Environmental protection water encaustic tile coating and preparing method thereof

A kind of color tile coating, environmental protection technology, applied in the direction of coating, can solve the problems of wasting resources, high cost, polluting the environment, etc., and achieve the effect of collective health and benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

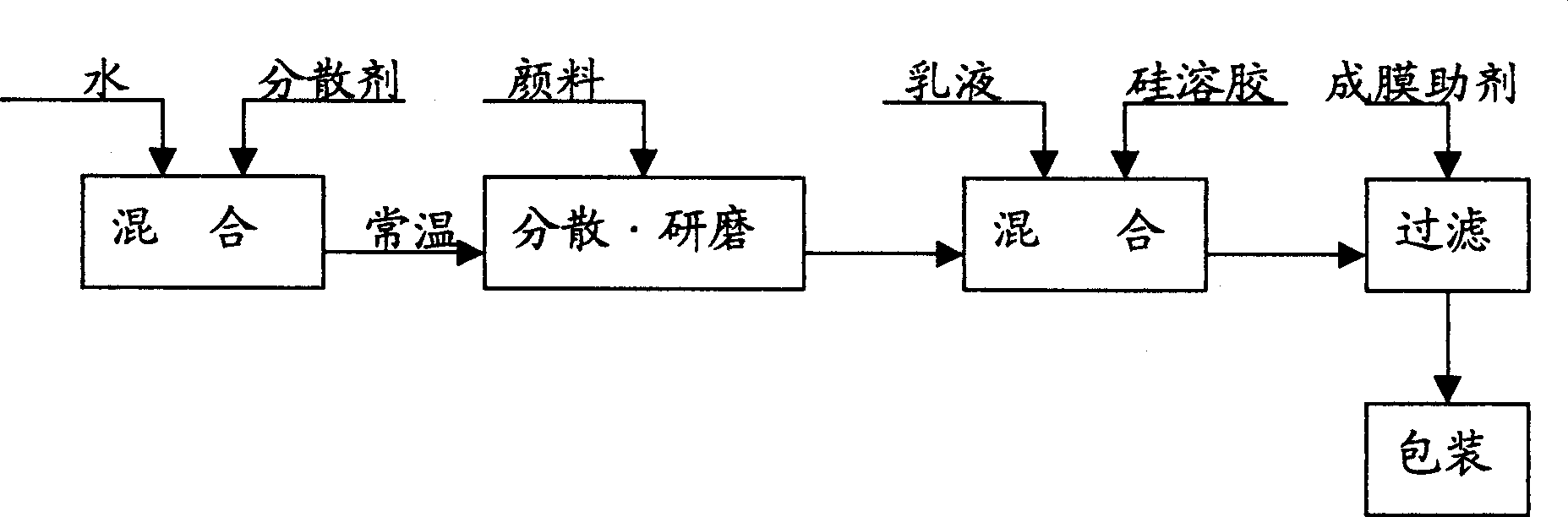

Method used

Image

Examples

Embodiment 1

[0026] 25.8 parts of water, 0.3 parts of sodium hexametaphosphate as dispersant, 0.18 parts of foam control agent 681F, 0.1 part of wetting agent OP-10, 12 parts of iron red pigment (organic or inorganic pigment), high-speed dispersion (1500 rpm) 20 minutes, after grinding, add 50 parts of styrene-acrylic emulsion (styrene / acrylate copolymer emulsion), slowly add 10 parts of silica sol, 1.5 parts of film-forming aid lauryl alcohol ester, 0.12 parts of fungicide YN-187, mix slowly (60 rpm) 20 minutes. Finally, the filter bag is the finished product.

Embodiment 2

[0028] 15.8 parts of water, 0.5 parts of dispersant 5040, 0.18 parts of foam control agent 681F, 4 parts of 3132 red paste, 9 parts of iron red, after high-speed dispersion, add 55-60 parts of styrene-acrylic emulsion after grinding, slowly add 8 parts of silica sol , 0.5 parts of propylene glycol (or ethylene glycol) as film-forming aid, 1.8 parts of lauryl alcohol ester as film-forming aid, 0.1 part of defoamer D309A, 0.12 part of bactericide, mixed at a slow speed, filtered and packaged is the finished product.

Embodiment 3

[0030] 31.63 parts of water, 0.2 parts of sodium hexametaphosphate dispersant, 0.2 parts of foam control agent, 12 parts of iron red, after high-speed dispersion and grinding, add 48 parts of pure acrylic emulsion (acrylate polymer emulsion), slowly add 6 parts of silica sol, 1.7 parts of film-forming aid lauryl alcohol ester, 0.12 parts of fungicide, slow mixing and filtration packaging is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com