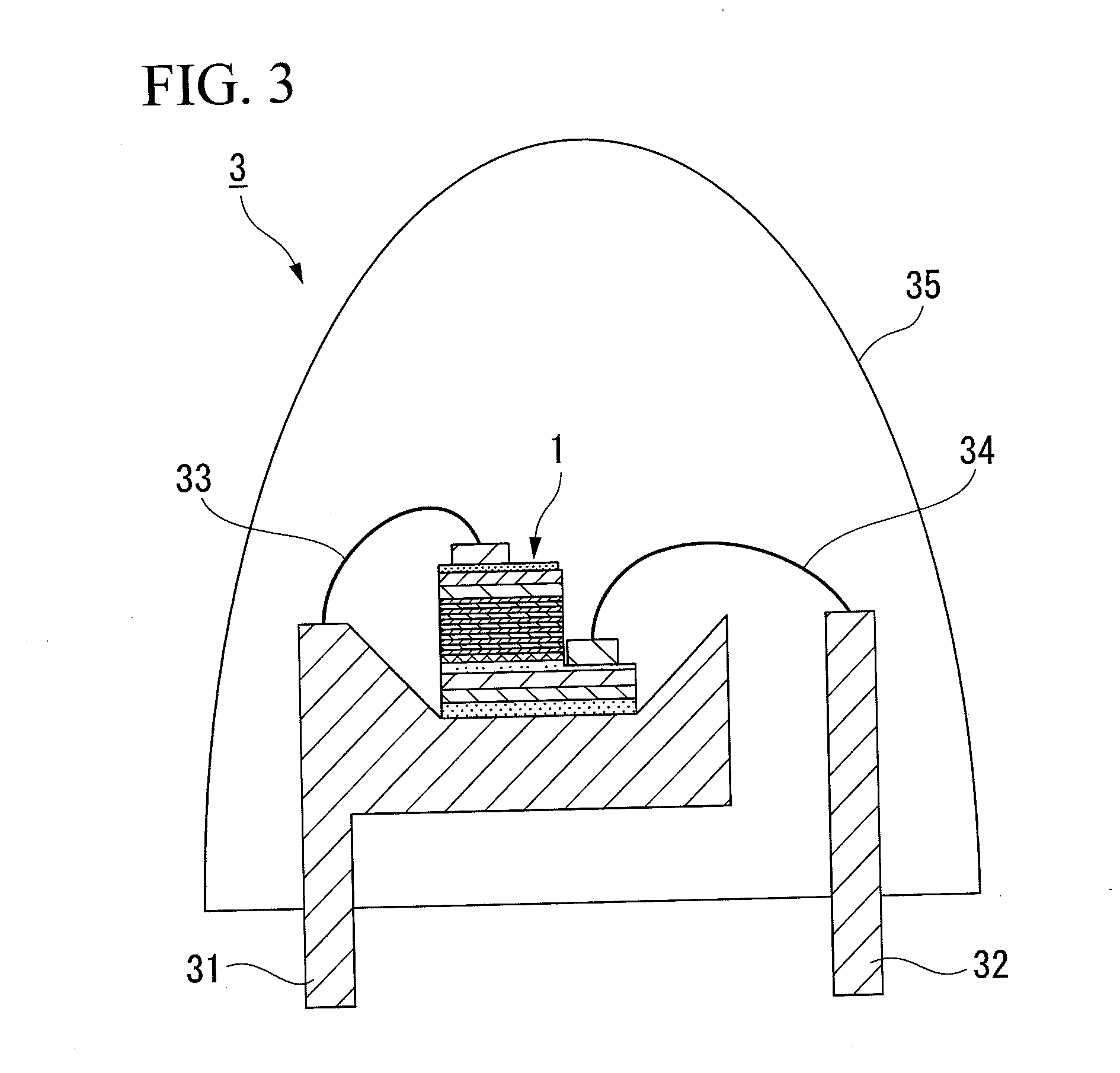

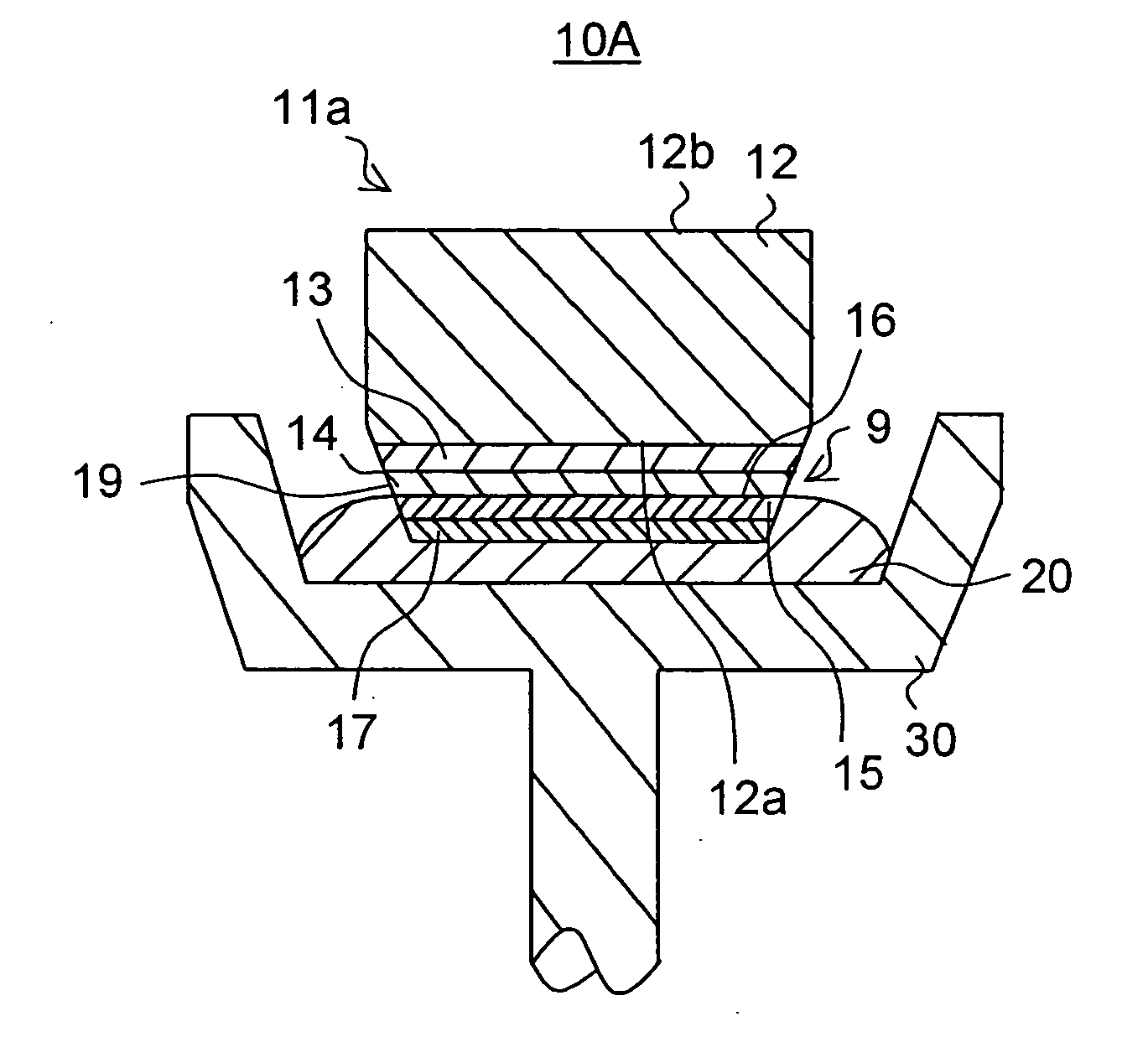

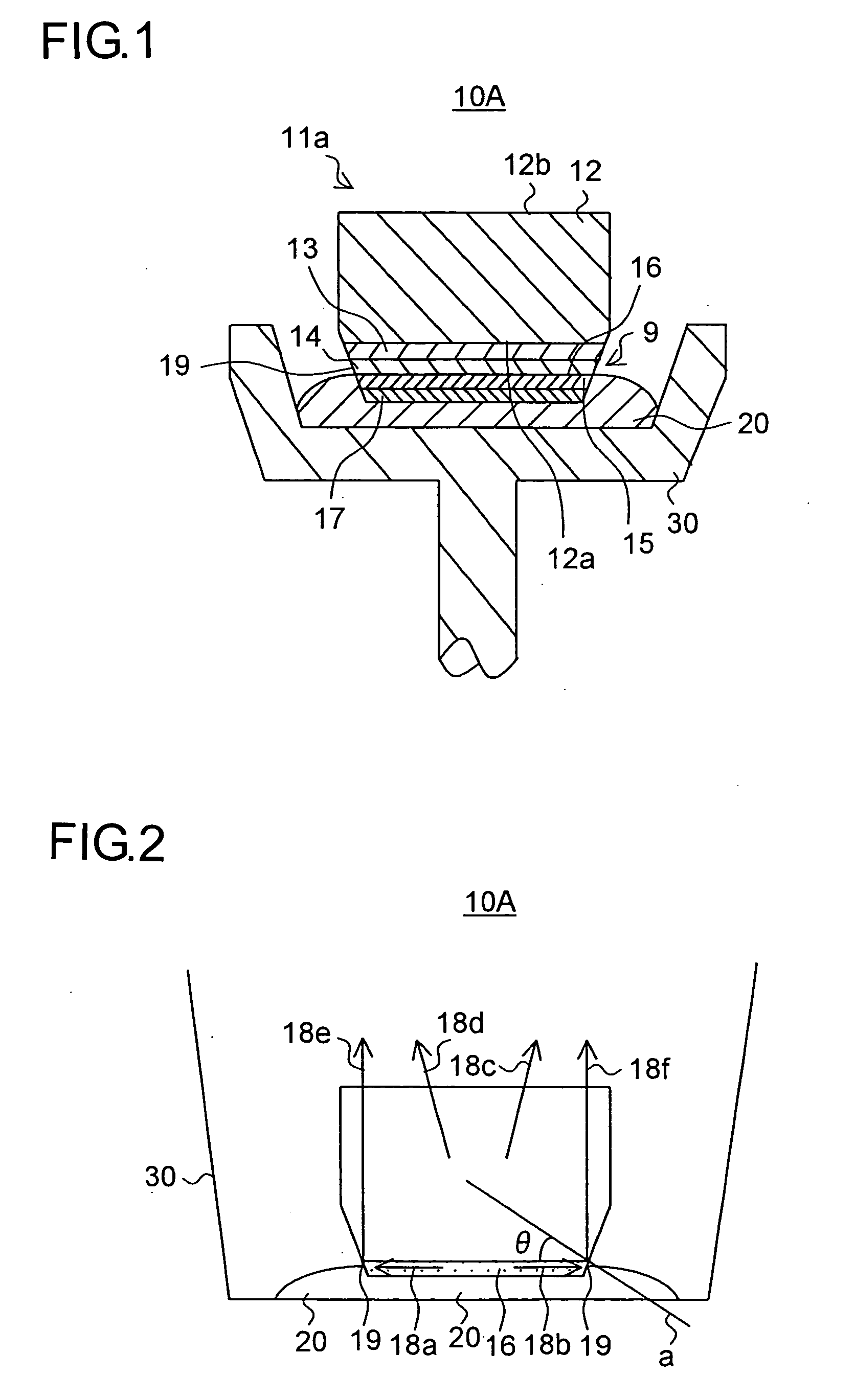

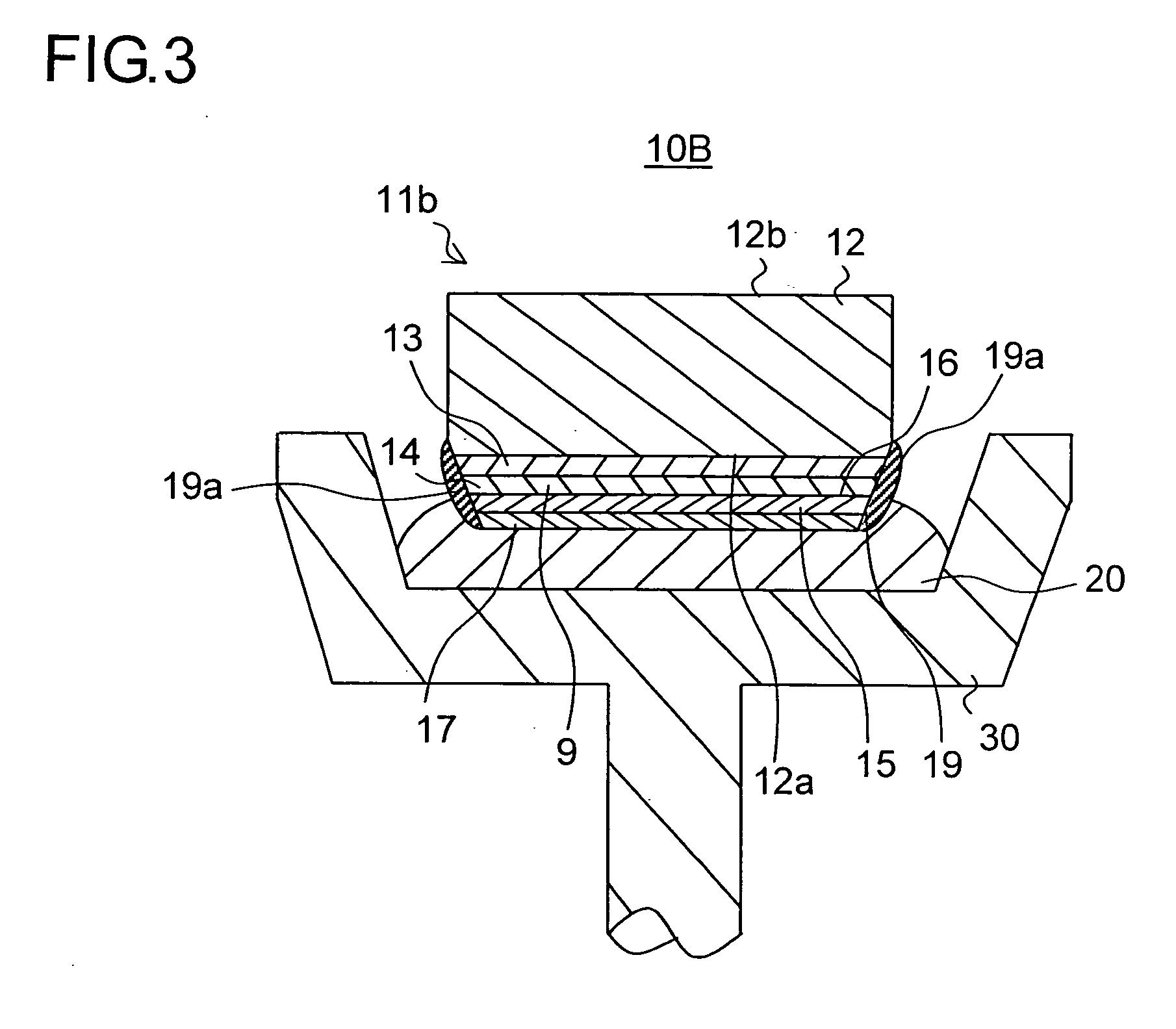

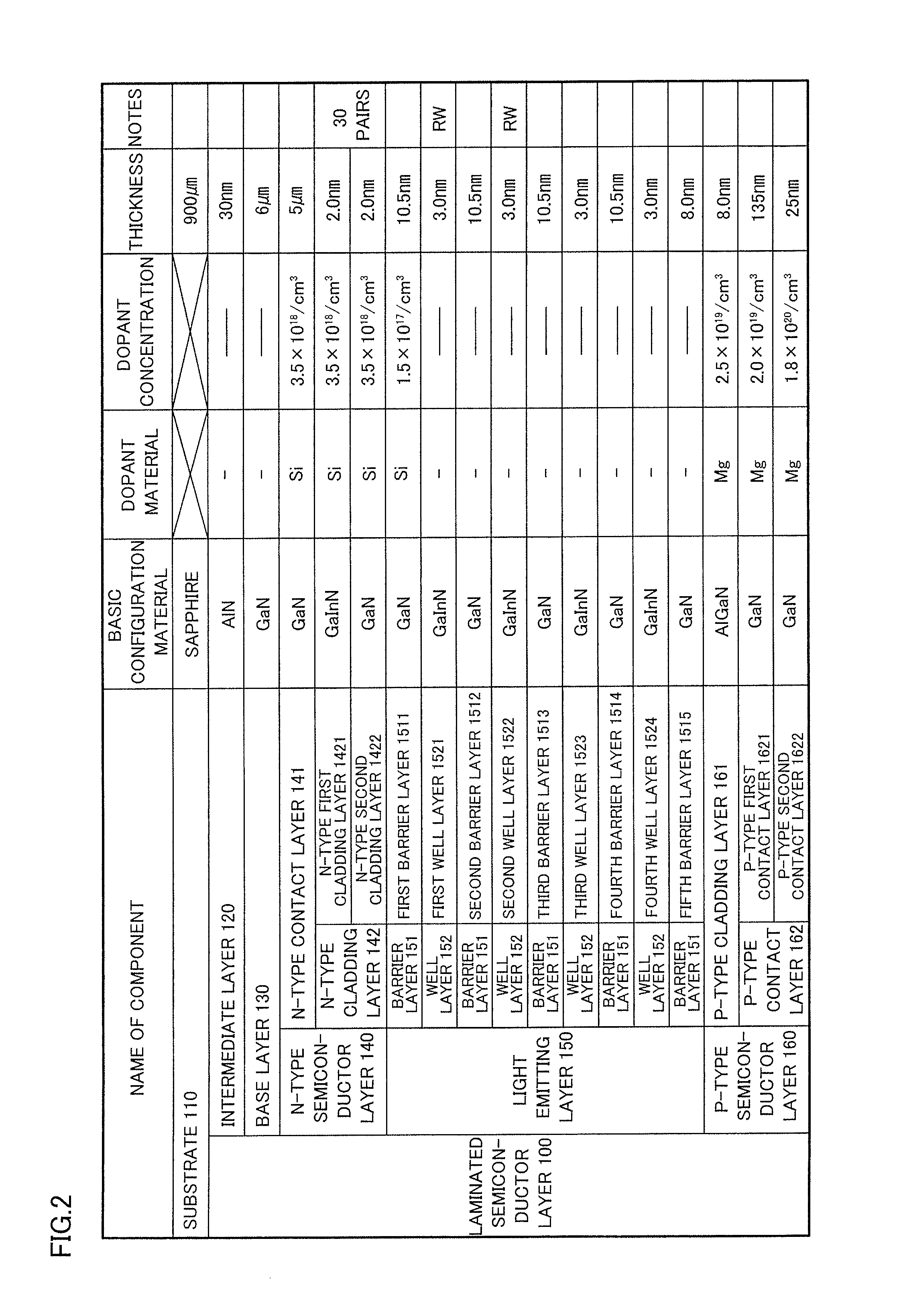

Light-emitting diode

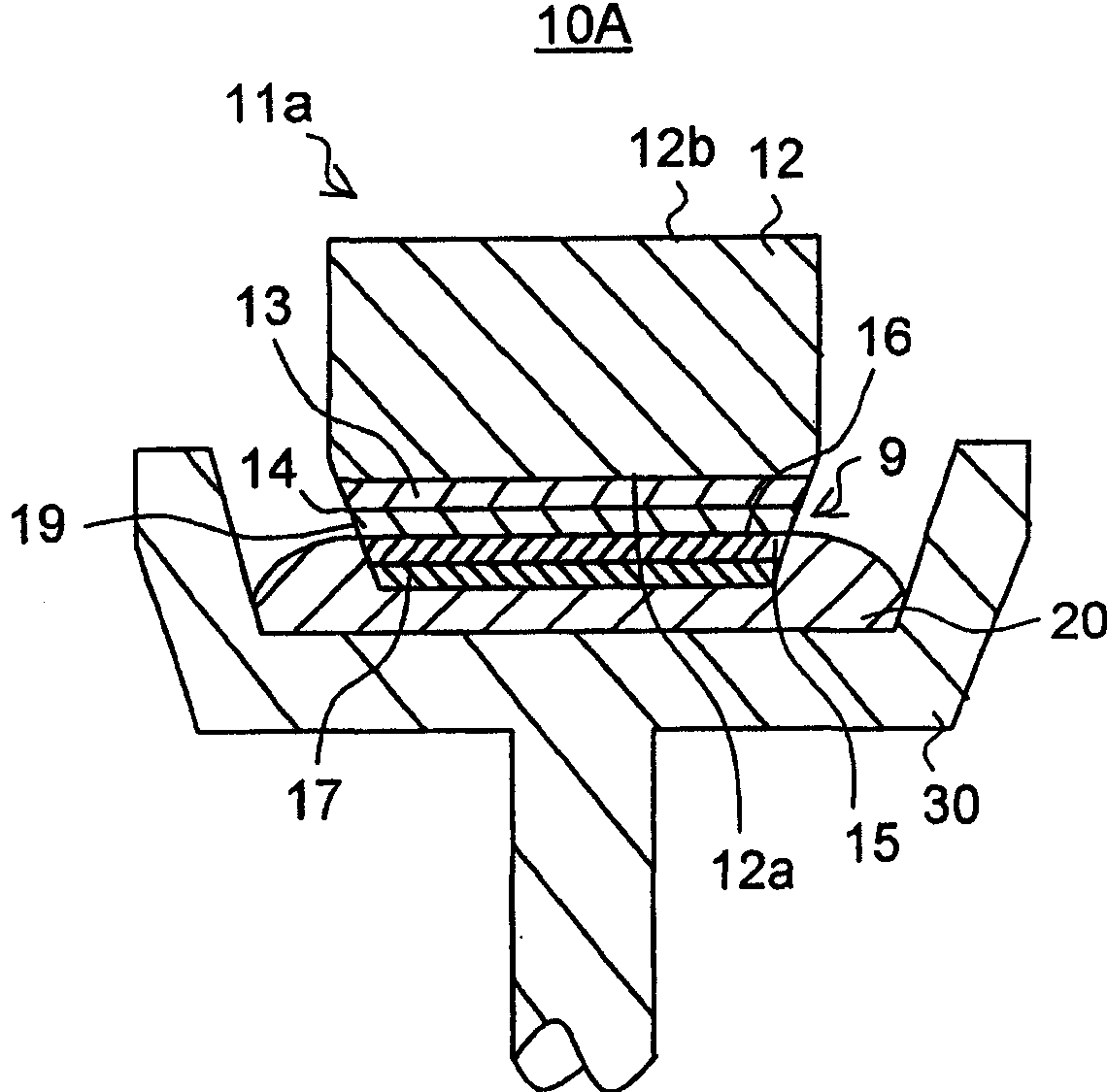

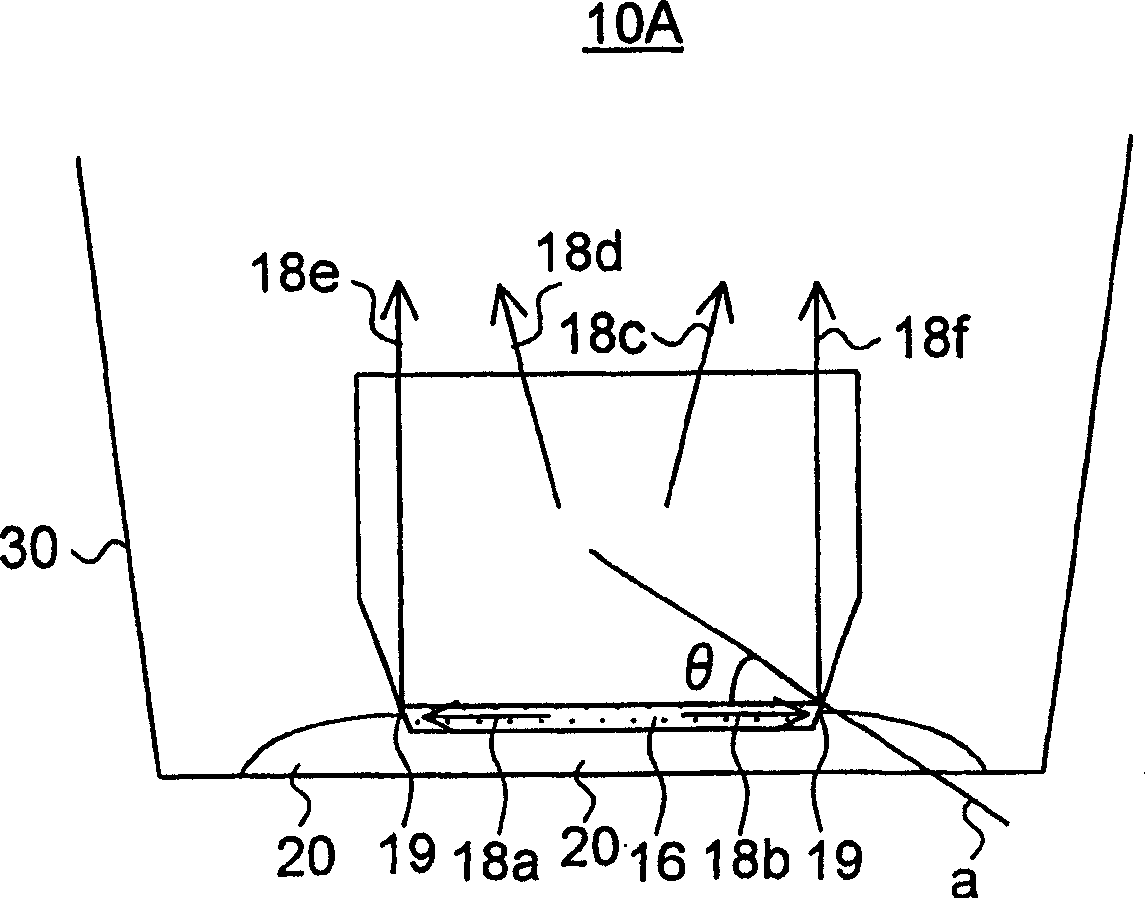

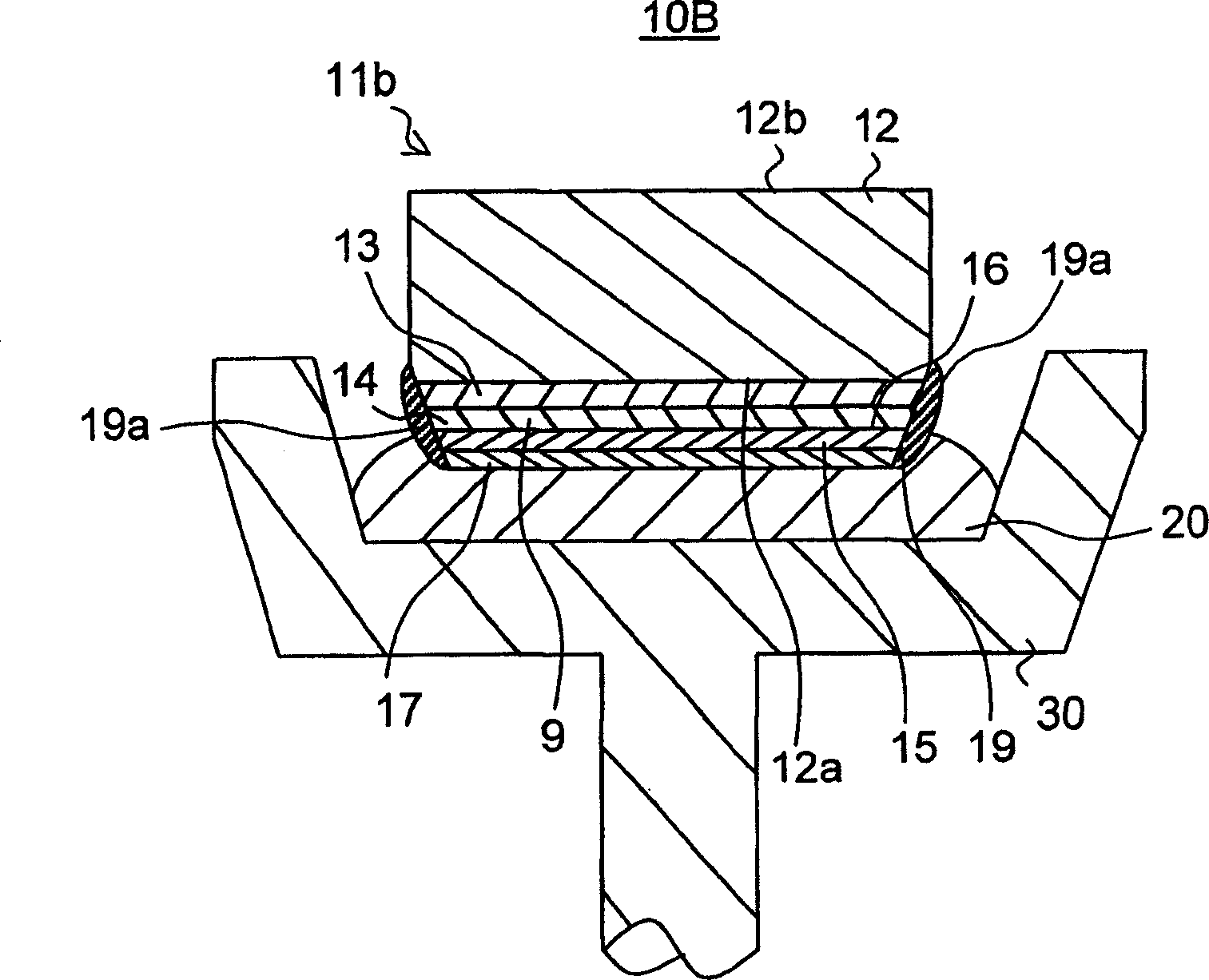

InactiveUS20060043433A1High luminous outputLessened light shieldingTransistorSolid-state devicesLight-emitting diodeLight emission

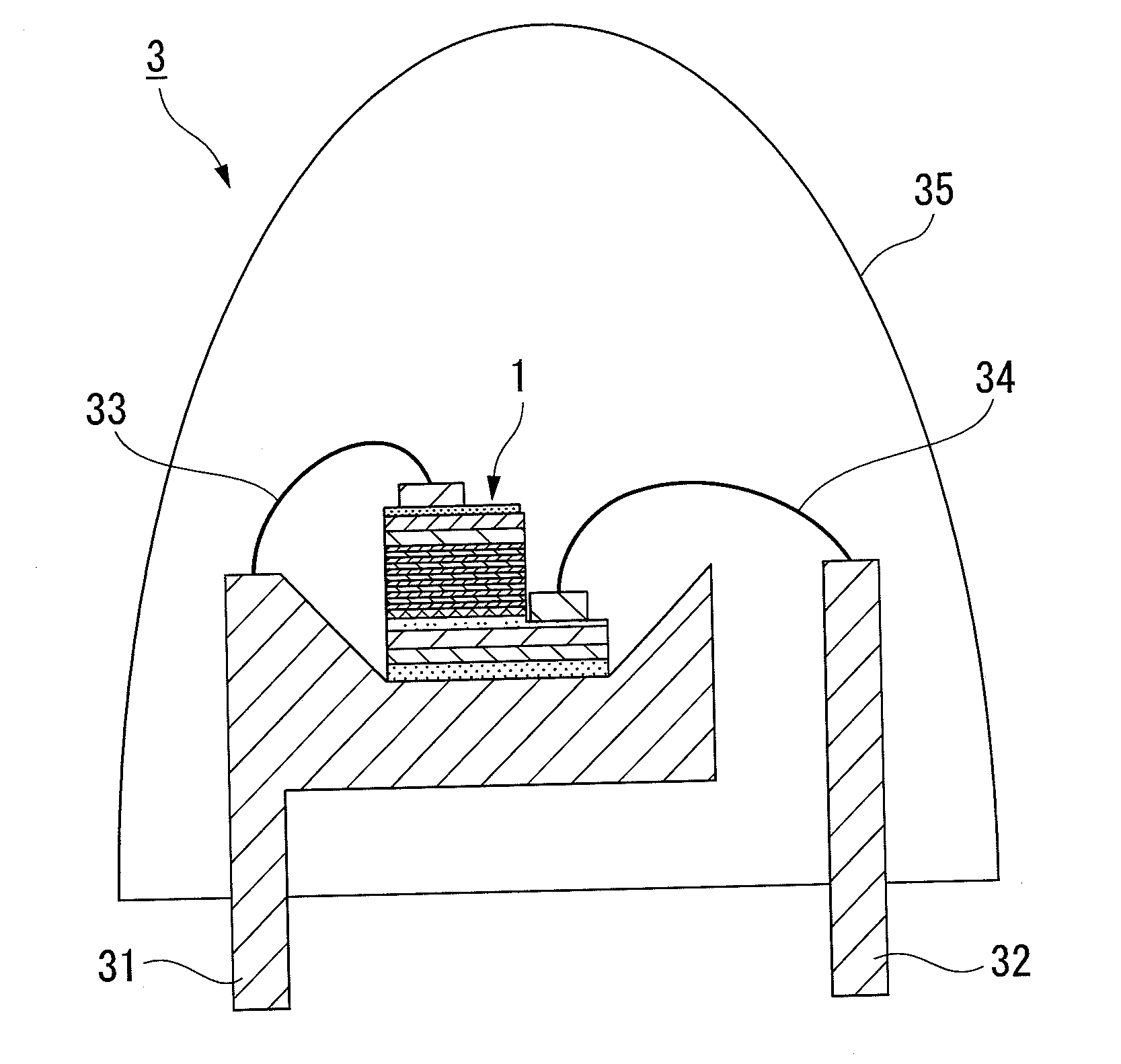

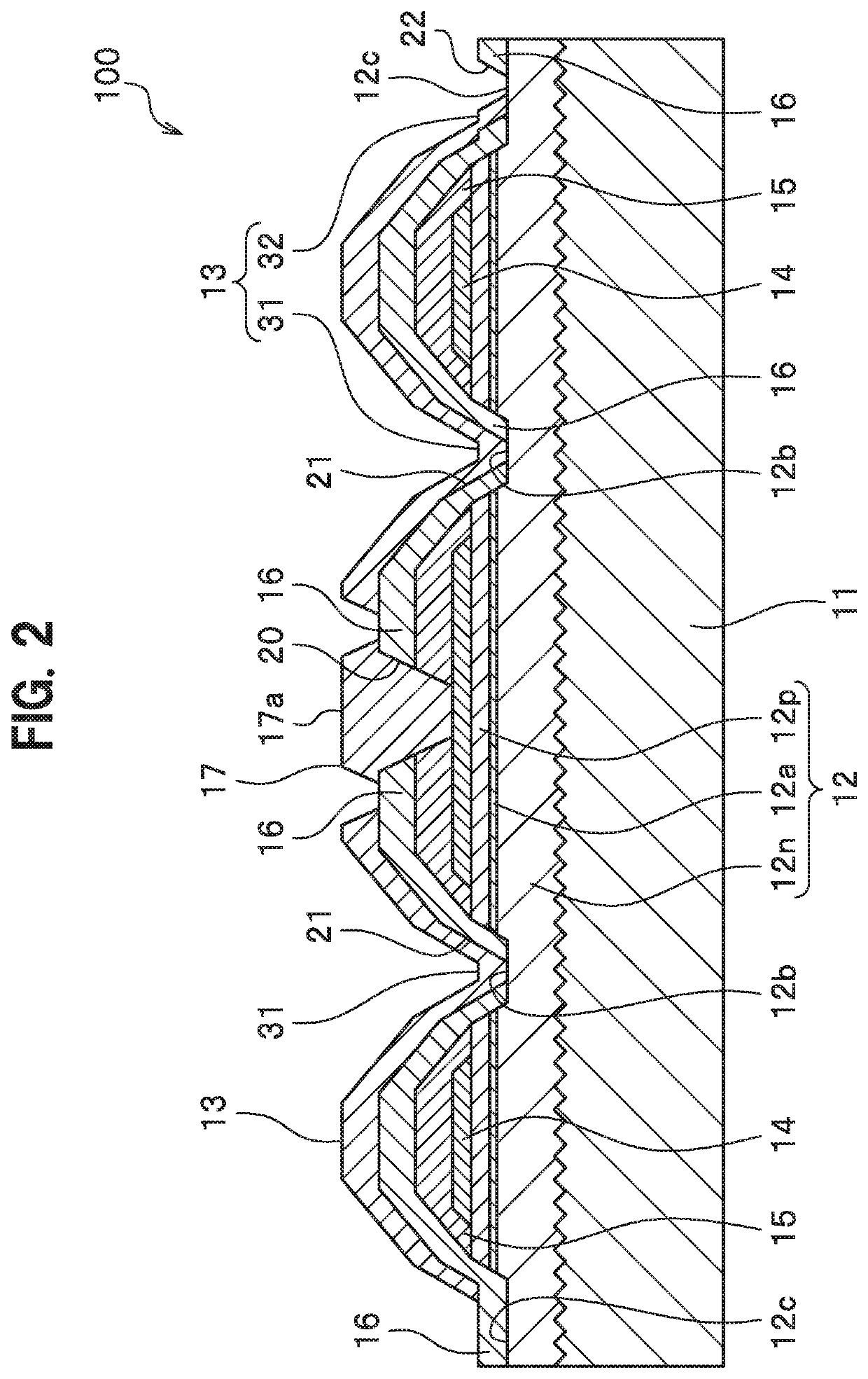

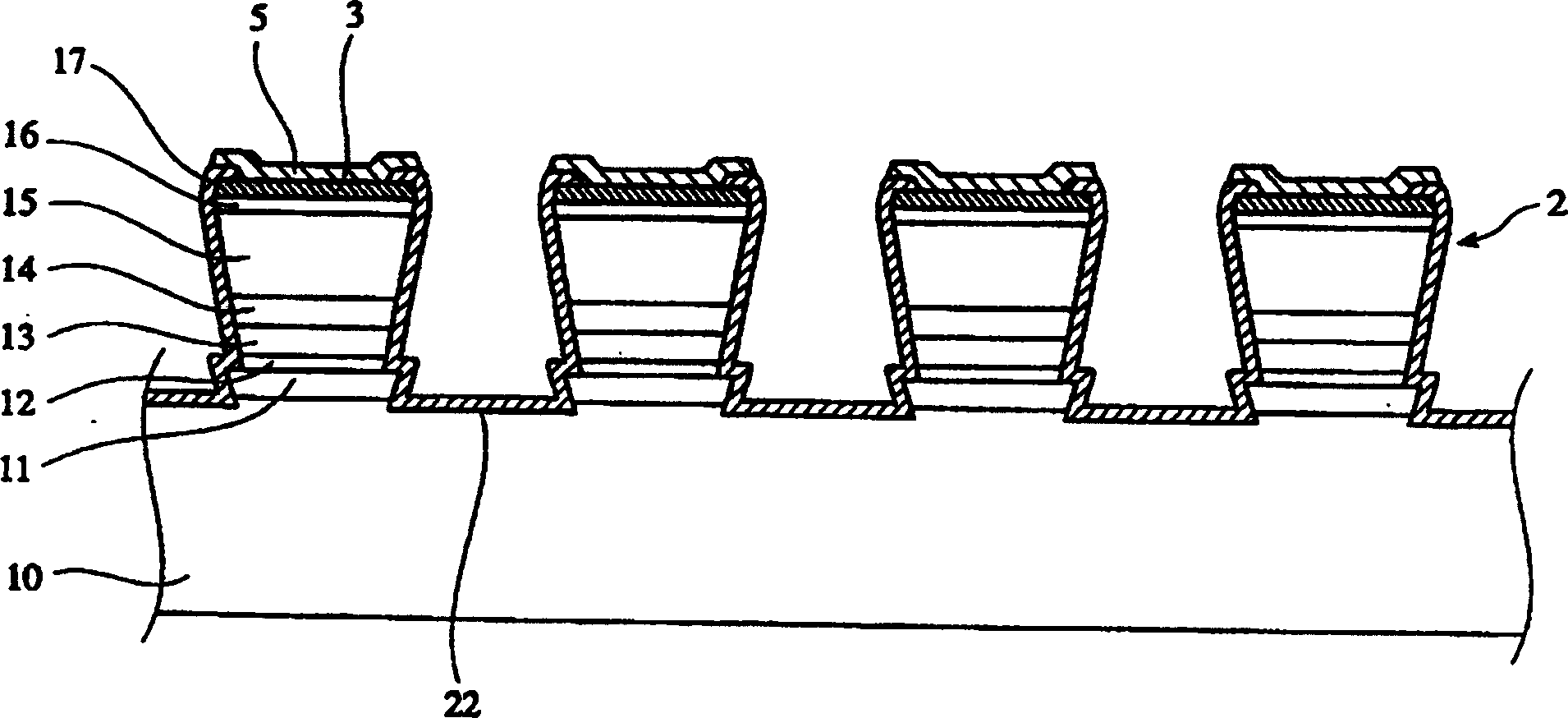

A light-emitting diode 10A has a light-emitting element 11a fixed to a leadframe 30 with a conductive adhesive material 20, the light-emitting element 11a having a semiconductor layer 9 including a light-emitting layer 16 laid on a first surface 12a of a translucent substrate 12, a second surface 12b thereof facing away from the first surface 12a being used as a light emission observation surface. A side surface of the semiconductor layer 9 is an inclined surface inclined relative to the first surface 12a, and an angle θ between a normal “a” to the inclined surface and a crystal surface on which the light-emitting layer 16 grows is equal to an angle at which light emitted by the light-emitting layer 16 is totally reflected toward the translucent substrate 12.

