Dust-removal carbon drying device

A drying device and carbon black technology, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of poor drying effect of carbon black and difficulty in dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

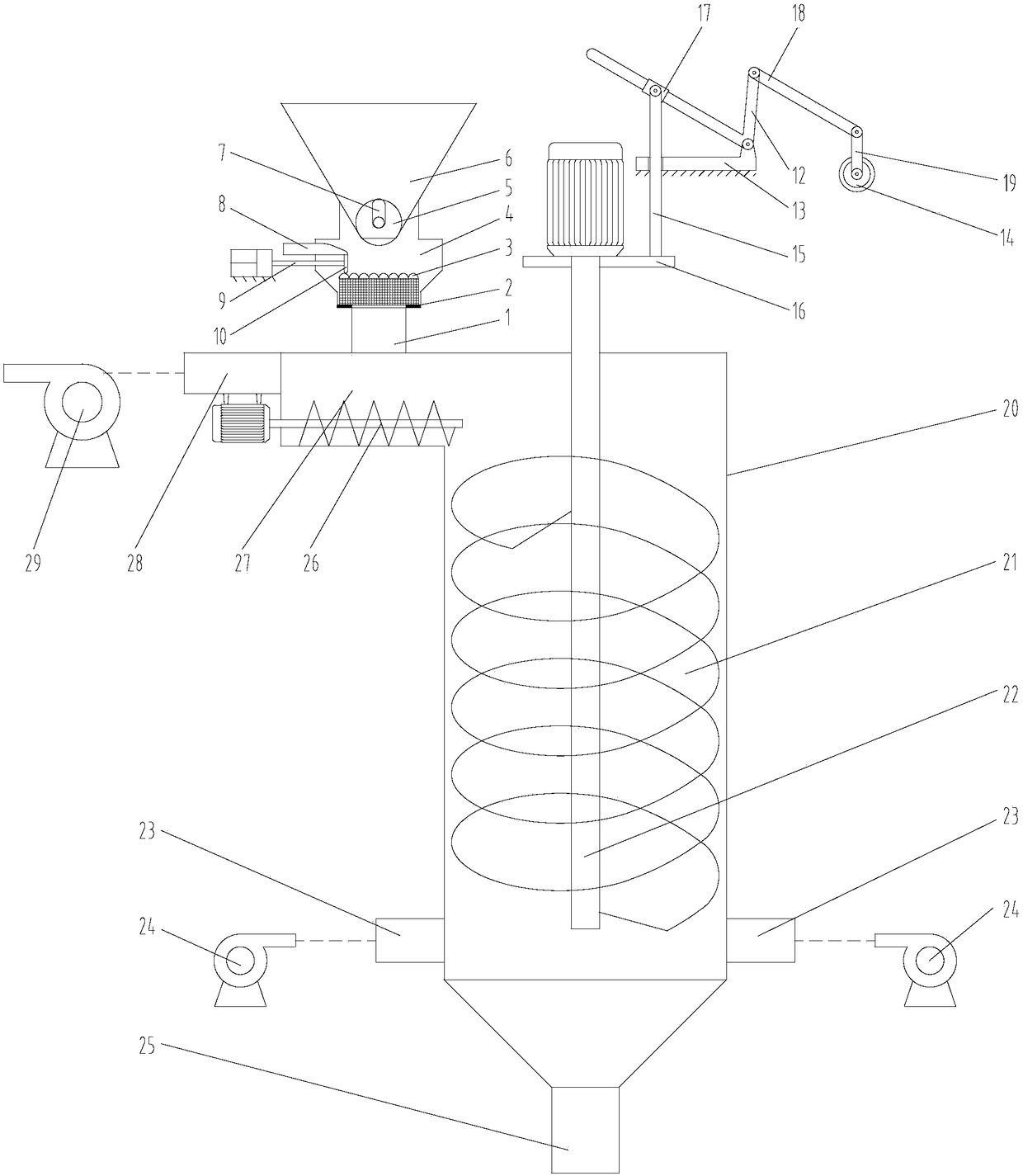

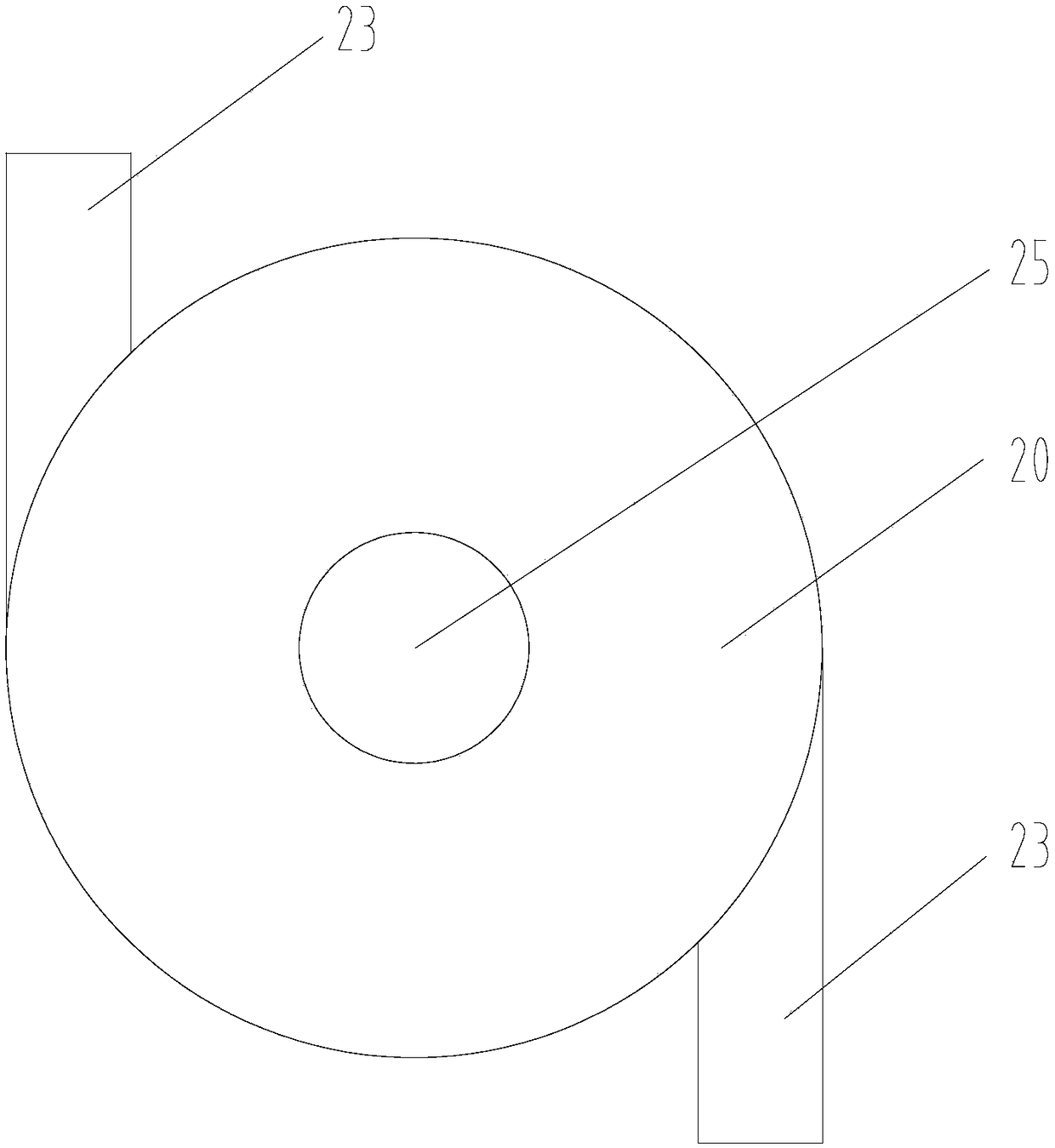

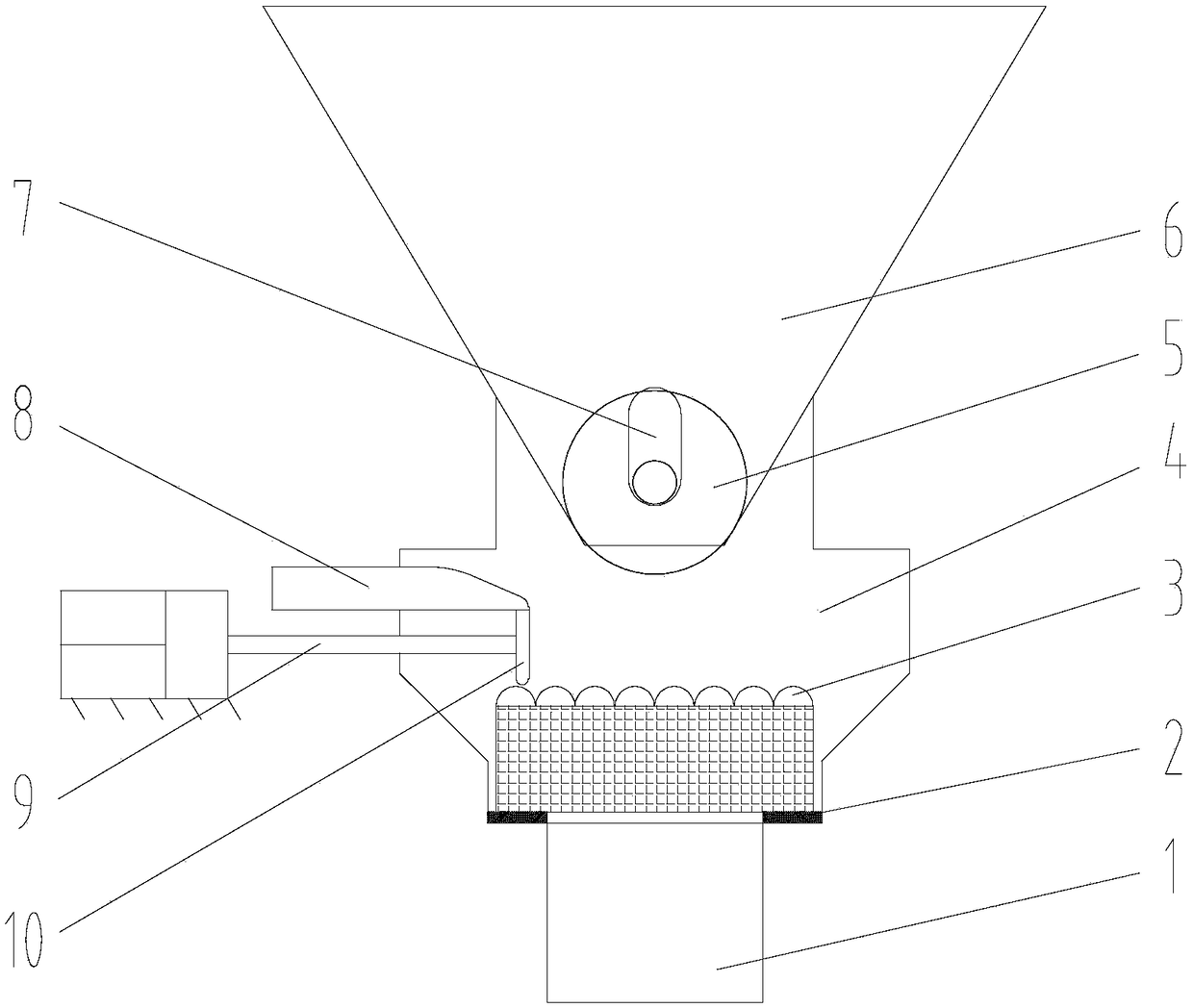

[0037] Such as figure 1 , figure 2 As shown, the present invention provides a dedusting carbon black drying device, including a vertical cylinder 20, the top of the cylinder 20 is closed; the upper part of the cylinder 20 is connected with a feed port 27, the free end of the feed port 27 An exhaust port 28 is connected; the upper part of the feed port 27 is connected with a feed assembly; the cylinder 20 is coaxially pierced with a