Recovery and using method of solution and unreaction monomer in process of producting polymer by solution polymerization process

A technological process and polymerization technology, applied in the field of polymer production, can solve the problems of high production cost, large investment in equipment, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. A method for recycling solvents and unreacted monomers in the process of producing isoprene rubber by solution polymerization. This embodiment includes supplementary distillation and refining of fresh monomer (dehydration, removal of light components and removal of heavy components) and separation and distillation of the condensed oil phase (dehydration of solvent and unreacted monomers, removal of light components and removal of heavy components) ).

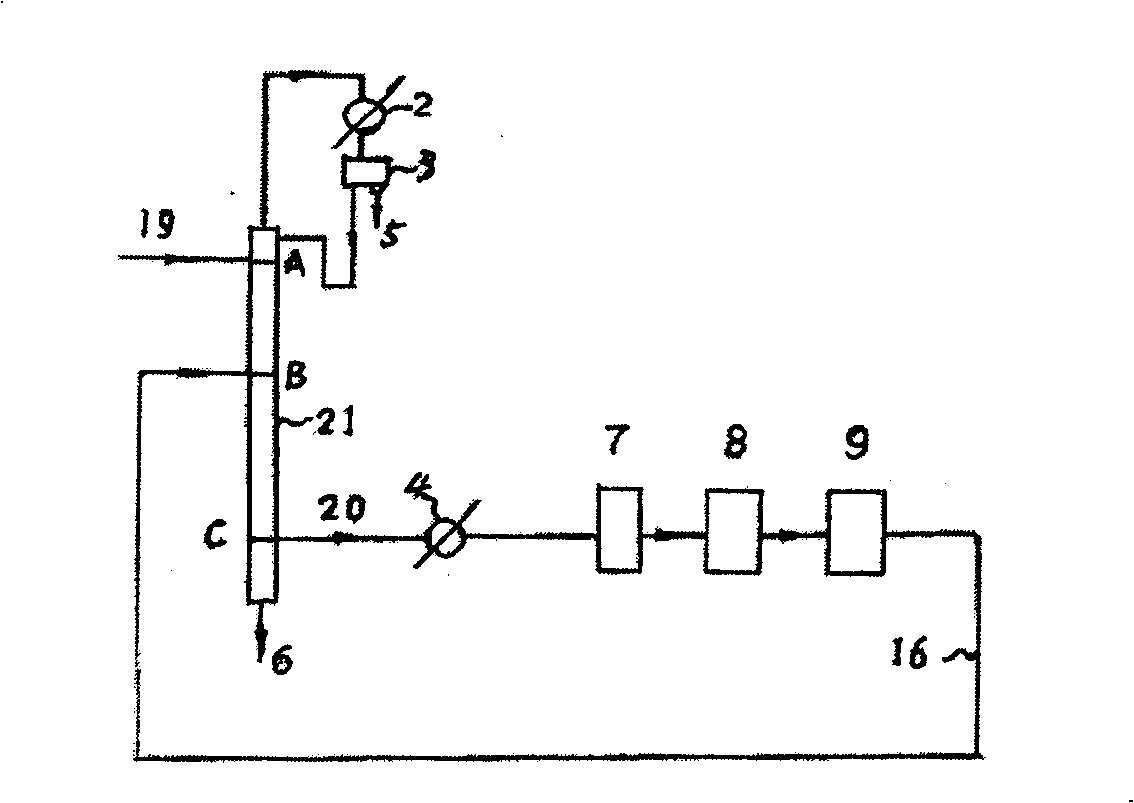

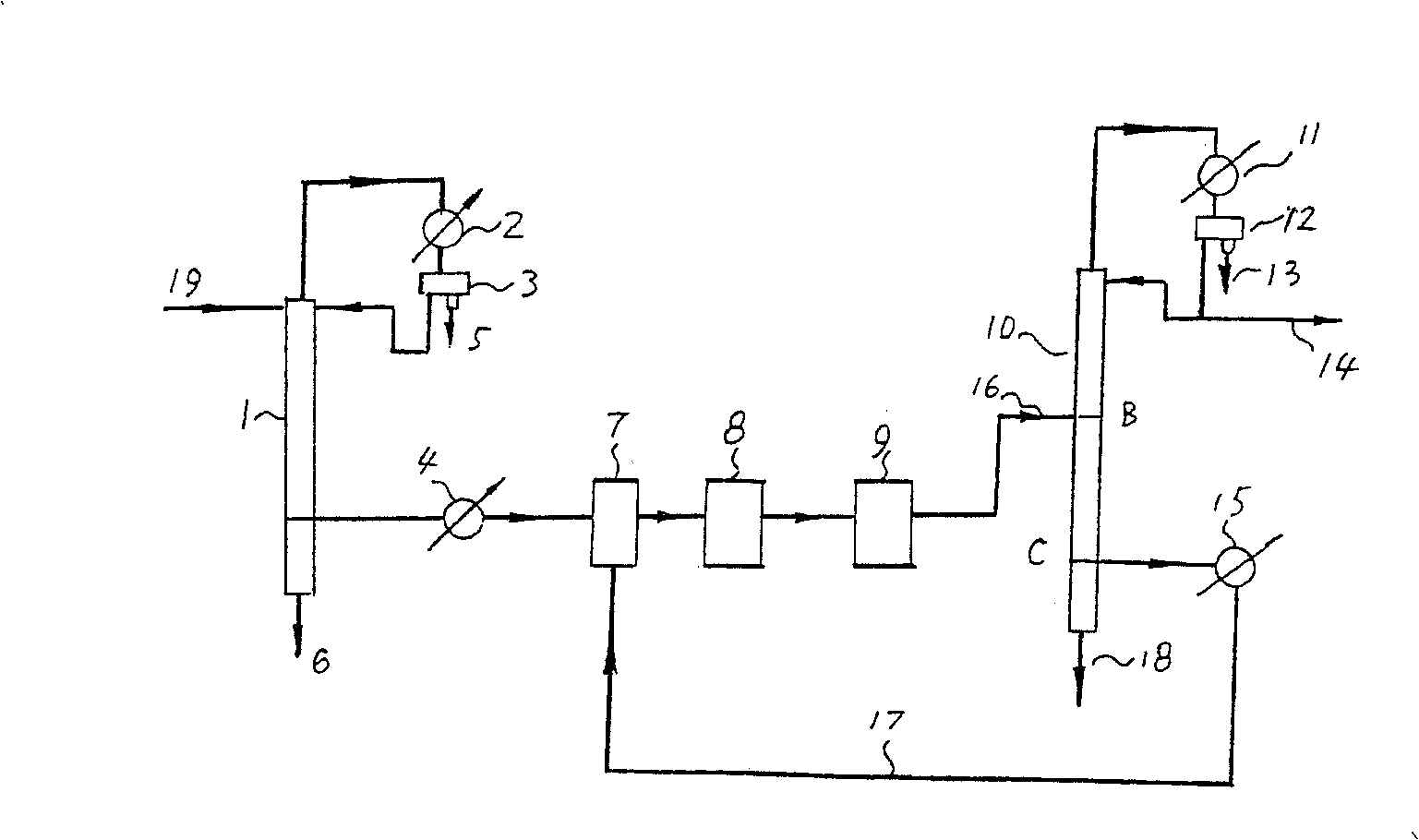

[0026] Such as figure 1 As shown, the condensed oil phase 16 (unreacted monomer mass concentration 11%, and containing 450ppm water and a small amount of heavy components) that reclaims from the coagulation process enters the recovery refining tower 21 (nominal diameter is 70 millimeters, The middle part B (25 theoretical plates from the top of the tower) is equipped with 4×6 metal rolling ring random packing). Supplementary fresh monomer 19 enters from the upper part A of the rectification section (10 th...

Embodiment 2

[0030] Example 2, a method for recycling solvents and unreacted monomers in the process of producing isoprene rubber by solution polymerization is as in Example 1. The condensed oil phase 16 that reclaims from coagulation operation 9 is 20 liters / hour (unreacted monomer concentration 1.5%, and contains 440ppm water