Owner:SANYO ELECTRIC CO LTD +1

Light-emitting diode and method of manufacturing the same

ActiveUS20150034900A1Improve efficiencyLight extraction efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesEtchingTransparent conducting film

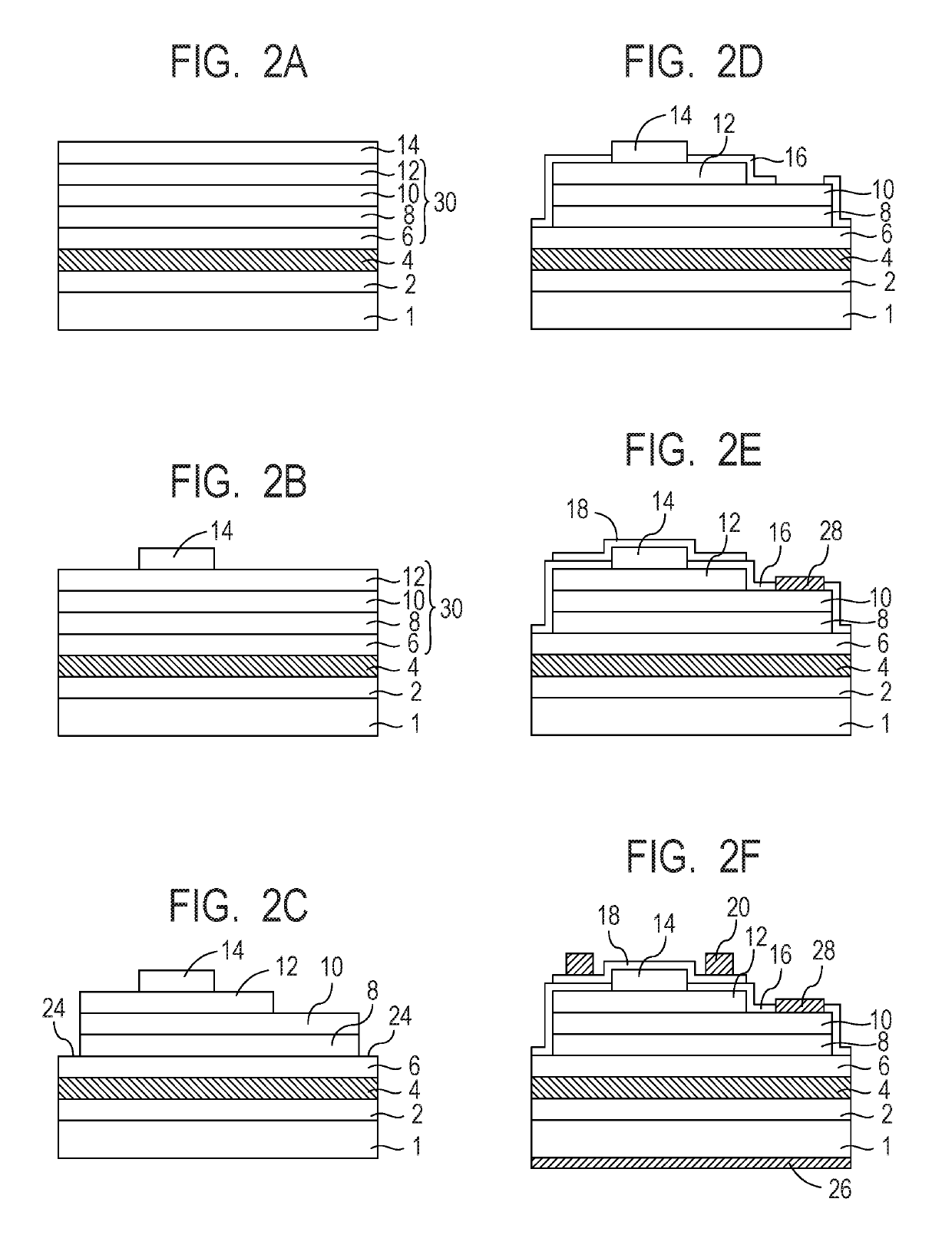

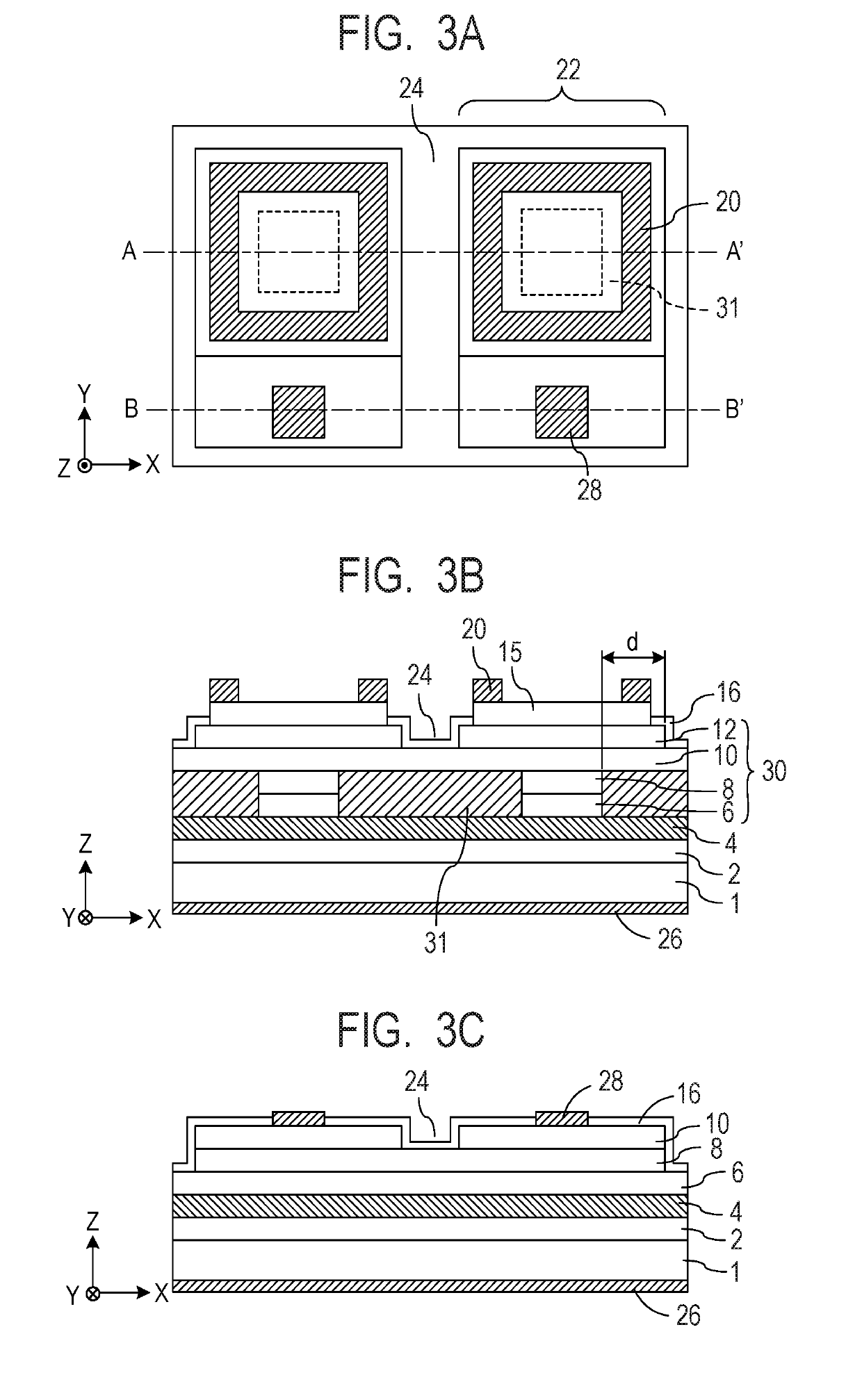

A light-emitting diode and manufacturing method, including a flat portion and a mesa structure. An inclined side surface is formed by wet etching such that a cross-sectional area of the mesa structure is continuously reduced toward a top surface. A protective film covers the flat portion, the inclined side surface, and a peripheral region of the top surface of the mesa structure. The protective film includes an electrical conduction window arranged around a light emission hole and from which a compound semiconductor layer is exposed. A continuous electrode film contacts the exposed compound semiconductor layer, covers the protective film formed on the flat portion, and has the light emission hole on the top surface. A transparent conductive film is formed between a reflecting layer and the layer at a position that corresponds to the electrical conduction window and in a range surrounded by the electrical conduction window.

Owner:SHOWA DENKO KK

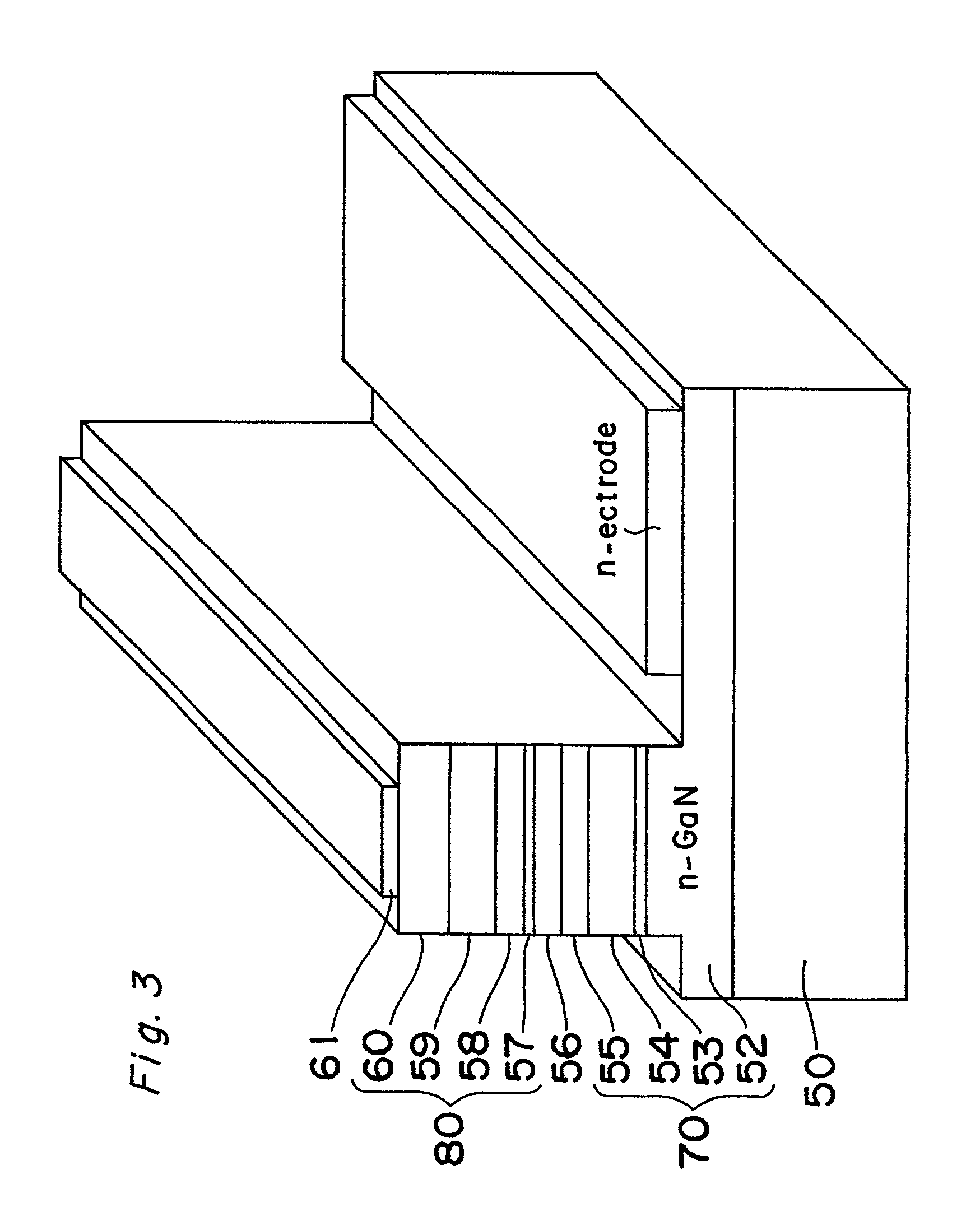

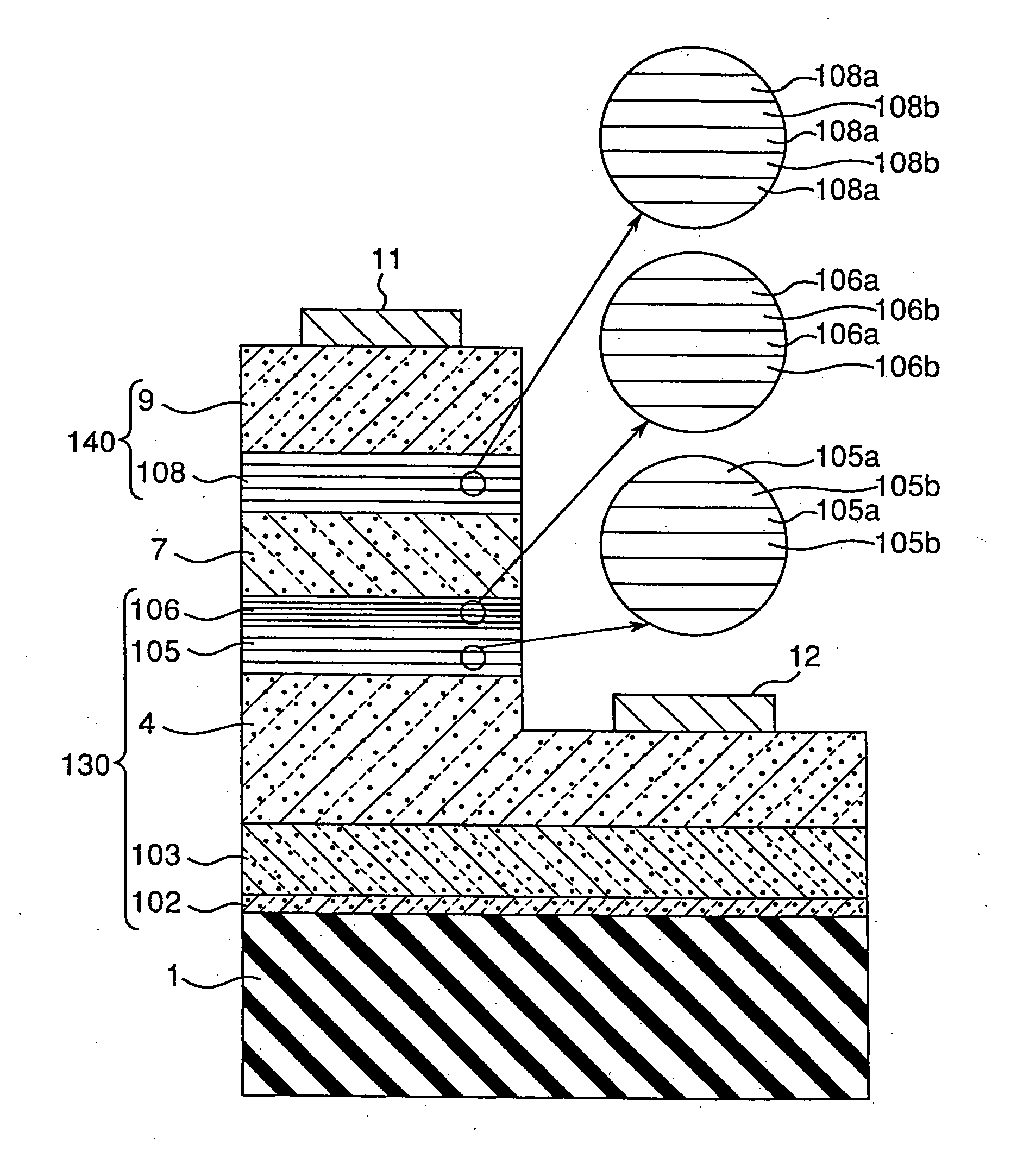

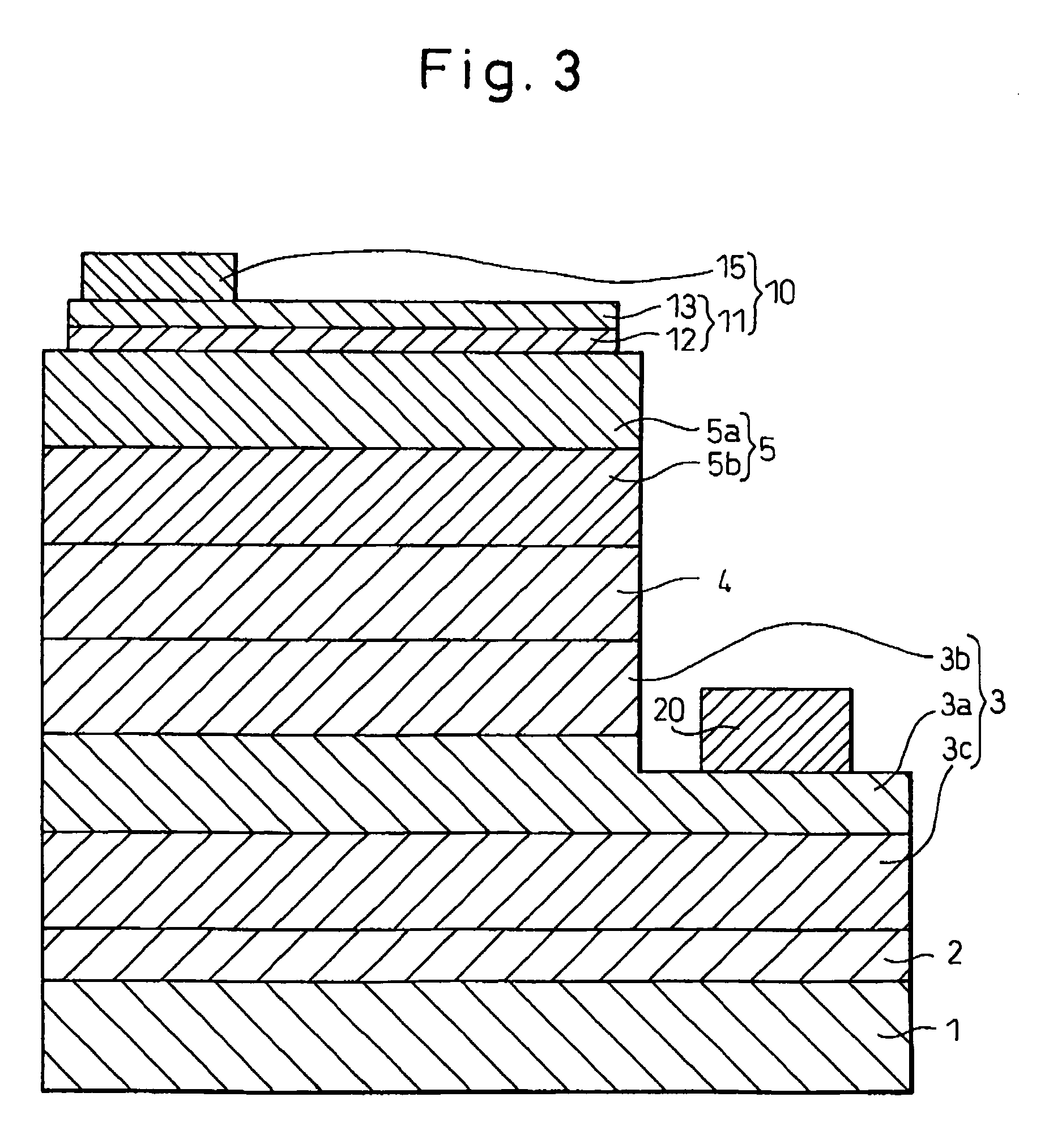

Pn Junction Type Group III Nitride Semiconductor Light-Emitting Device

ActiveUS20080230794A1Dispersion suppressionHigh luminous outputOptical wave guidanceLaser detailsLight emitting deviceNitride semiconductors

