Colored tile compression molding device

A technology of pressing and molding and color tile, which is applied in the field of color tile pressing and molding device, can solve the problems of burrs, burrs, and unstable pressing effect on tile embryos, and achieve the effect of improving efficiency and quality, avoiding deformity and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

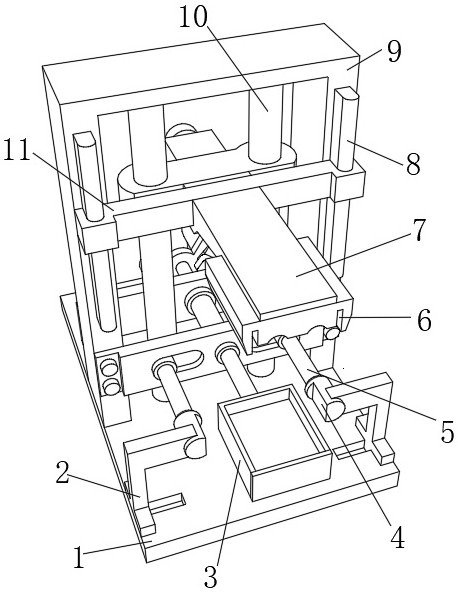

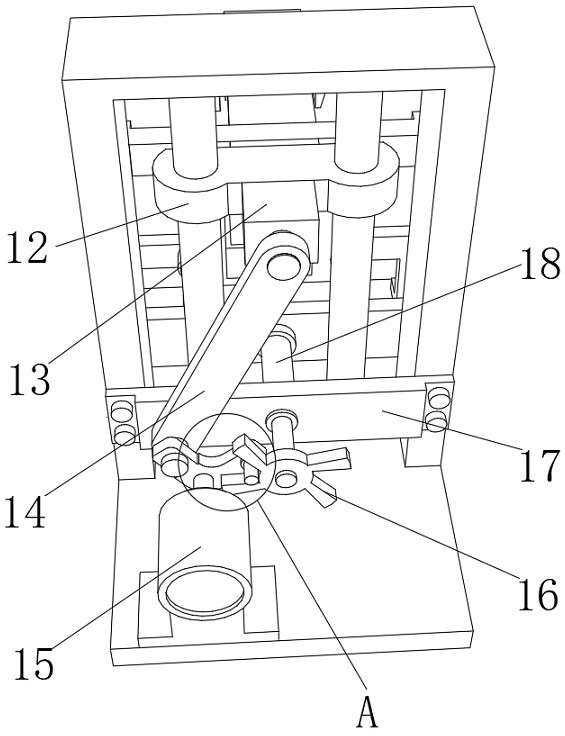

[0030] Color tile press molding device, such as Figure 1-5 As shown, it includes a base 1, the top middle outer wall of the base 1 is fixed with a bracket 9 by bolts, and the top outer wall of the bracket 9 is screwed with two sliding posts 10, and the peripheral outer walls of the two sliding posts 10 are slidably connected with sliding Block 12, the front and back bottom outer walls of support 9 are respectively fixed with mounting plate 17 by bolts, and one side outer wall of slide block 12 is provided with intermittent rotation elevating mechanism, and one end of intermittent rotation elevating mechanism is provided with rotating rod 18, and rotating rod 18 runs through the two mounting plates 17, and the end of the rotating rod 18 is threadedly connected to the forming seat 3, the forming seat 3 is provided with a partition plate 22, and the other side outer wall of the slider 12 is fixed with a fixing plate 7 by bolts, And the bottom outer wall of the fixed plate 7 is f...

Embodiment 2

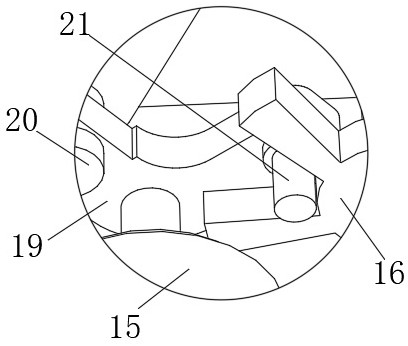

[0037] Color tile press molding device, such as Figure 5 As shown, the inner wall of one side of the forming seat 3 has a receiving groove, and one side of the partition plate 22 is welded with a telescopic block, and a spring 24 is arranged in the telescopic block, and the two ends of the spring 24 are respectively welded with a clamping block 23 , the clamping block 23 is adapted to the receiving groove, and one side of the partition plate 22 is provided with an insertion groove, and a sealing plate is inserted in the insertion groove.

[0038] Through the cooperation of the spring 24 and the clamping block 23, the partition plate 22 can be effectively installed in the receiving groove inside the forming seat 3, thereby ensuring the loading and unloading and replacement of the partition plate 22, and at the same time, by clamping the sealing plate In the insertion groove, the sealing effect of the forming seat 3 in the pressing and forming process is guaranteed, and the saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com