Preparing method of magnetic powder for dry pressing anisotropic permanent-magnetic ferrite

A manufacturing method and permanent magnet technology, which is applied in the field of permanent magnet material preparation, can solve problems such as large water consumption, high energy consumption, and complicated process flow, and achieve the effects of reducing water consumption, reducing process flow, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

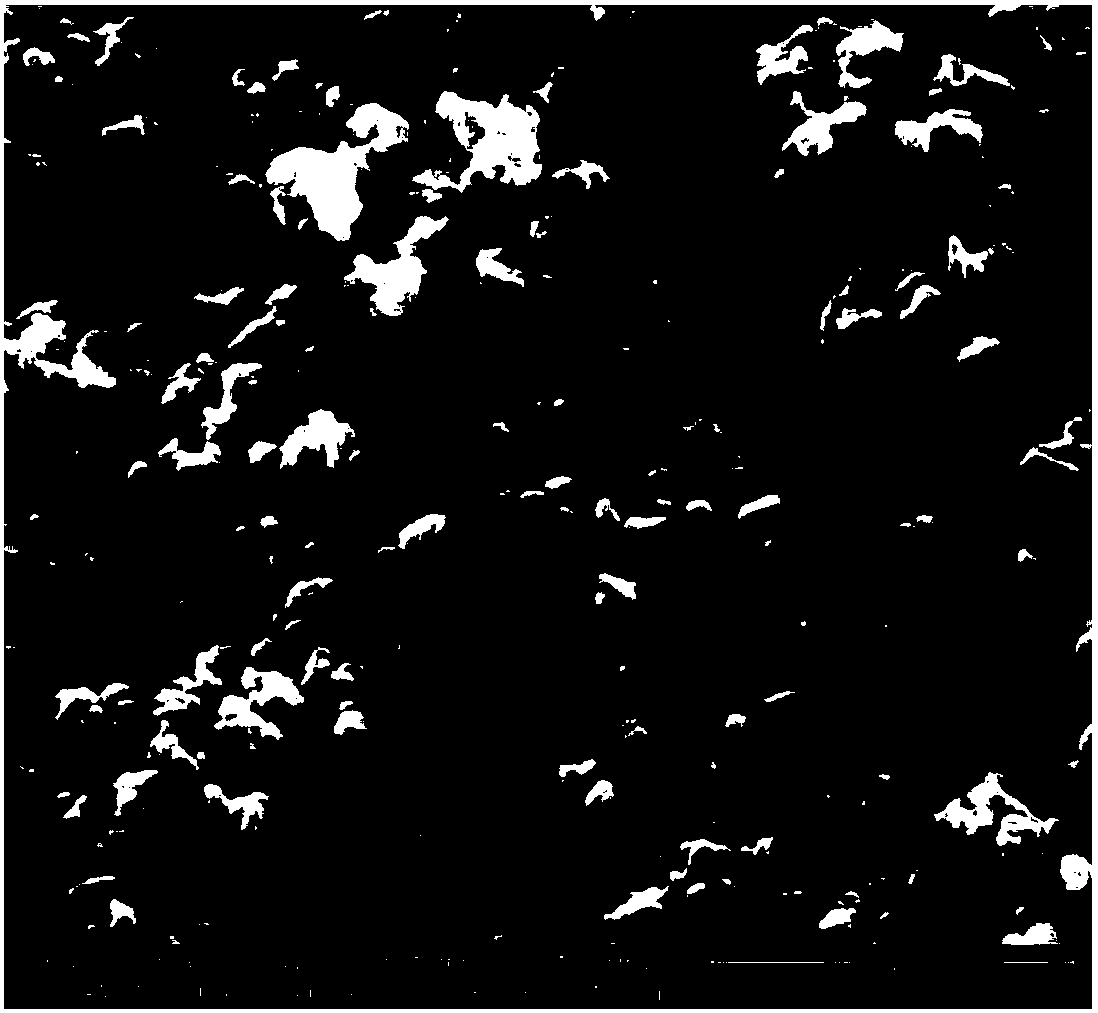

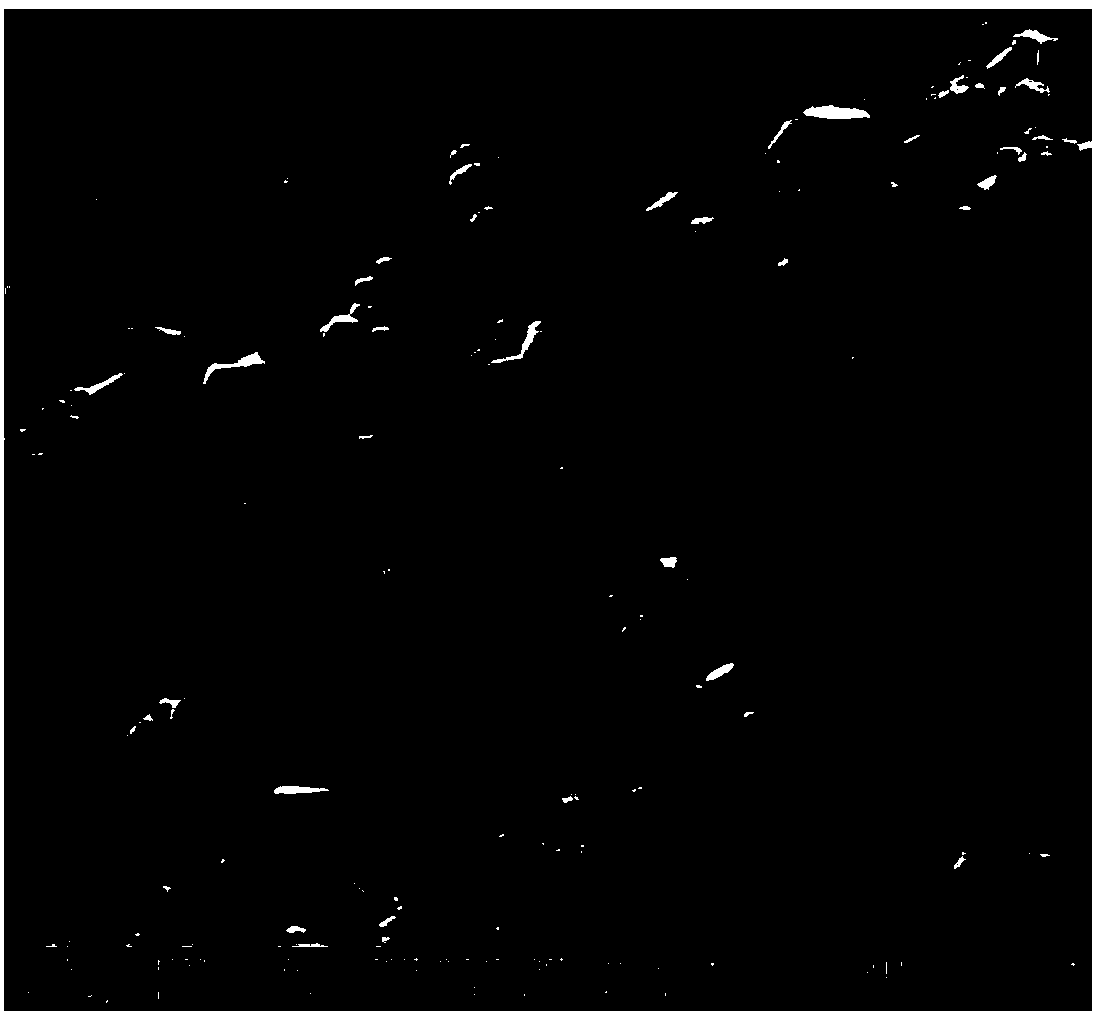

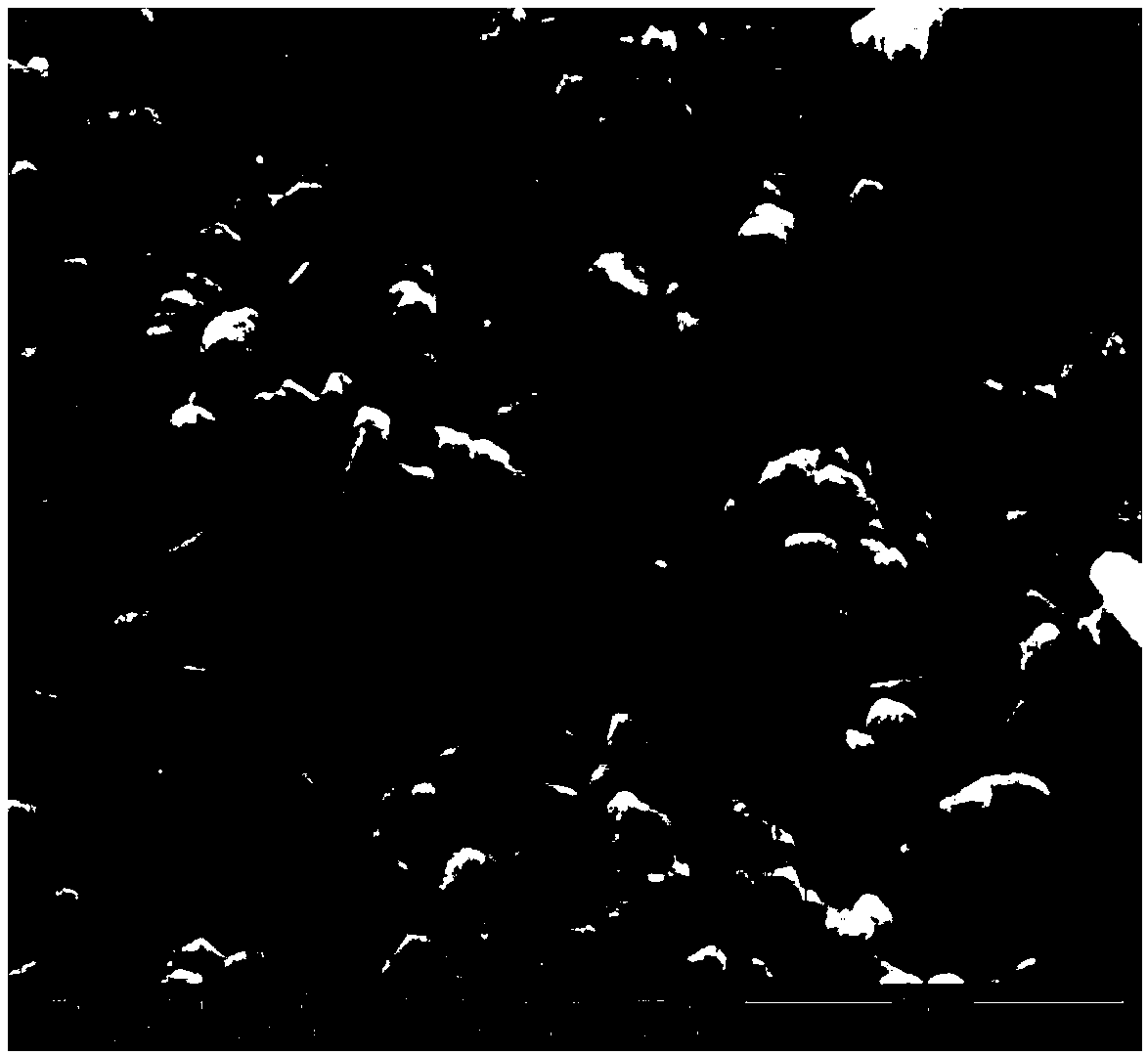

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for manufacturing magnetic powder for dry-pressing anisotropic permanent ferrite, comprising the following steps:

