Preparation method of low-sodium and high-activity special alpha-Al2O3 micro powder

A high-activity, micro-powder technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of unfavorable industrialization promotion, cumbersome process flow, and low yield, and achieve reasonable particle size distribution, high chemical purity, and transformation high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

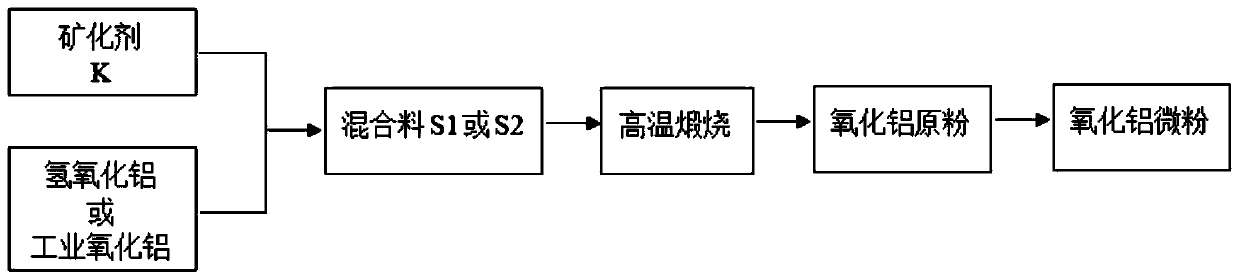

Method used

Image

Examples

Embodiment 1

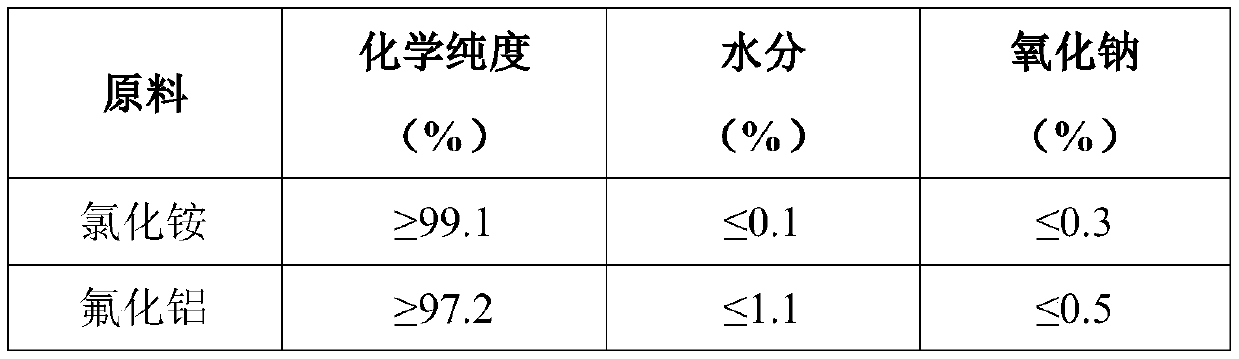

[0037] First, ammonium chloride and aluminum fluoride are mixed according to weight 10:1 to obtain mineralizer K1; industrial alumina (25% content under 325 mesh sieve, BET=70m 2 / g,Na 2 O=0.45%) and mineralizer K1 were placed in a high-performance mixer (Eirich brand, RV24 type) and mixed for 20 minutes according to the weight ratio of 100:1, and the mixer speed was 100 rpm to obtain the mixture S1-1 ; Place S1-1 in a high-temperature furnace for high-temperature calcination. The temperature rise curve of the high-temperature furnace is set at 10°C / min, the temperature is raised to 1100°C, and the temperature is kept at this temperature for 1 hour; after natural cooling, the calcined material is placed in In the ball mill, the ratio of ball to material is 8:1, the weight ratio of grinding balls with different diameters is 40mm:30mm:20mm=2:7:1, the diameter of the mill is 30cm, the diameter is 50cm, and the set speed is 60 rpm. The milling time is 10 hours, and the active α-A...

Embodiment 2

[0040] Ammonium chloride and aluminum fluoride are mixed according to weight ratio 10:1.5 to obtain mineralizer K2; Industrial alumina (content 25% under 325 mesh sieves, BET=68m 2 / g,Na 2 O=0.49%) and mineralizer K2 according to the weight ratio are 100:1.5 and are placed in the high-performance mixer (Ei Lixu brand, RV24 type) and mix the materials for 20 minutes, the mixer speed is 100 rpm, and the mixture S1-2 is obtained. ; The mixture S1-2 is placed in a high-temperature furnace for calcination, the temperature rise curve of the high-temperature furnace is set at 10°C / min, the temperature is raised to 1200°C, and the temperature is kept at this temperature for 2 hours; after natural cooling, the calcined material is placed in In the ball mill, the ratio of ball to material is 8:1, the weight ratio of grinding balls with different diameters is 40mm:30mm:20mm=2:7:1, the diameter of the mill is 30cm, the diameter is 50cm, and the set speed is 60 rpm , the milling time was ...

Embodiment 3

[0043] Ammonium chloride and aluminum fluoride are mixed according to weight ratio 10:2 to obtain mineralizer K3; 2 / g,Na 2 O=0.36%) and mineralizer K3 weight ratio is 100:2 and is placed in high-performance mixer (Ei Lixu brand, RV24 type) and carries out mixing 20 minutes, and mixer speed 100 revs / min, obtains mixture S1-3 ;Put the mixture S1-3 in a high-temperature furnace for calcination, set the temperature rise curve of the high-temperature furnace at 10°C / min, raise the temperature to 1150°C, and keep it at this temperature for 1.5 hours; after natural cooling, the calcined alumina Put it in a ball mill, the ratio of ball to material is 8:1, the weight ratio of grinding balls with different diameters is: 40mm:30mm:20mm=2:7:1, the diameter of the grinder is 30cm, the diameter is 50cm, and the set speed is 60 rpm / min, the grinding time is 5 hours; the final active α-Al 2 o 3 Micronized R-03.

[0044] Active α-Al in this example 2 o 3 Micronized D 50 =1.6μm, the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com