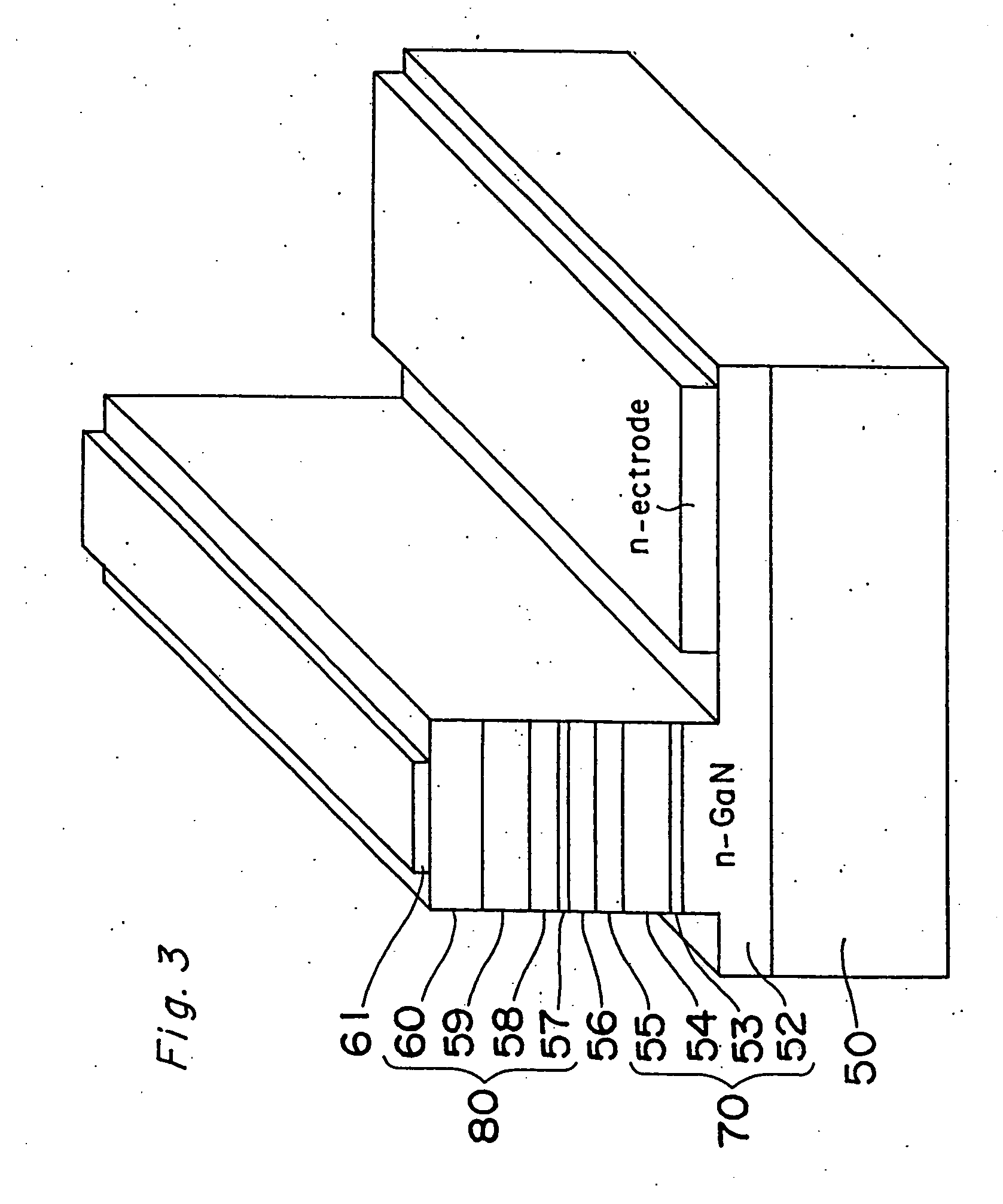

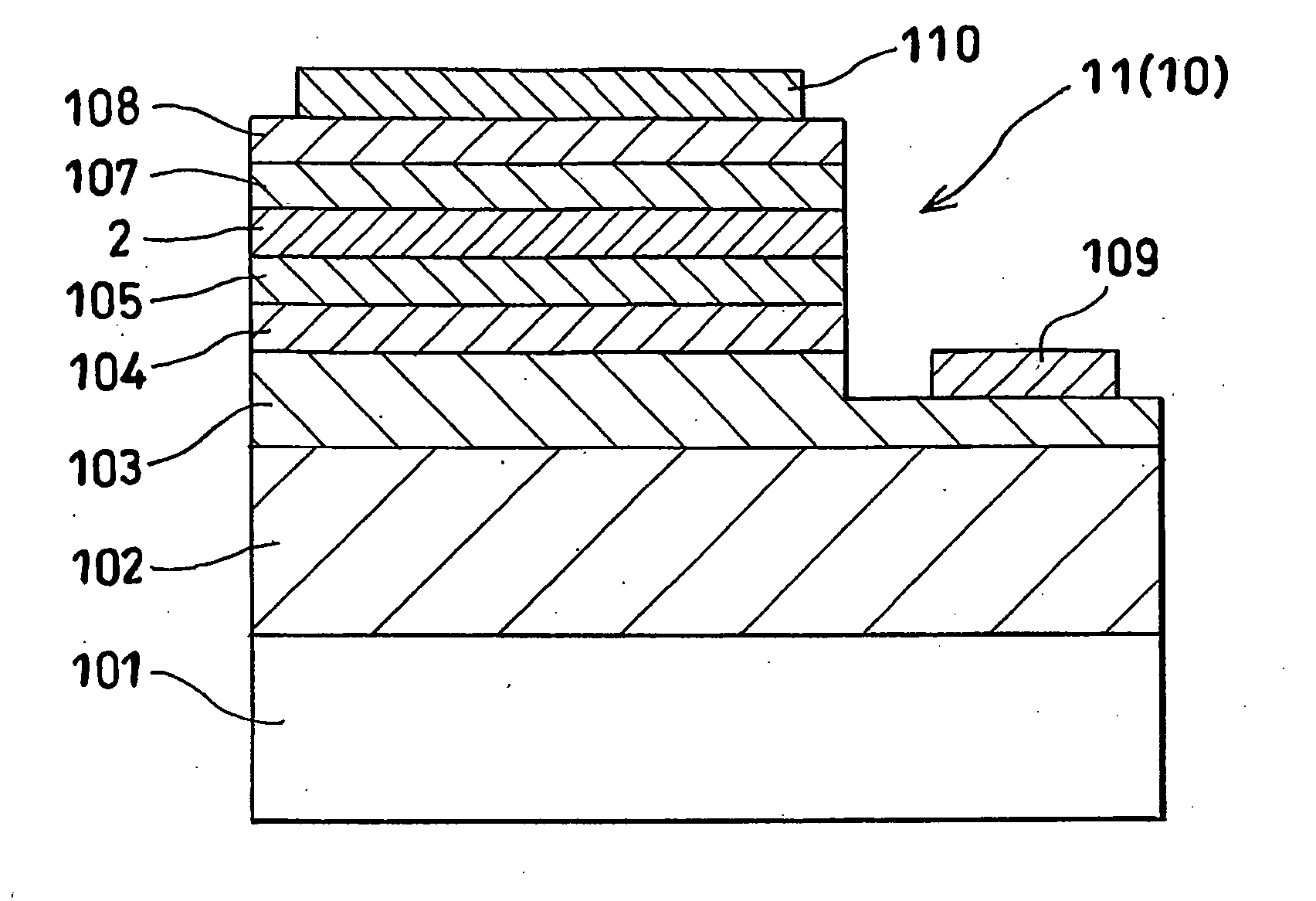

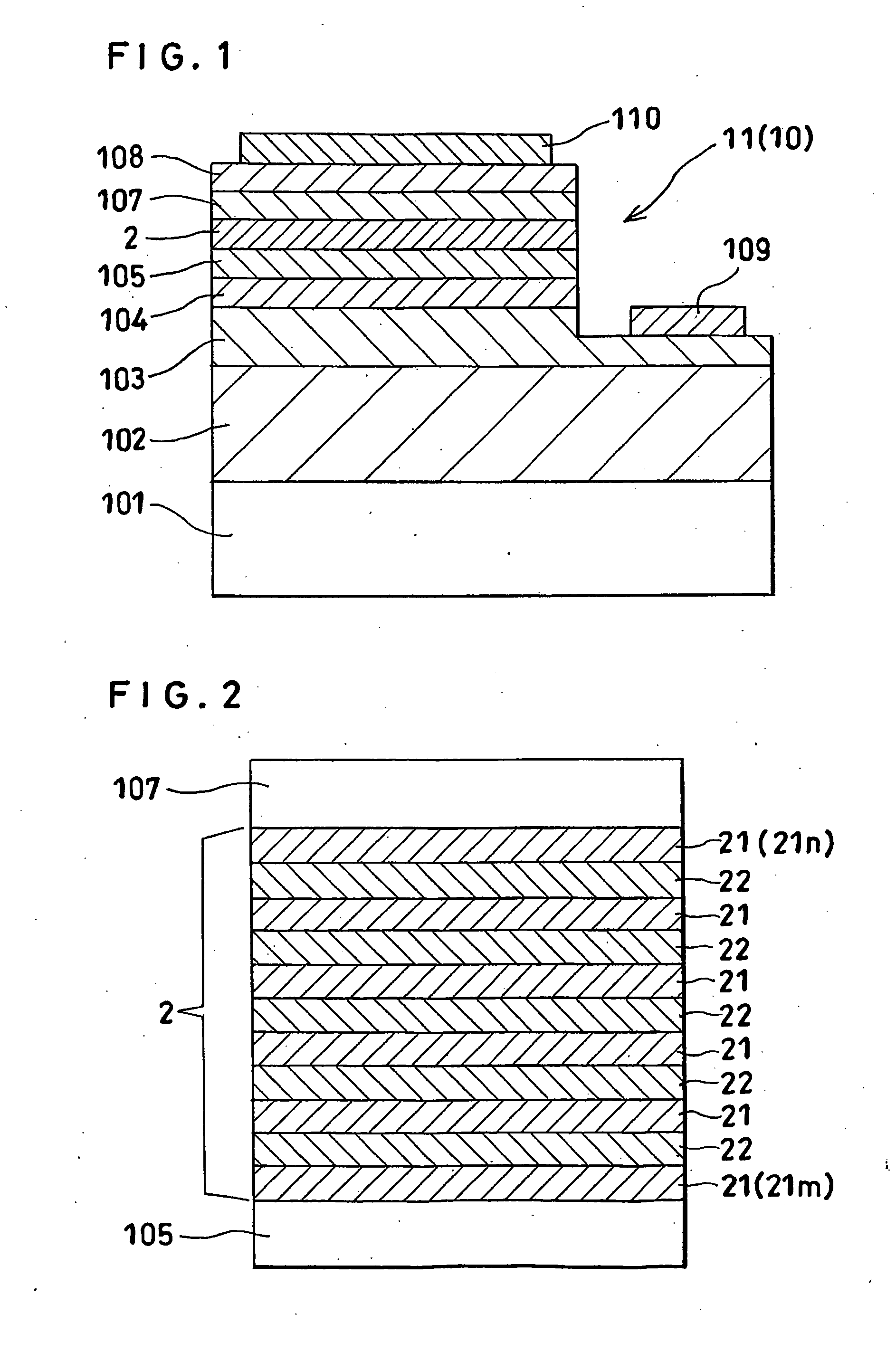

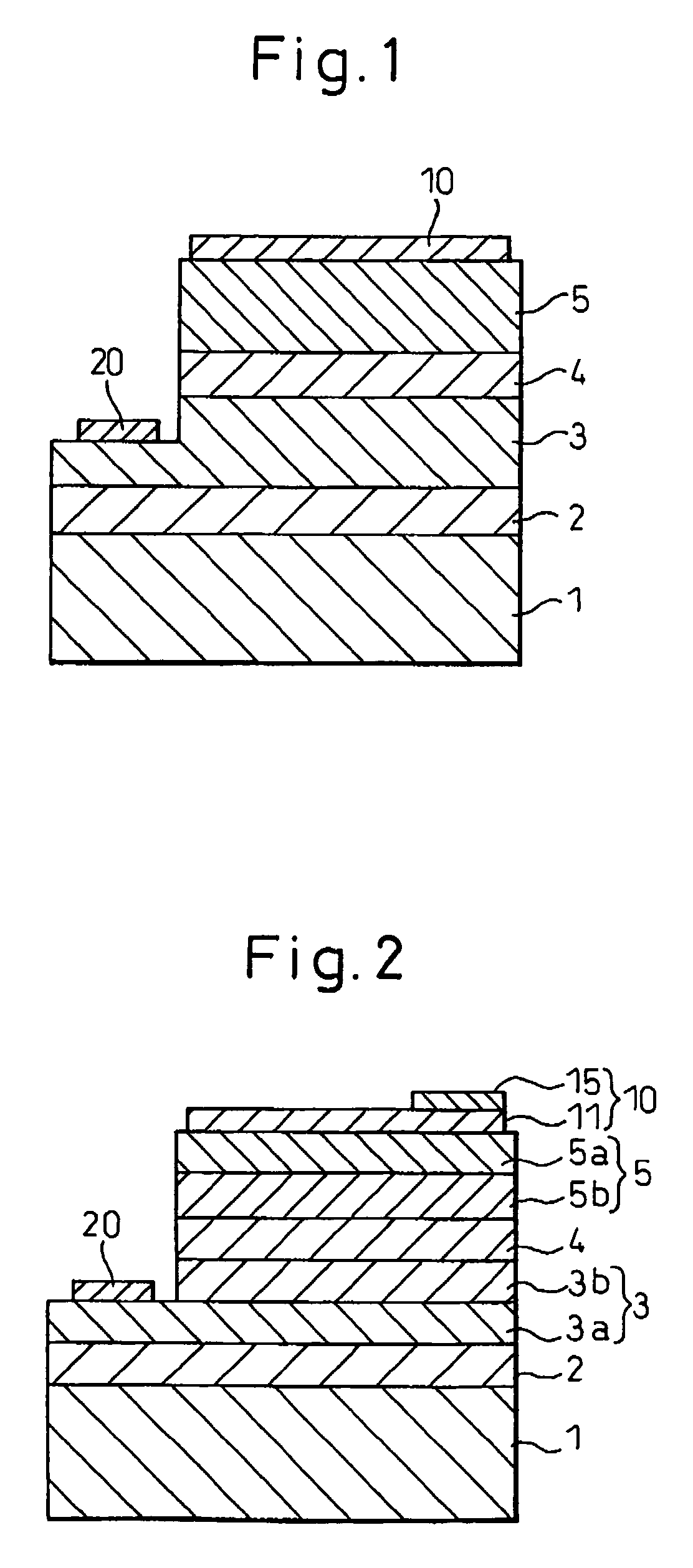

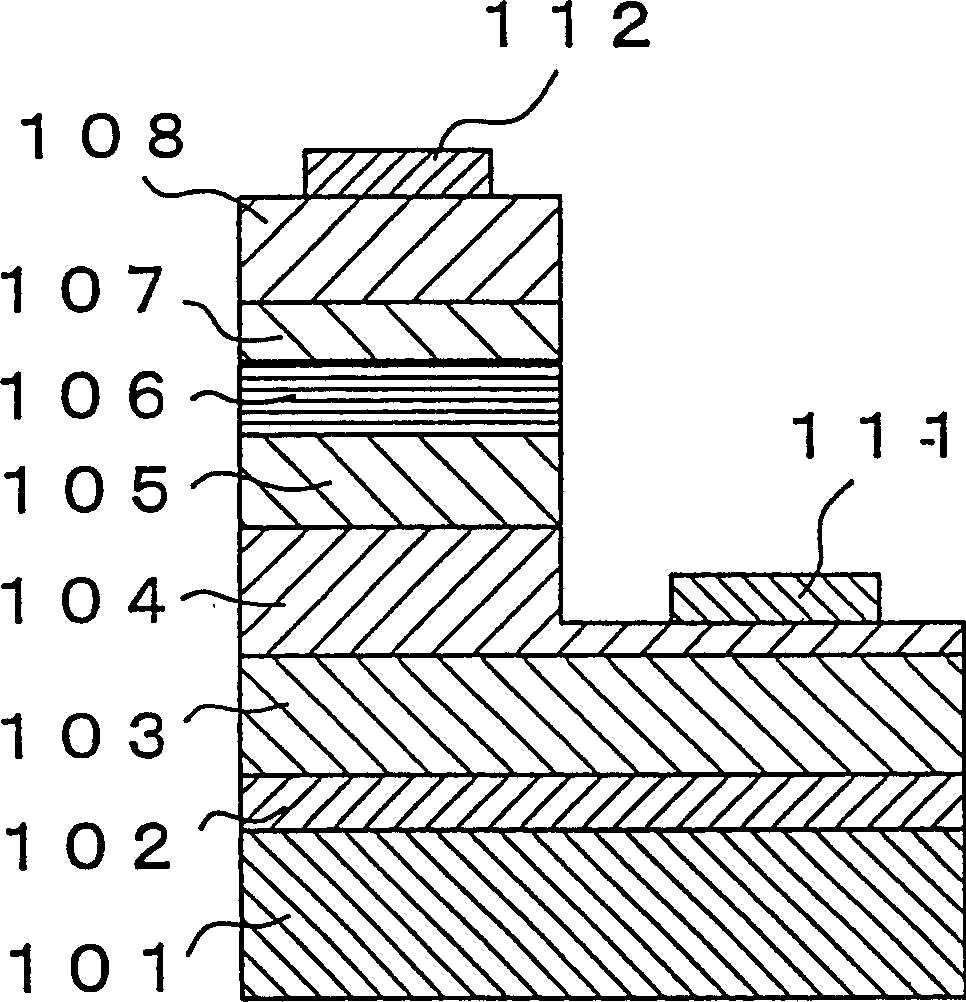

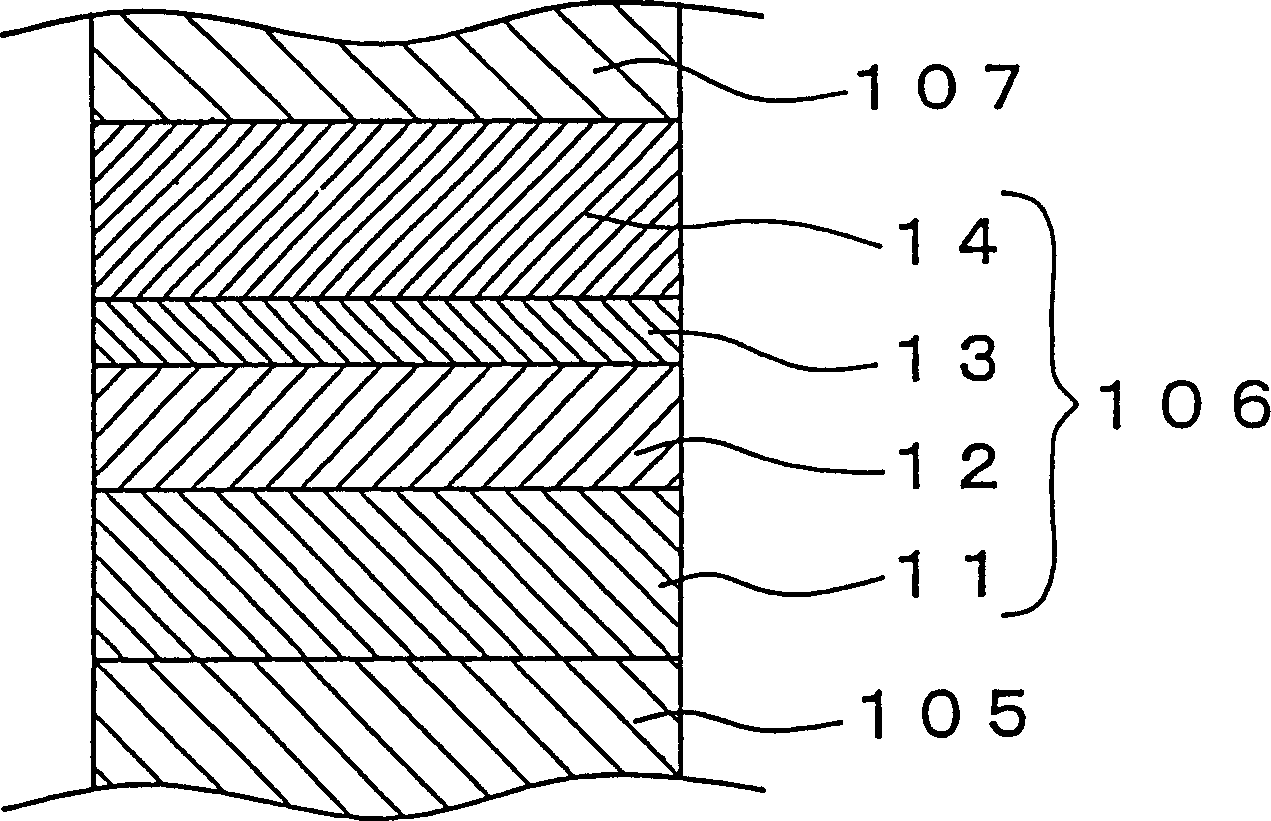

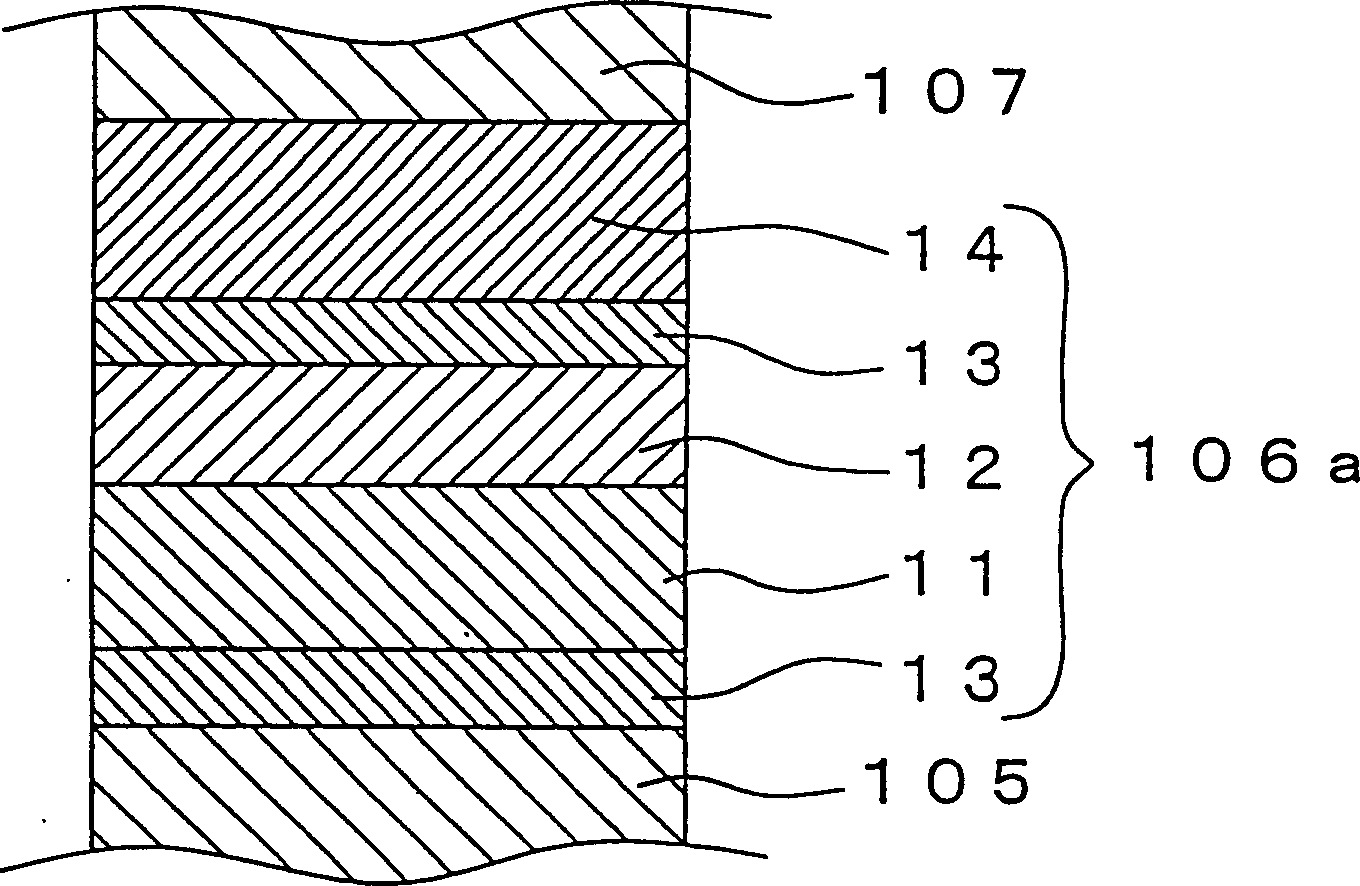

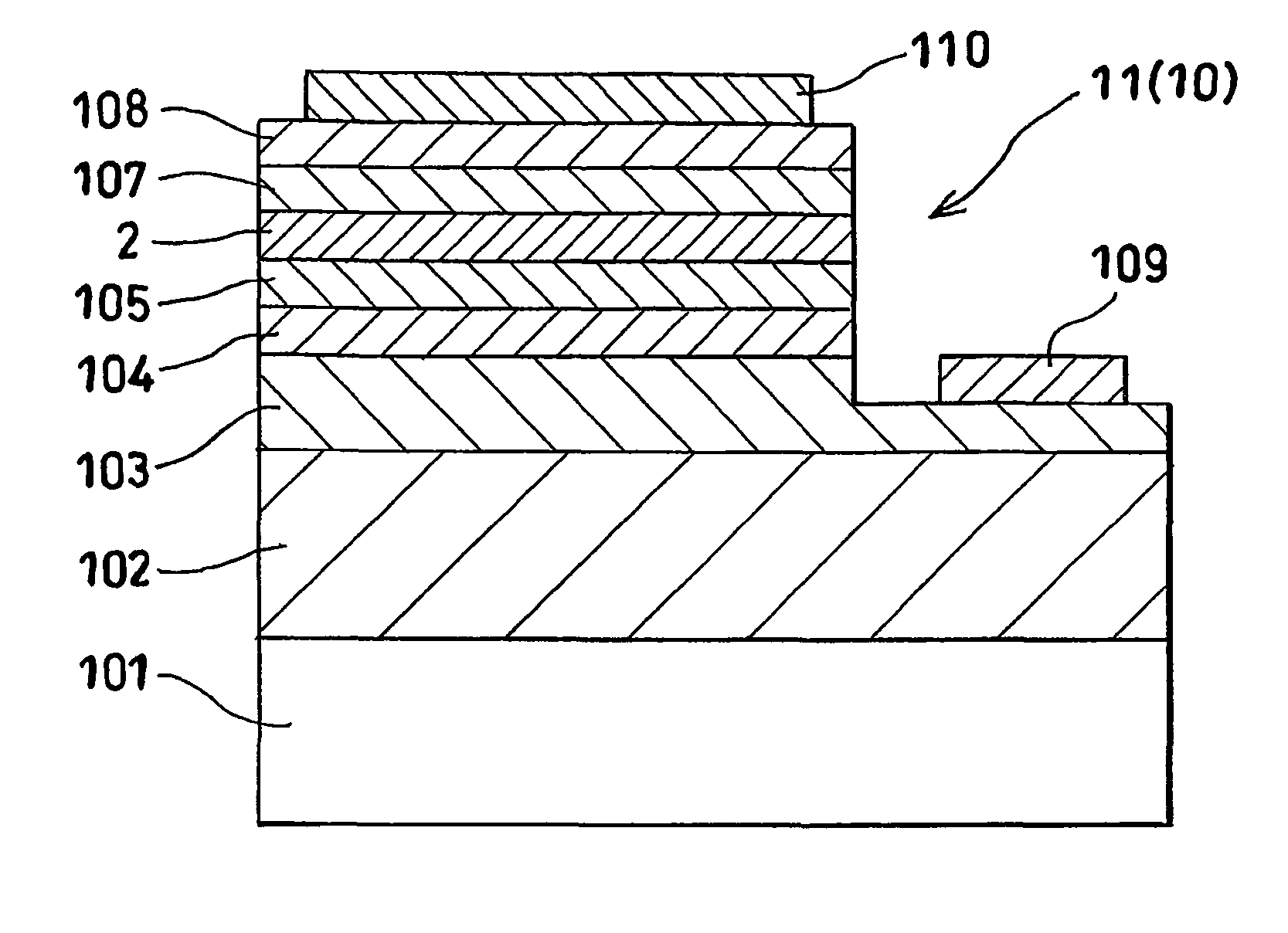

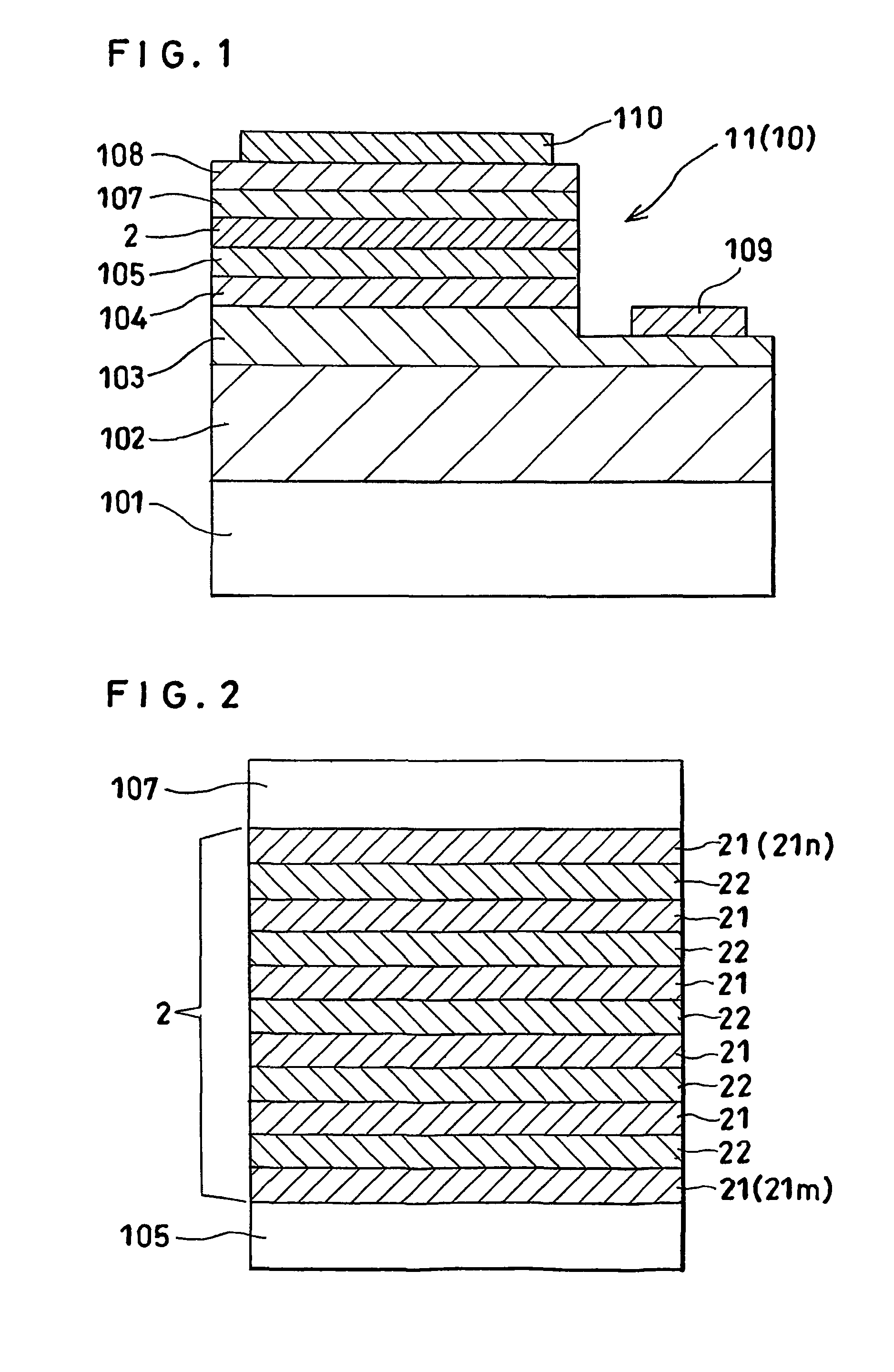

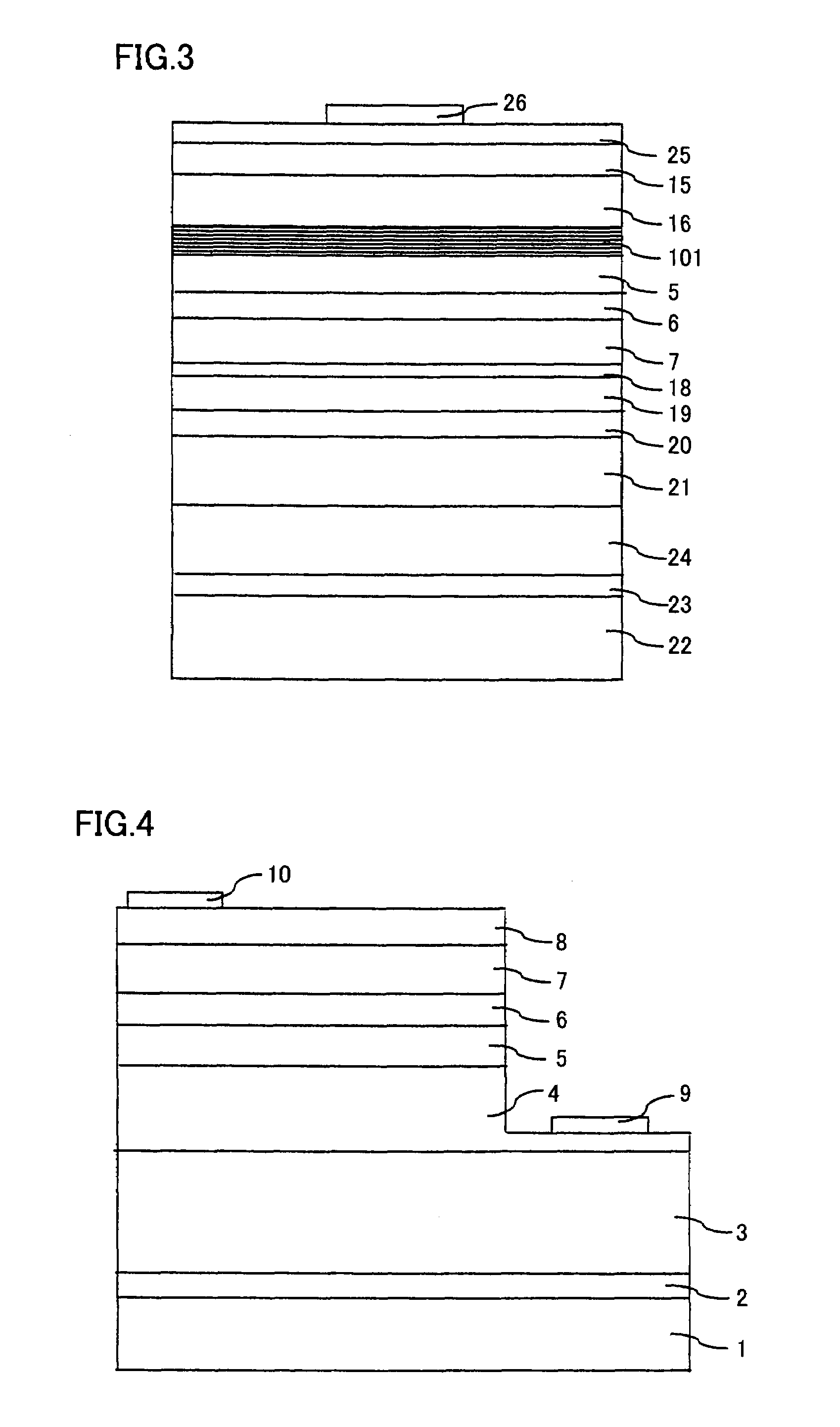

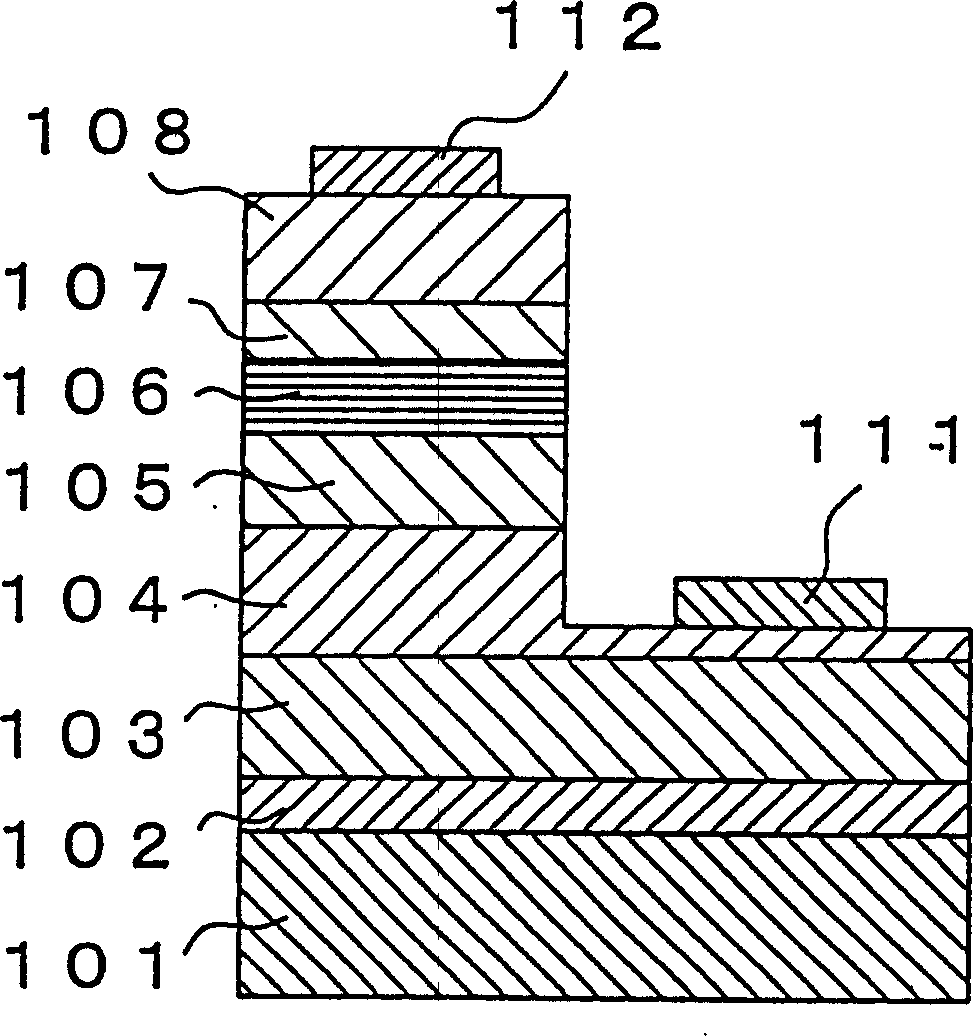

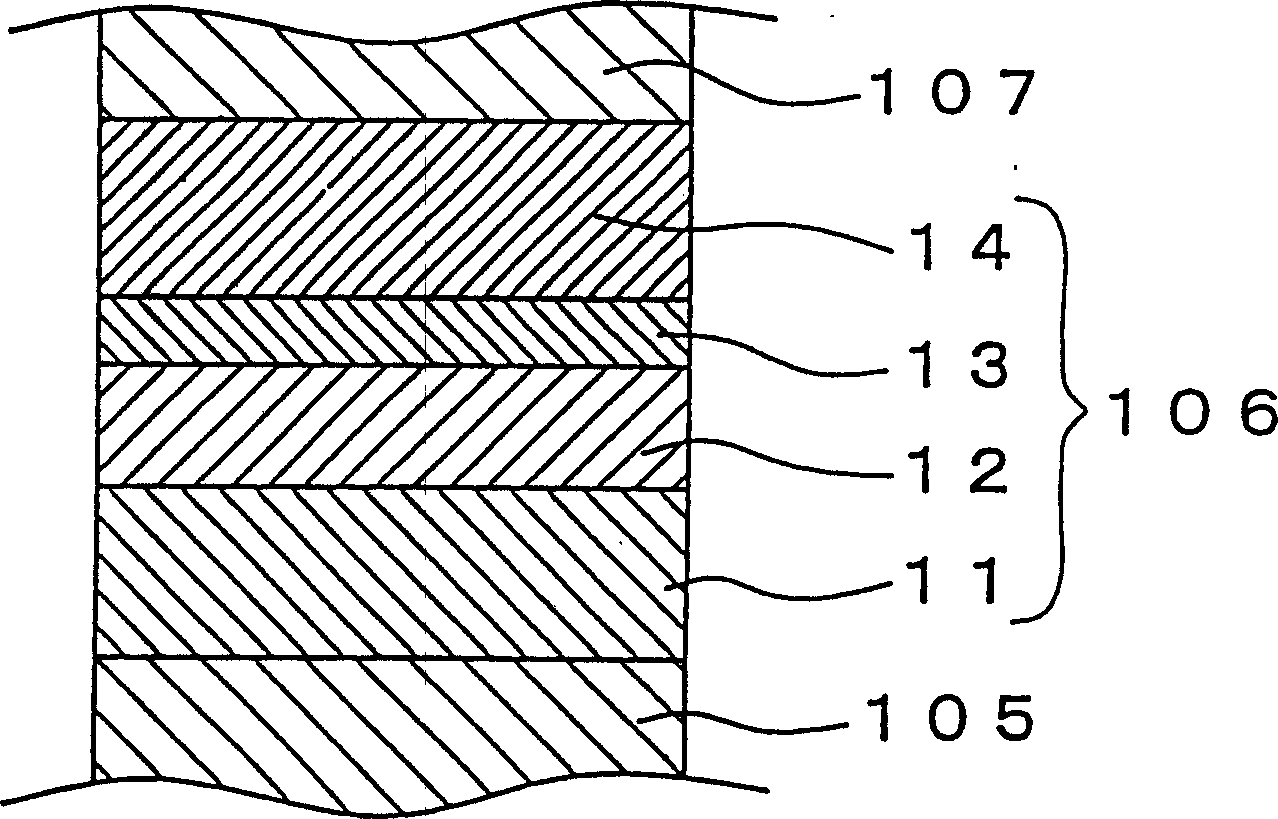

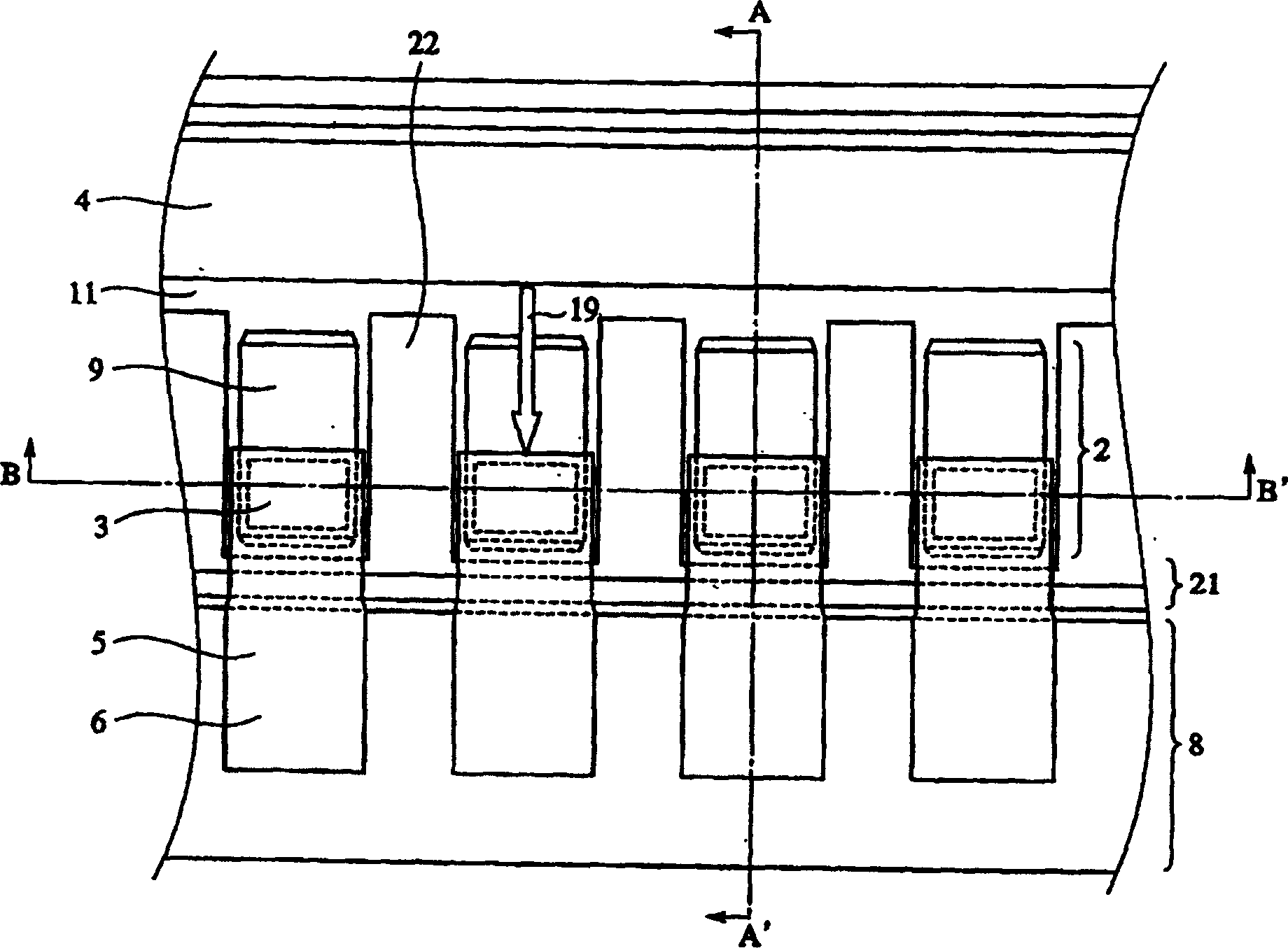

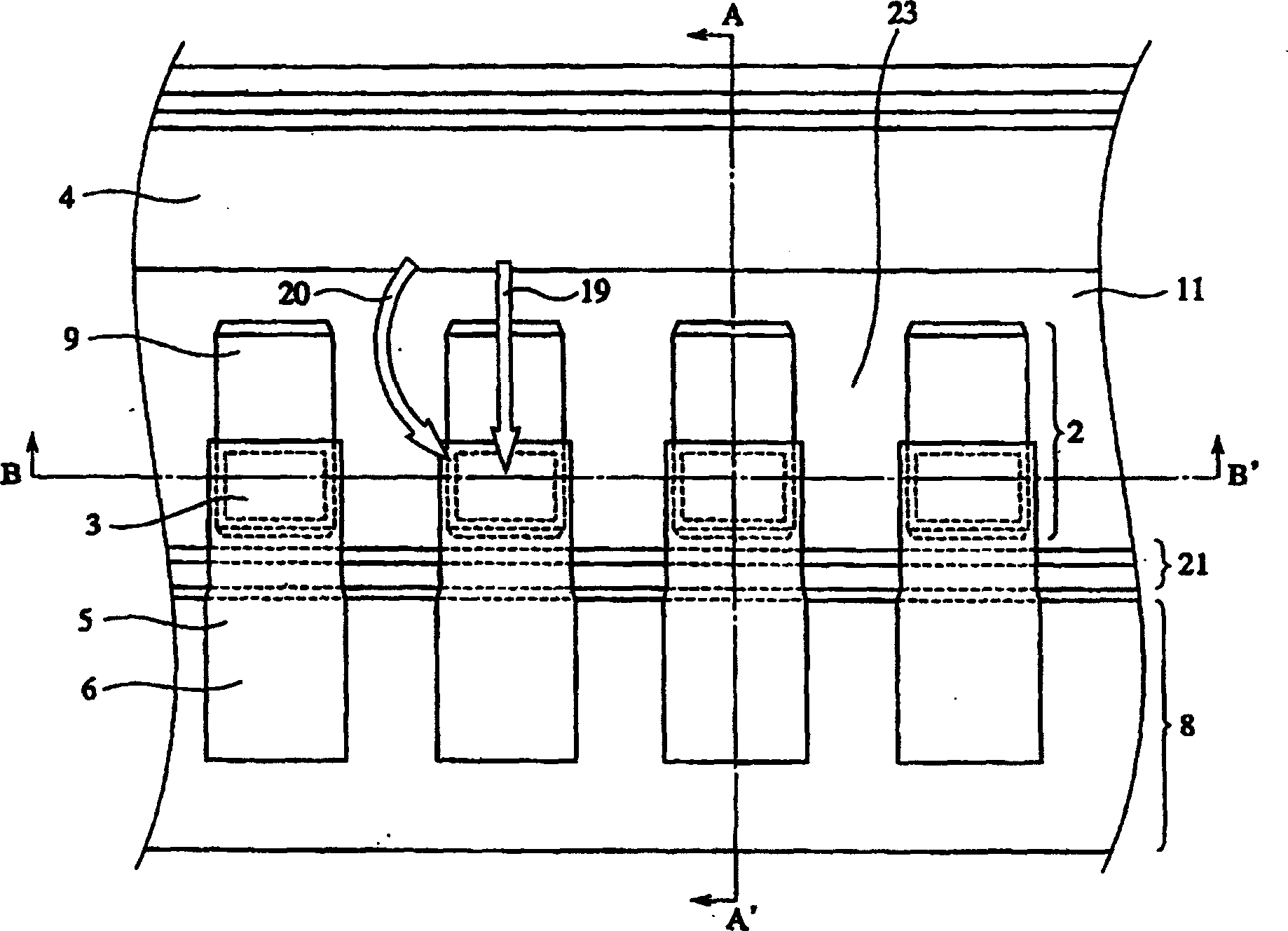

A pn junction type Group III nitride semiconductor light-emitting device 10 (11) of the present invention has a light-emitting layer 2 of multiple quantum well structure in which well layers 22 and barrier layers 21 including Group III nitride semiconductors are alternately stacked periodically between an n-type clad layer 105 and a p-type clad layer 107 which are formed on a crystal substrate and which include Group III nitride semiconductors, in which one end layer 21m of the light-emitting layer 2 is closest to and opposed to the n-type clad layer, and the other end layer 21n of the light-emitting layer 2 is closest to and opposed to the p-type clad layer, both the one and the other end layers are barrier layers, and the other end layer 21n is thicker than the barrier layer of the one end layer.