[0042] The ferrite pre-fired material uses the following raw materials:

[0043] Iron oxide (i.e. iron red): 1200 grams (particle size is 0.70 μm, purity greater than 98.5%);

[0044] Strontium carbonate: 190 grams (particle size is 1.8 μm, purity is greater than 97.5%);

[0045] Use a vibration mill to mix the materials (mix the above-mentioned iron oxide and strontium carbonate), granulate, pre-fire at 1100°C for 2 hours to make ferrite calcined material, and coarsely crush the ferrite calcined material into an average particle size It is a coarse powder of about 2 μm, and 1.0% of the weight of the coarse powder is added to the coarse powder. 3 and 0.35% SiO 2 , vibrated and milled for 2 hours, the average particle size of the magnetic powder is 1.40 μm, and then adding 1.0% camphor powder and 0.3% calcium stearate ac...

Embodiment 2、 Embodiment 3

[0047] According to the above-mentioned process of Example 1, only changing the low-temperature pre-calcination temperature to 1150°C and 1180°C, respectively, Example 2 and Example 3 for preparing dry-pressed magnetic powder were obtained.

Embodiment 4~6

[0049] According to the process in the above-mentioned examples 1, 2 and 3, but change the CaCO in the secondary batching 3 and SiO 2 , adding 1.0% CaCO by weight to the coarse powder from the original 3 and 0.35% SiO 2 , instead adding 0.75% of CaCO by weight of coarse powder 3 and 0.3% SiO 2 , to obtain embodiment 4, implementation 5 and implementation 6 of preparing dry-pressed magnetic powder respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com