Method for preparing nickel-containing solid particle briquette

A solid particle, ferronickel technology, applied in the chemical industry, can solve the problems of increased drying cost, high cost, secondary oxidation of metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

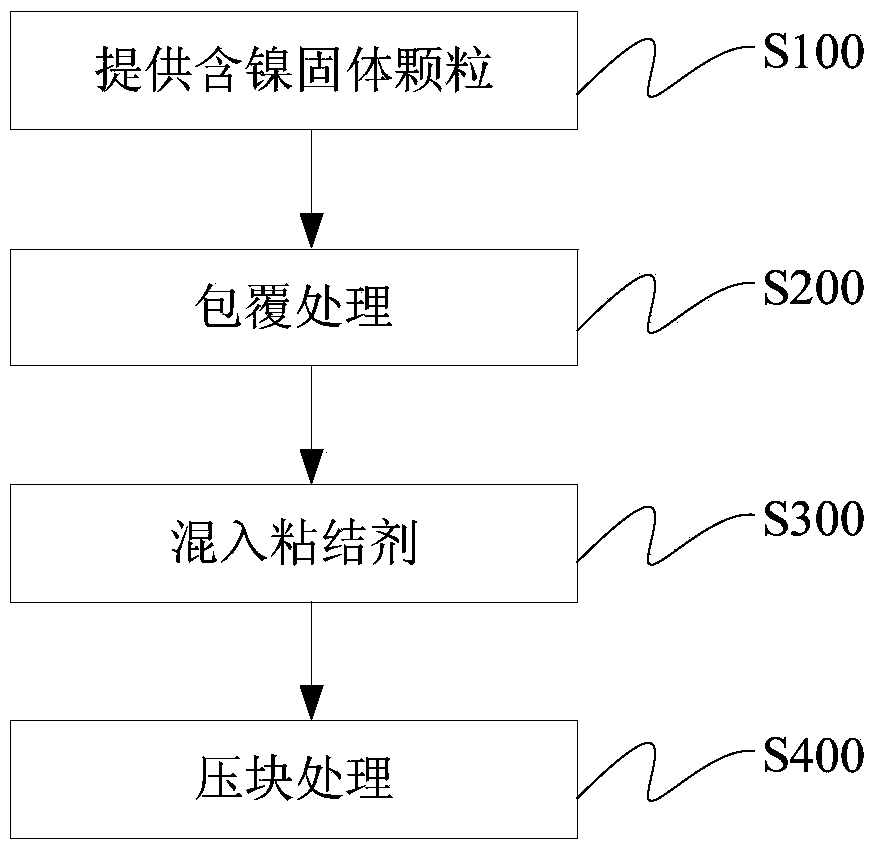

Method used

Image

Examples

preparation example Construction

[0037] The method for preparing a nickel-containing solid particle briquette according to an embodiment of the present invention further includes: coating the nickel-containing solid particle provided above with an organic coating agent. According to specific embodiments of the present invention, the type and composition of the organic coating agent are not particularly limited. According to a specific example of the present invention, the organic coating agent used in the above method may include hydrocarbons that are liquid at normal temperature, for example, alkanes that are liquid at normal temperature.

[0038]According to a specific example of the present invention, the organic coating agent may be lubricating oil, such as gear oil, such as waste gear oil. This takes advantage of a further reduction in production costs. The "waste gear oil" described in the embodiments of the present invention refers to the waste gear oil replaced by engines, compressors, etc. The nick...