Owner:TOYODA GOSEI CO LTD

Gallium nitride-based compound semiconductor light-emitting device

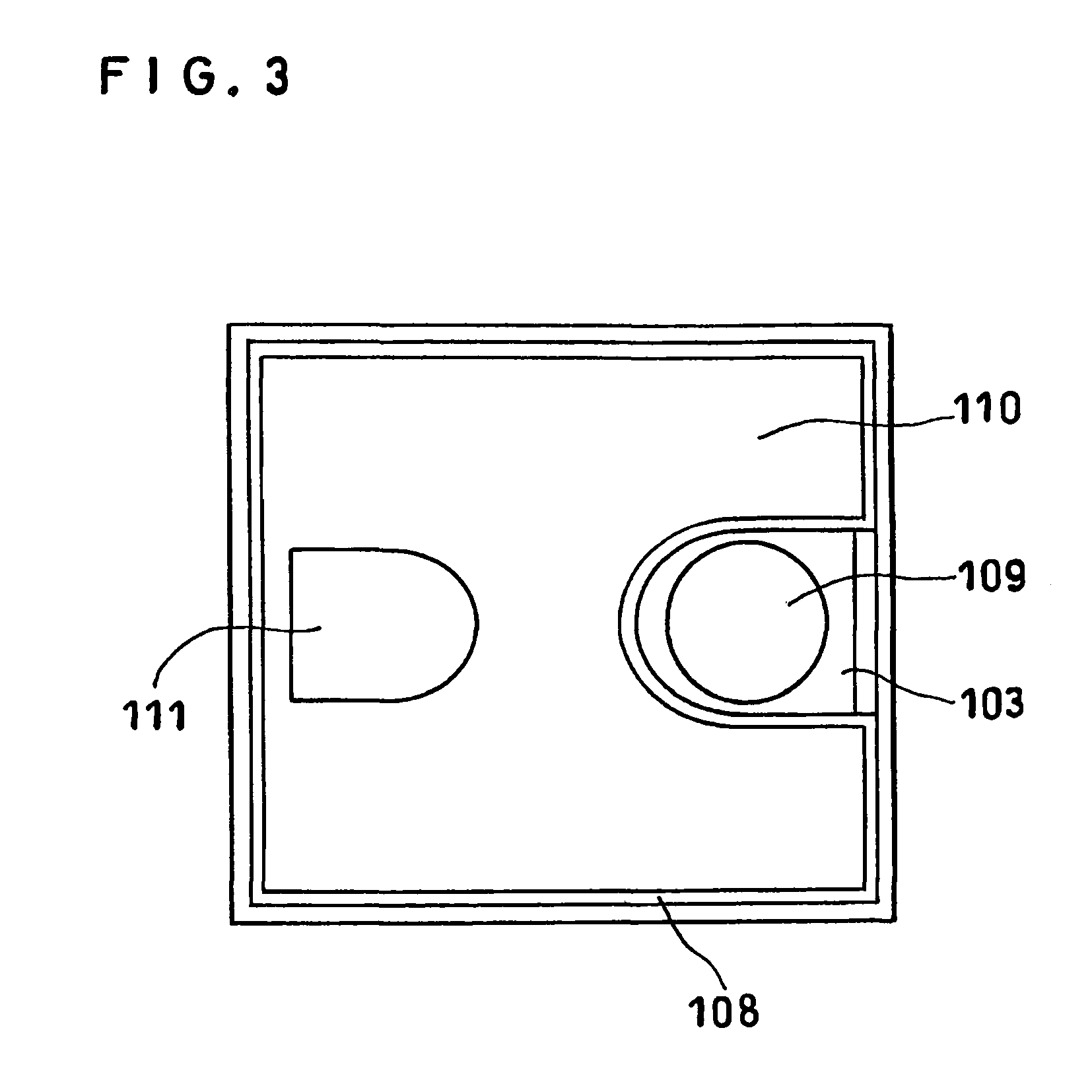

ActiveUS7741653B2Reduce the driving voltageHigh luminous outputSemiconductor devicesTransparent conducting filmGallium nitride

A gallium nitride-based compound semiconductor light-emitting device having an n-type semiconductor layer, a light-emitting layer and a p-type semiconductor layer formed in this order on a substrate. Each layer includes a gallium nitride-based compound semiconductor, the light-emitting device has a negative electrode and a positive electrode provided on the n-type semiconductor layer and on the p-type semiconductor layer, respectively, the positive electrode is at least partially formed of a transparent electrically conducting film, the transparent electrically conducting film is at least partially in contact with the p-type semiconductor layer, a semiconductor metal mixed layer containing a Group III metal component is present on the semiconductor side surface of the transparent electrically conducting film, and the thickness of the semiconductor metal mixed layer is from 0.1 to 10 nm.

Owner:TOYODA GOSEI CO LTD

Light emitting diode

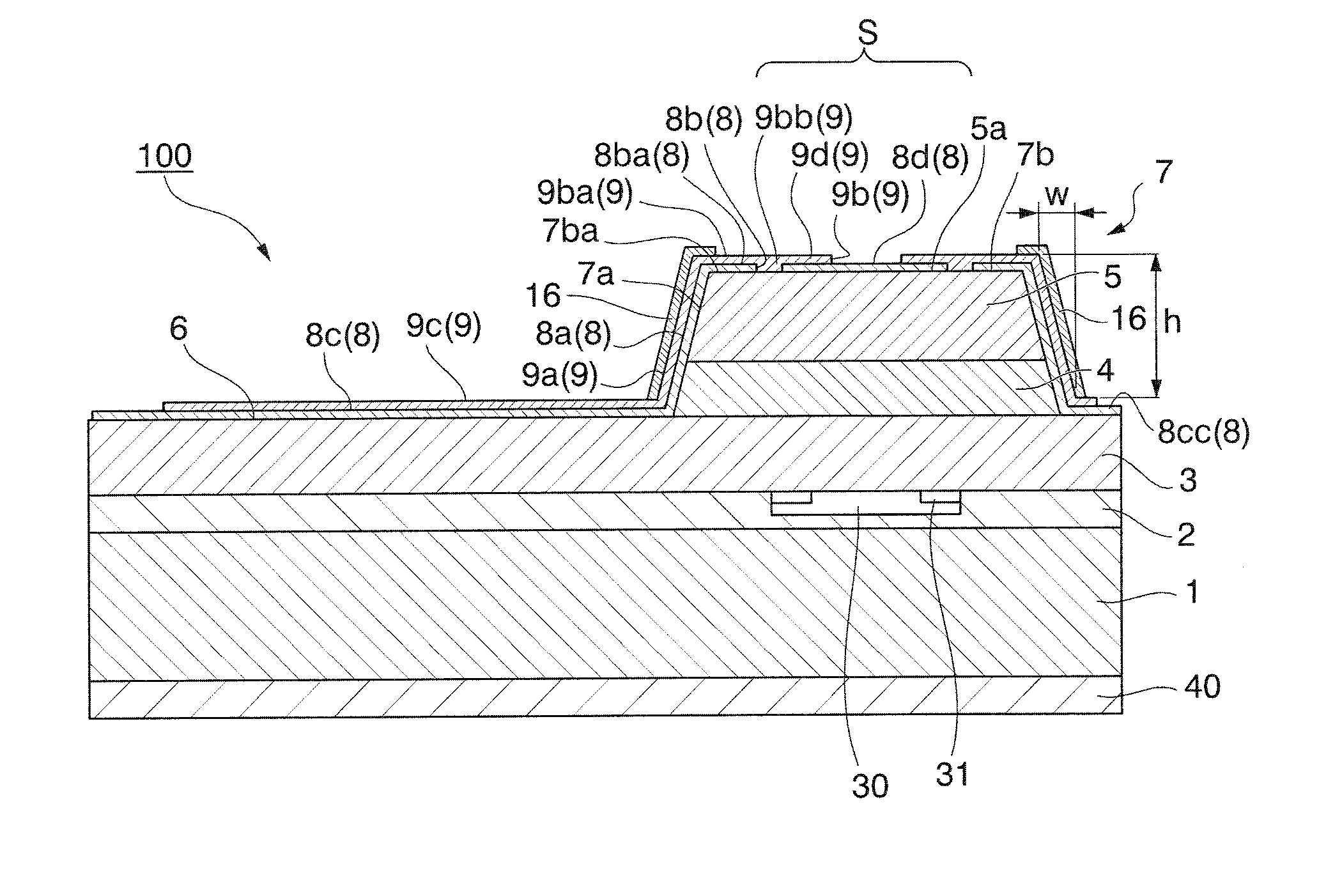

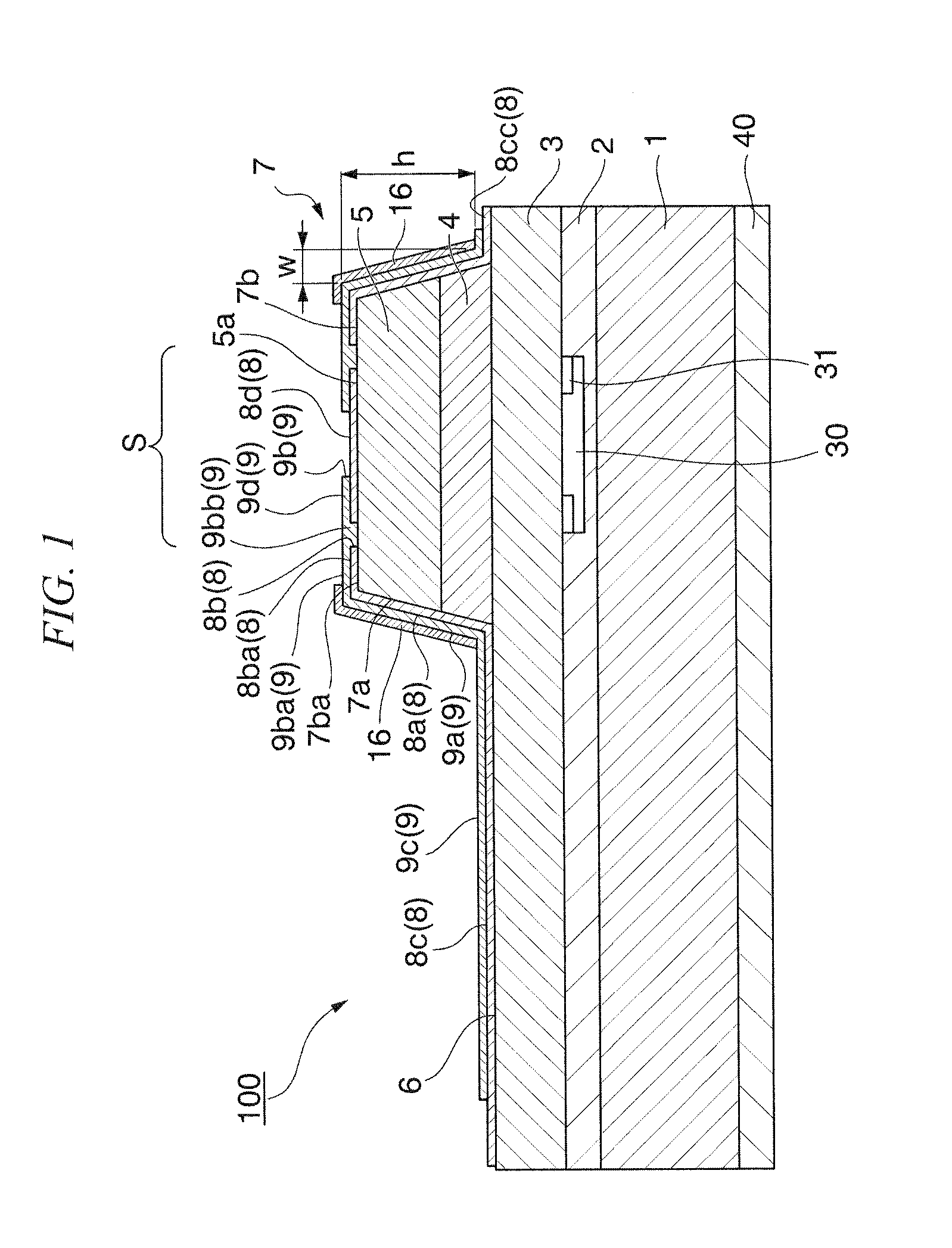

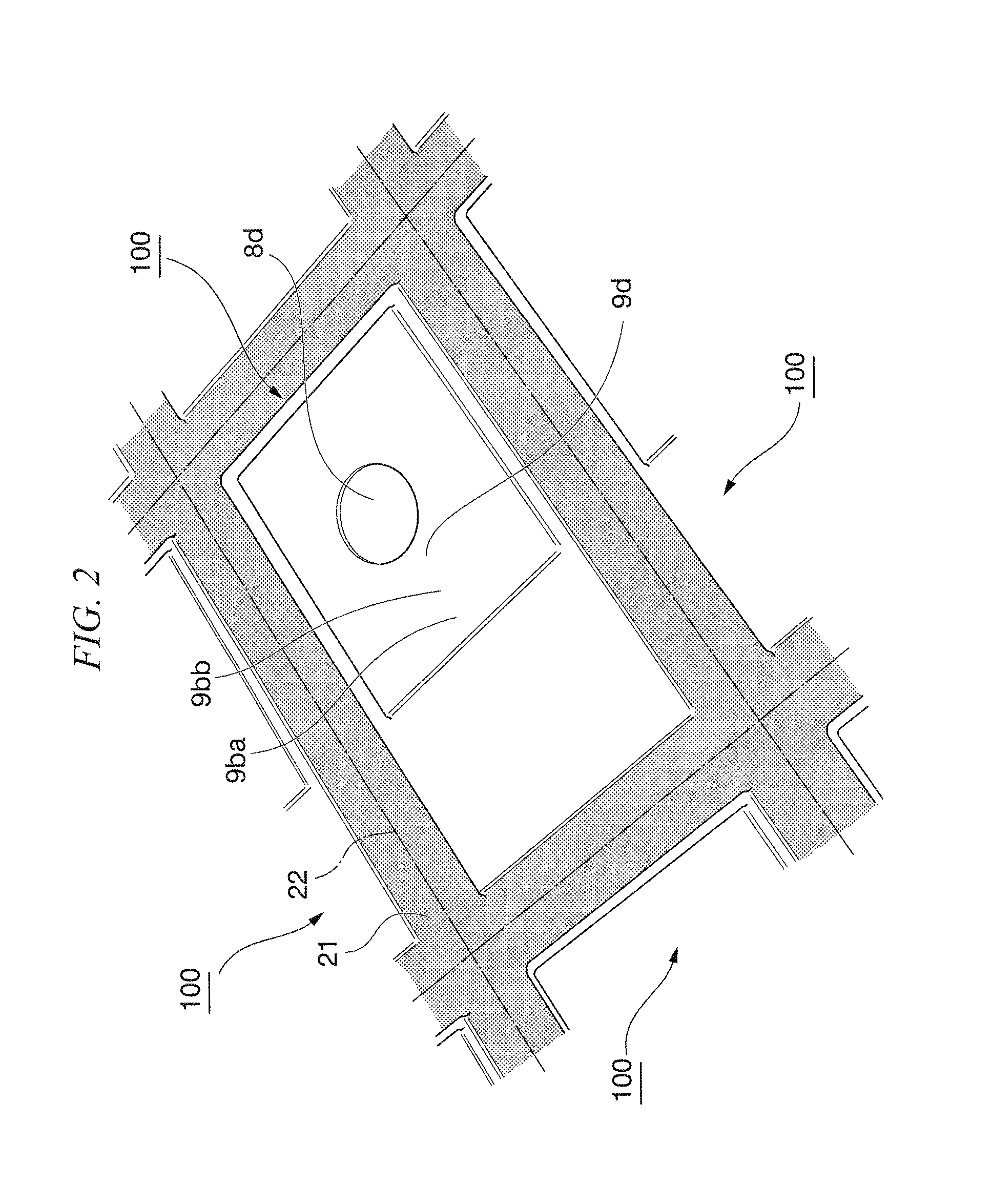

InactiveUS8138516B2High luminous outputSmall driving currentSolid-state devicesSemiconductor devicesElectrical conductorActive layer

A light emitting diode is provided, comprising: a substrate; a metal wiring layer disposed on the substrate; alight emitting element provided on the metal wiring layer; wherein the light emitting element comprises: a semiconductor light emitting layer having a first semiconductor layer, an active layer, and a second semiconductor layer formed from the substrate side sequentially; a transparent insulating layer provided on the substrate side of the semiconductor light emitting layer; a first electrode part and a second electrode part provided on the substrate side of the transparent insulating layer in such a manner as being separated from each other, and joined to the metal wiring layer; a first contact part provided so as to pass through the transparent insulating layer and electrically connecting the first electrode part and the first semiconductor layer; and a second contact part provided so as to pass through the transparent insulating layer, the first semiconductor layer, and the active layer, and electrically connecting the second electrode part and the second semiconductor layer.

Owner:SUMITOMO CHEM CO LTD

Gallium nitride-based compound semiconductor light-emitting device

ActiveUS20090224282A1High crystallinityLower resistanceSemiconductor devicesCompound (substance)Transparent conducting film

An object of the present invention is to provide a gallium nitride-based compound semiconductor light-emitting device with low driving voltage and high light emission output, which has a positive electrode comprising a transparent electrically conducting layer put into direct contact with a p-type semiconductor layer.The inventive gallium nitride-based compound semiconductor light-emitting device comprises an n-type semiconductor layer, a light-emitting layer and a p-type semiconductor layer which are formed in this order on a substrate, wherein each layer comprises a gallium nitride-based compound semiconductor, the light-emitting device has a negative electrode and a positive electrode provided on the n-type semiconductor layer and on the p-type semiconductor layer, respectively, the positive electrode is at least partially formed of a transparent electrically conducting film, the transparent electrically conducting film is at least partially in contact with the p-type semiconductor layer, a semiconductor metal mixed layer containing a Group III metal component is present on the semiconductor side surface of the transparent electrically conducting film, and the thickness of the semiconductor metal mixed layer is from 0.1 to 10 nm.

Owner:TOYODA GOSEI CO LTD

Light-emitting device

A light-emitting device having an active layer made of a nitride semiconductor containing In, especially a light-emitting device emitting a light of long wavelength (above 550 nm) and having an improved output power, wherein the active layer is formed between an n-type semiconductor layer and a p-type semiconductor layer and includes a well layer made of Inx1Ga1-x1N (x1>0) containing In and a first barrier layer formed on the well layer and made of Aly2Ga1-y2N (y2>0) containing Al.

Owner:NICHIA CORP

Light emitting element

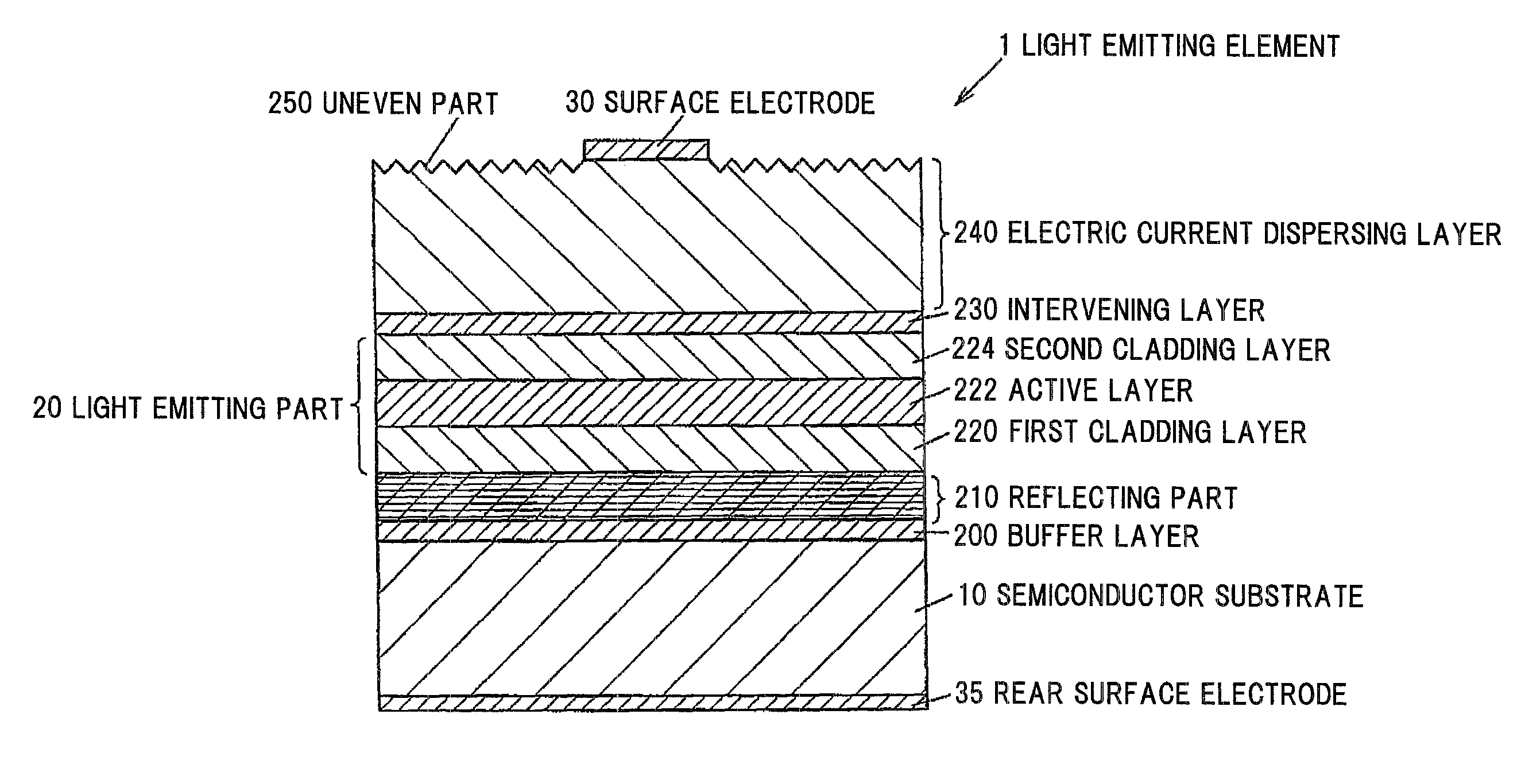

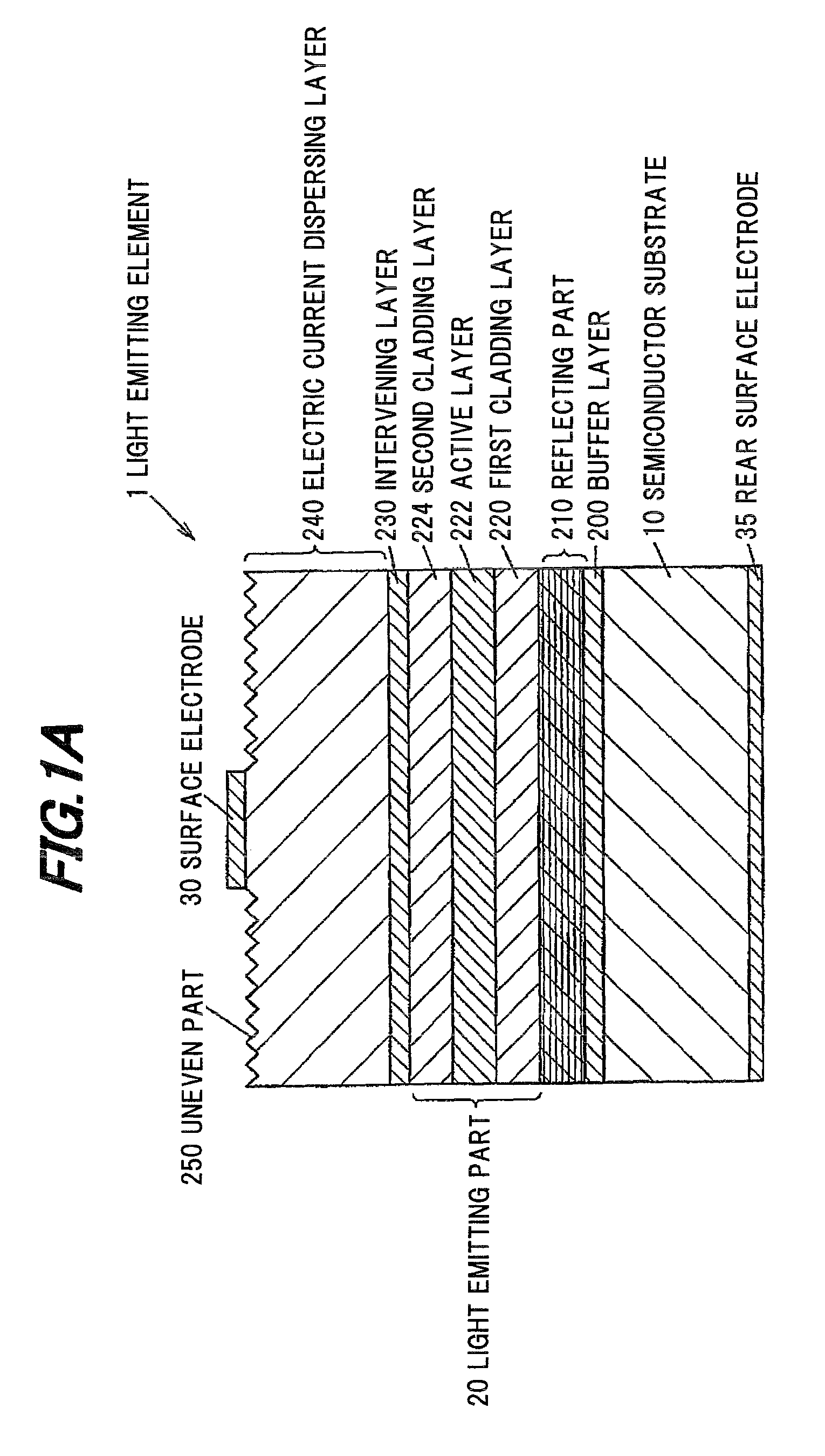

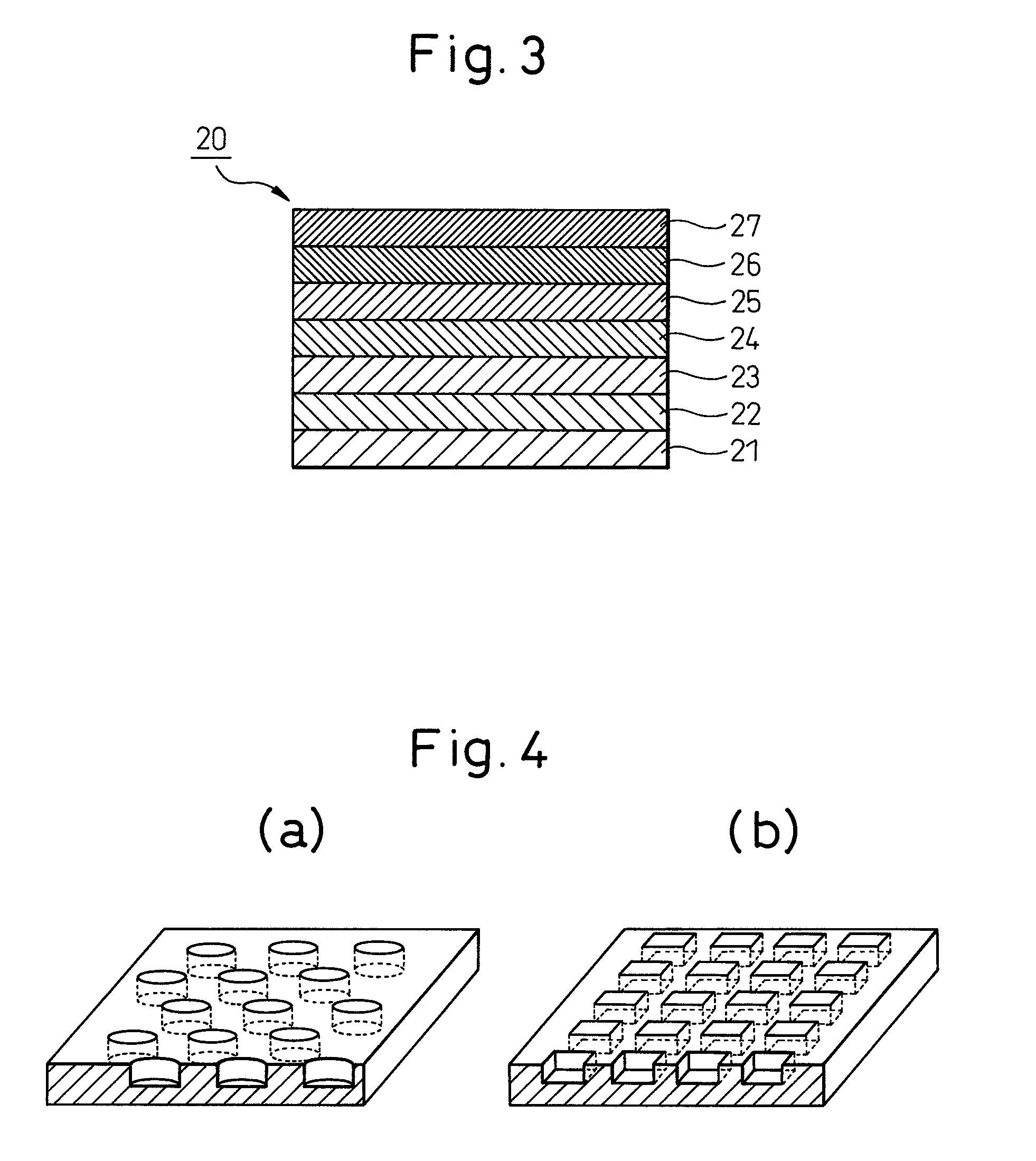

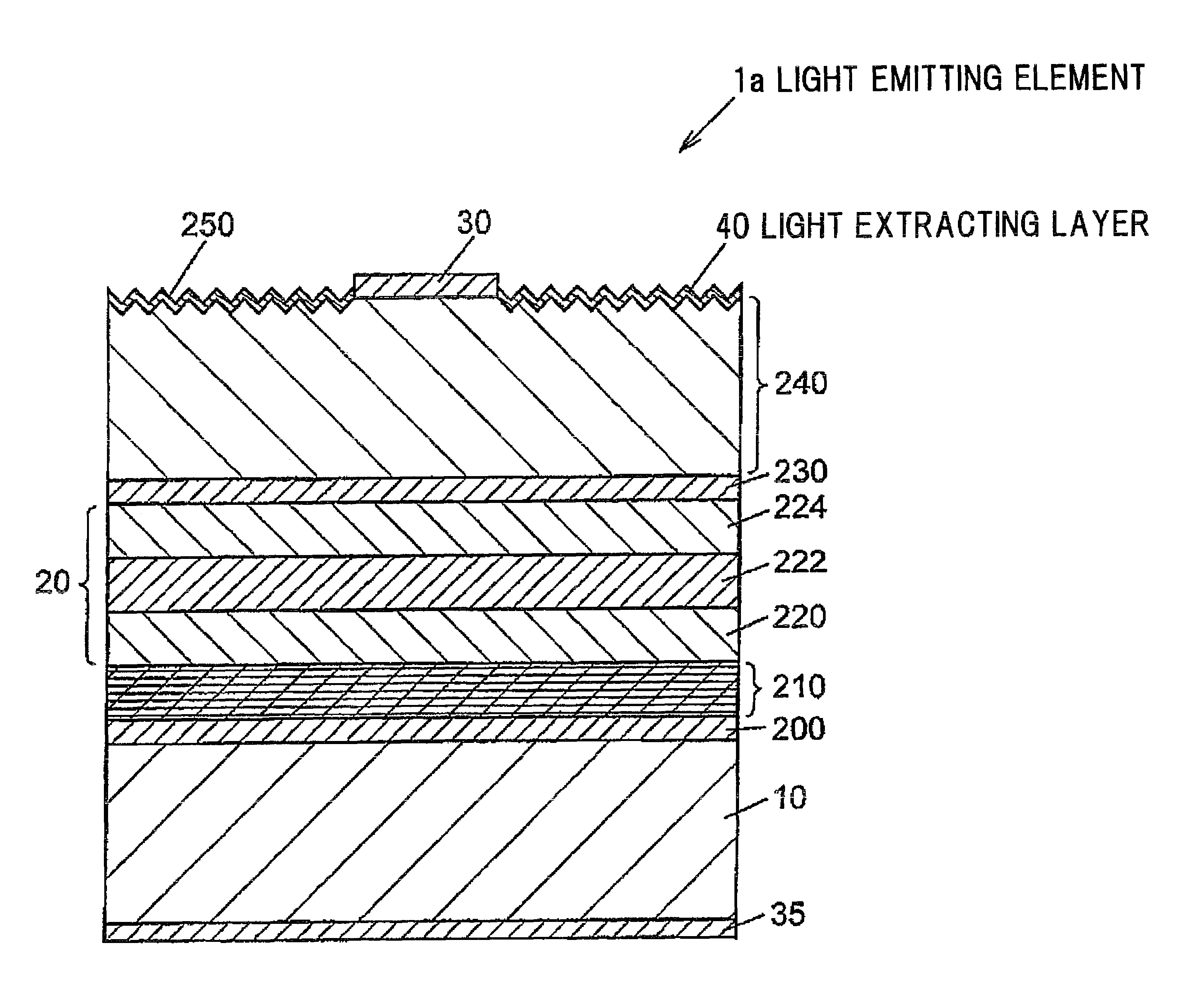

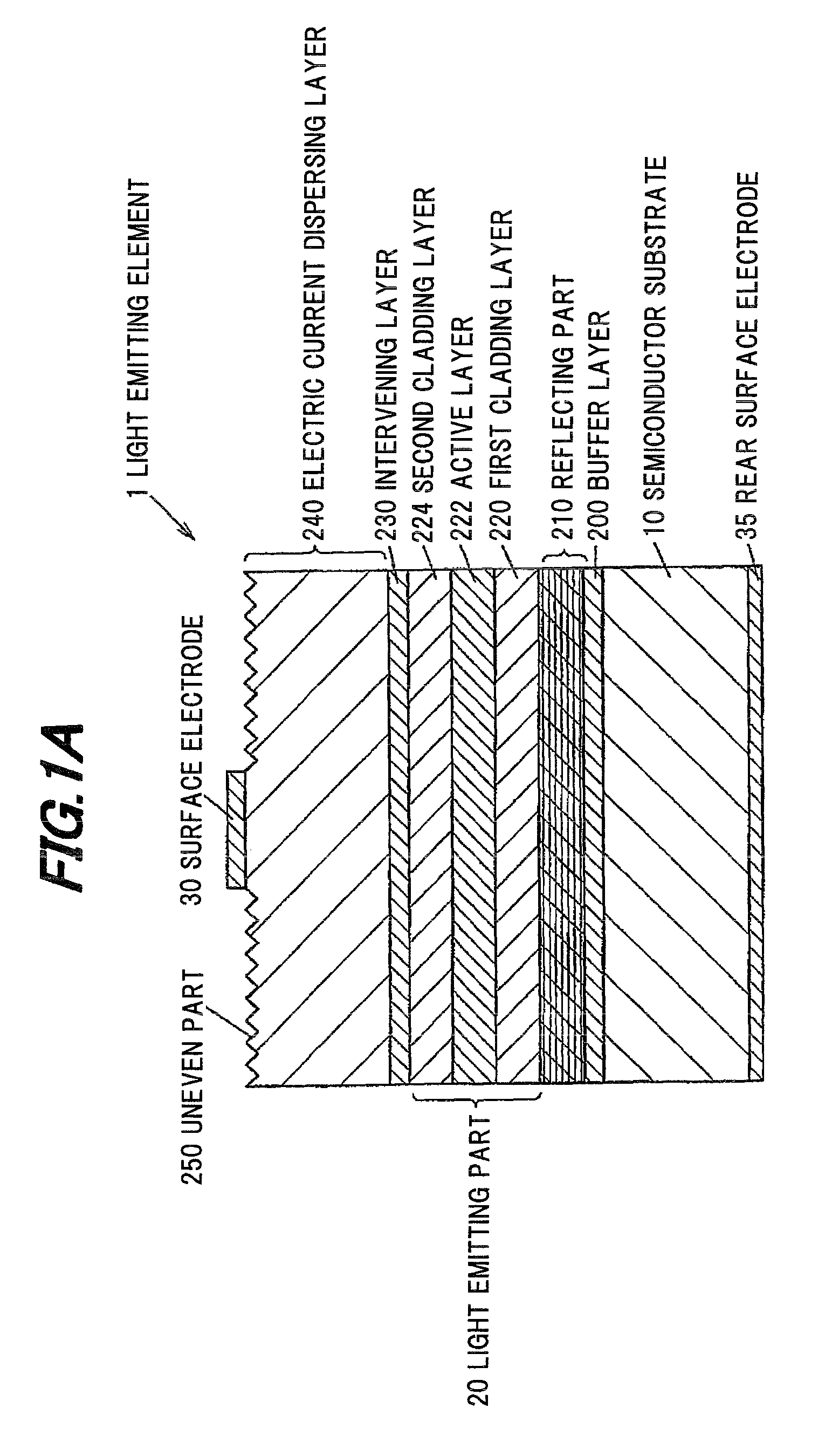

InactiveUS20110079800A1Enhance light emission outputIncrease thicknessSolid-state devicesSemiconductor devicesElectrical conductorRefractive index

