Kelp probiotic fermented feed and preparation method thereof

A technology of fermented feed and probiotics, applied in animal feed, animal feed, application, etc., can solve the problems of high labor cost and time cost, loss of nutrients, prolonging fermentation time, etc., to improve immunity, improve digestibility, The effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

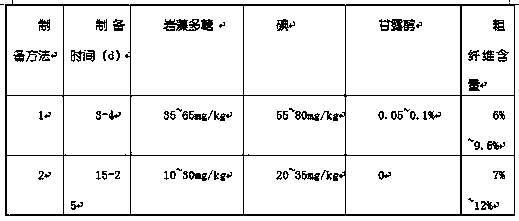

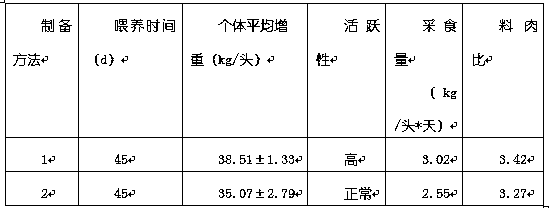

Embodiment 1

[0021] The preparation steps of a kind of kelp probiotic fermented feed are as follows:

[0022] 1) Break fresh kelp, add 3 times the mass of water, add 10% mass of alginate lyase, start stirring, control the stirring speed between 180r / min-220r / min, and control the temperature at 30-35°C , After 30min-60min, the viscosity of the feed liquid is significantly reduced. After continuing the enzymatic hydrolysis for 2~3h, the enzymatic hydrolysis is completed, and the enzymatic hydrolysis kelp liquid is obtained.

[0023] 2) Add fermentation auxiliary materials to the enzymatic kelp liquid obtained in step 1). 1 kg of enzymatic kelp liquid corresponds to 0.3 kg of soybean meal, 0.3 kg of bran, and 0.4 kg of corn bran. Adjust the water content of the system to 50%. Stir evenly with the fermentation auxiliary material to obtain the fermentation mixture.

[0024] 3) Autoclave the fermentation mixture at 121°C, add Bacillus subtilis, Bacillus licheniformis, yeast and lactic acid bact...

Embodiment 2

[0033] The preparation steps of a kind of kelp probiotic fermented feed are as follows:

[0034] 1) Crush fresh kelp, add 2 times the mass of water, add 8% mass of alginate lyase, start stirring, control the stirring speed between 180r / min-220r / min, and control the temperature at 30-35°C , After 30min-60min, the viscosity of the feed liquid is significantly reduced. After continuing the enzymatic hydrolysis for 2~3h, the enzymatic hydrolysis is completed, and the enzymatic hydrolysis kelp liquid is obtained.

[0035] 2) Add fermentation auxiliary materials to the enzymatic kelp liquid obtained in step 1). 1 kg of enzymatic kelp liquid corresponds to 0.25 kg of soybean meal, 0.4 kg of bran, and 0.35 kg of corn bran. Adjust the water content of the system to 40%. Stir evenly with the fermentation auxiliary material to obtain the fermentation mixture.

[0036] 3) Autoclave the fermentation mixture at 121°C, add Bacillus subtilis, Bacillus licheniformis, yeast and lactic acid bac...

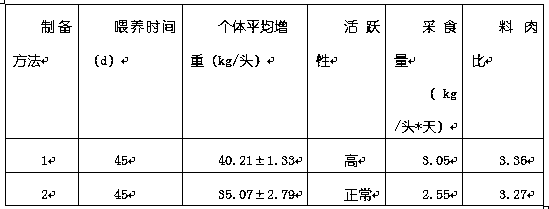

Embodiment 3

[0045] The preparation steps of a kind of kelp probiotic fermented feed are as follows:

[0046] 1) Break fresh kelp, add 4 times the mass of water, add 12% mass of alginate lyase, start stirring, control the stirring speed between 180r / min-220r / min, and control the temperature at 30-35°C , After 30min-60min, the viscosity of the feed liquid is significantly reduced. After continuing the enzymatic hydrolysis for 2~3h, the enzymatic hydrolysis is completed, and the enzymatic hydrolysis kelp liquid is obtained.

[0047] 2) Add fermentation auxiliary materials to the enzymatic kelp liquid obtained in step 1). 1 kg of enzymatic kelp liquid corresponds to 0.4 kg of soybean meal, 0.25 kg of bran, and 0.35 kg of corn bran. Adjust the water content of the system to 45%. Stir evenly with the fermentation auxiliary material to obtain the fermentation mixture.

[0048] 3) Autoclave the fermentation mixture at 121°C, add Bacillus subtilis, Bacillus licheniformis, yeast and lactic acid ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com