System for automatically and quickly distributing drilling liquid

An automatic control system and drilling fluid technology, applied in mixer accessories, dissolving, mixing machines, etc., can solve problems such as not being able to meet the requirements of the slurry mixing process, and achieve the effects of easy moisture agglomeration, reducing labor intensity, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

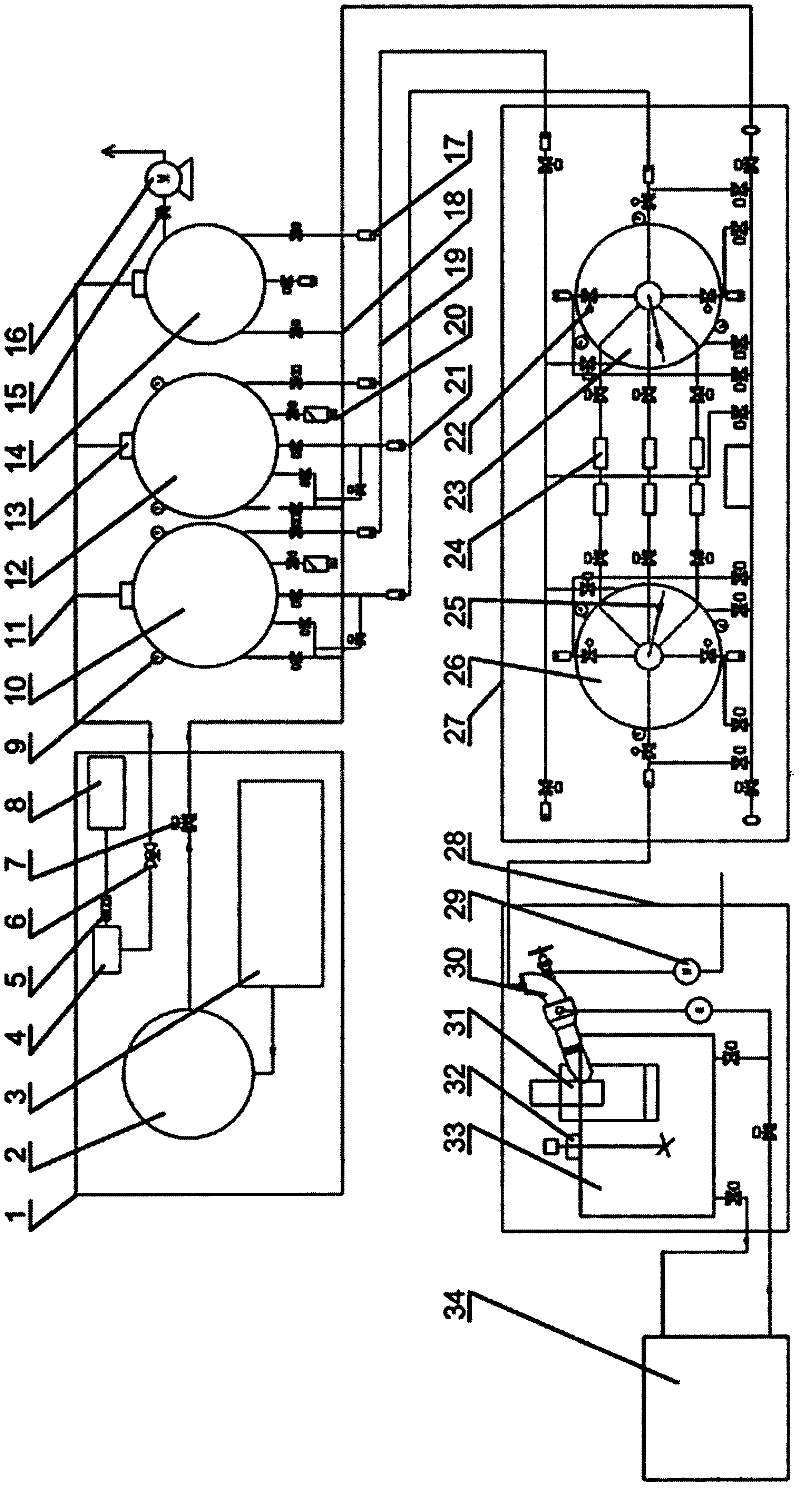

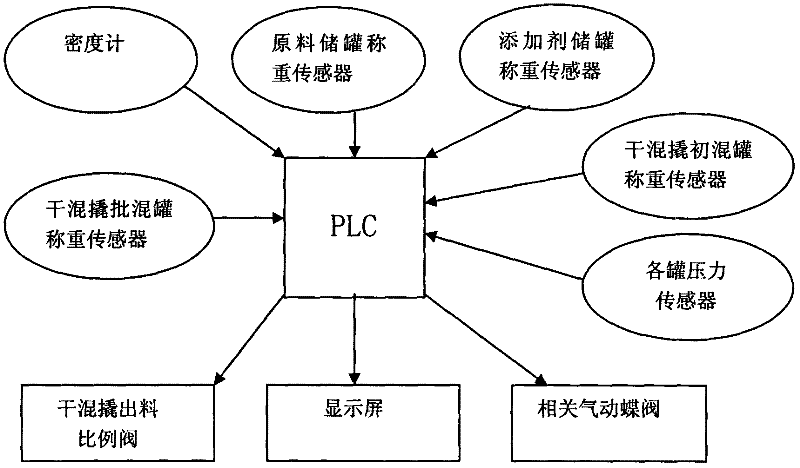

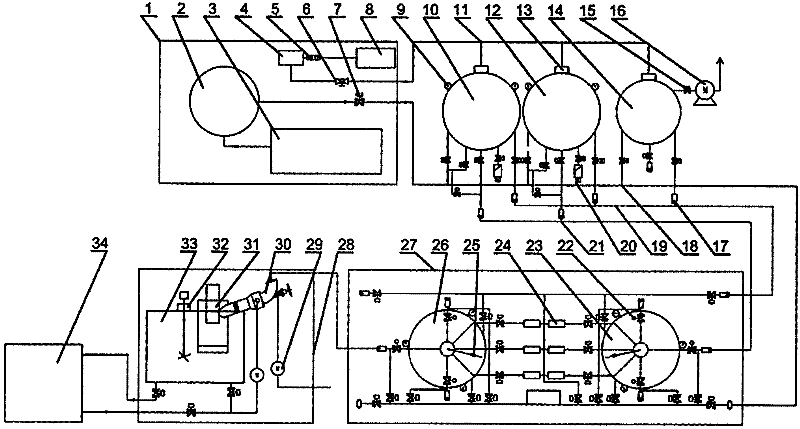

[0017] The present invention includes a programmable PLC automatic control system, an air source system, a storage system, a dry mixing system and a slurry mixing system, and is characterized in that the air source system includes air storage tanks 2 evenly distributed on the blower skid 1, a large air compressor machine 3, dry cooler 4, small air compressor 8 and gas supply pipeline; the storage system includes raw material storage tank 10, additive storage tank 12, dust removal tank 14, which are arranged at the bottom of raw material storage tank and additive storage tank The weighing sensor, the raw material gas pipeline and the dust removal pipeline; the dry mixing system includes the initial mixing tank 23 uniformly distributed on the dry mixing skid, the batch mixing tank 26, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com