Gold ore tailing sand concrete encaustic tile and manufacturing technique

A technology of gold mine tailings and production technology, which is applied to roofs, roof coverings, and buildings using tiles/slate tiles. It can solve the problems of tailings slag polluting the environment, achieve good decorative effects, smooth tile surfaces, and solve long-term problems. The effect of accumulating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

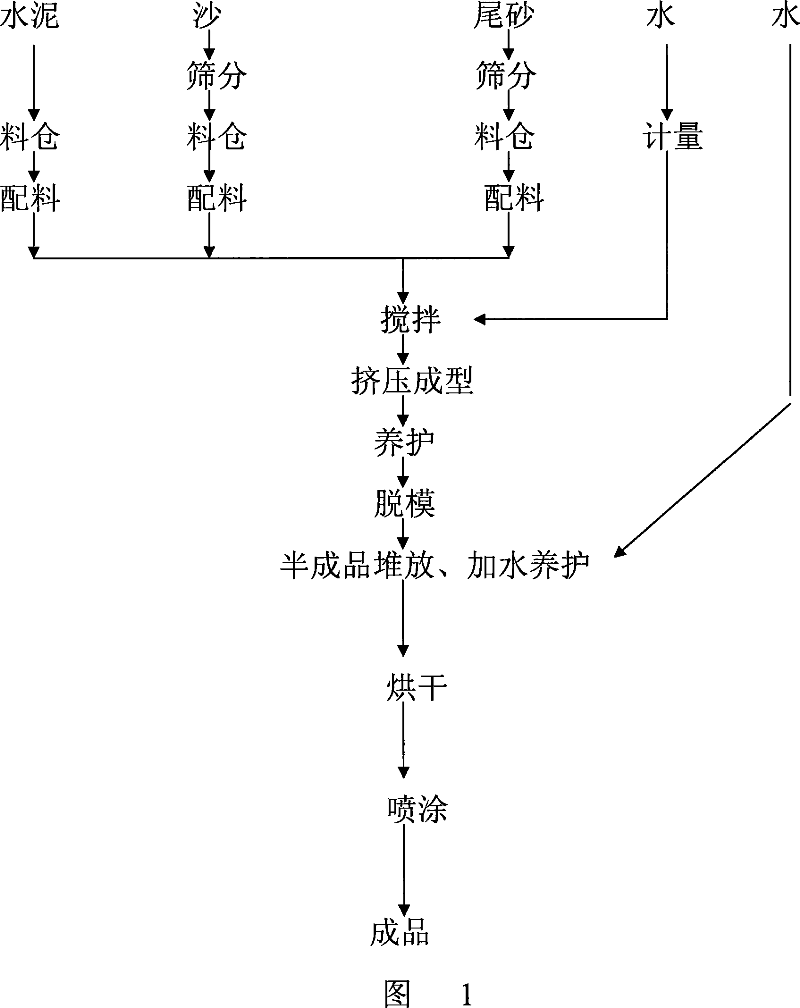

[0023] Referring to Figure 1, the production process of gold mine tailings concrete colored tiles adopts a fully automatic cement tile filter press molding machine and its production line, which completely changes the shortcomings of roughness and poor compactness of tiles produced by traditional extrusion or rolling production lines. , the new process adopts the method of 120 tons of high-pressure molding, using gold tailings as aggregate, cement, sand and other plastic concrete as raw materials, using a special mold, after drainage and filtration, automatic demoulding, natural maintenance, automatic spraying And other processes to make it shape.

[0024] The raw materials for the production of cement tiles must use a wheel-type quantitative forced mixer, equipped with a mixer with a capacity of 350 liters, a motor power of 4KW, and a mixing time of 5-10 minutes to make the materials evenly mixed and the concrete to achieve good workability.

[0025] Raw material ratio:

[0...

Embodiment 2

[0047] The difference from Example 1 is that the ratio of raw materials for gold ore tailings concrete colored tiles is

[0048] Cement 40%, gold mine tailings 40%, yellow sand 20%, plasticizer rock sand crystal quality is one thousandth of the material gold mine tailings, cement, sand, fiber quality is the material gold mine tailings, cement, Five thousandths of the sand, the cement-bone ratio (cement: aggregate) is 1:1.5, and the water-cement ratio (water:material) is 1:0.25.

Embodiment 3

[0050] The difference from Example 1 is that the ratio of raw materials for gold ore tailings concrete colored tiles is

[0051] Cement 30%, gold mine tailings 55%, yellow sand 15%, plasticizer rock sand crystal quality is 6 / 1000 of materials gold mine tailings, cement, sand, fiber quality is materials gold mine tailings, cement, Ten thousandths of the sand, the cement-to-bone ratio (cement: aggregate) is 1:2.0, and the water-cement ratio (water:material) is 1:0.35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com