A light emitting element according to an embodiment of the invention includes a semiconductor substrate, a light emitting part having a first conductivity type first cladding layer; a second conductivity type second cladding layer different from the first cladding layer in the conductivity type and an active layer sandwiched between the first cladding layer and the second cladding layer, a reflecting part for reflecting a light emitted from the active layer, disposed between the semiconductor substrate and the light emitting part so as to have a thickness of 1.7 μm to 8.0 μm and an electric current dispersing layer disposed on a side of the light emitting part opposite to the reflecting part, having a uneven part on the surface thereof, wherein the reflecting part is formed so as to have at least three pair layers formed of a first semiconductor layer and a second semiconductor layer different from the first semiconductor layer, the first semiconductor layer has a thickness TA defined by the formula (1), if peak wavelength of the light emitted from the active layer is λP, refractive index of the first semiconductor layer is nA, refractive index of the second semiconductor layer is nB, refractive index of the first cladding layer is nIn, and incident angle of light to the second semiconductor layer is θ, the second semiconductor layer has a thickness TB defined by the formula (2), and a plurality of pair layers of the reflecting part have a different thickness to each other according as values of the incident angle of light θ in the formulae (1) and (2) are different with respect to each pair layer, and at least one pair layer includes the first semiconductor layer and the second semiconductor layer defined by that the incident angle of light θ is not less than 50 degrees.TA=λp4nA1-(nInsinθnA)2(1)TB=λp4nB1-(nInsinθnB)2(2)

Owner:SUMITOMO CHEM CO LTD

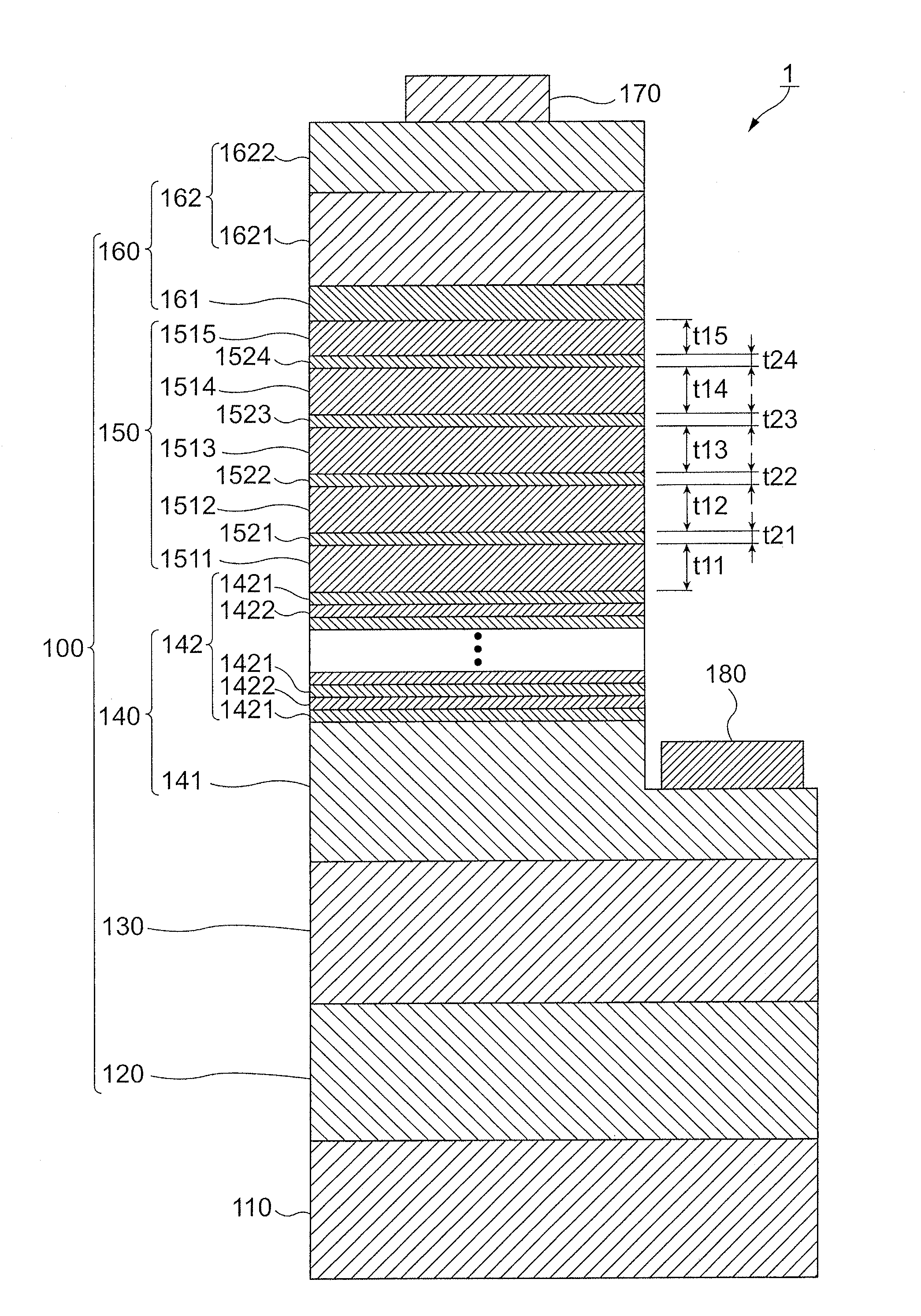

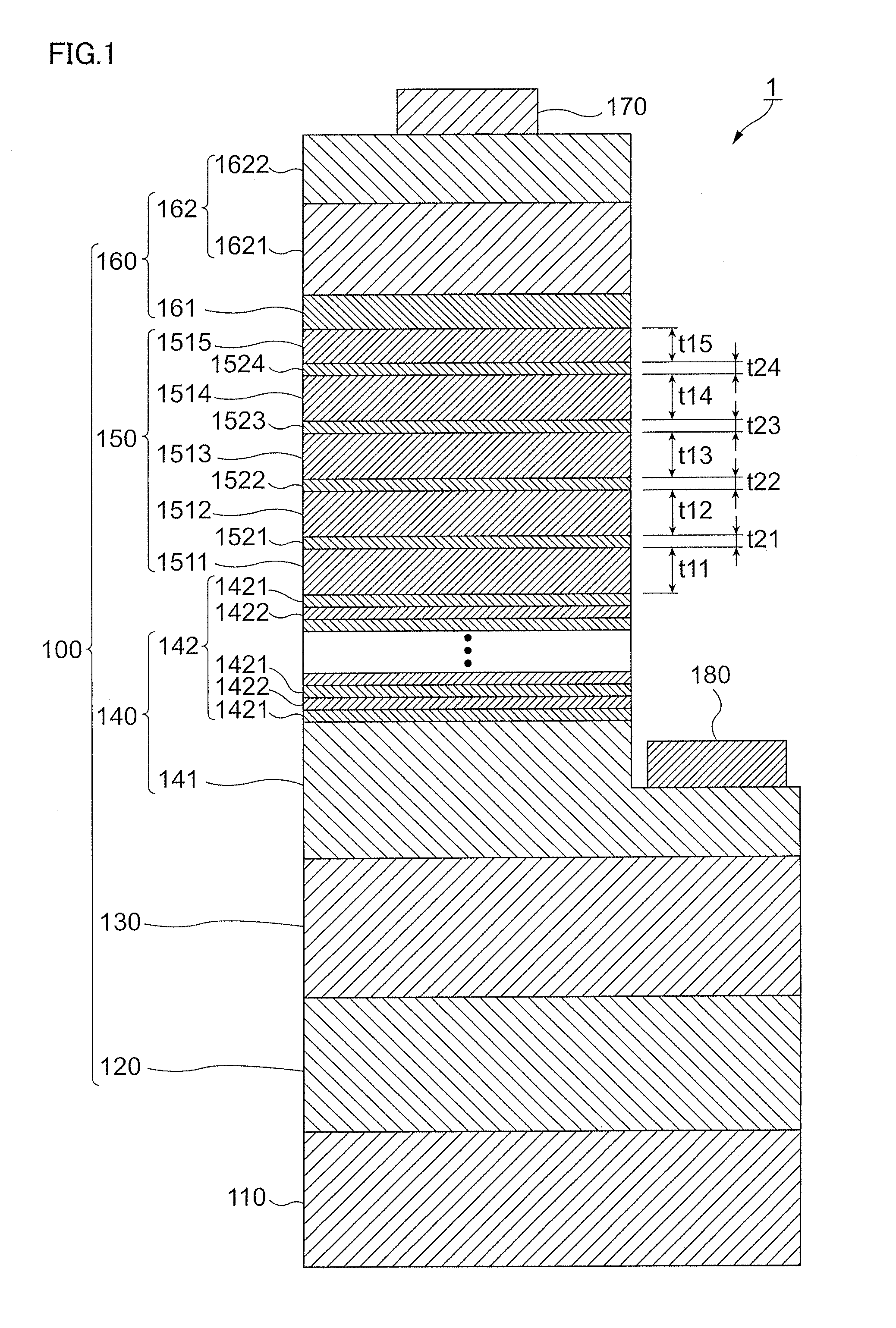

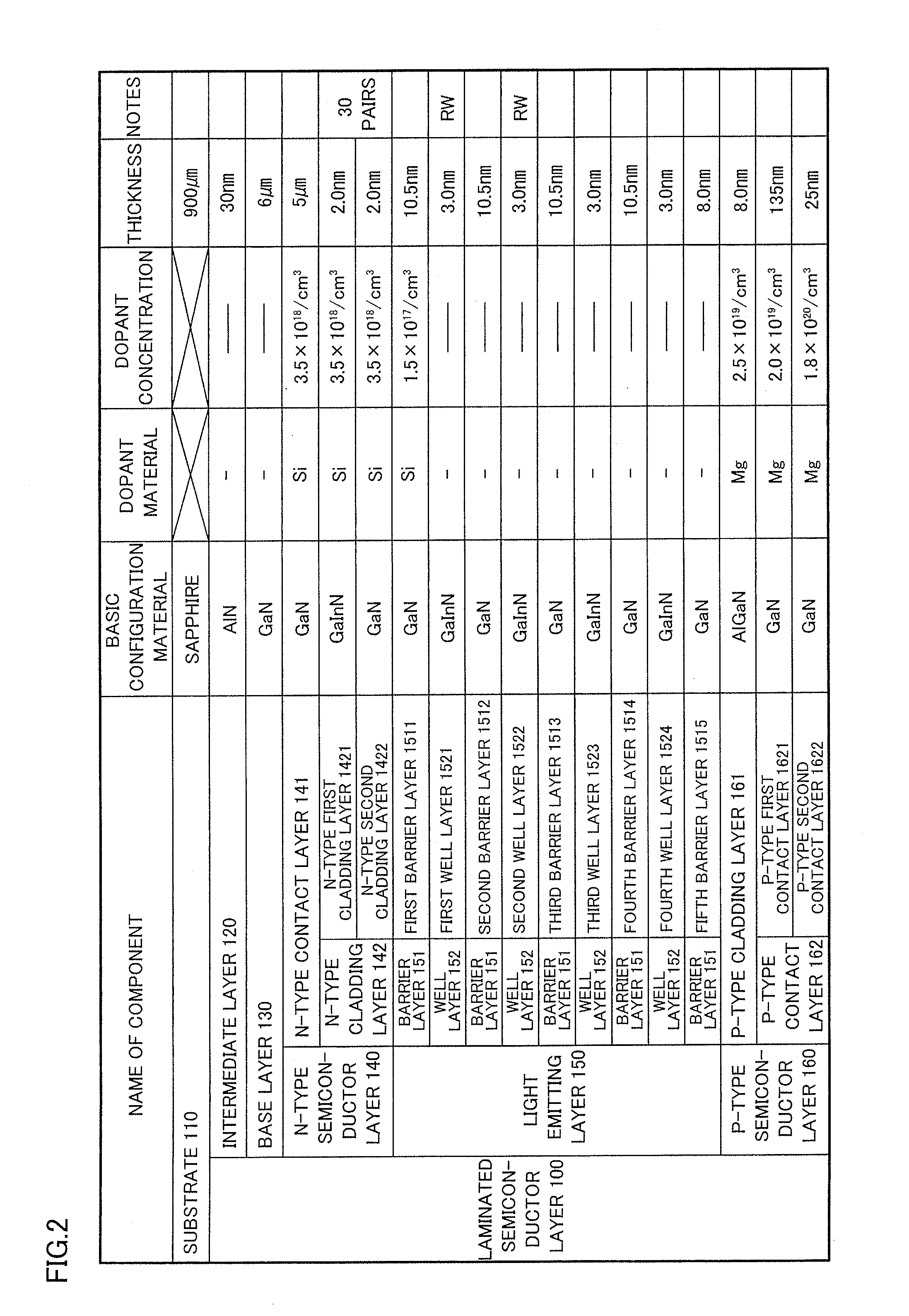

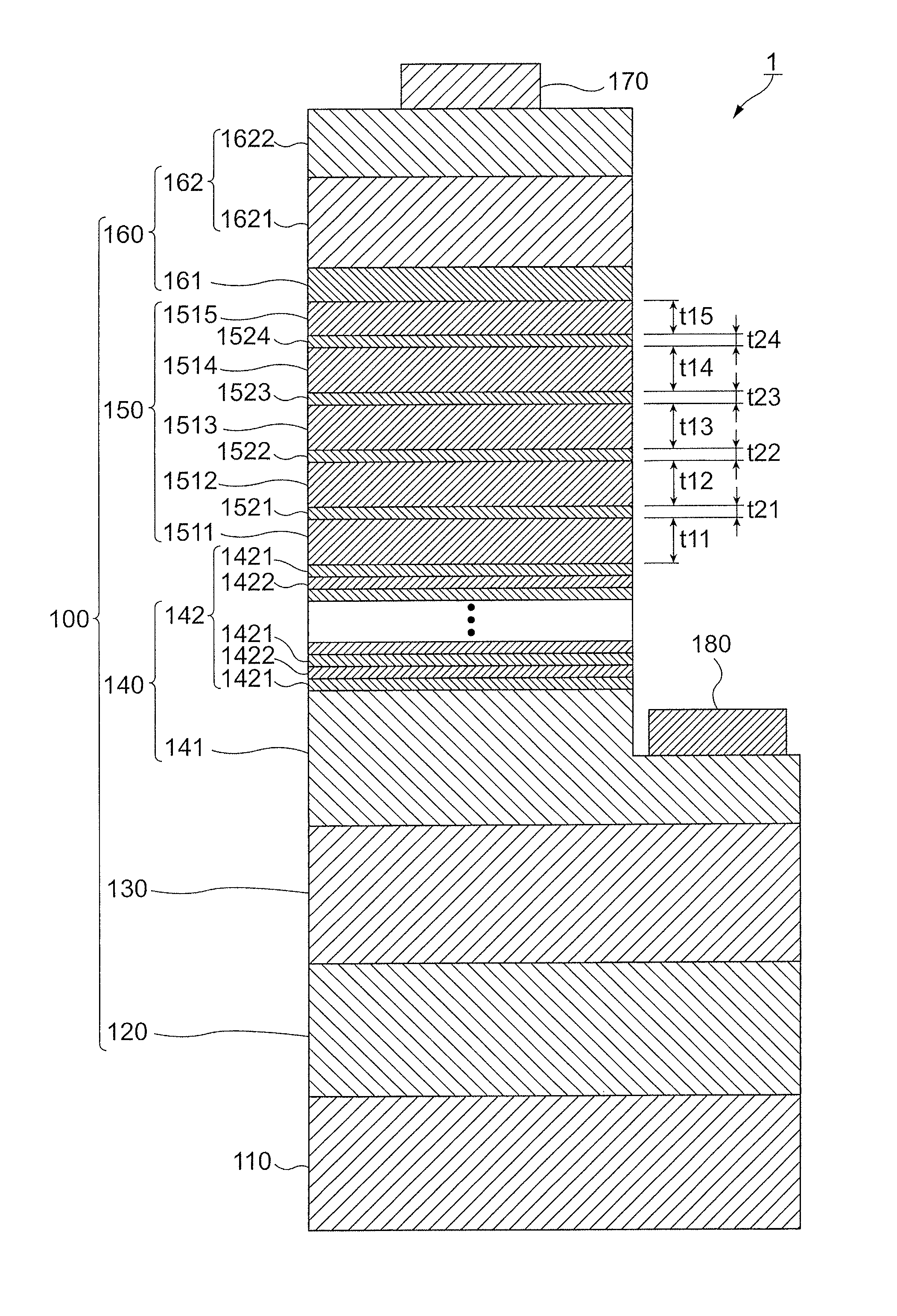

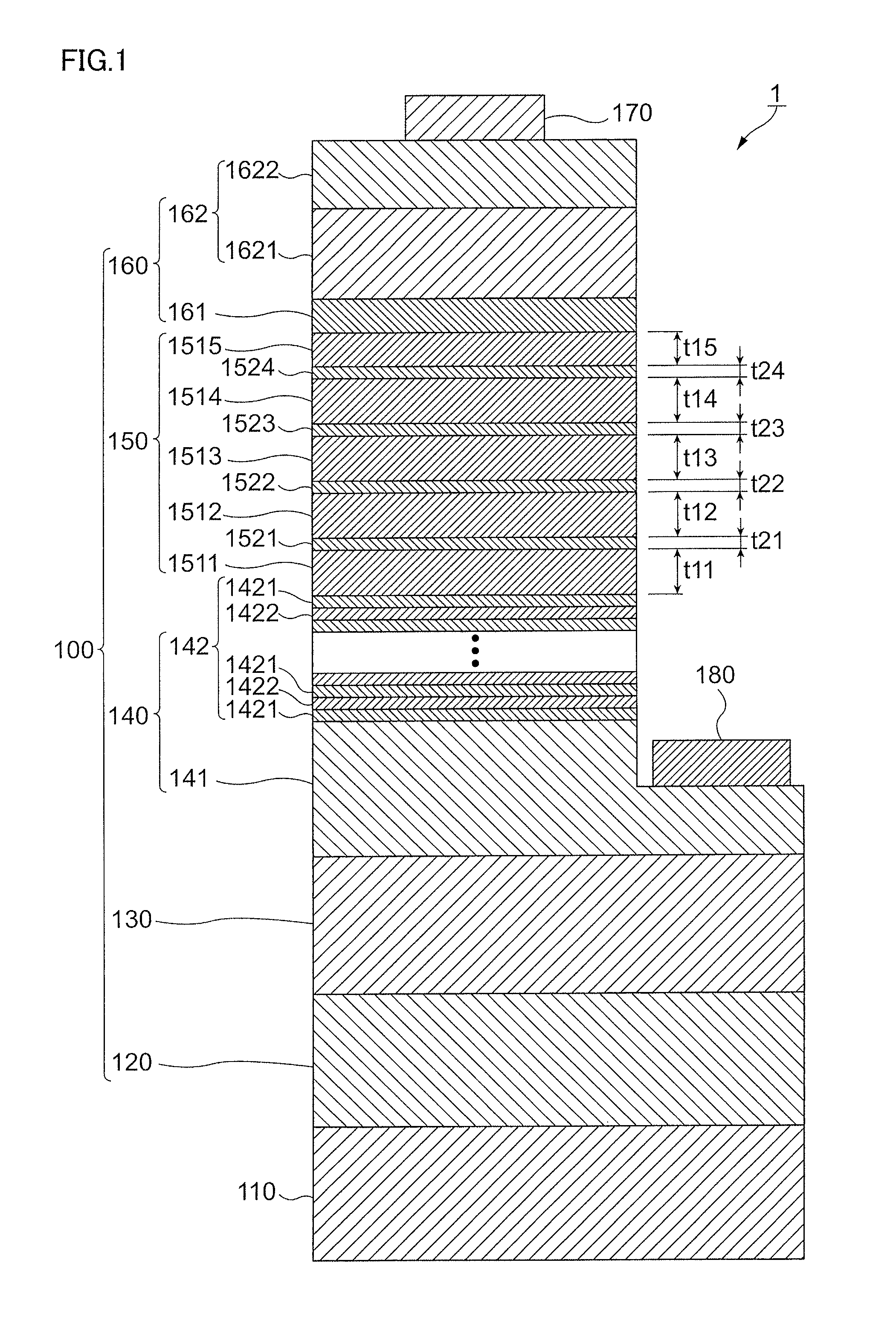

Semiconductor light emitting element and light emitting device

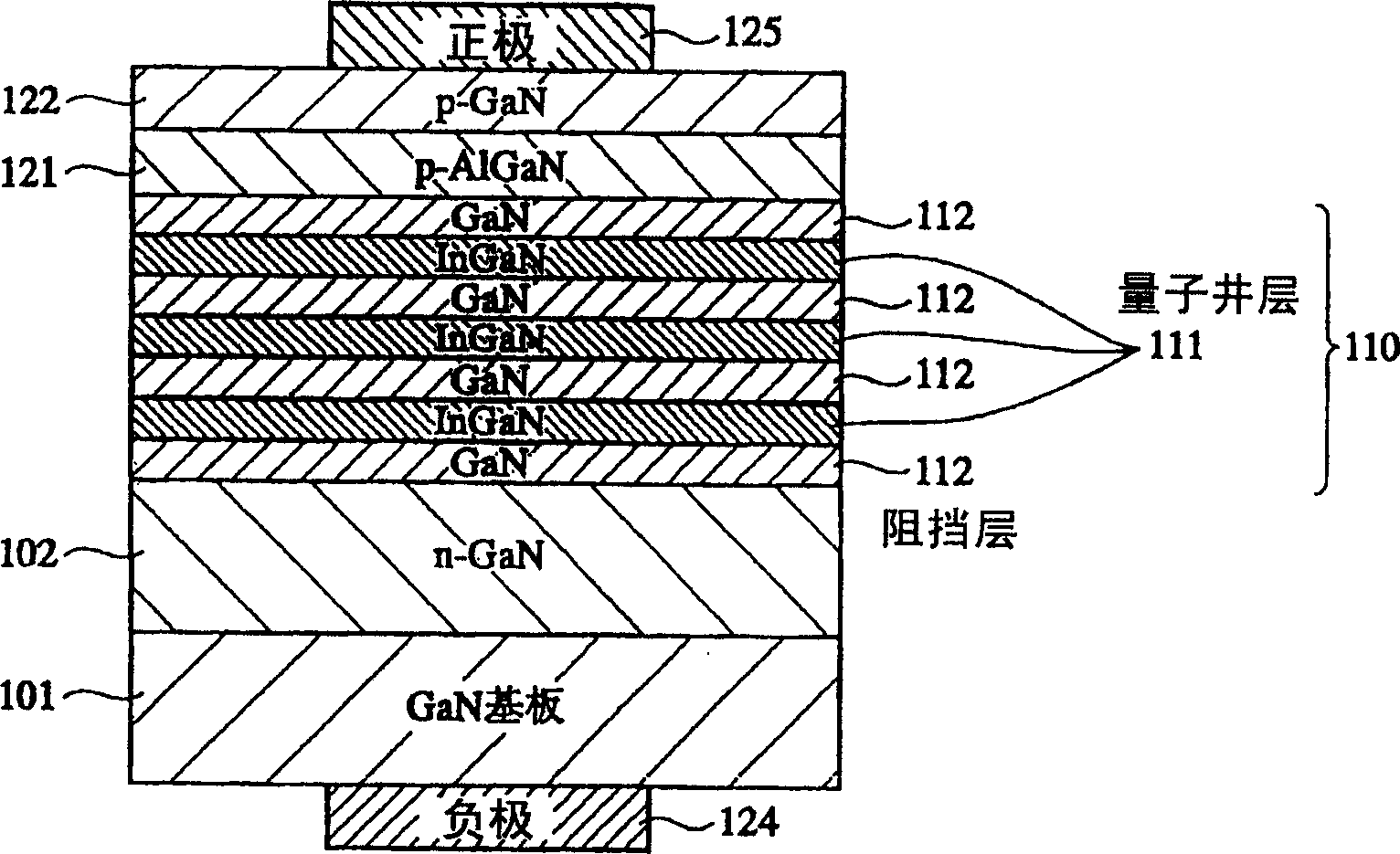

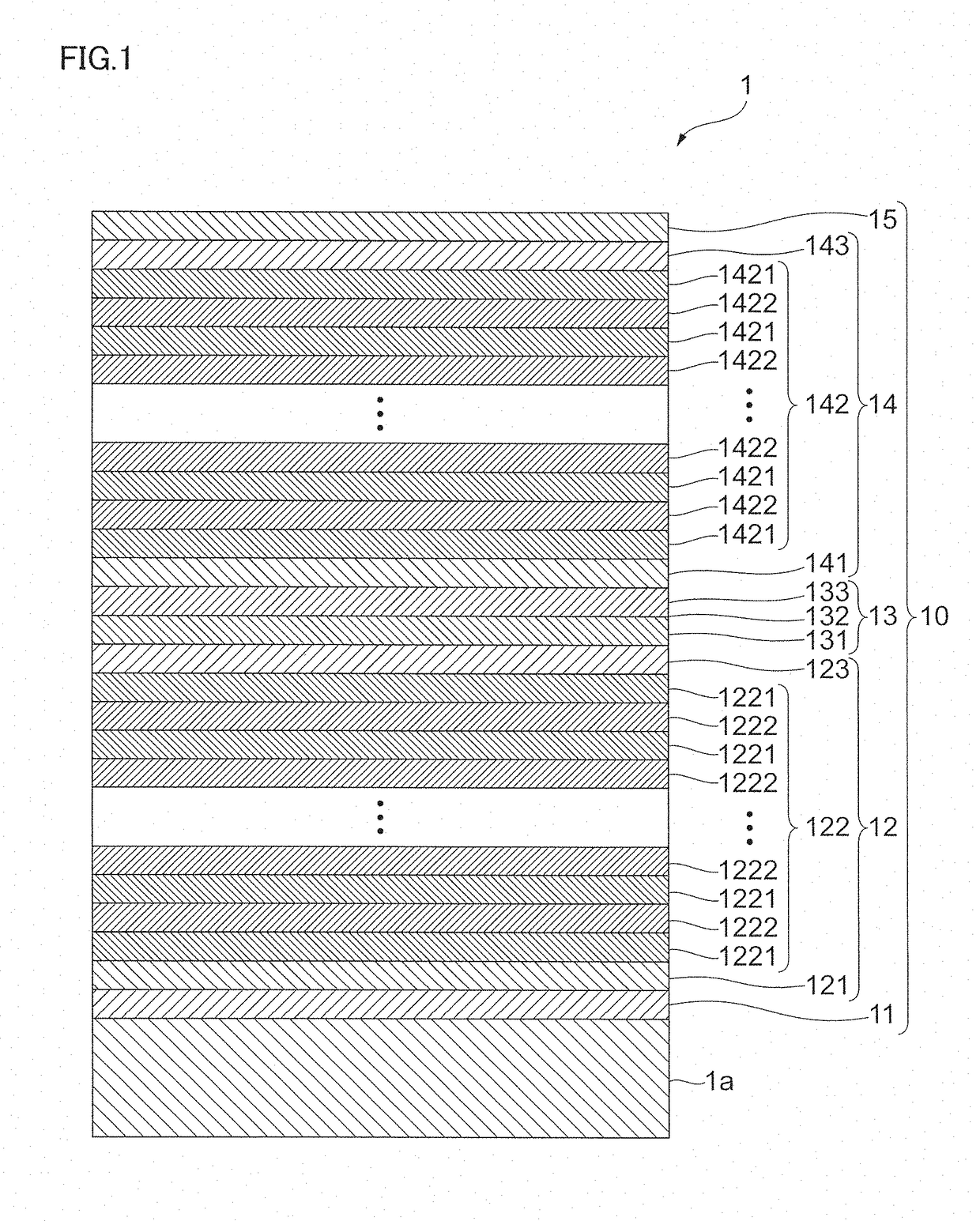

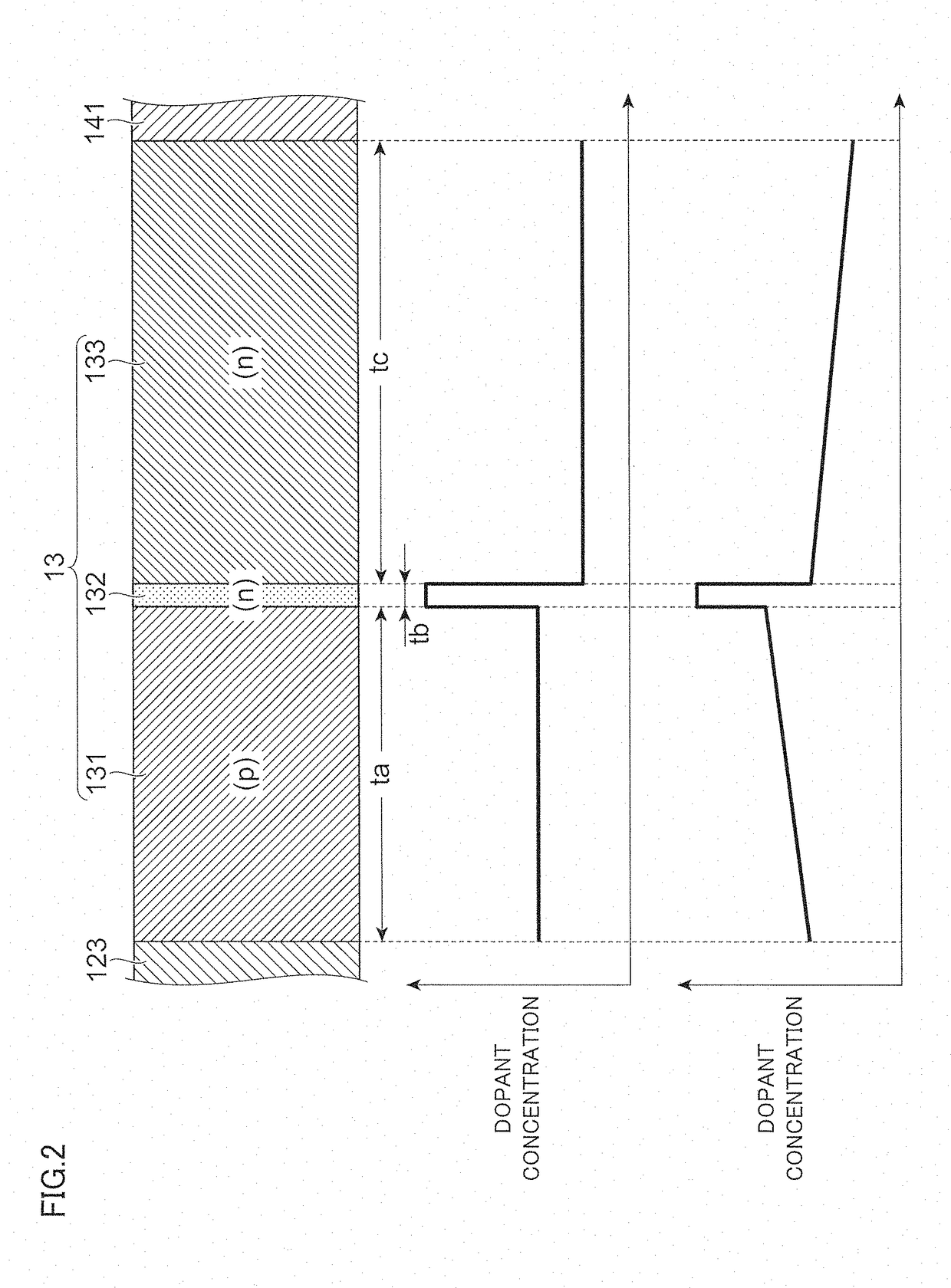

In a semiconductor light emitting element outputting light indicating green color by using a group III nitride semiconductor, light emission output is improved. A semiconductor light emitting element includes: an n-type cladding layer containing n-type impurities (Si); a light emitting layer laminated on the n-type cladding layer; and a p-type cladding layer containing p-type impurities and laminated on the light emitting layer. The light emitting layer has a barrier layer including first to fifth barrier layers and a well layer including first to fourth well layers, and has a multiple quantum well structure to sandwich one well layer by two barrier layers. The light emitting layer is configured such that the first to fourth well layers are set to have a composition to emit green light, and the first barrier layer is doped with n-type impurities, whereas the other barrier layers are not doped with n-type impurities.

