LED array

A technology of light-emitting diodes and arrays, applied in optics, printing, instruments, etc., can solve the problems of light-emitting diode luminous output decline, etc., and achieve the effect of increasing recombination and increasing luminous output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

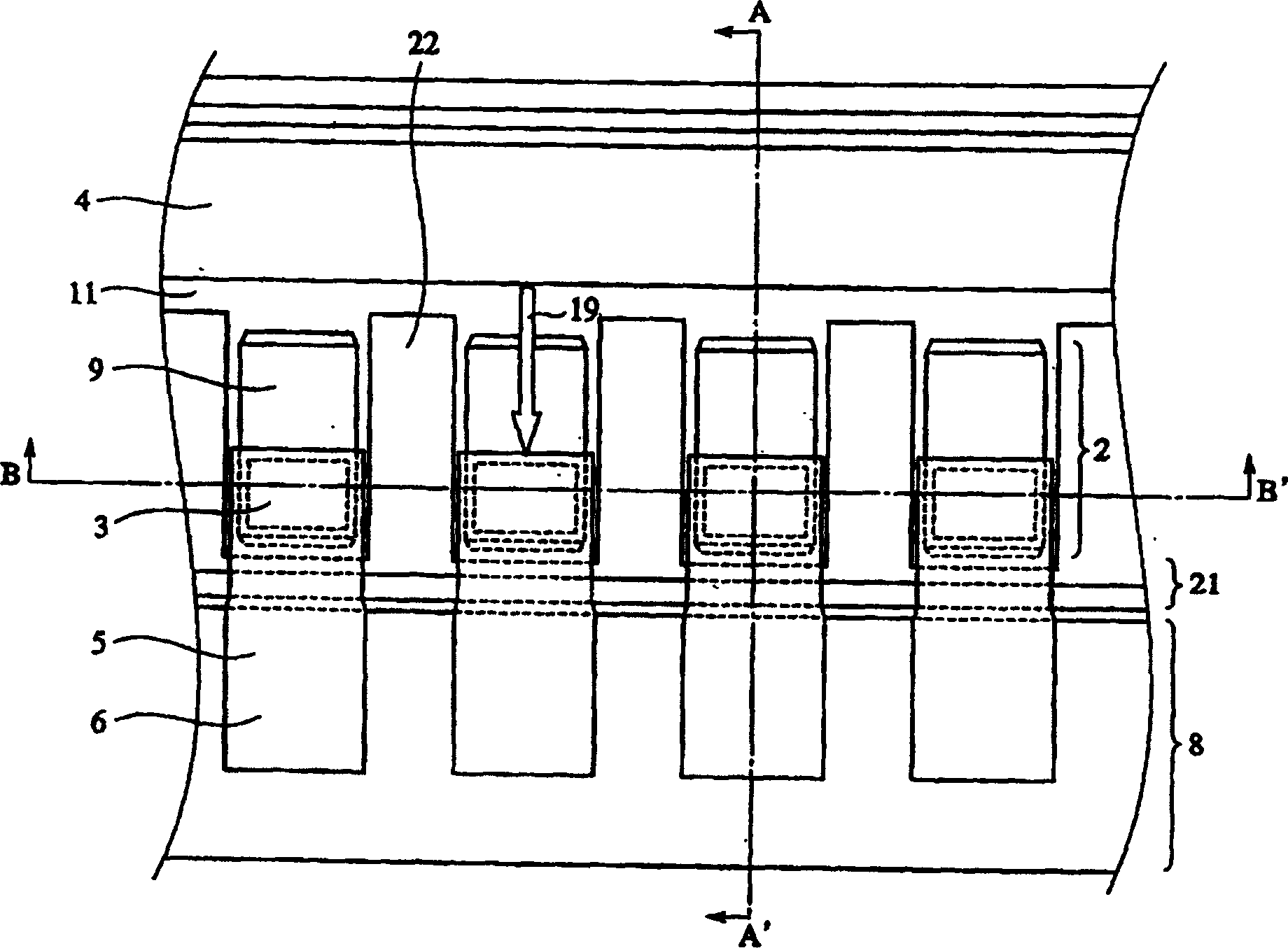

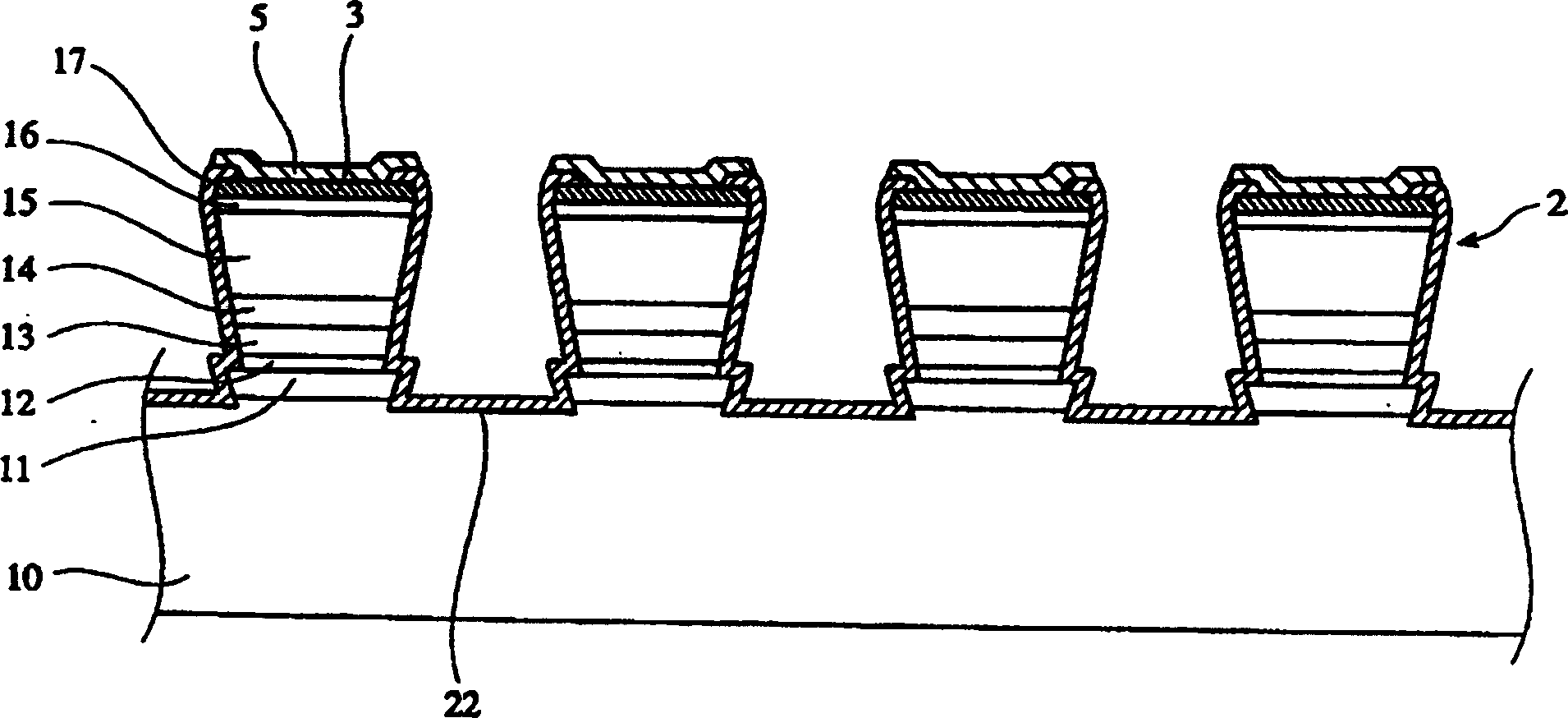

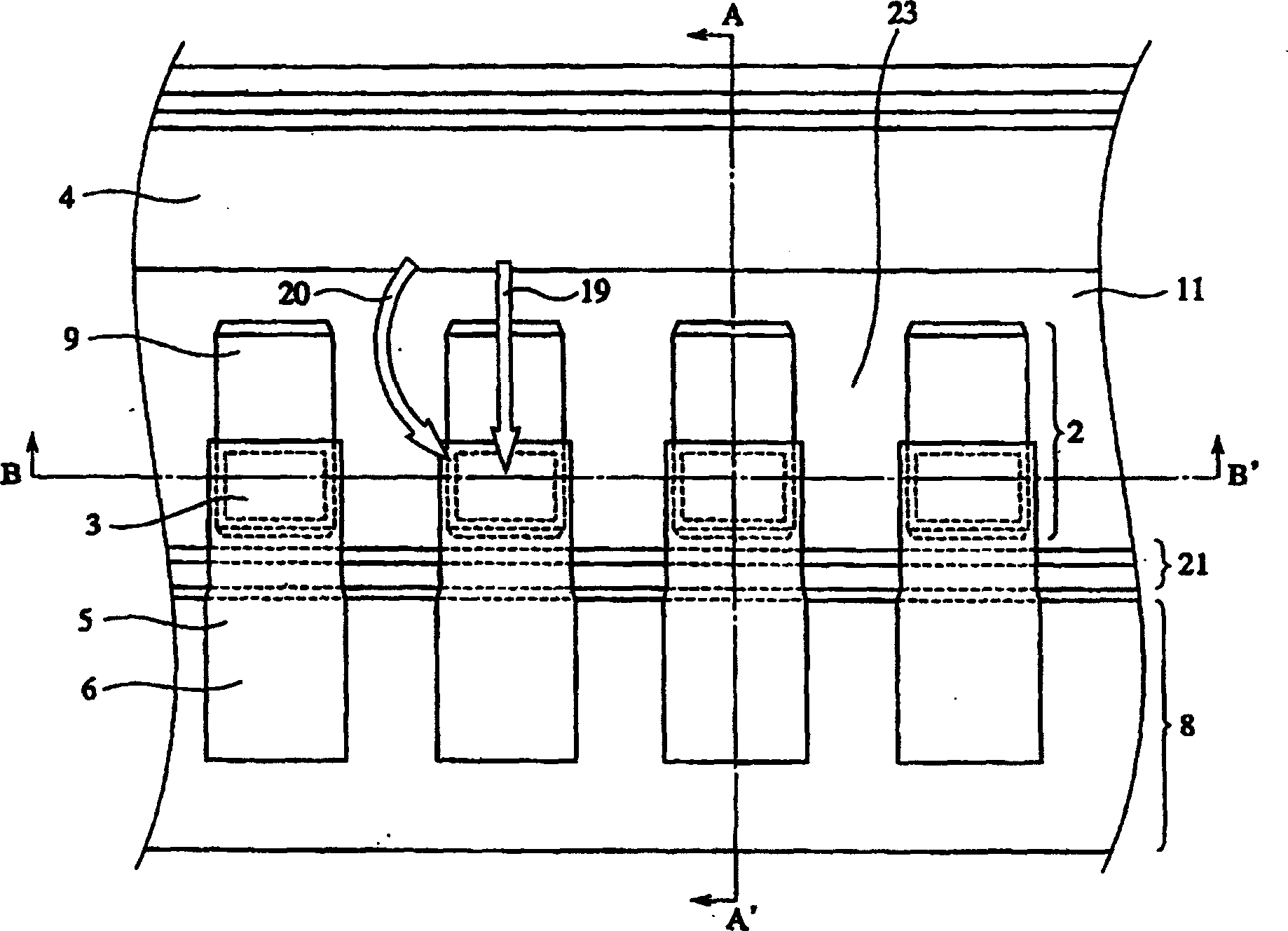

[0020] [1] Structure of LED array

[0021] like figure 1 , figure 2 and Figure 4 ( figure 1 The A-A′ section and image 3 As shown in the A-A' cross-section of the same), the light emitting diode array of the present invention has a substrate 10, a conductive layer 11 formed on the entire surface of the substrate 10, a plurality of light emitting parts 2 independently formed on the conductive layer 11, and a plurality of light emitting parts 2 in the light emitting part 2. The first electrode 3 partially formed thereon and the second electrode 4 formed on the conductive layer 11 at a position close to the light emitting portion 2 . In addition, in figure 1 In , the insulating layer is omitted to clearly show the underlying layer. In the illustrated embodiment, each light-emitting portion 2 is provided with mesa-type etching grooves on the epitaxial layer uniformly formed on the substrate 10 , and is a part of each independent epitaxial layer portion.

[0022] (1) Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com