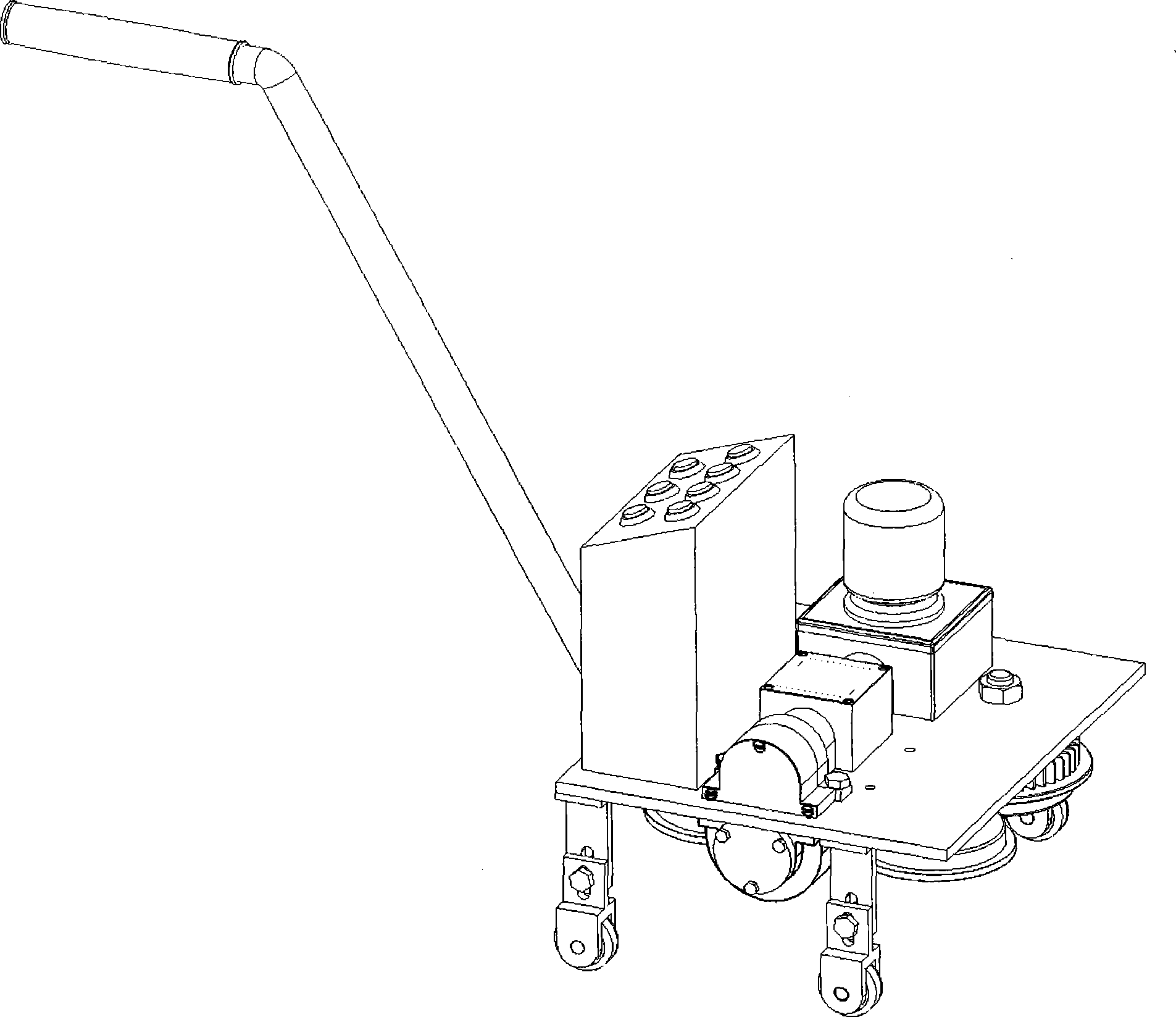

Full-automatic edge locking machine for encaustic tiles

A fully automatic and seaming machine technology, which is applied to tools used in roofing engineering, roofing, construction, etc., can solve problems such as low work efficiency, poor seaming quality, and high labor intensity, and achieve high work efficiency and high seaming quality Good, low labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