Owner:TOYODA GOSEI CO LTD

Light-emitting diode

InactiveCN1735976AHigh luminous outputReduced shieldingSolid-state devicesSemiconductor devicesCrystal planeLead frame

A light emitting diode (10A) produced by securing a light emitting element (11a) to a lead frame (30) with a conductive adhesive material (20) is disclosed wherein the light emitting element (11a) comprises a semiconductor layer (9) including a light emitting layer (16) which is formed on a first surface (12a) of a translucent substrate (12) whose second surface (12b) is opposite to the first surface (12a) and serves as an emission observing surface. The semiconductor layer (9) has a side face (19) inclined to the first surface (12a) and the angle theta between a normal (a) to the inclined side face (19) and a crystal plane for growing the light emitting layer (16) is set such that the light emitted from the light emitting layer (16) is totally reflected toward the translucent substrate (12).

Owner:SANYO ELECTRIC CO LTD +1

Compound semiconductor light-emitting device and method for manufacturing the same

ActiveUS7972952B2Improve manufacturing yieldHigh luminous outputSemiconductor/solid-state device detailsSolid-state devicesLight emitting deviceCompound semiconductor

A compound semiconductor light-emitting device which includes an n-type semiconductor layer, a light-emitting layer and a p-type semiconductor layer, that are made of a compound semiconductor, formed on a substrate, the n-type semiconductor layer and the p-type semiconductor layer are stacked so as to interpose the light-emitting layer therebetween, a first conductive transparent electrode and a second conductive electrode. The first conductive transparent electrode is made of an IZO film containing an In2O3 crystal having a bixbyite structure. Also discussed is a method of manufacturing the device.

Owner:TOYODA GOSEI CO LTD

Light emitting element

InactiveUS8350277B2High luminous outputIncreasing the thicknessSolid-state devicesSemiconductor devicesElectrical conductorSemiconductor package

A light emitting element includes a semiconductor substrate, a light emitting part having a first and second conductivity type cladding layers and an active layer sandwiched between the cladding layers. A reflecting part is disposed between the substrate and the light emitting part. A current dispersing layer disposed on a side of the light emitting part opposite to the reflecting. The reflecting part has at least three pair layers of first and second semiconductor layers, the first semiconductor layer has a first thickness, the second semiconductor layer has a second thickness and a plurality of pair layers of the reflecting part have a different thickness to each other as values of the incident angle of light are different with respect to each pair layer. At least one pair layer is defined by the incident angle of light being not less than 50 degrees.

Owner:SUMITOMO CHEM CO LTD

Pn junction type group III nitride semiconductor light-emitting device

ActiveUS7781777B2Dispersion suppressionHigh luminous outputOptical wave guidanceLaser detailsLight emitting deviceNitride semiconductors

A pn junction type Group III nitride semiconductor light-emitting device 10 (11) of the present invention has a light-emitting layer 2 of multiple quantum well structure in which well layers 22 and barrier layers 21 including Group III nitride semiconductors are alternately stacked periodically between an n-type clad layer 105 and a p-type clad layer 107 which are formed on a crystal substrate and which include Group III nitride semiconductors, in which one end layer 21m of the light-emitting layer 2 is closest to and opposed to the n-type clad layer, and the other end layer 21n of the light-emitting layer 2 is closest to and opposed to the p-type clad layer, both the one and the other end layers are barrier layers, and the other end layer 21n is thicker than the barrier layer of the one end layer.

Owner:TOYODA GOSEI CO LTD

Semiconductor light emitting device

InactiveUS8344414B2Reduce the driving voltageHigh luminous outputSemiconductor devicesInter layerContact layer

A semiconductor light emitting device with which a driving voltage is able to be kept low is provided. The semiconductor light emitting device includes: an n-type cladding layer; an active layer; a p-type cladding layer containing AlGaInP; an intermediate layer; and a contact layer containing GaP in this order, wherein the intermediate layer contains Ga1-aInaP (0.357≦a≦0.408), and has a thickness of from 10 nm to 20 nm both inclusive.

Owner:SONY CORP

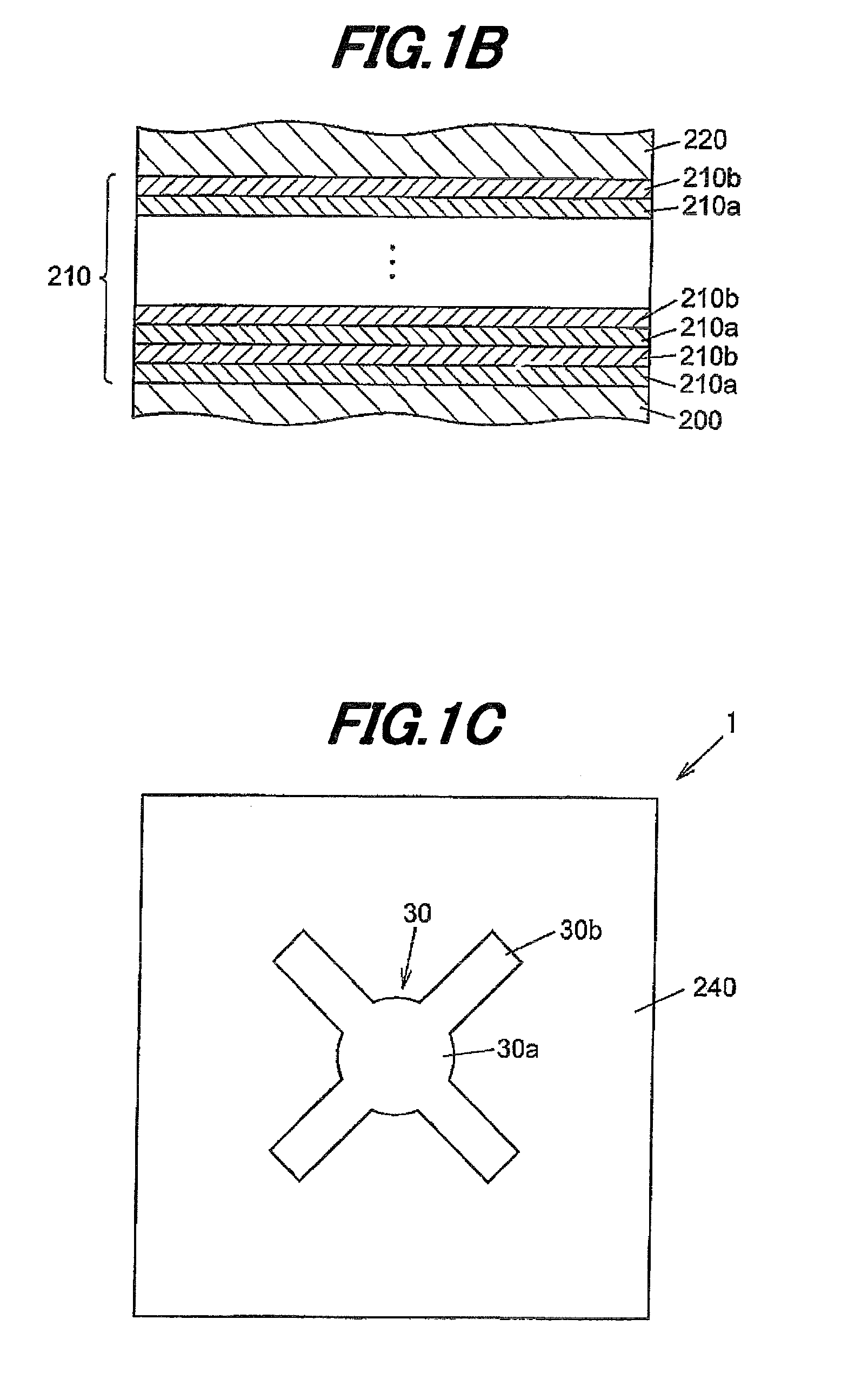

Nitride semiconductor light emitting device and manufacturing method thereof

ActiveUS7700384B2Lower forward voltageHigh luminous outputSemiconductor/solid-state device manufacturingSemiconductor lasersActive layerLight emission

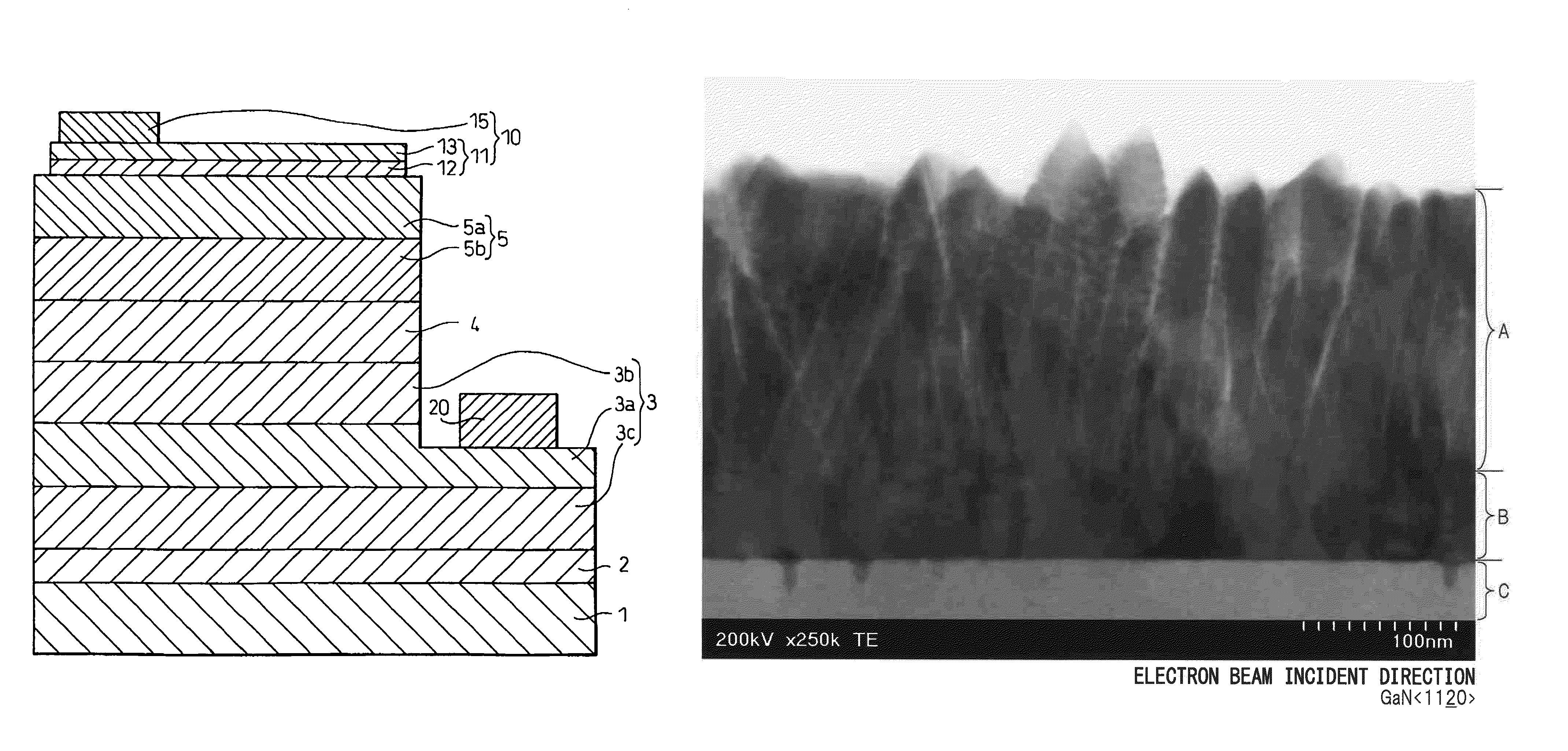

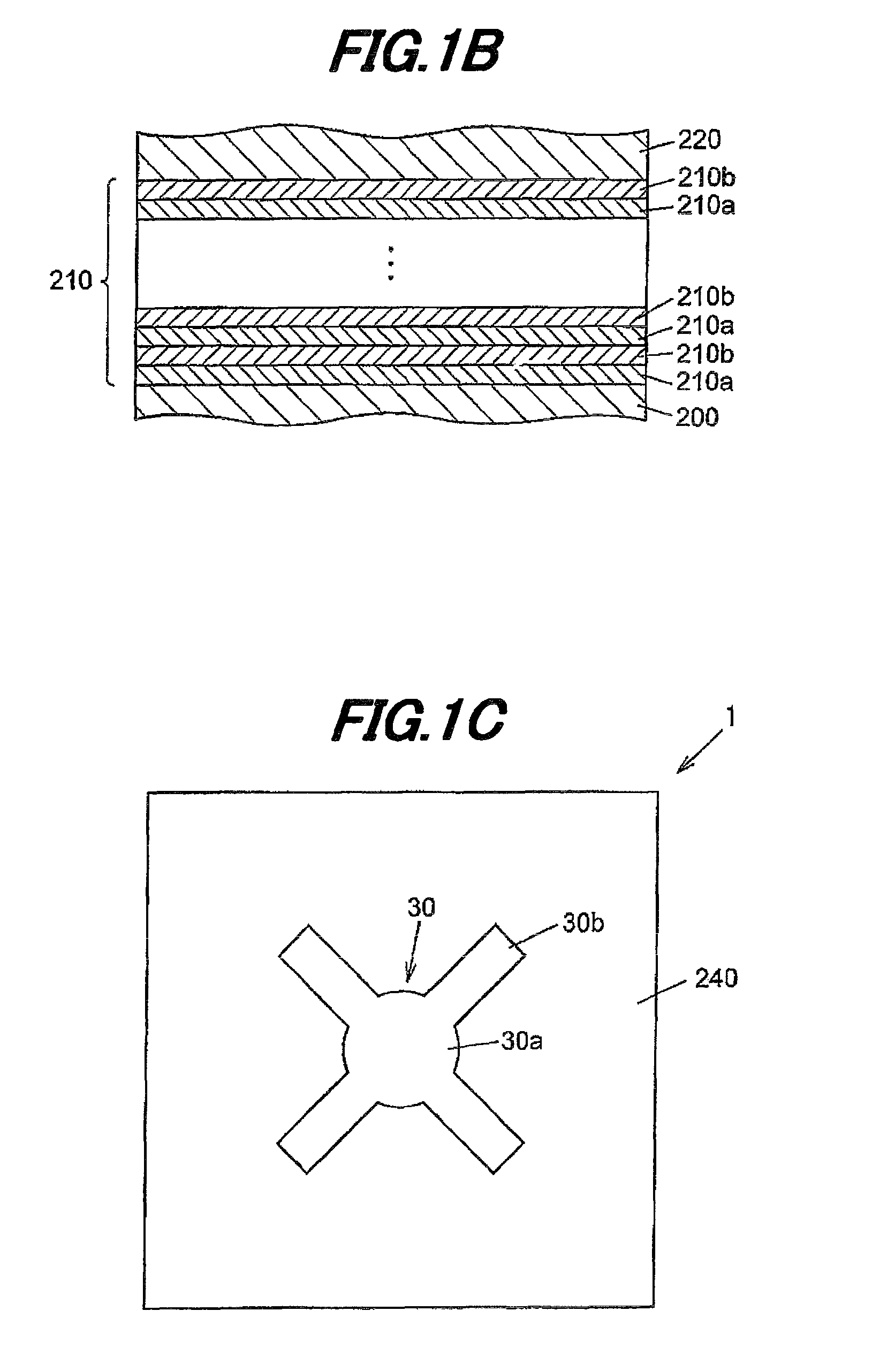

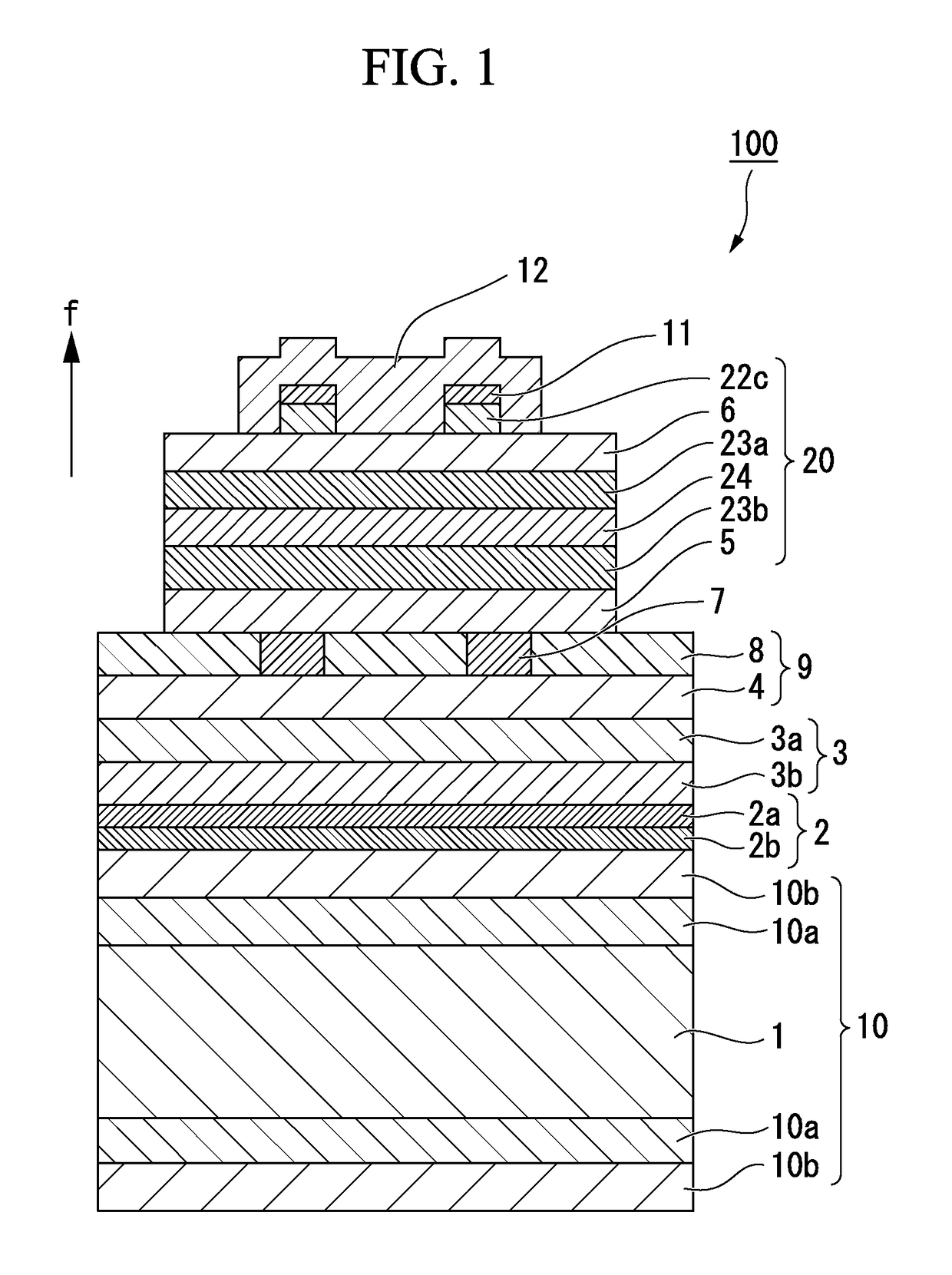

An object is to provide a nitride semiconductor light emitting device capable of attaining high light emission output while lowering Vf, as well as to provide a manufacturing method thereof. The invention relates to a nitride semiconductor light emitting device, including at least an n-type nitride semiconductor, a p-type nitride semiconductor and an active layer formed between said n-type nitride semiconductor and said p-type nitride semiconductor, wherein the n-type nitride semiconductor includes a multi-layered nitride semiconductor layer having at least twice repeated stacked structure consisting of a first nitride semiconductor layer and a second nitride semiconductor layer, the multi-layered nitride semiconductor layer is formed in contact with the active layer, the first nitride semiconductor layer is a layer containing an n-type impurity, and the second nitride semiconductor layer is an undoped layer or a layer containing said n-type impurity to a concentration lower than said first nitride semiconductor layer.

Owner:SHARP FUKUYAMA LASER CO LTD

Semiconductor light emitting device

InactiveUS20110031528A1Reduce the driving voltageHigh luminous outputSemiconductor devicesInter layerContact layer

A semiconductor light emitting device with which a driving voltage is able to be kept low is provided. The semiconductor light emitting device includes: an n-type cladding layer; an active layer; a p-type cladding layer containing AlGaInP; an intermediate layer; and a contact layer containing GaP in this order, wherein the intermediate layer contains Ga1-aInaP (0.357≦a≦0.408), and has a thickness of from 10 nm to 20 nm both inclusive.

Owner:SONY CORP

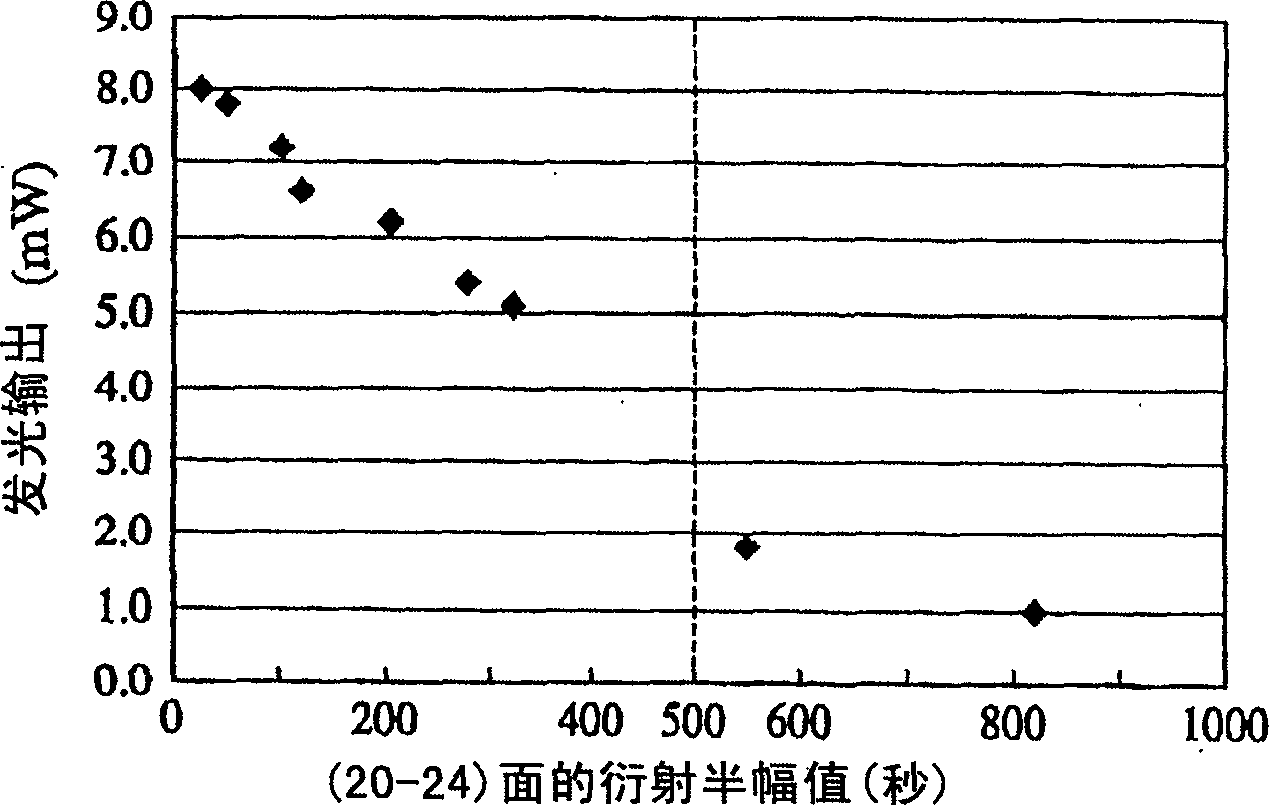

Self-supported nitride semiconductor substrate and its production method, and light-emitting nitride semiconductor device using it

ActiveCN1649181AImprove featuresHigh luminous outputPolycrystalline material growthSemiconductor/solid-state device manufacturingVoltageX-ray

A self-supported nitride semiconductor substrate of 10 mm or more in diameter having an X-ray diffraction half width of 500 seconds or less in at least one of a {20-24} diffraction plane and a {11-24} diffraction plane.