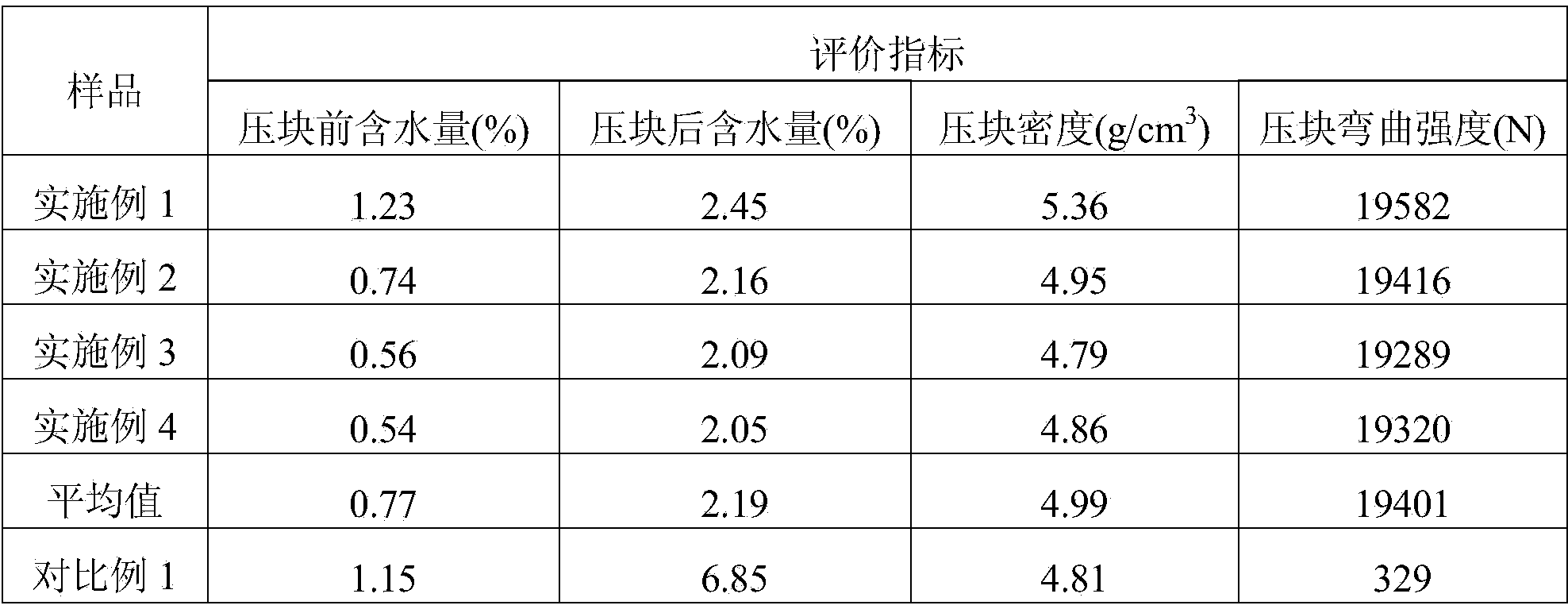

Embodiment 1

[0061] A laterite nickel ore grinding product is provided, with an average particle size of 75 microns and a water content of 1.23% by weight.

[0062] In a paddle mixer, the gear oil was mixed with the grinding product and stirred for 90 minutes, wherein, based on 100 parts by weight of the grinding product, the amount of gear oil was 0.3 parts by weight; in the paddle mixer, slaked lime was added and dry mixed for 3 Minutes, wherein, based on 100 parts by weight of the milled product, the consumption of slaked lime is 3.6 parts by weight; in the paddle mixer, add the syrup waste liquid and mix for 3 minutes, wherein, based on 100 parts by weight of the milled product, the syrup waste liquid The dosage is 6.0 parts by weight; the temperature of the material rises significantly, reaching 83° C. through testing. 3.15t / cm is used on a 400-ton hydraulic briquetting machine 2 Under pressure, the mixture obtained in the paddle mixer was compacted so as to obtain a diameter of 110 ...

Embodiment 2

[0064] A laterite nickel ore grinding product is provided, with an average particle size of 75 microns and a water content of 0.74% by weight.

[0065] In a paddle mixer, the gear oil was mixed with the grinding product and stirred for 90 minutes, wherein, based on 100 parts by weight of the grinding product, the amount of gear oil was 0.3 parts by weight; in the paddle mixer, slaked lime was added and dry mixed for 3 Minutes, wherein, based on 100 parts by weight of the milled product, the consumption of slaked lime is 3.6 parts by weight; in the paddle mixer, add the syrup waste liquid and mix for 3 minutes, wherein, based on 100 parts by weight of the milled product, the syrup waste liquid The dosage is 6.0 parts by weight; the temperature of the material rises significantly, reaching 83° C. through testing. 3.15t / cm is used on a 400-ton hydraulic briquetting machine 2 The mixture obtained in the paddle mixer was compacted under pressure so as to obtain a diameter of 110 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com