Low-energy-consumption low-sludge-yield SBR process

A low energy consumption and sludge technology, applied in water/sludge/sewage treatment, aerobic and anaerobic process treatment, biological water/sewage treatment, etc., can solve high energy consumption, aggravate energy crisis, increase sewage treatment cost, etc. problems, to achieve the effect of reducing water and electricity consumption per ton, facilitating sludge settlement and dehydration, and reducing sludge yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

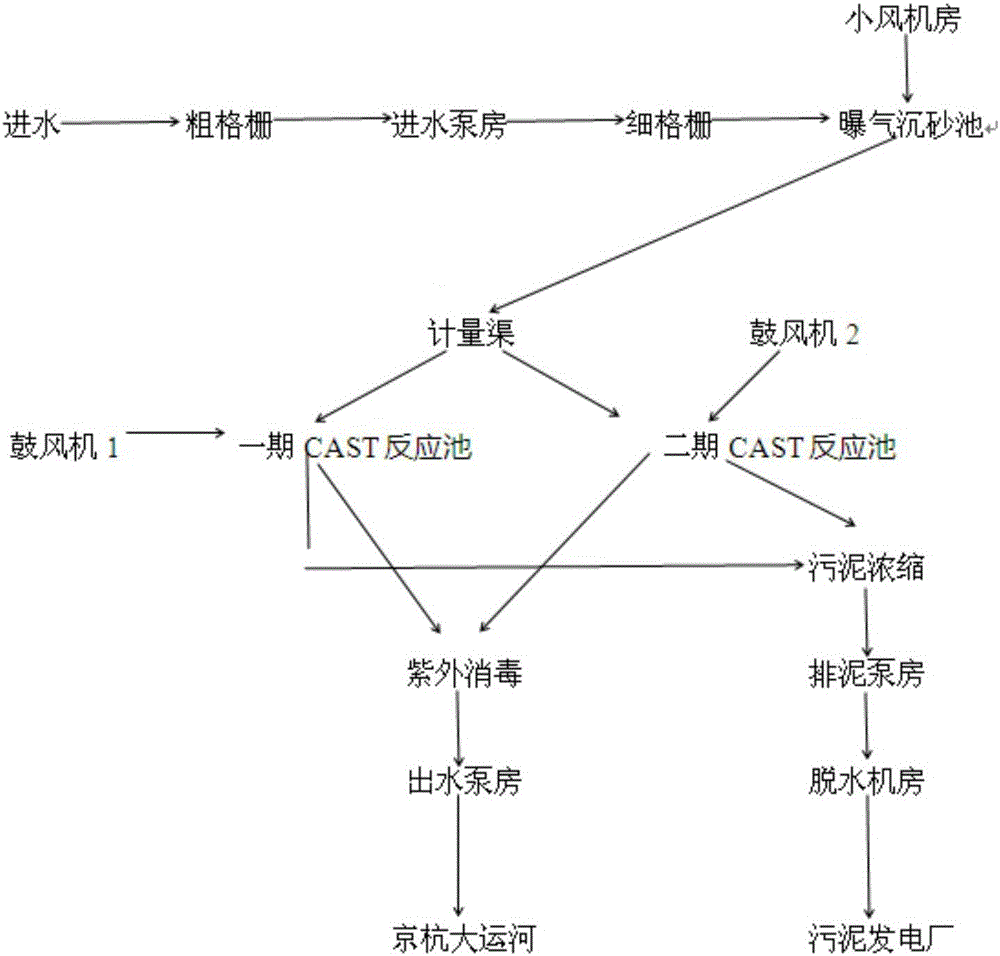

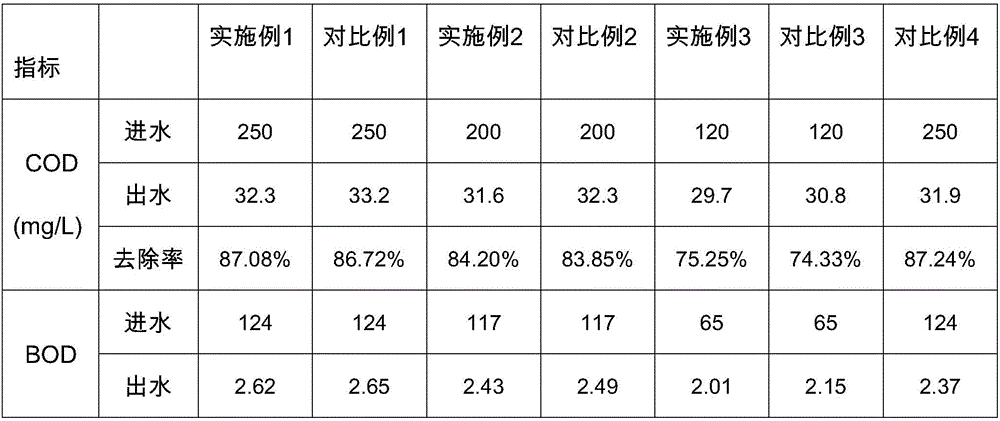

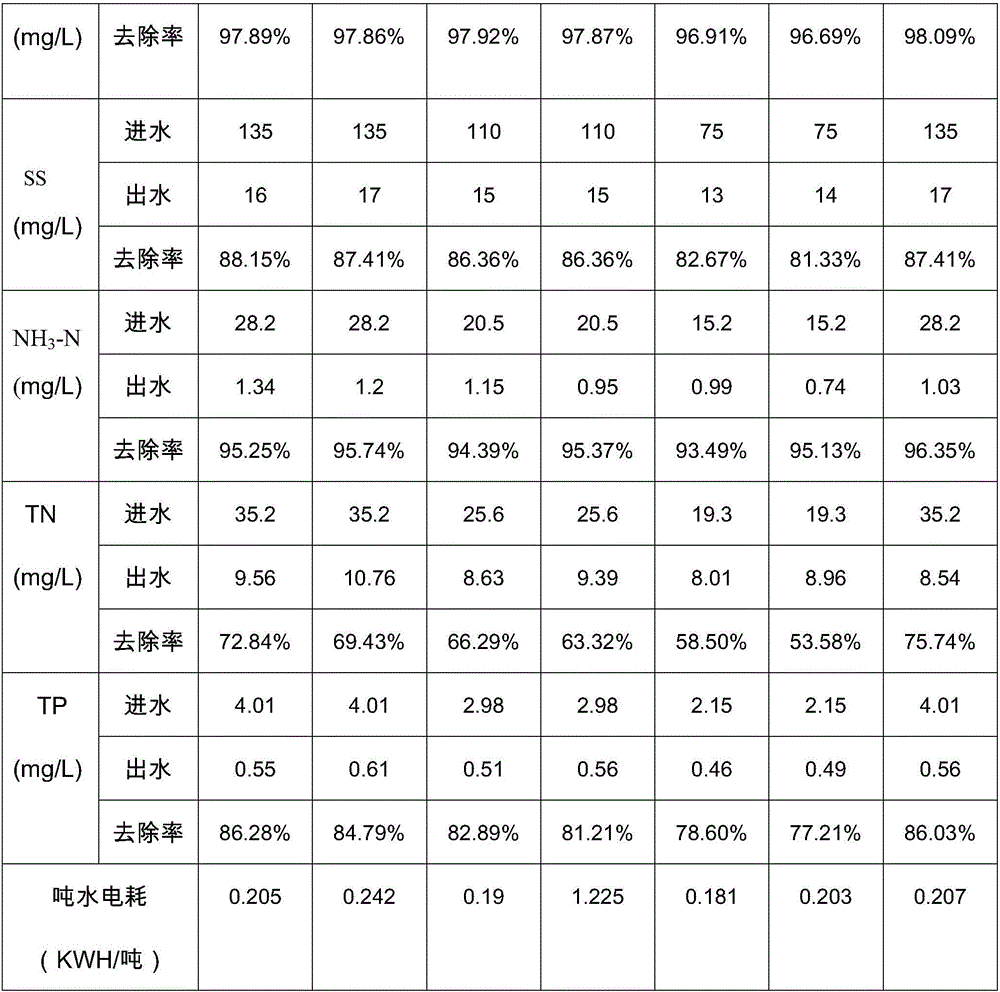

[0021] A low energy consumption and low sludge yield SBR process, such as figure 1 As shown, it specifically includes the following steps:

[0022] 1) water ingress

[0023] The sewage first passes through the coarse screen to remove large particles of impurities, and then is lifted by the inlet pump room to flow through the fine screen and aeration desilting tank to further remove suspended solids and fine sand, and then enters the metering channel, where it is distributed and metered ( The COD in the sewage entering the SBR reaction tank is 250mg / L, the BOD is 124mg / L, the SS is 135mg / L, and the NH 3 -N is 28.2mg / L, TN is 35.2mg / L, TP is 4.01mg / L) and the sludge returned from the main aeration area of the SBR reaction tank (the sludge from the main aeration area is returned to the biological selection area The reflux ratio is 22%) into the biological selection zone of the SBR reaction tank at the same time, then flows into the anoxic zone of the SBR reaction tank, and fi...

Embodiment 2

[0034] The sewage treatment steps are the same as in implementation 1, the difference is that the COD in the sewage entering the SBR reaction tank is 200mg / L, the BOD is 117mg / L, the SS is 110mg / L, the NH3-N is 20.5mg / L, and the TN is 25.6mg / L, TP is 2.98mg / L,), correspondingly, in step 2), the control total aeration time is 1.5h.

Embodiment 3

[0038] The sewage treatment steps are the same as in implementation 1, the difference is that the COD in the sewage entering the SBR reaction tank is 120mg / L, the BOD is 65mg / L, the SS is 75mg / L, the NH3-N is 15.2mg / L, and the TN is 19.3mg / L, TP is 2.15mg / L), correspondingly, in step 2), the control total aeration time is 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com