Wet fermentation feed for laying hens and production process of wet fermentation feed

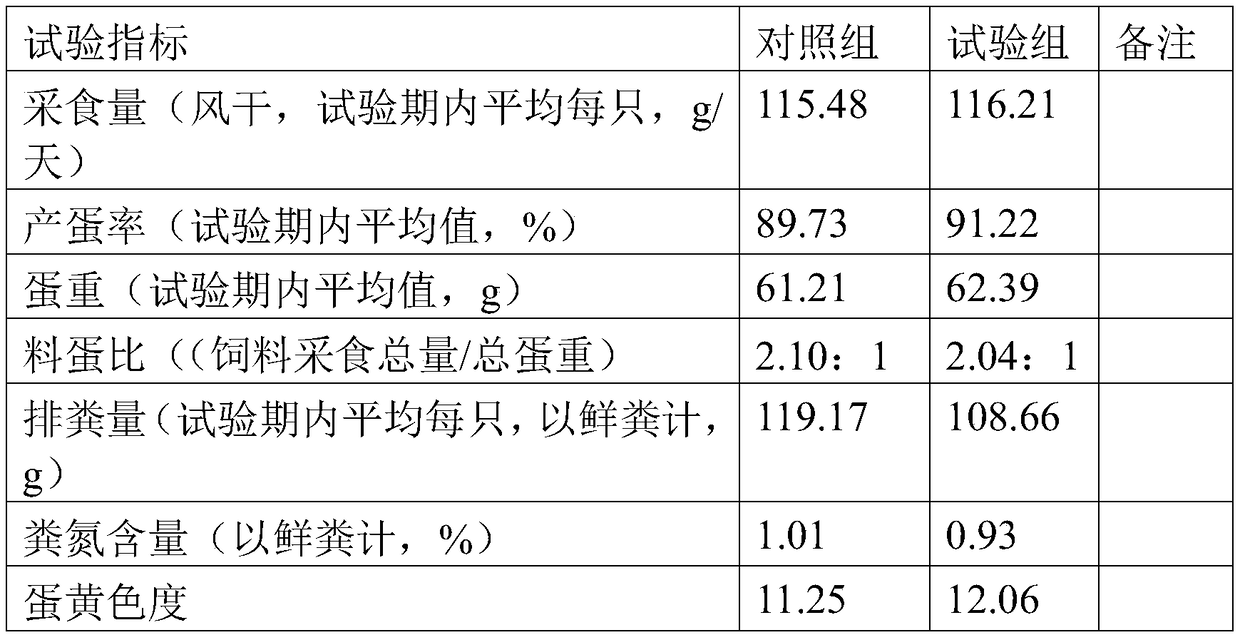

A production process and wet fermentation technology, which is applied in the field of wet fermented feed for laying hens and its preparation, can solve the problems of low digestion and utilization rate, antibiotic-free health care of laying hens, achieve improved flavor, reduce the incidence of digestive tract diseases, and reduce dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A wet fermented feed for laying hens, comprising the following ingredients by weight: seaweed (wet) 30wt%; distiller's grains (wet) 12wt%; sesame meal 5wt%; rapeseed meal 5wt%; cotton meal 5wt%; corn germ meal 10wt% ; Corn DDGS5wt%; Rice husk powder 5wt%; Molasses 10wt%; Calcium hydrogen phosphate 1.5wt%; Stone powder 4wt%; Zeolite powder 4wt%; ; Composite enzyme 0.7wt%; Microecological bacteria 1.2wt%.

[0031] (1) Start up: turn on the power of the mixer;

[0032] (2) Feeding at the large material feeding port: while keeping the mixer running, put in successively 5wt% of sesame meal; 5wt% of rapeseed meal; 5wt% of cotton meal; 10wt% of corn germ meal; 5wt% of corn DDGS; Molasses 10wt%; Calcium hydrogen phosphate 1.5wt%; Stone powder 4wt%; Zeolite powder 4wt%; Seaweed (wet) 30wt%; Distiller's grains (wet) 12wt%;

[0033] (3) Feed intake of small material feeding port: while keeping the mixer running, put in 98% betaine hydrochloride 0.8wt% successively; Multi-mineral...

Embodiment 2

[0037] A wet fermented feed for laying hens, comprising the following ingredients by weight: seaweed (wet) 38wt%; distiller's grains (wet) 10wt%; sesame meal 6.4wt%; rapeseed meal 3wt%; cotton meal 5wt%; corn germ meal 12wt% %; corn DDGS5wt%; rice husk powder 5wt%; molasses 5wt%; calcium hydrogen phosphate 1wt%; stone powder 3wt%; zeolite powder 3wt%; ; Composite enzyme 0.7wt%; Microecological bacteria 1.5wt%.

[0038] (1) Start up: turn on the power of the mixer;

[0039] (2) Feeding at the large material feeding port: while keeping the mixer running, successively put in 6.4wt% of sesame meal; 3wt% of rapeseed meal; 5wt% of cotton meal; 12wt% of corn germ meal; 5wt% of corn DDGS; 5wt% of rice husk powder; Calcium hydrogen phosphate 1wt%; Stone powder 3wt%; Zeolite powder 3wt%; Seaweed (wet) 38wt%; Distiller's grains (wet) 10wt%;

[0040] (3) Feed feeding of small material feeding port: while keeping the mixer running, put in 98% betaine hydrochloride 0.8wt% successively; Mu...

Embodiment 3

[0044]A wet fermented feed for laying hens, comprising the following ingredients by weight: seaweed (wet) 45wt%; sesame meal 6wt%; rapeseed meal 3.3wt%; cotton meal 5.5wt%; corn germ meal 12wt%; corn DDGS 5wt%; Rice husk powder 6wt%; Molasses 7wt%; Calcium hydrogen phosphate 1wt%; Stone powder 3wt%; Zeolite powder 3wt%; 98% betaine hydrochloride 0.7wt%; ; Probiotics 1wt%.

[0045] (1) Start up: turn on the power of the mixer;

[0046] (2) Feeding at the large material feeding port: while keeping the mixer running, put in successively 6wt% of sesame meal; 3.3wt% of rapeseed meal; 5.5wt% of cotton meal; 12wt% of corn germ meal; 5wt% of corn DDGS; 6wt% of rice hull powder Calcium hydrogen phosphate 1wt%; Stone powder 3wt%; Zeolite powder 3wt%; Seaweed (wet) 45wt%;

[0047] (3) Feed feeding of small material feeding port: while keeping the mixer running, put in 98% betaine hydrochloride 0.7wt% successively; Multi-mineral premix 0.8wt%; Composite enzyme 0.7wt%; Microecological ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com