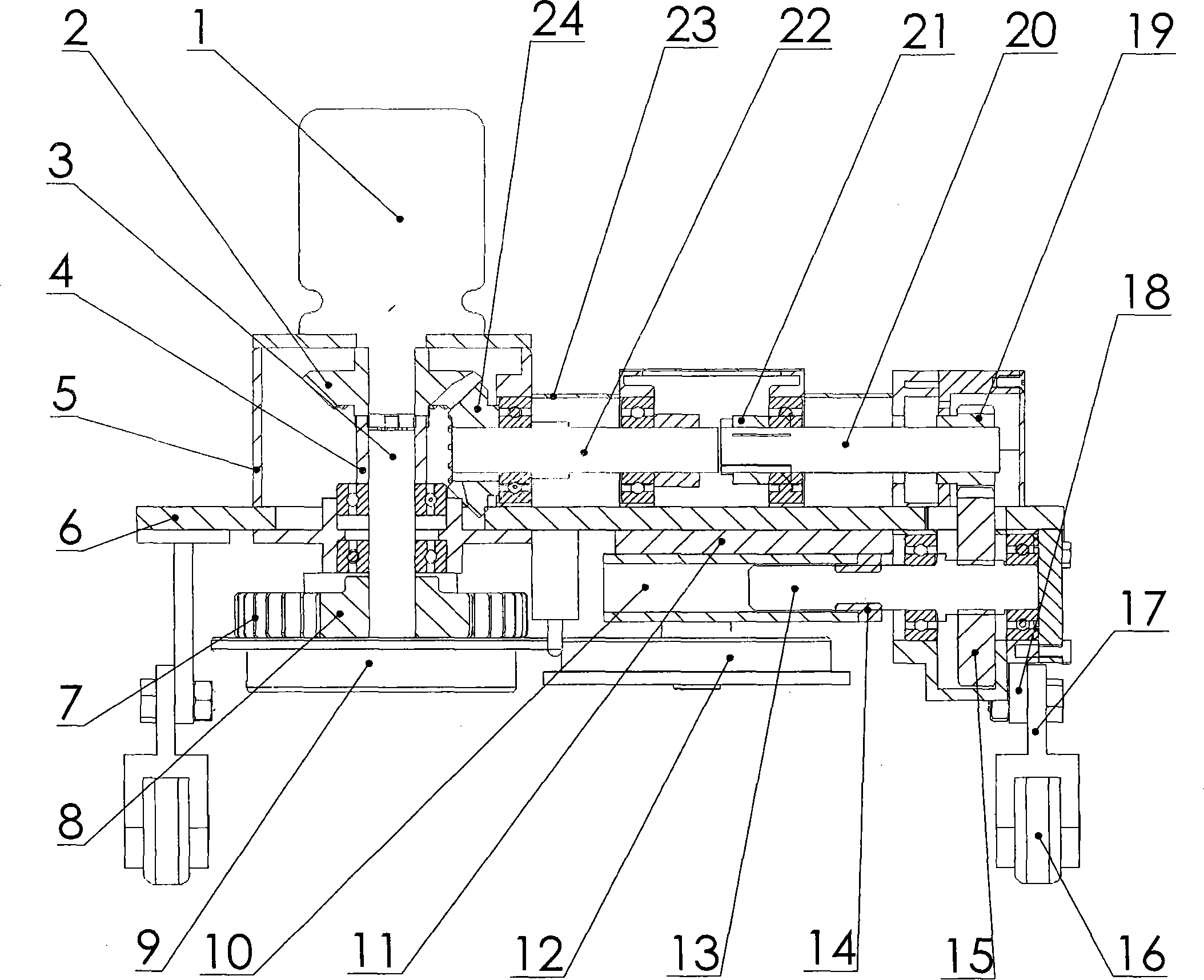

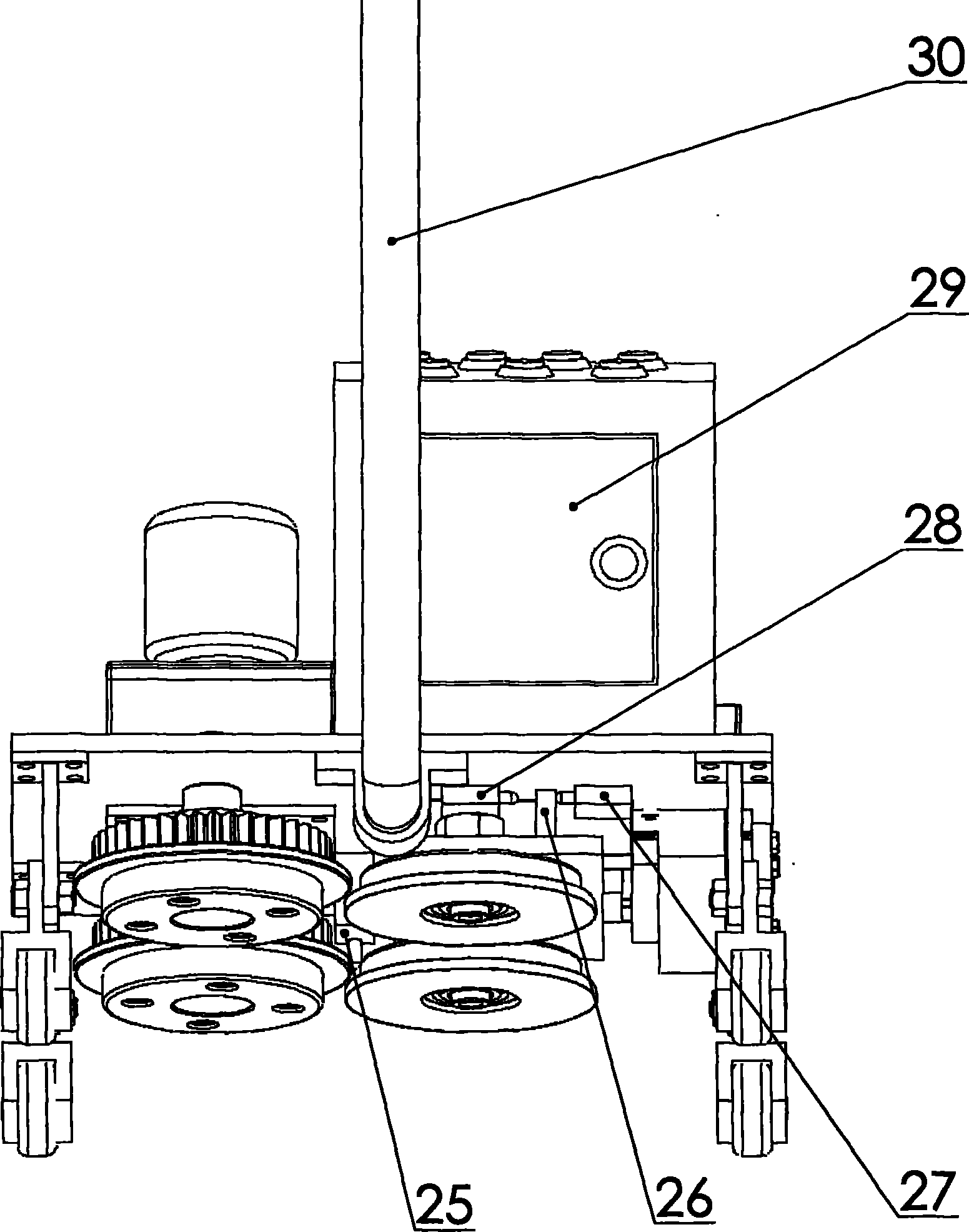

[0014] refer to figure 2 , image 3 : The main body plate 6 is arranged horizontally, with a square hole in the middle, a plug-in speed box 5 is fixed above the square hole, the motor 1 is fixed above the center of the plug-in speed box 5, a bevel gear 1 is installed on the motor 1 shaft, and the transmission shaft 3 is installed on the main body board In the square hole of 6, the electromagnetic clutch-4 is installed in the middle of the transmission shaft 3 and the bevel gear-2, the other end of the transmission shaft 3 is equipped with a pinion 8, and the mandrels of the two large gears 7 are fixed on the main body plate 6, and the two Two large gears 7 mesh with pinion 8 at the same time, and the bottom of two large gears 7 is equipped with active seaming forming wheel 9, and coaxial with large gear 7; Shaft one 22 is horizontally arranged, and one end is equipped with bevel gear two 24, Bevel gear 2 24 meshes with bevel gear 1 2, shaft 2 20 is also arranged horizontally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com