Lightweight encaustic tiles in high strength

A light-weight, colorful tile technology, applied to tile/slate tile roofs, roof coverings, ceramic molding machines, etc., can solve the impact on use and promotion, manufacturing cost and strength are not ideal, moisture absorption and brine resistance sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

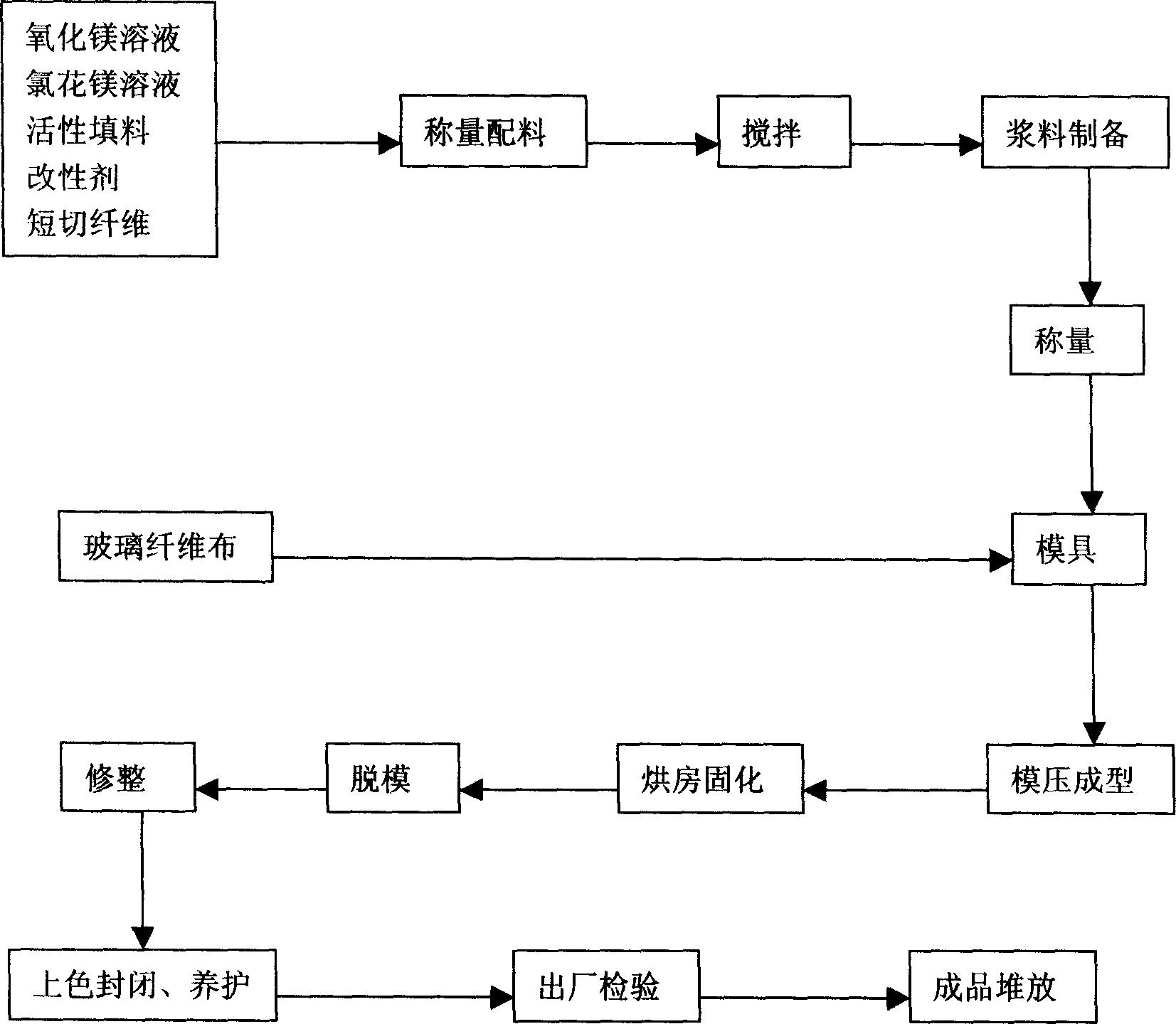

Method used

Image

Examples

Embodiment Construction

[0006] The base material is selected using reduced MgO-MgCl 2 -H 2 O system, that is, magnesium oxychloride cement (inorganic glass fiber reinforced plastic) composite components. The system introduces MgO from lightly burned powder, and introduces MgCl from refined halogen flakes. 2 , H 2 O is well water without CI. When the concentration of the halogen sheet solution is constant (25-30°Be), and the MgO content in the lightly burned powder is 85-90%, the ratio (Wet) of the lightly burned powder to the brine is in the range of 0.8-1.4, and the crystal phase structure 5Mg(OH 2 ).MgCl.8H 2 O (abbreviated as 5.1.8 crystal phase), high-strength magnesium composites are expected to be obtained. Add organic admixtures such as PAV modified urea-formaldehyde resin, polyacrylic acid liquid, etc. to the ingredients to block capillary channels and prevent the seepage of MgCI and the infiltration of external moisture. In addition, active filler substances, such as fly ash, diatomac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com