Owner:SUMITOMO CHEM CO LTD

Semiconductor light emitting element

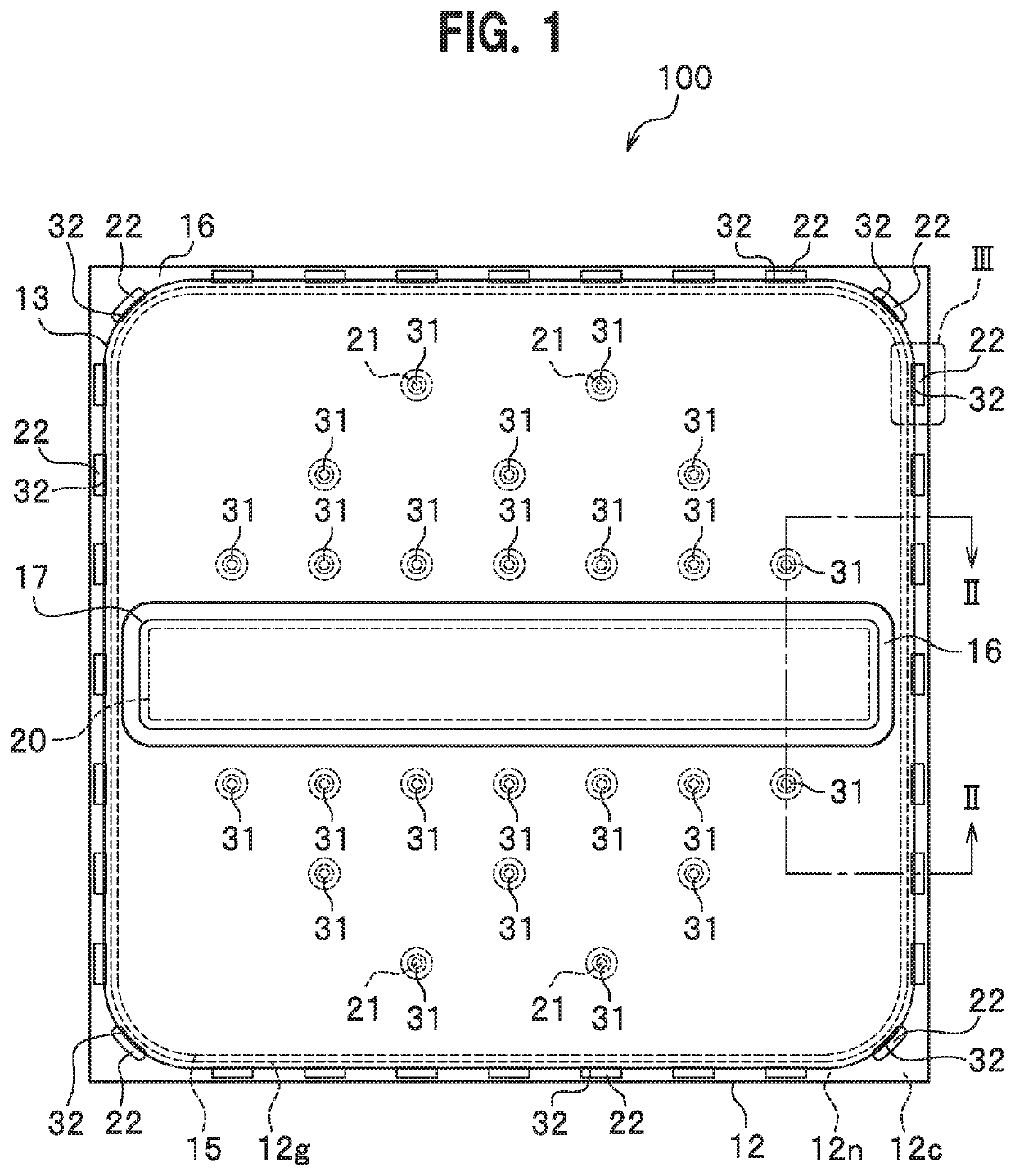

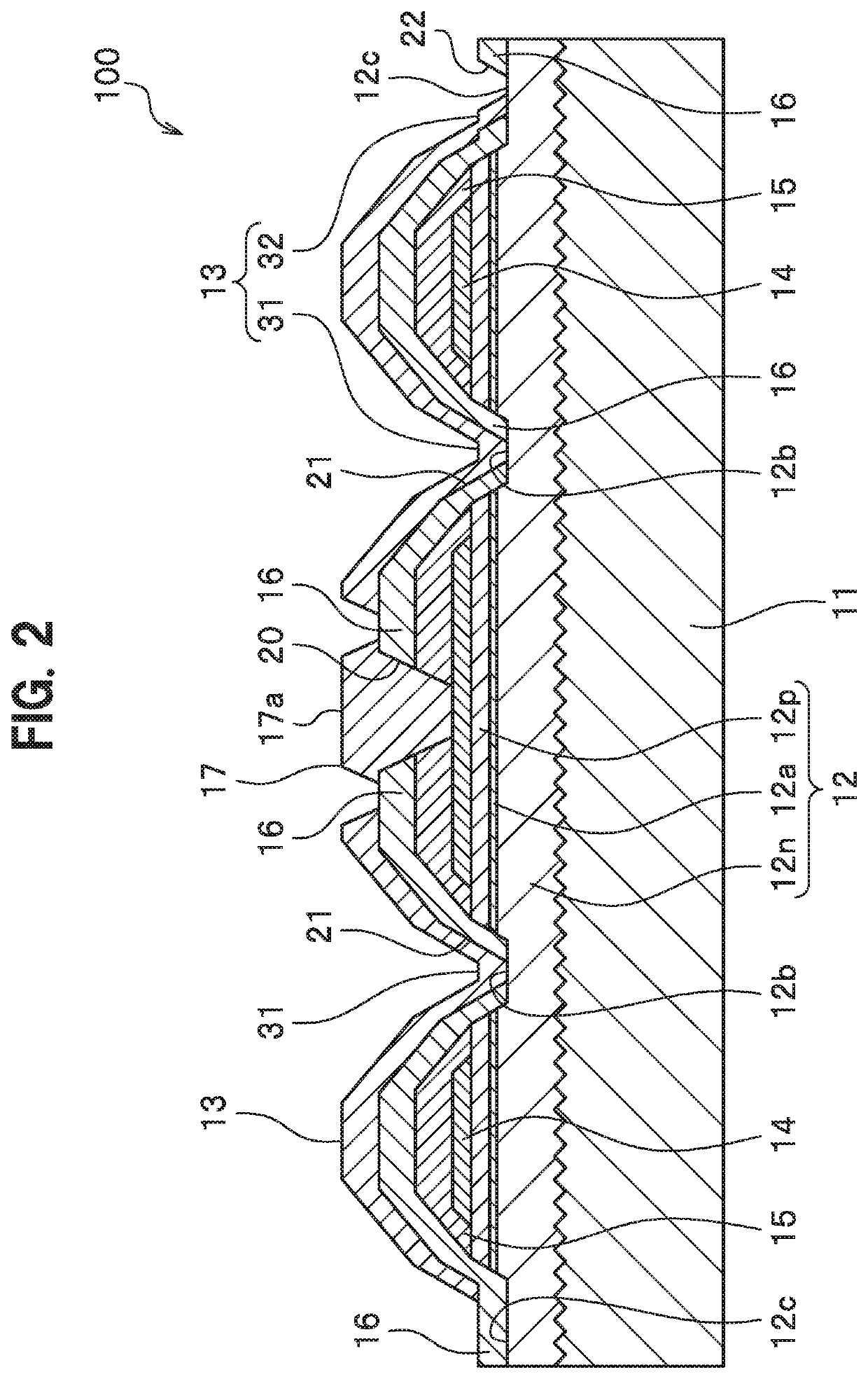

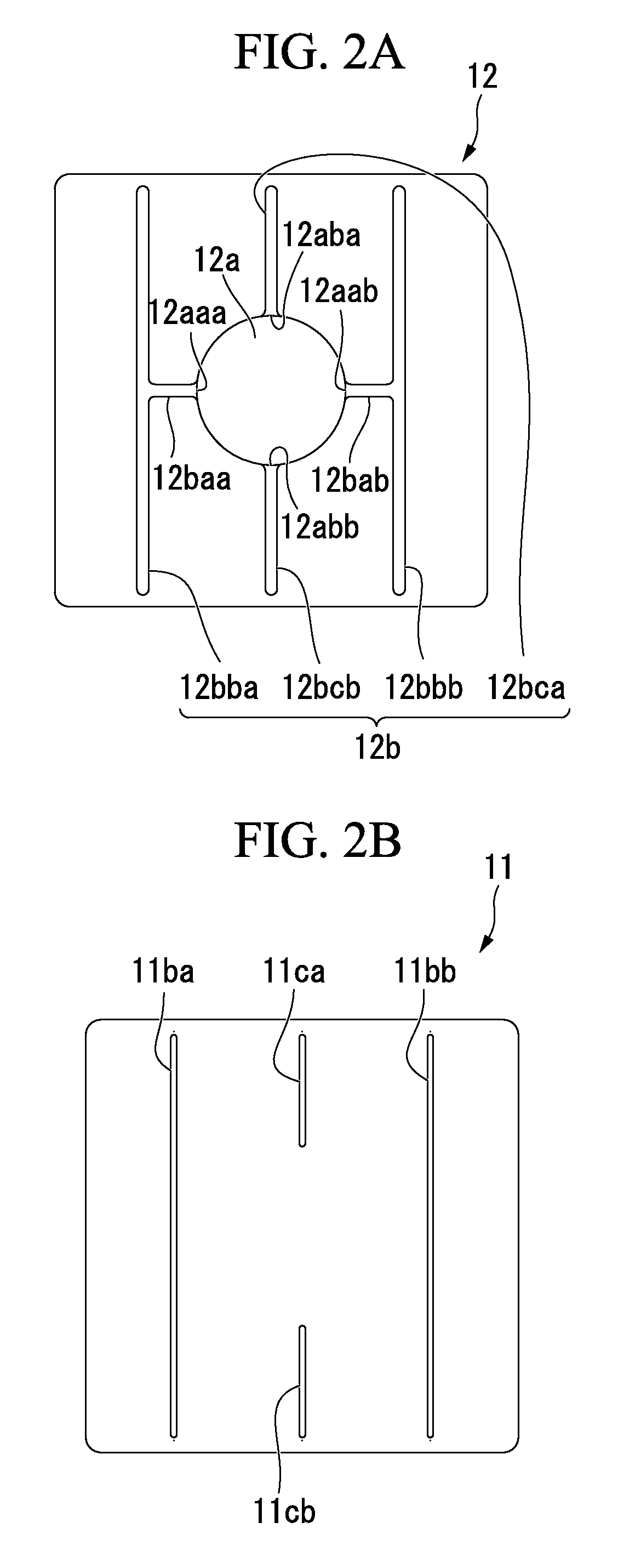

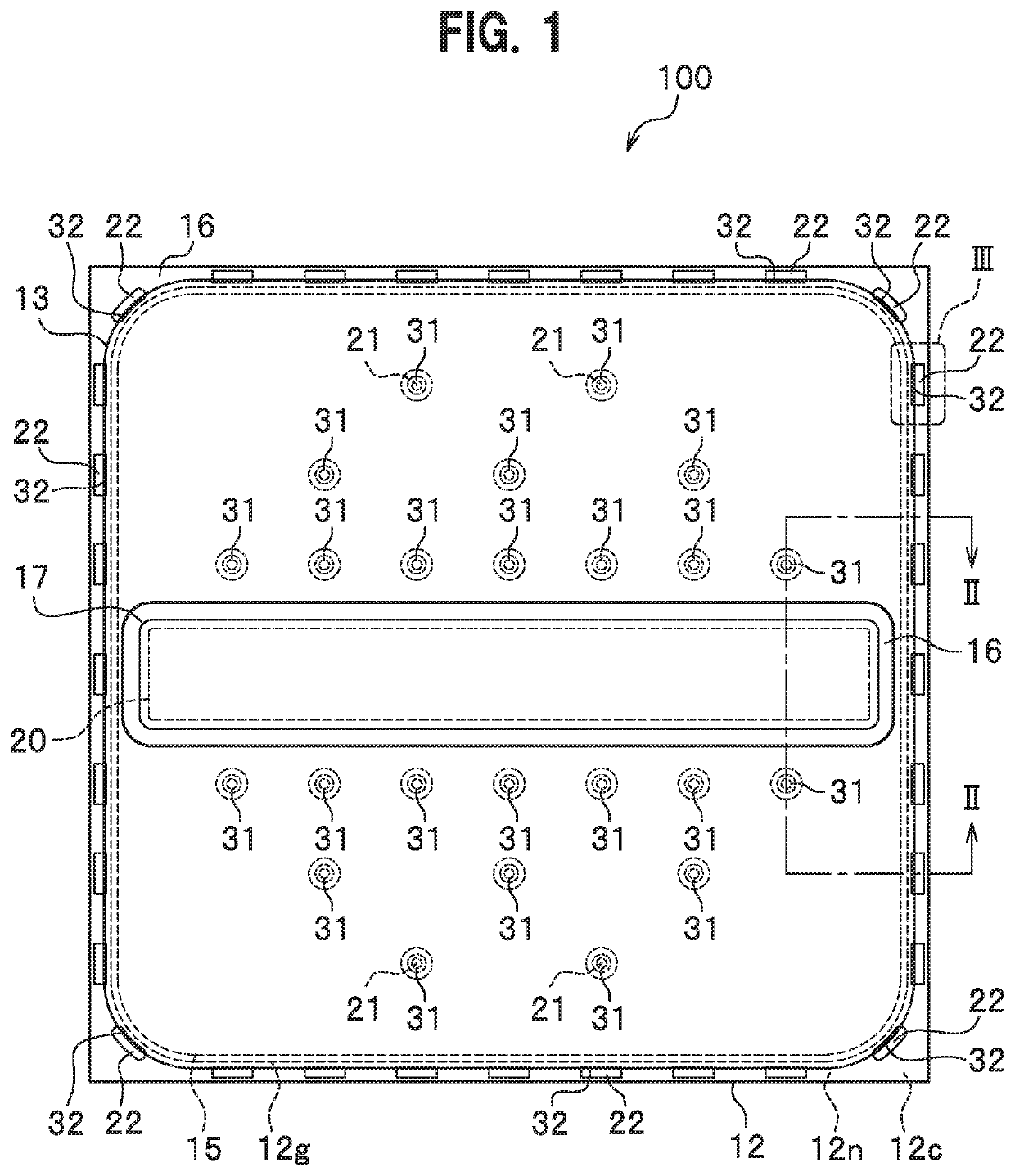

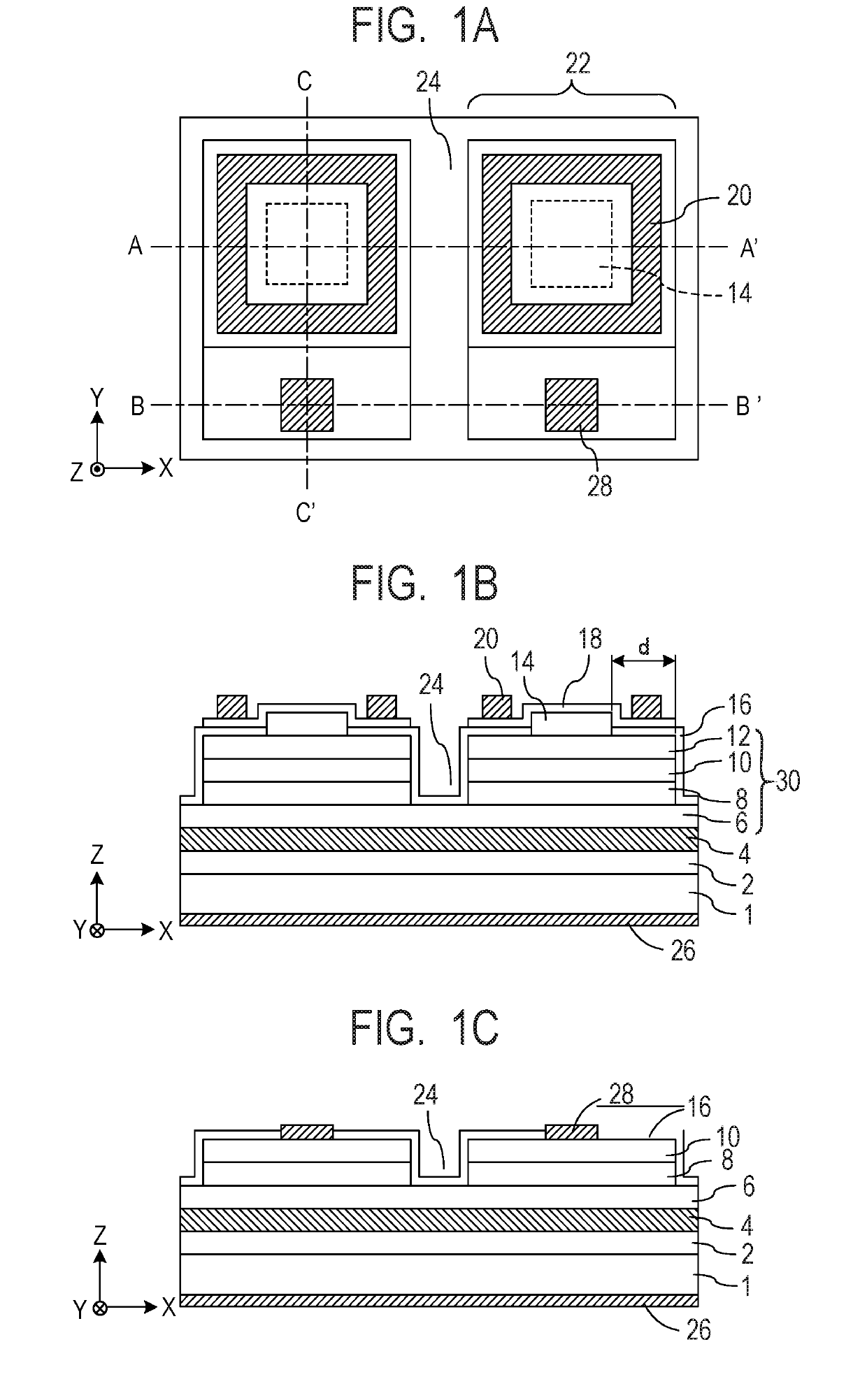

A semiconductor light emitting element includes a semiconductor layered body including an n-side semiconductor layer and a p-side semiconductor layer disposed above the n-side semiconductor layer, an insulating film defining a plurality of first n-side openings on the n-side semiconductor layer in an inner region and a plurality of second n-side openings on an outer peripheral region of the n-side semiconductor layer, an n-electrode disposed extending over the insulating film and the outer peripheral region of the n-side semiconductor layer and including: a plurality of first n-contact portions, each electrically connected with the n-side semiconductor layer through a respective one of the first n-side openings, and a plurality of second n-contact portions, each electrically connected with the n-side semiconductor layer through a respective one of the second n-side openings, at at least four corners of the outer peripheral region of the n-side semiconductor layer.