rotating shaft 22, the upper end of the rotating shaft 22 extends out of the cylinder 20, and is configured to drive it A rotating drive device; a spiral plate 21 is fixed on the outer circumference of the rotating shaft 22, and the outer edge of the spiral plate 21 is matched with the inner wall of the cylinder 20; the plate surface of the spiral plate 21 is evenly provided with a plurality of vent holes The upper part of the cylinder 20 is provided with a lifting shaft 22 and a lifting assembly of the driving device; the lower section of the cylind...

Embodiment 2

[0051] Such as Figure 1-Figure 5 As shown, the present invention provides a dedusting carbon black drying device, including a vertical cylinder 20, the top of the cylinder 20 is closed; the upper part of the cylinder 20 is connected with a feed port 27, the free end of the feed port 27 An exhaust port 28 is connected; the upper part of the feed port 27 is connected with a feed assembly; the cylinder 20 is coaxially pierced with a rotating shaft 22, the upper end of the rotating shaft 22 extends out of the cylinder 20, and is configured to drive it Rotating driving equipment; a spiral plate 21 is fixed on the outer circumference of the rotating shaft 22, and the outer edge of the spiral plate 21 is matched with the inner wall of the cylinder 20; the plate surface of the spiral plate 21 is evenly provided with a plurality of ventilation holes The upper part of the barrel 20 is provided with a lifting shaft 22 and a lifting assembly of the driving device; the lower section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com