and a small amount of heavy component) and enters the middle part B of recovery tower 21 (10 theoretical plates away from the tower top), Supplementary 0.5 liter / hour fresh monomer 19 enters 21 from the upper part A of the rectifying section (5 theoretical plates from the top of the tower). The tower top monomer undergoes total reflux through the tower top condenser 2, and its reflux flow is 0.2 times of the feed amount, and free water 5 can be separated from the reflux tank 3 regularly. Solvents and monomers pass through the dehydration section of the stripping section at C (15 theoretical plates away from the tower kettle) in the form of vapor phase side line extr...

Embodiment 3

[0032]Embodiment 3, a method for recycling solvents and unreacted monomers in the process of producing polymer isoprene rubber by solution polymerization is as in Embodiment 1. The condensed oil phase 16 that reclaims from condensing operation 9 is 20 liters / hour (30% of unreacted monomer concentration, and contains 460ppm water and a small amount of heavy component) and enters the middle part B of recovery tower 21 (from tower top 40 theoretical plates), Supplementary fresh monomer 19 of 6.8 liters / hour enters 21 from the upper part A of the rectification section (15 theoretical plates from the top of the column). The tower top monomer undergoes total reflux through the tower top condenser 2, and its reflux flow is three times that of the feed amount, and free water 5 can be separated from the reflux tank 3 regularly. Solvents and monomers pass through the dehydration section of the stripping section at C (5 theoretical plates away from the tower kettle) in the form of vapor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com