Process for preparing biomass granular fuel and granulating machine used in the process

A technology of biomass pellets and pelletizers, which is applied to biofuels, waste fuels, and presses for material molding. It can solve the problems of high energy consumption, high production costs, and low work efficiency, so as to improve work efficiency and reduce Energy consumption and the effect of saving the cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

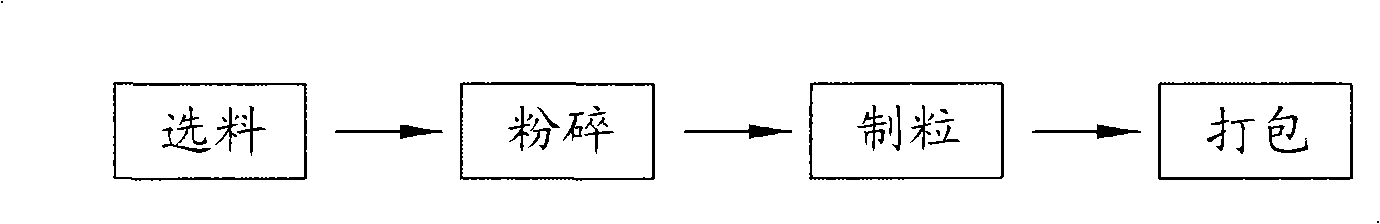

[0020] like figure 1 As shown, the preparation process of a kind of biomass particle fuel of the present invention, first adopts crop stalks, agricultural and forestry wastes as raw materials, feeds raw materials into pulverizer and pulverizes, and makes raw material particle size be 4~5mm, sends pulverized raw materials to into the feed port of the biomass pellet fuel granulator for compression molding, and the compressed pellet fuel is directly sent to the baler for packaging.