Owner:NICHIA CORP

Light-emitting device

Owner:NICHIA CORP

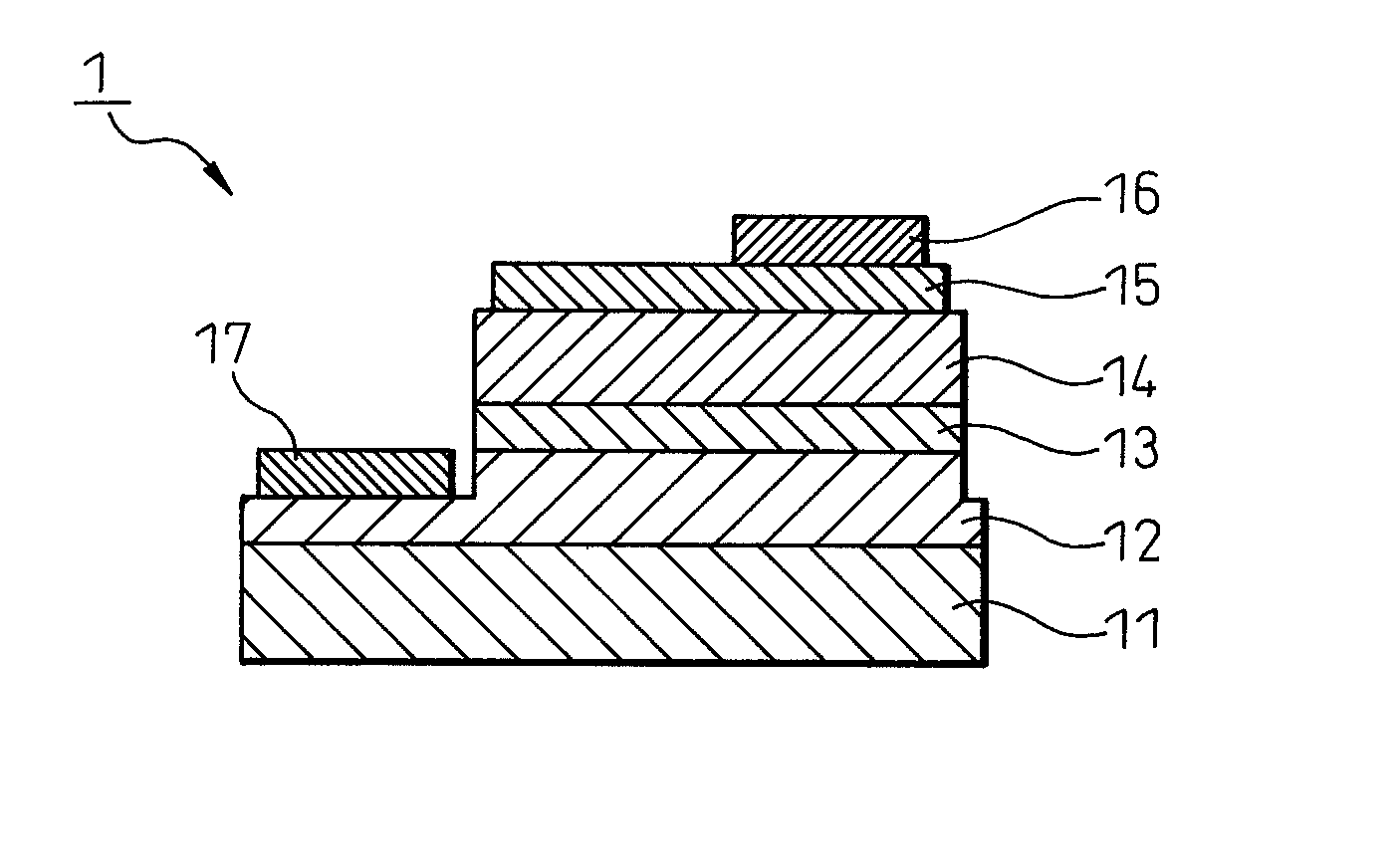

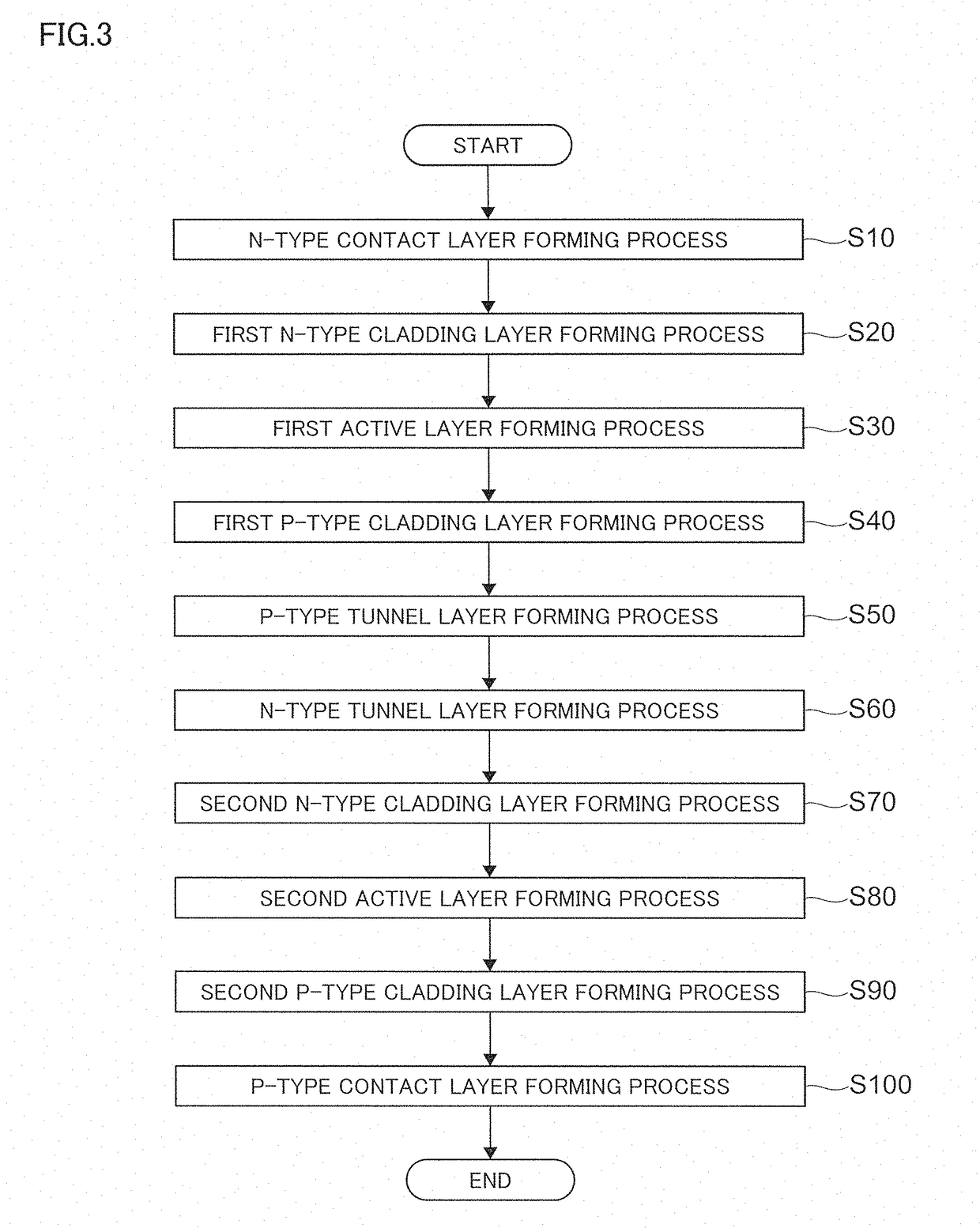

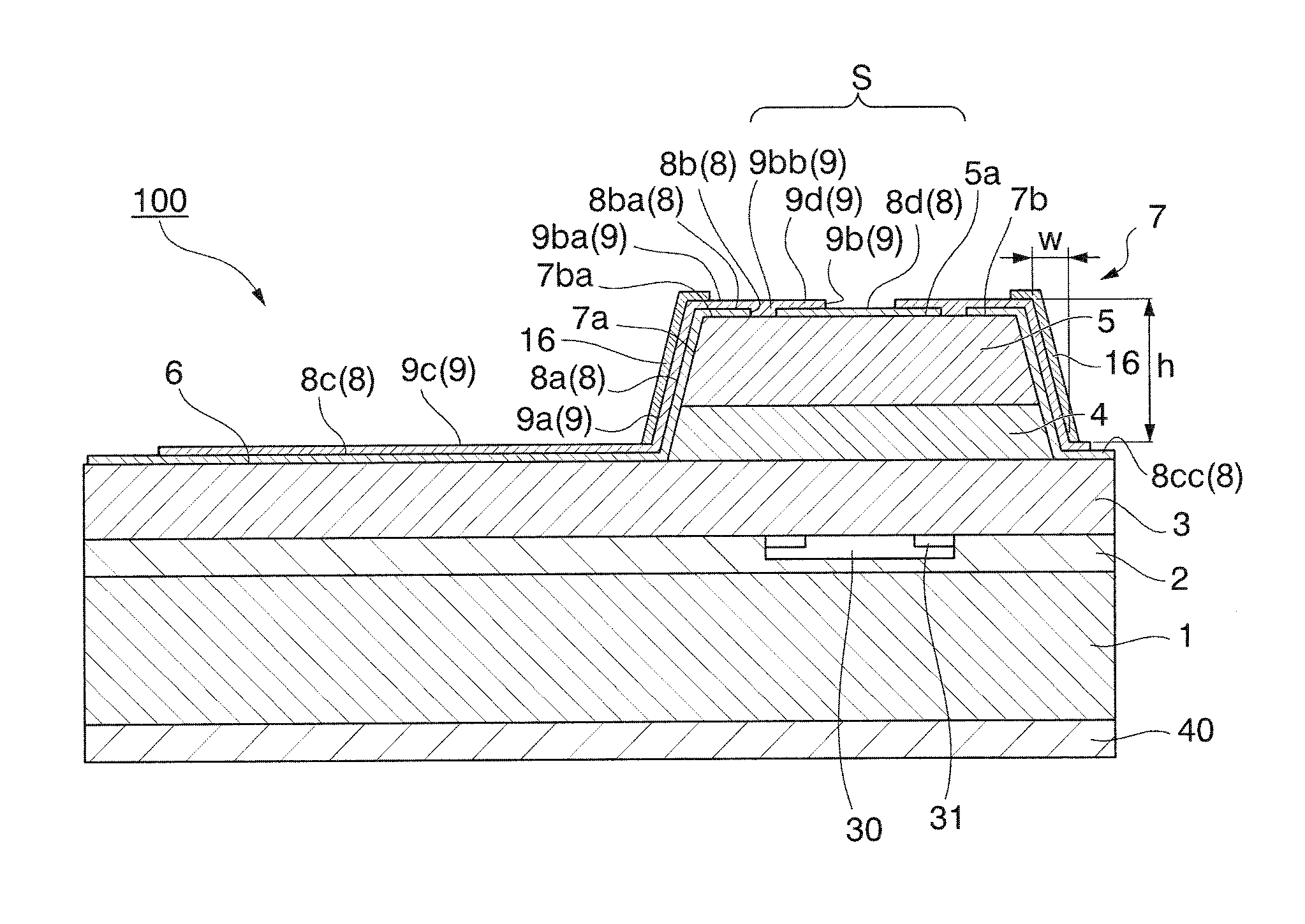

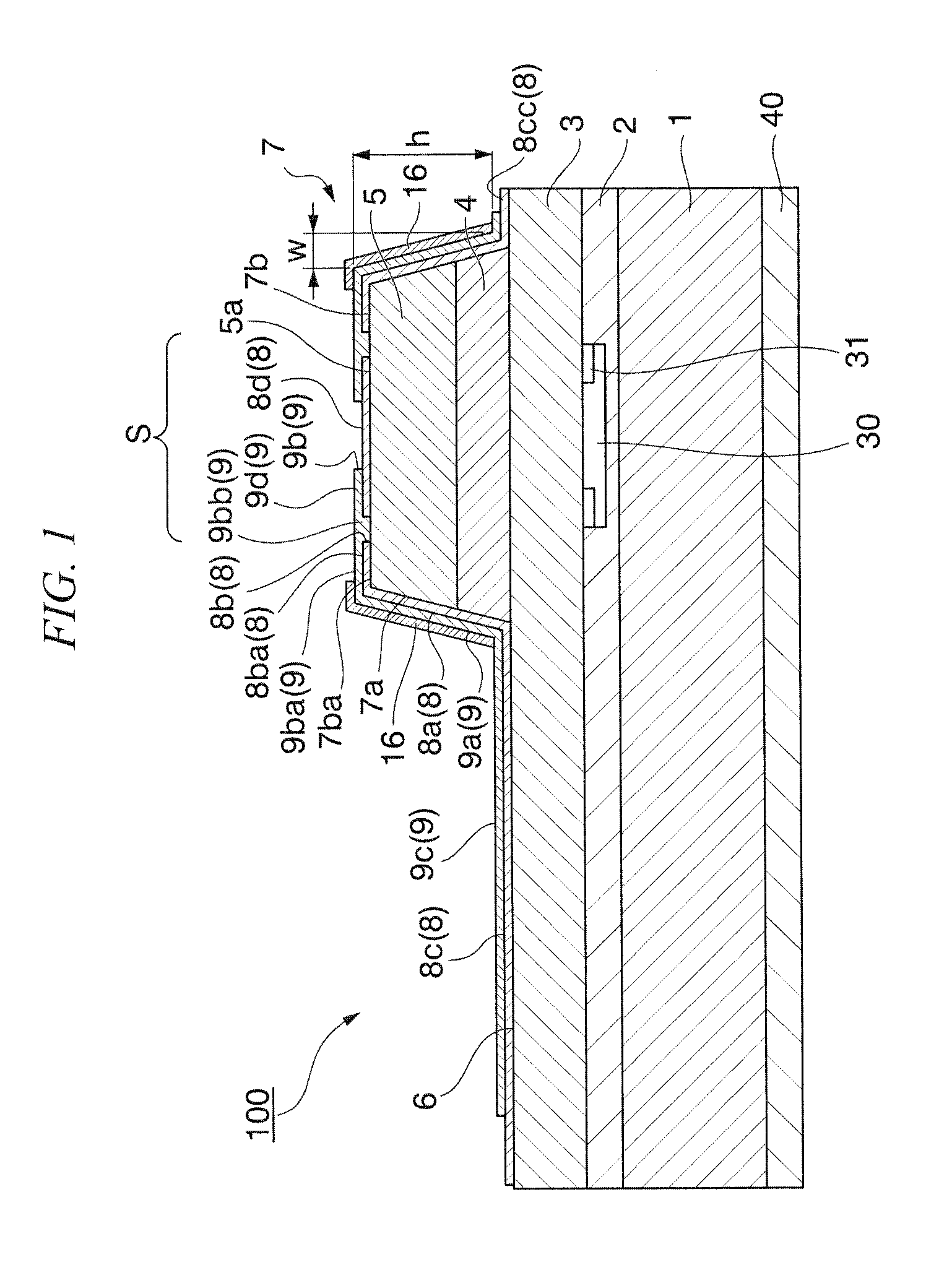

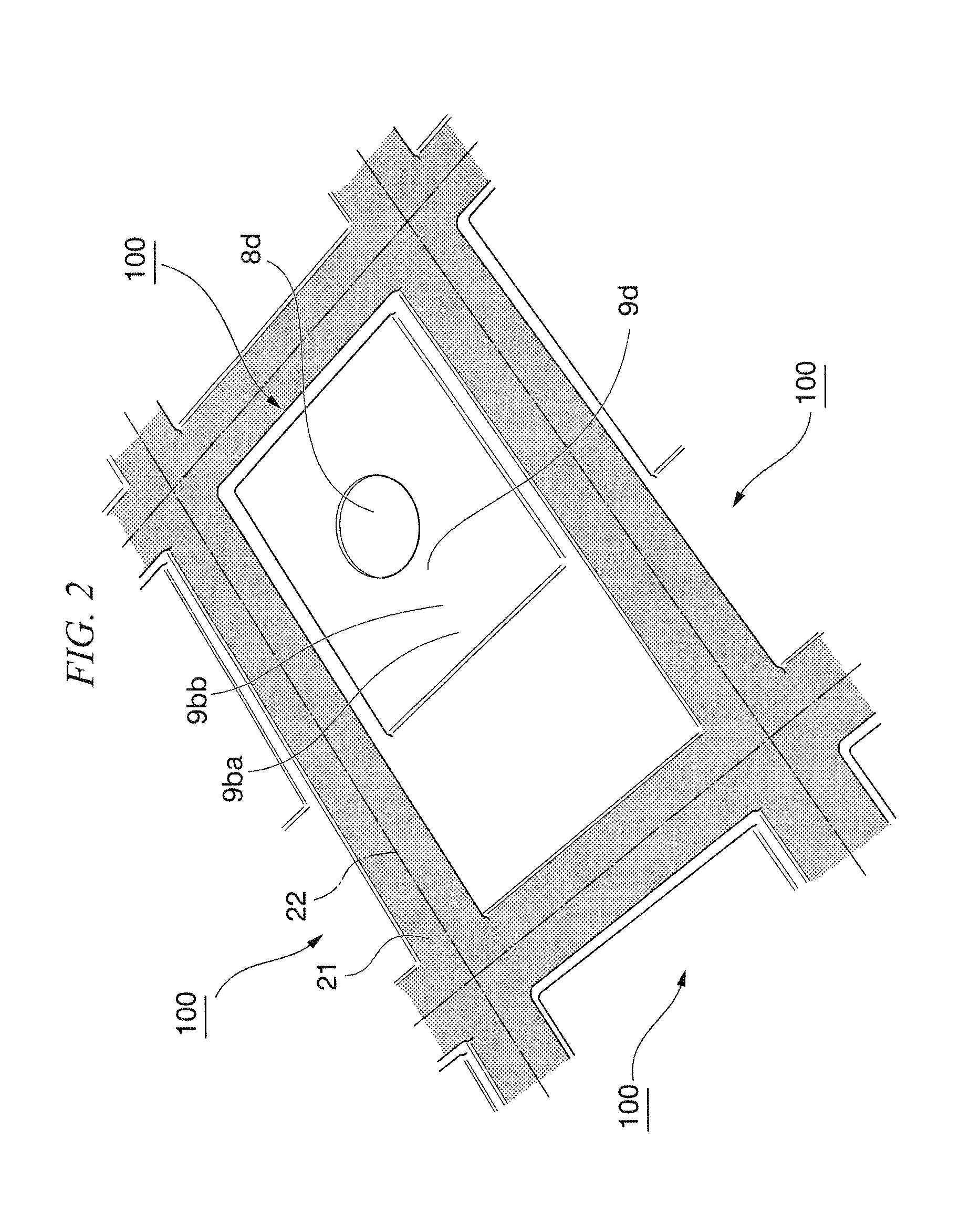

Light-emitting diode and method for manufacturing tunnel junction layer

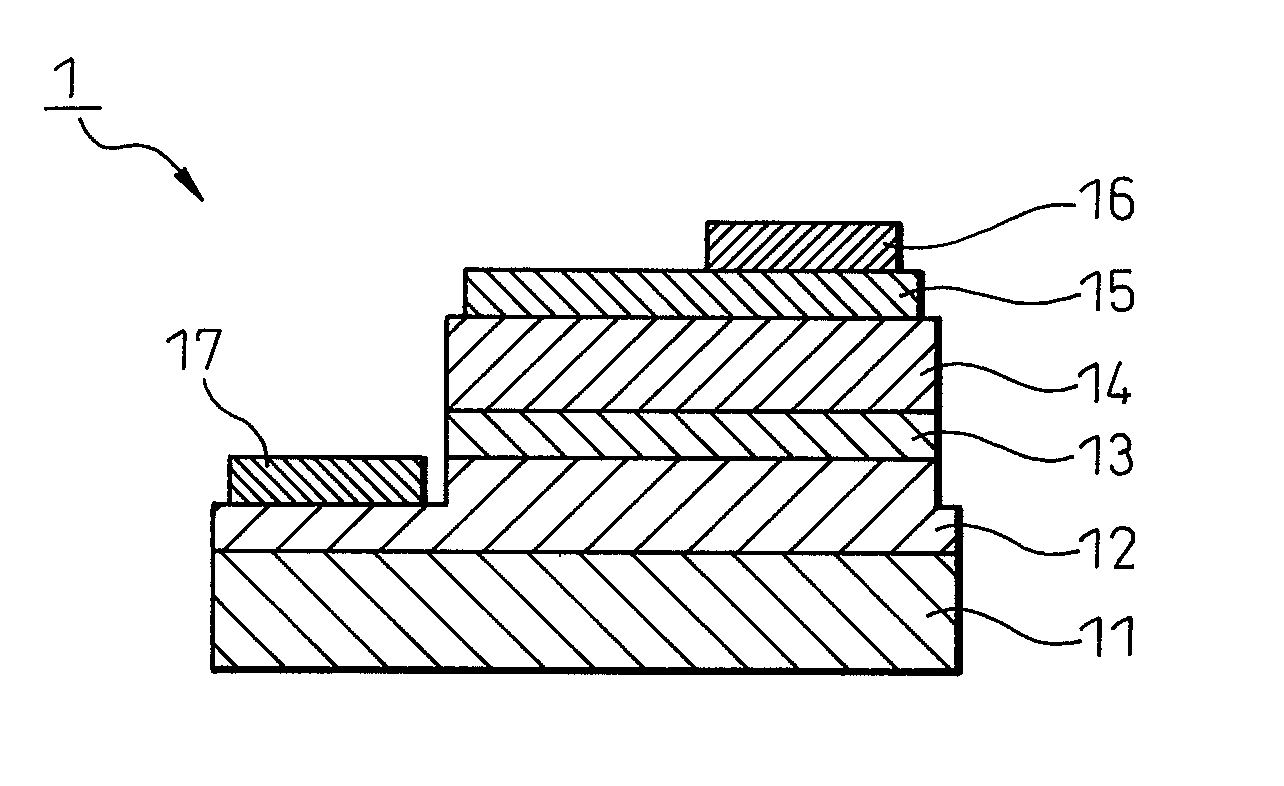

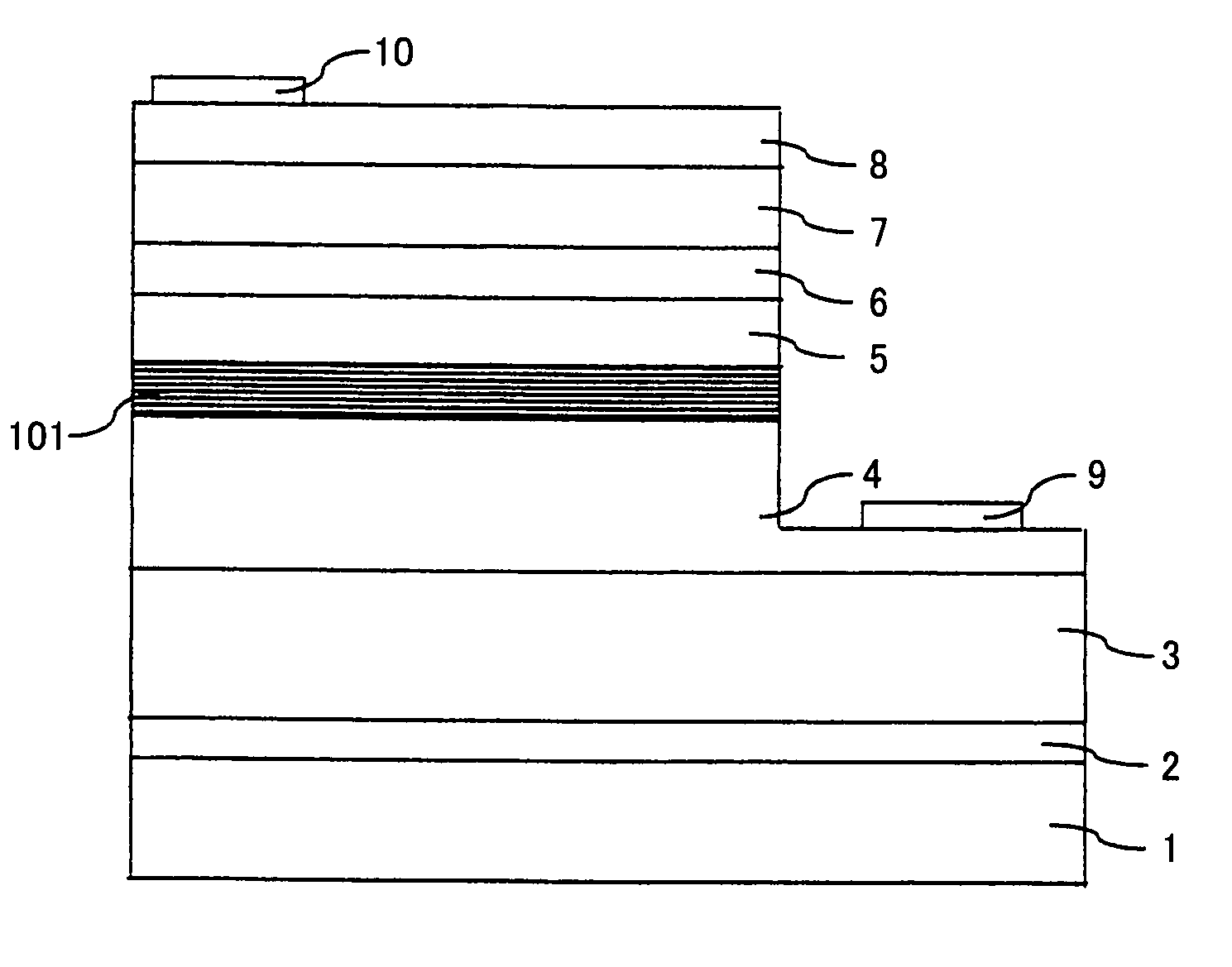

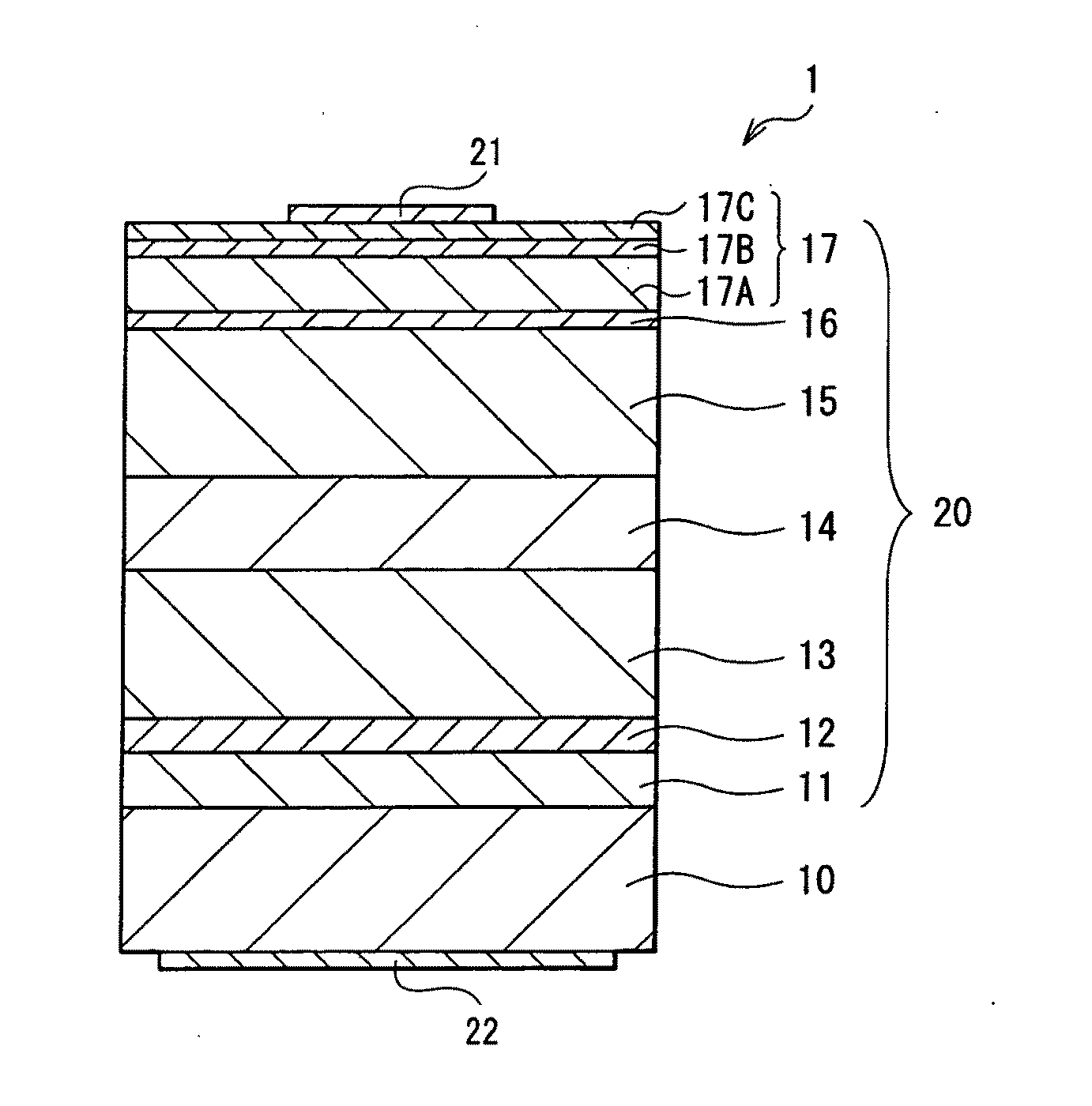

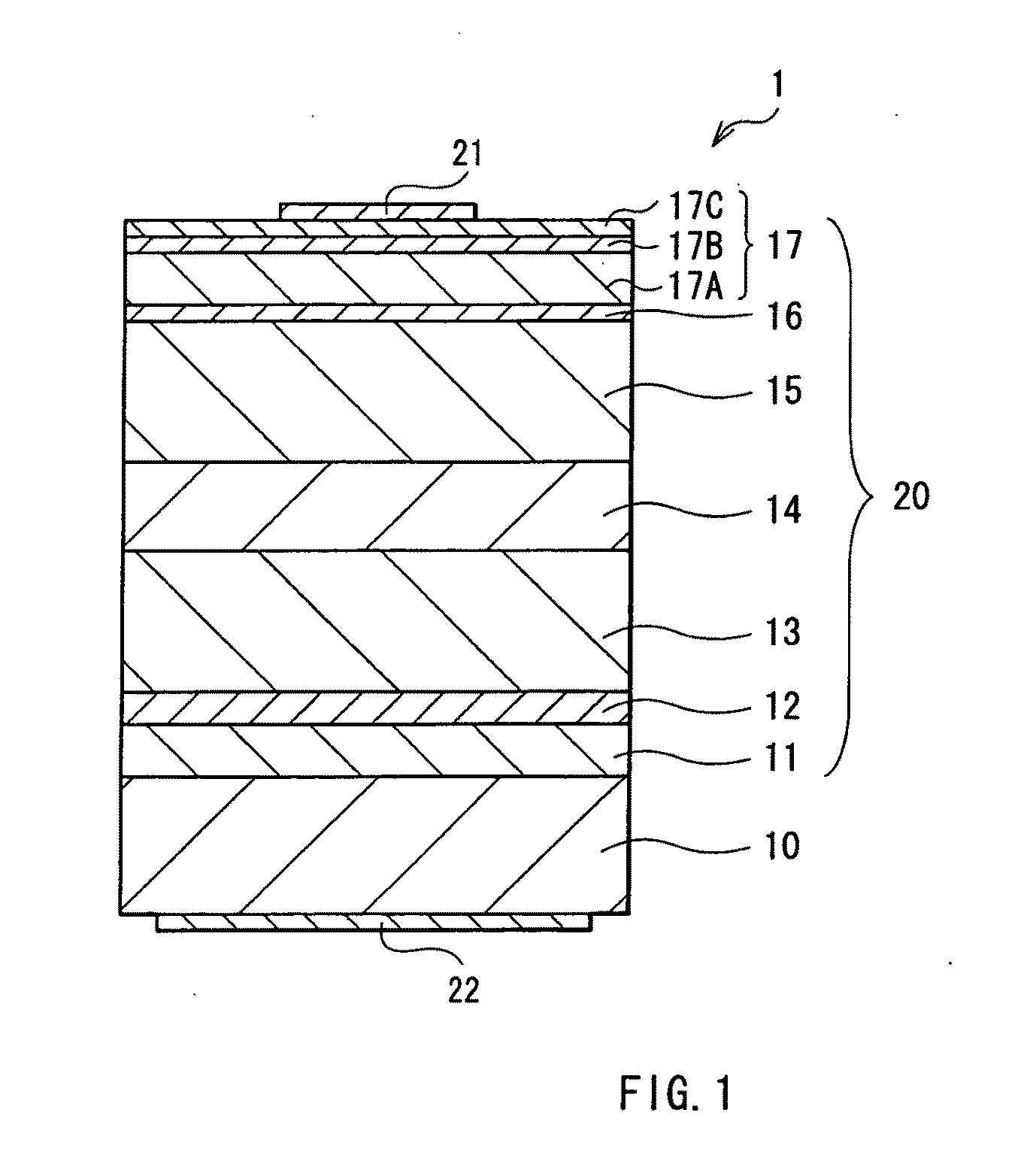

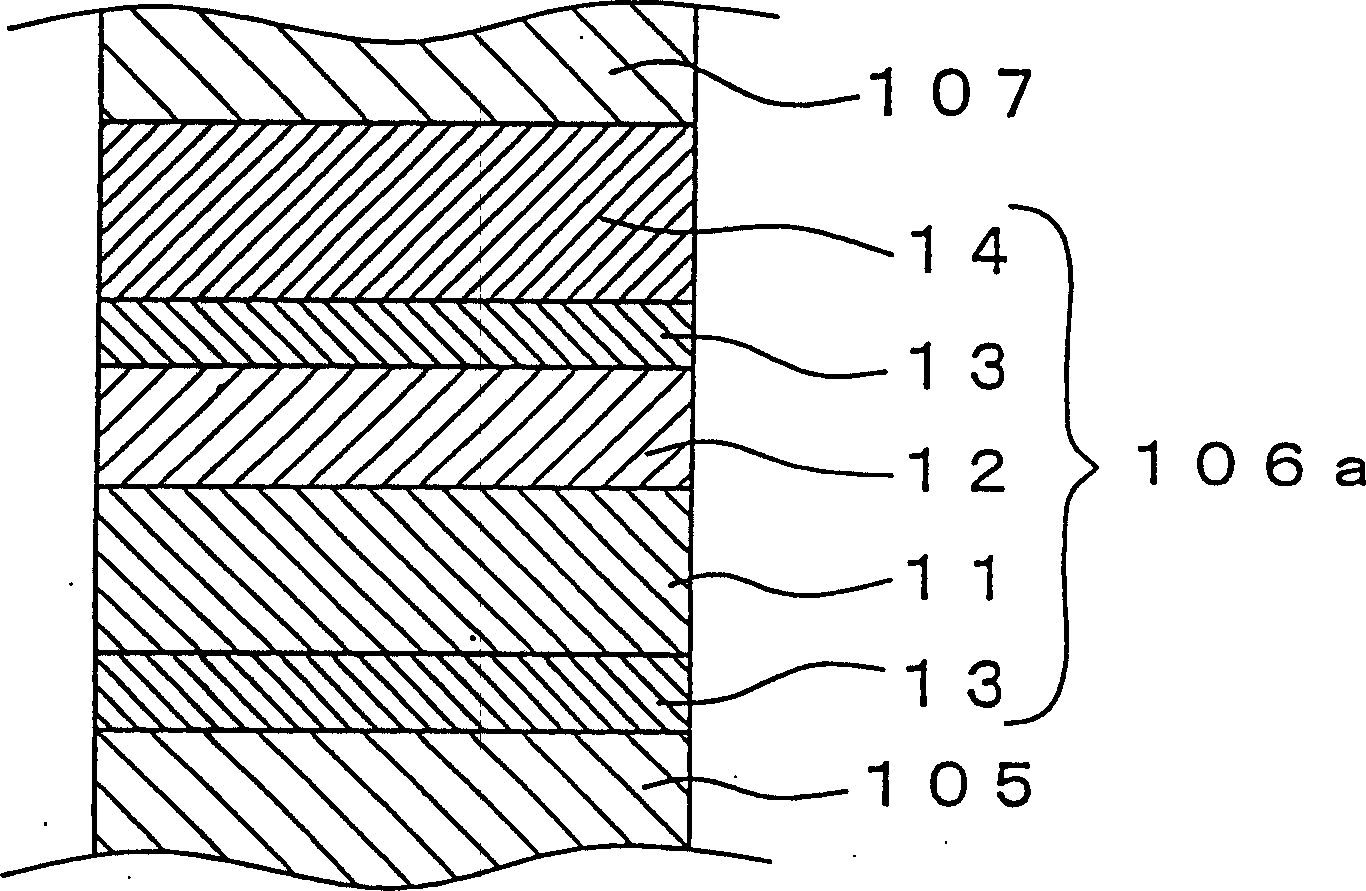

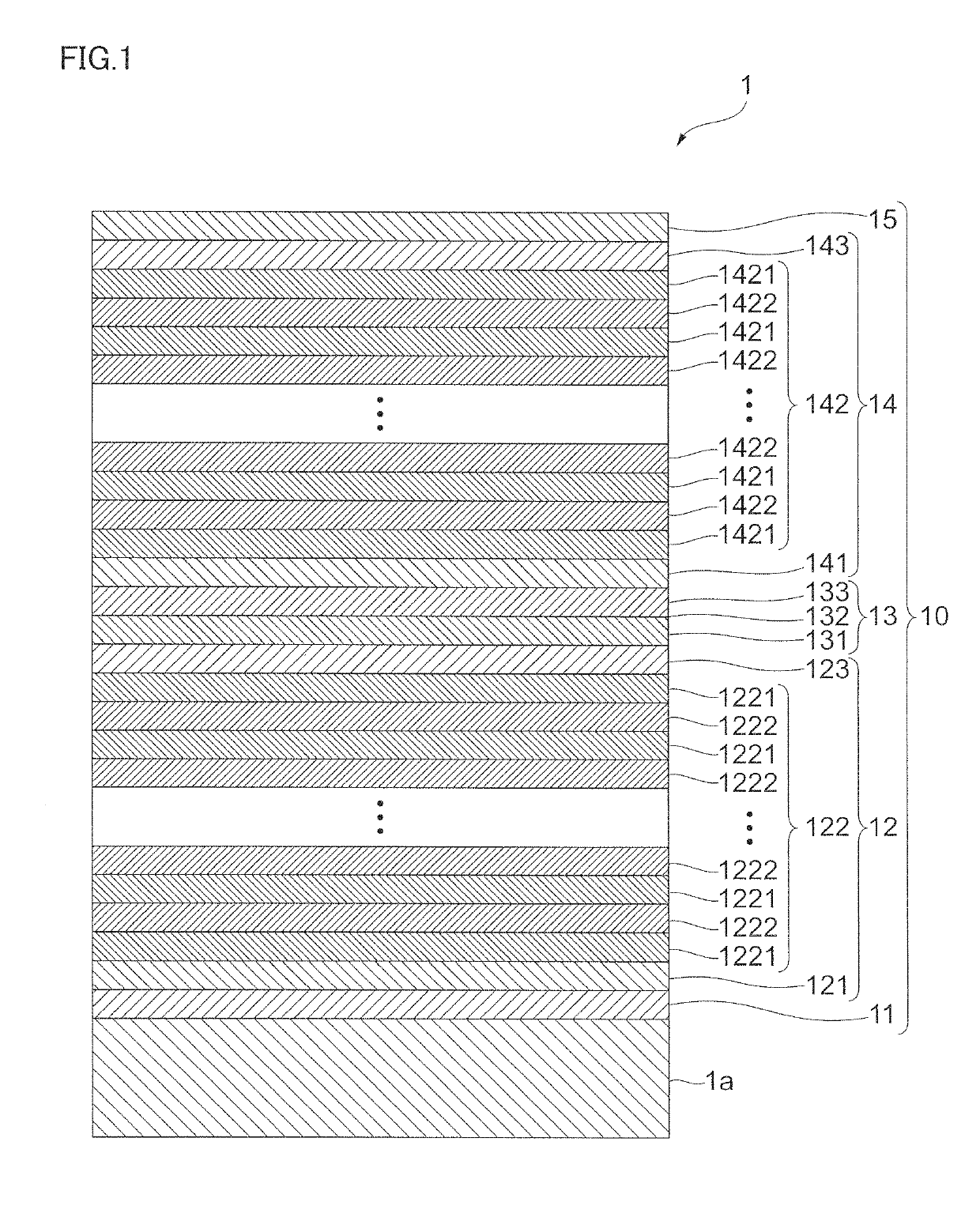

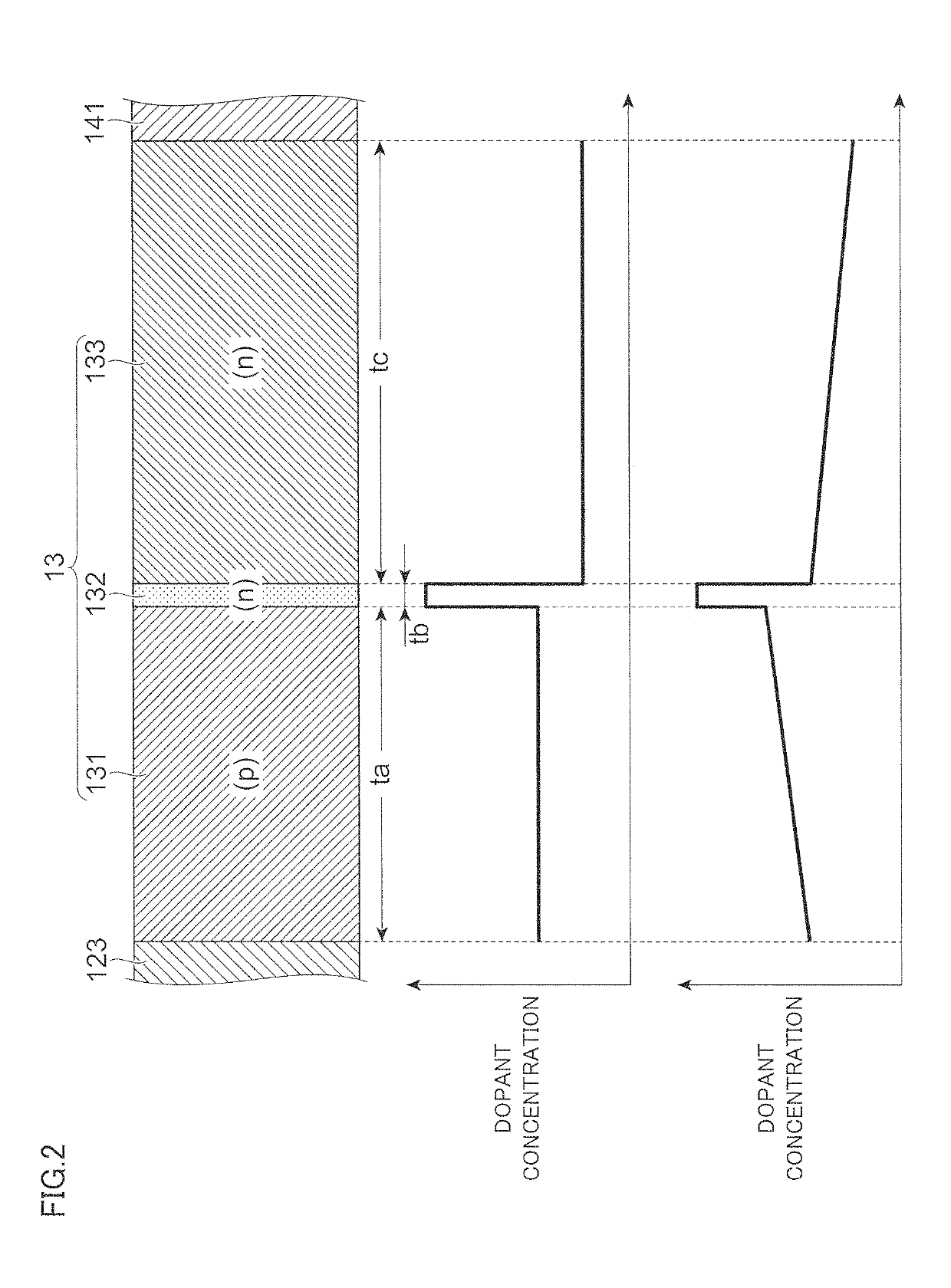

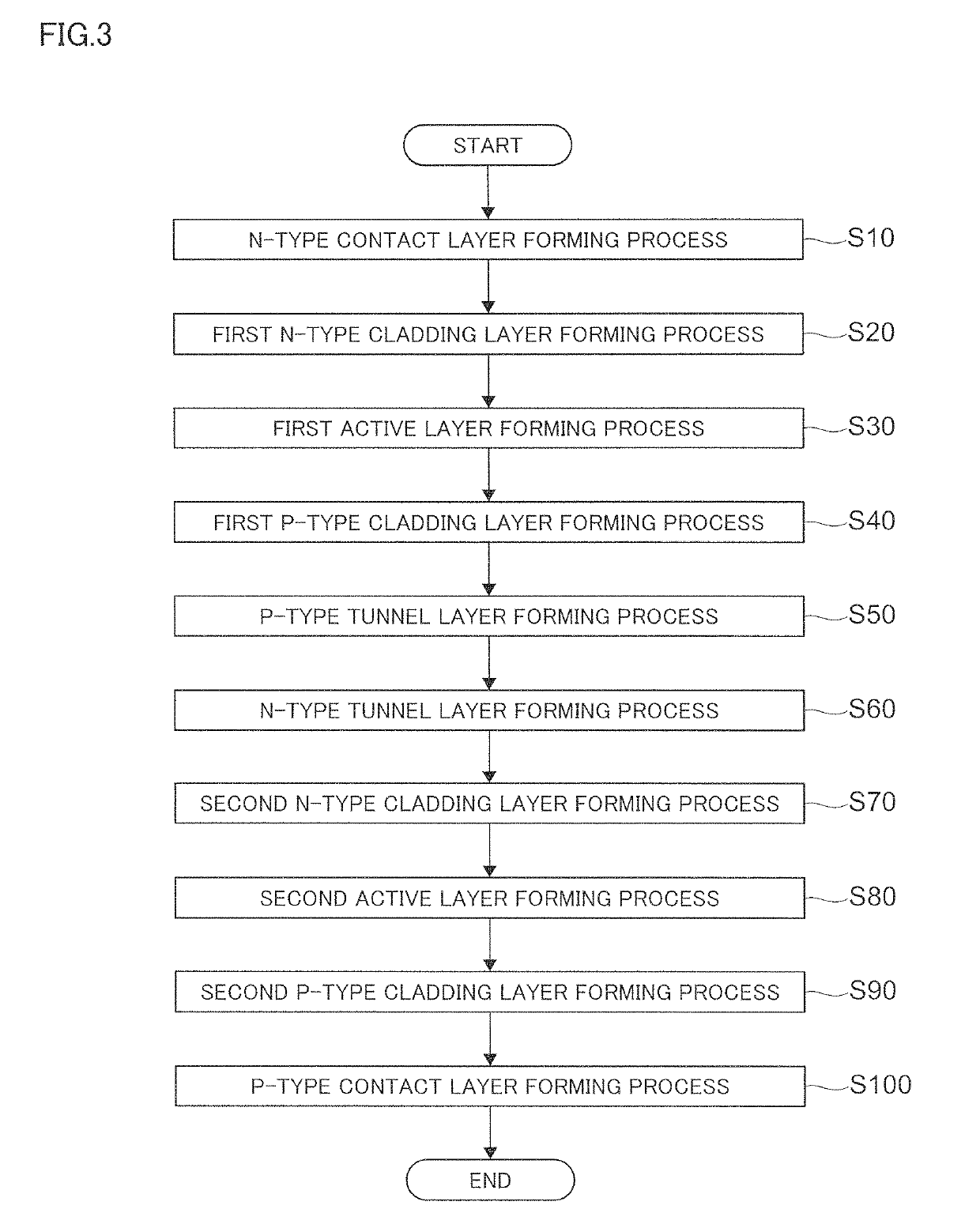

A light-emitting element layer 10 includes: an n-type contact layer 11; a first light-emitting layer 12; a tunnel junction layer 13; a second light-emitting layer 14; and a p-type contact layer 15 laminated in this order. The first light-emitting layer 12 and the second light-emitting layer 14 emit light of the same wavelength. The tunnel junction layer 13 includes: a p-type tunnel layer 131 made of AlGaAs containing p-type impurities (C); and an n-type tunnel layer 133 made of GaInP containing n-type impurities (Te). A highly n-type impurities-doped layer 132 having a higher concentration of n-type impurities than the n-type tunnel layer 133 is arranged between the p-type tunnel layer 131 and the n-type tunnel layer 133.

Owner:RESONAC PHOTONICS CORP

Light-emitting diode and method of manufacturing the same

ActiveUS9318656B2Improve efficiencyLight extraction efficiencySemiconductor devicesEtchingTransparent conducting film

A light-emitting diode and manufacturing method, including a flat portion and a mesa structure. An inclined side surface is formed by wet etching such that a cross-sectional area of the mesa structure is continuously reduced toward a top surface. A protective film covers the flat portion, the inclined side surface, and a peripheral region of the top surface of the mesa structure. The protective film includes an electrical conduction window arranged around a light emission hole and from which a compound semiconductor layer is exposed. A continuous electrode film contacts the exposed compound semiconductor layer, covers the protective film formed on the flat portion, and has the light emission hole on the top surface. A transparent conductive film is formed between a reflecting layer and the layer at a position that corresponds to the electrical conduction window and in a range surrounded by the electrical conduction window.

Owner:SHOWA DENKO KK

Semiconductor light emitting element and light emitting device

ActiveUS8963122B2High luminous outputSemiconductor/solid-state device manufacturingSemiconductor devicesGreen-lightLight emission

In a semiconductor light emitting element outputting light indicating green color by using a group III nitride semiconductor, light emission output is improved. A semiconductor light emitting element includes: an n-type cladding layer containing n-type impurities (Si); a light emitting layer laminated on the n-type cladding layer; and a p-type cladding layer containing p-type impurities and laminated on the light emitting layer. The light emitting layer has a barrier layer including first to fifth barrier layers and a well layer including first to fourth well layers, and has a multiple quantum well structure to sandwich one well layer by two barrier layers. The light emitting layer is configured such that the first to fourth well layers are set to have a composition to emit green light, and the first barrier layer is doped with n-type impurities, whereas the other barrier layers are not doped with n-type impurities.

Owner:TOYODA GOSEI CO LTD

Light-emitting diode, light-emitting diode lamp, and illumination device

InactiveUS9705043B2Optimize location relationshipLower forward voltageSemiconductor devicesOhmic contactLight-emitting diode

Owner:SHOWA DENKO KK

Light-emitting diode and method for manufacturing tunnel junction layer

A light-emitting element layer 10 includes: an n-type contact layer 11; a first light-emitting layer 12; a tunnel junction layer 13; a second light-emitting layer 14; and a p-type contact layer 15 laminated in this order. The first light-emitting layer 12 and the second light-emitting layer 14 emit light of the same wavelength. The tunnel junction layer 13 includes: a p-type tunnel layer 131 made of AlGaAs containing p-type impurities (C); and an n-type tunnel layer 133 made of GaInP containing n-type impurities (Te). A highly n-type impurities-doped layer 132 having a higher concentration of n-type impurities than the n-type tunnel layer 133 is arranged between the p-type tunnel layer 131 and the n-type tunnel layer 133.

Owner:RESONAC PHOTONICS CORP

Semiconductor light emitting element

ActiveUS20200044128A1Lower forward voltageHigh luminous outputSemiconductor devicesSemiconductorMaterials science

A semiconductor light emitting element includes a semiconductor layered body including an n-side semiconductor layer and a p-side semiconductor layer disposed above the n-side semiconductor layer, an insulating film defining a plurality of first n-side openings on the n-side semiconductor layer in an inner region and a plurality of second n-side openings on an outer peripheral region of the n-side semiconductor layer, an n-electrode disposed extending over the insulating film and the outer peripheral region of the n-side semiconductor layer and including: a plurality of first n-contact portions, each electrically connected with the n-side semiconductor layer through a respective one of the first n-side openings, and a plurality of second n-contact portions, each electrically connected with the n-side semiconductor layer through a respective one of the second n-side openings, at at least four corners of the outer peripheral region of the n-side semiconductor layer.

Owner:NICHIA CORP

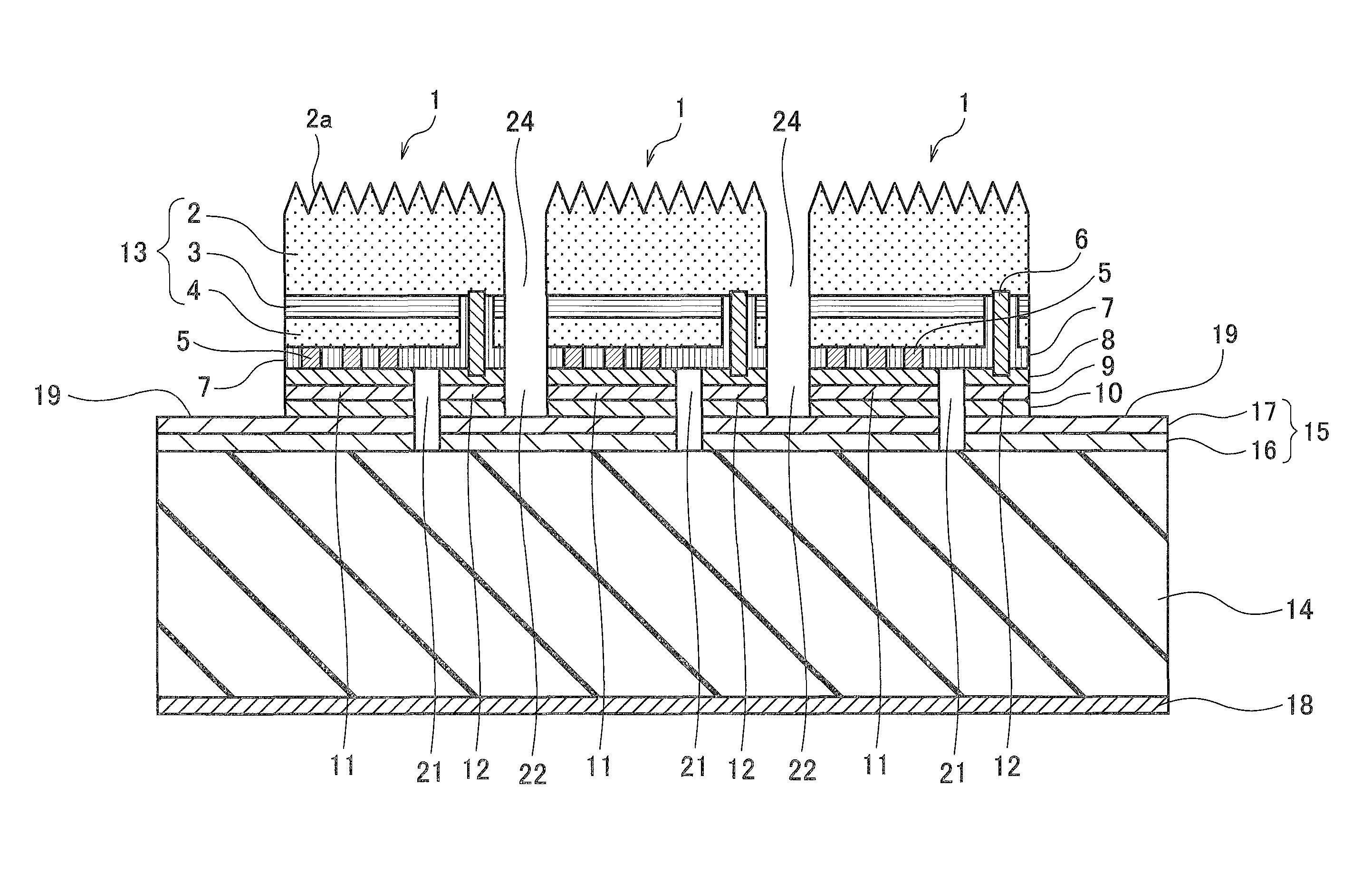

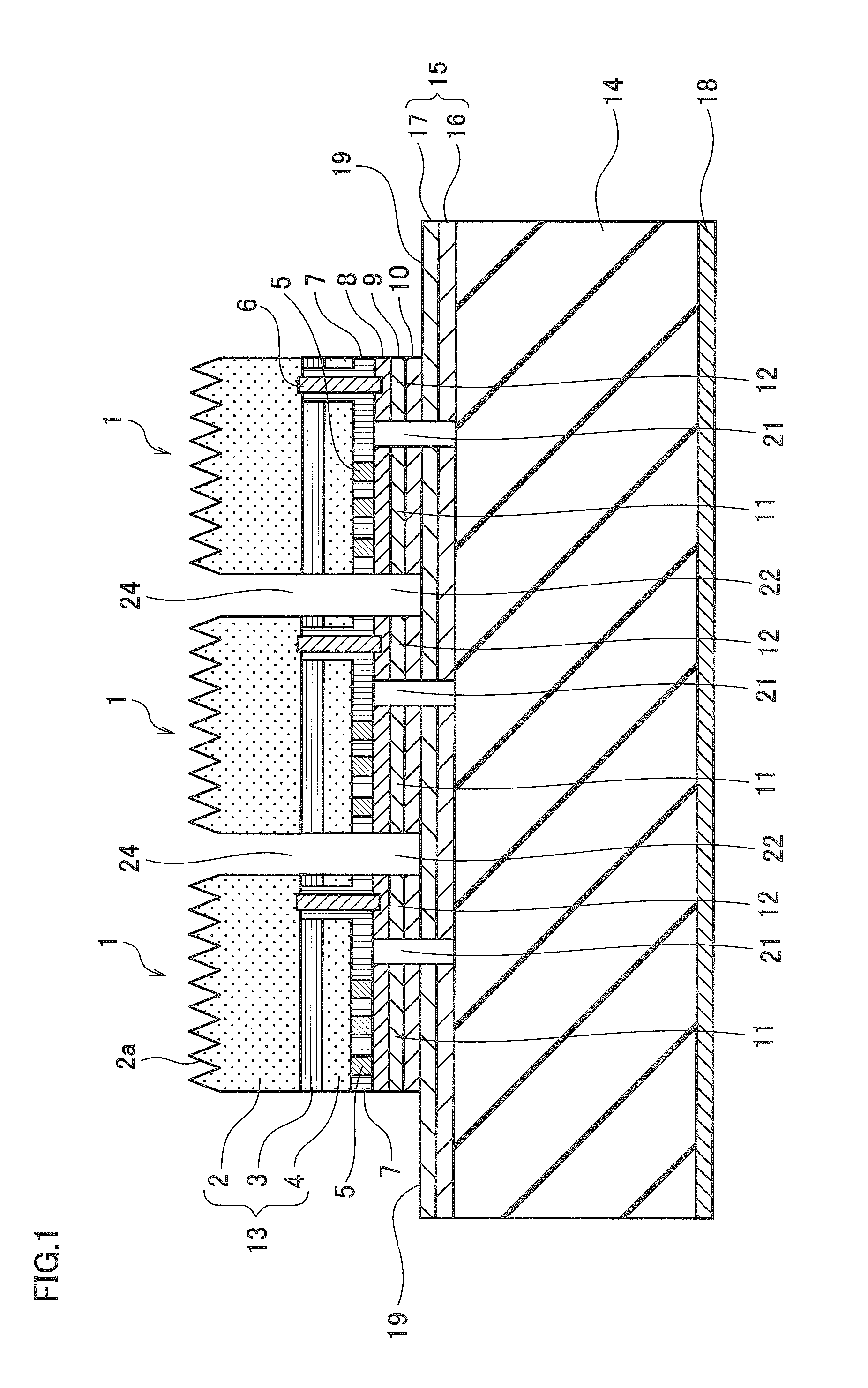

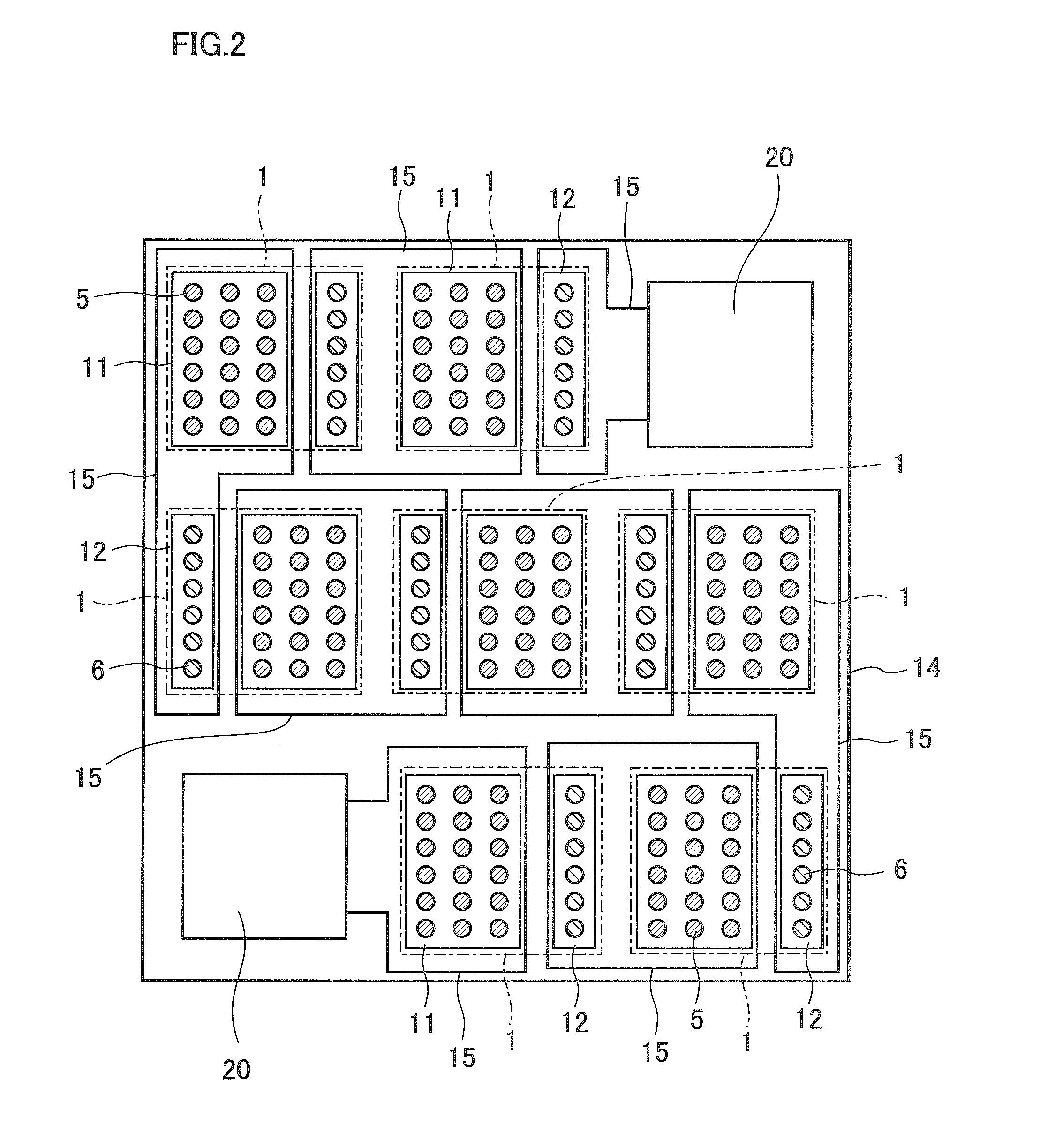

LED array

InactiveCN1248063CIncreased recombinationHigh luminous outputSolid-state devicesElectrographic process apparatusLed arrayEngineering

The present invention relates to a light-emitting diode array for large light-emitting output, especially for a light-emitting diode array adapt for printer light source of the electronic photo manner. A light-emitting diode array comprising a conductive layer formed on a substrate, a plurality of separate light-emitting parts formed on the conductive layer, a first electrode formed on at least part of a top surface of each light-emitting part, and a second electrode formed on the conductive layer near the light-emitting part, the second electrode being a common electrode for operating a plurality of the light-emitting parts, and regions of the conductive layer between the adjacent light-emitting parts being removed.

Owner:HITACHI CABLE

Light-emitting element array, and light exposure head and image forming apparatus using the same

InactiveUS20190168515A1Small variationImprove variationSolid-state devicesPrintingLight exposureOptoelectronics

In a light-emitting element array using light emitting thyristors, a light emitting output of each light emitting thyristor can be increased and a variation in the light emitting output can be suppressed. On a substrate, a thyristor having a mesa structure including a cathode layer, a gate layer, a gate layer, and an anode layer is formed. A contact layer is formed on the anode layer. A current constriction region is formed by a region in which the anode layer is in contact with the contact layer. A minimum distance from the current constriction region to a side surface of the mesa structure is greater than or equal to 4 μm.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com