A roll-pressed colored tile forming equipment

A technology of molding equipment and colored tiles, which is applied to ceramic molding machines, pressure rollers, supply devices, etc., can solve the problems of non-continuous work of colored tile machines, lack of motivation, and low tile production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

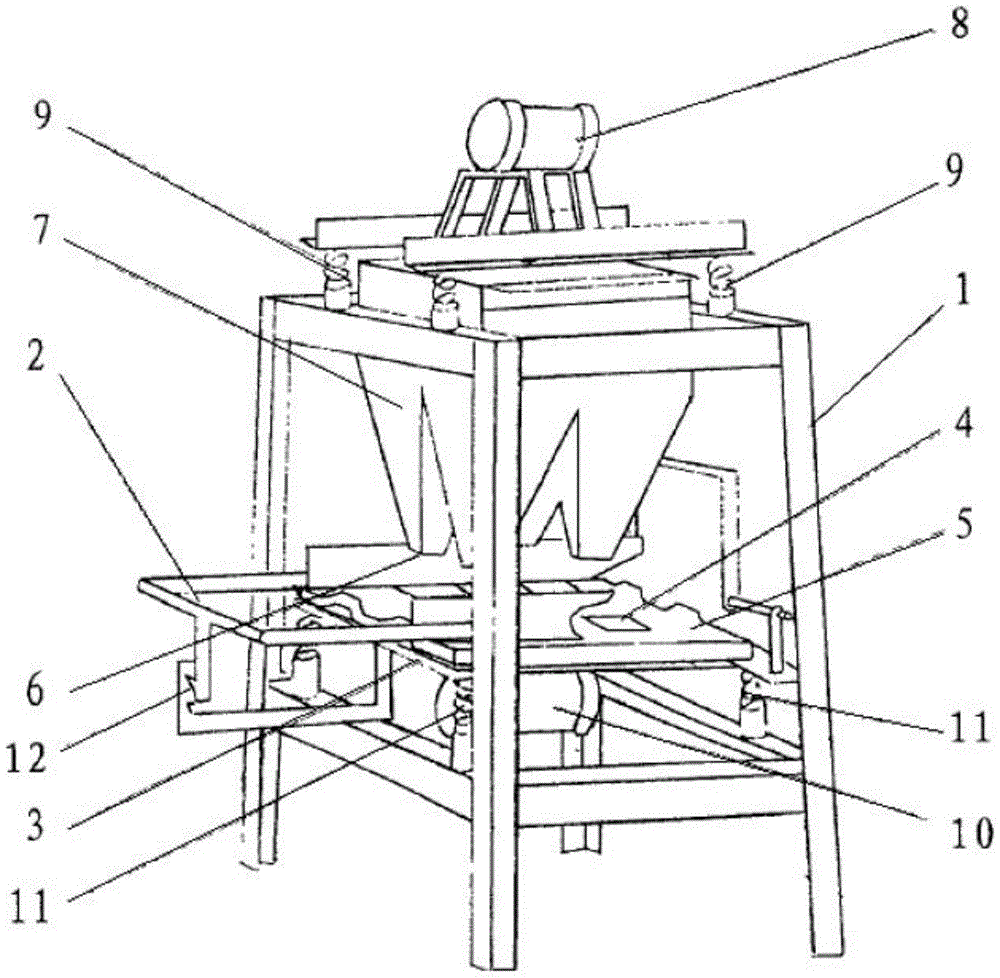

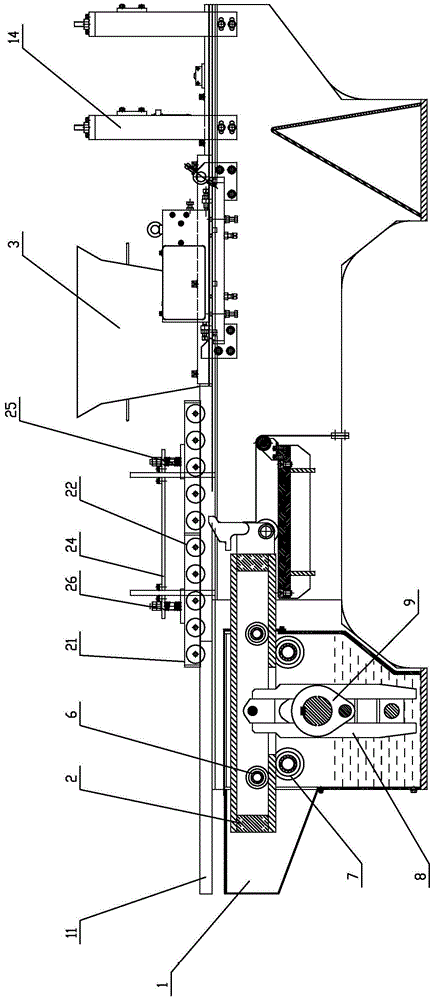

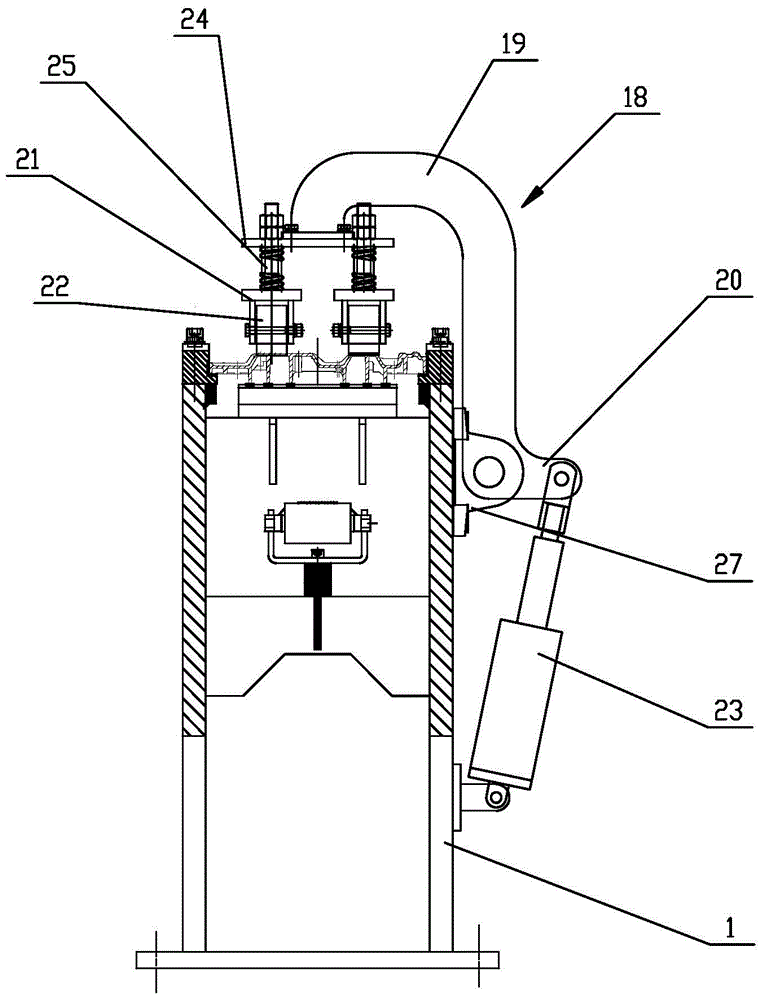

[0024] Such as Figure 3 to Figure 5 As shown, the present invention includes two racks 1 arranged in parallel, tile mold guide rails 11 are arranged on the top of the racks 1, and the shortest distance between the tile mold guide rails 11 on the top of the two parallel racks 1 is not less than the width of the tile mold. The tile mold guide rail 11 is used to limit the tile mold to move left and right.

[0025] A pair of driving swing arms 8 is fixedly arranged on the ram 2, and grooves are arranged on opposite sides of the pair of driving swing arms 8, and an eccentric wheel 9 is arranged in the groove, and the eccentric wheel 9 is fixedly connected with the shaft, and the shaft is installed on the shaft through a bearing. On the frame 1, the motor is connected to the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com