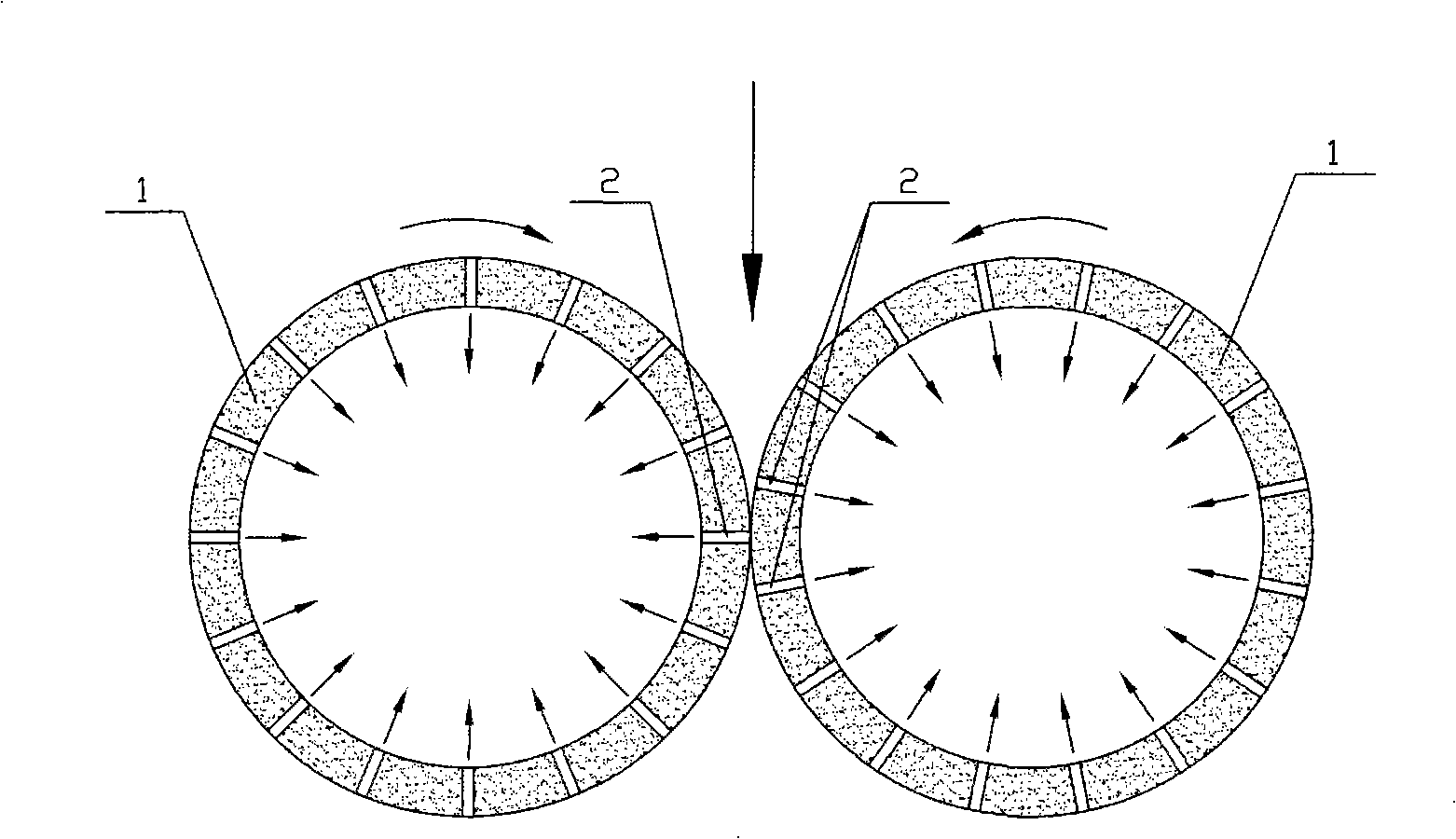

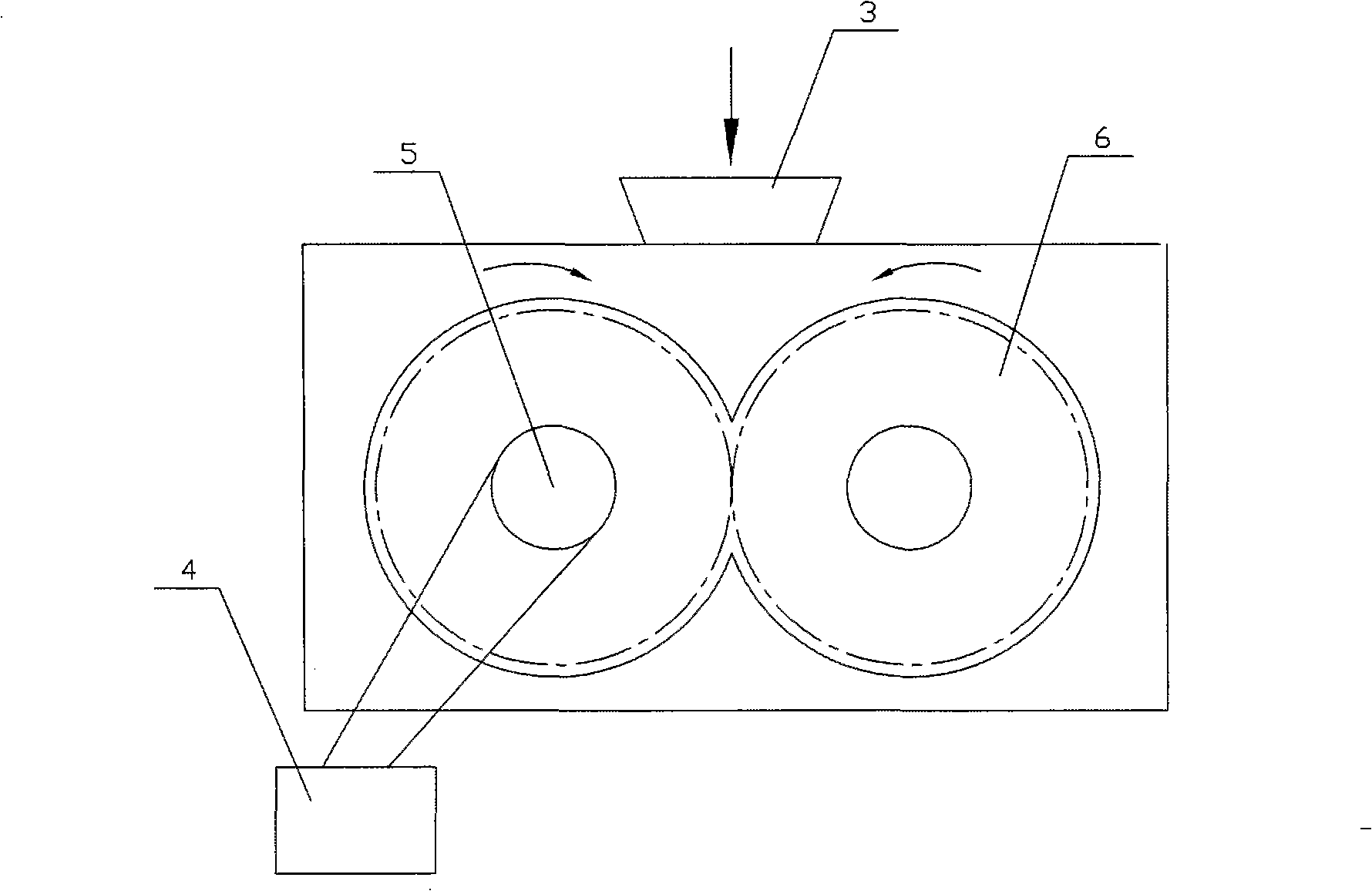

[0021] like figure 2 and image 3 As shown, it is a pelletizer for biomass pellet fuel in the present invention, including a feed port 3 and two ring dies 1, the two ring dies 1 are circumscribed cylinders and rotate in opposite directions, and the feed port 3 is located in the two ring dies 1 directly above the tangent point, each ring die 1 is evenly distributed with a number of pressing through holes 2, and the pressing through holes 2 on the same vertical section are all facing the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com