Preparation method of polyimide nanometer filtering membrane

A technology of polyimide nano and polyamic acid, which is applied in the field of preparation of polyimide nanofiltration membrane, can solve the problems of uncontrolled polyimide material solubility, and achieve the goal of eliminating precipitation and reducing solvent The effect of the amount and type of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

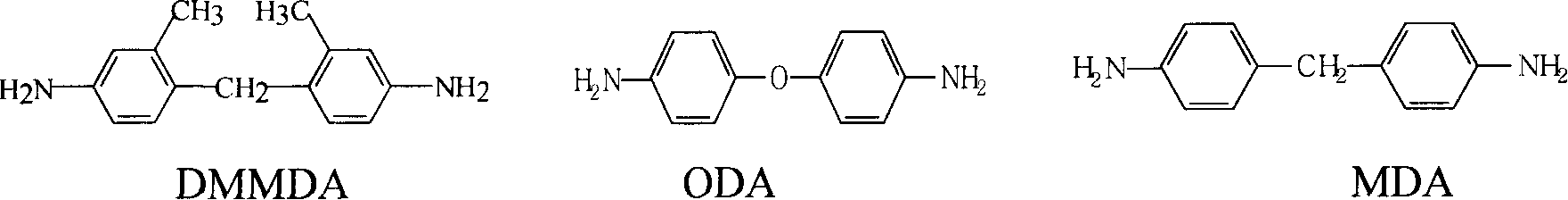

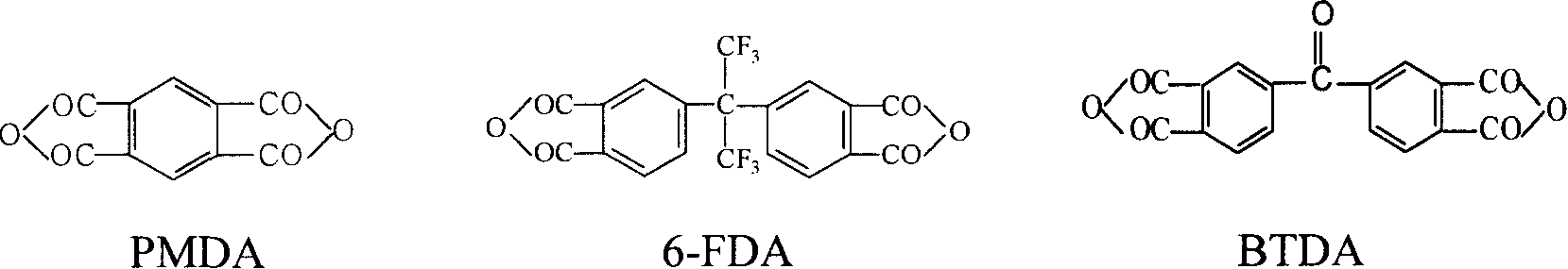

[0021] Synthesis of polyamic acid: 5g (0.025mol) of 4,4'-diaminodiphenyl ether (ODA) was dissolved in 80mL of N,N-dimethylacetamide, electromagnetically stirred, under nitrogen protection Add 5.45g (0.025mol) of pyromellitic dianhydride (PMDA) in batches to the solution, and stir the reaction at room temperature 8 After hours, a polyamic acid solution was obtained, and the concentration of this solution was 13.1 wt%.

[0022] Polyamic acid solution film-making process: Take 25 g of the above-mentioned synthesized polyamic acid solution, add 2.0 g of polyvinylpyrrolidone additive, mix well, filter with 300-mesh stainless steel mesh, and let the filtrate stand for degassing for 24 hours. Under dust-free conditions, at 25°C and relative humidity of 50%, apply the above-mentioned solution on a glass plate or a porous bottom layer, control the thickness of the film to about 25 μm, control the volatilization time for 25 seconds, and then immerse in water or ethanol Film formation i...

Embodiment 2

[0026] Synthesis of polyamic acid: Dissolve 4.9568g (0.025mol) of diphenylmethanediamine (MDA) in 80mL of N-methylpyrrolidone, stir electromagnetically, and add 8.0558g (0.025mol) to the solution in batches under nitrogen protection. mol) of benzophenone tetra-acid dianhydride (BTDA), stirred and reacted at room temperature for 8 hours to obtain a polyamic acid solution, and the concentration of this solution was 13.99 wt%.

[0027] Polyamic acid solution film-making process: Take 25 g of the above-mentioned synthesized polyamic acid solution, add 2.3 g of polyethylene glycol additive, mix well, filter with 300 mesh stainless steel mesh, and let the filtrate stand for degassing for 24 hours. Under dust-free conditions, at 25°C and relative humidity of 50%, apply the above-mentioned solution on a glass plate or a porous bottom layer, control the thickness of the film to about 25 μm, control the volatilization time for 25 seconds, and then immerse in water or ethanol Film format...

Embodiment 3

[0031] Synthesis of polyamic acid: 5.658g (0.025mol) of 3,3'dimethyldiphenylmethanediamine (DMMDA) was dissolved in 80mL of dimethylformamide, electromagnetically stirred, and poured into the solution under nitrogen protection Add 11.106g (0.025mol) of hexafluorodianhydride (6FDA) in batches, and stir the reaction at room temperature 8 After hours, a polyamic acid solution was obtained, and the concentration of this solution was 17.32 wt%.

[0032] Polyamic acid solution film-making process: Take 25g of the polyamic acid solution synthesized above, add 1.8g of polyvinyl alcohol additive, mix well, filter with 300-mesh stainless steel mesh, and let the filtrate stand for degassing for 24 hours. Under dust-free conditions, at 25°C and relative humidity of 50%, apply the above-mentioned solution on a glass plate or a porous bottom layer, control the thickness of the film to about 25 μm, control the volatilization time for 25 seconds, and then immerse in water or ethanol Film for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com