Uniform mixing equipment for biomass processing

A biomass and mixing technology, which is applied in the direction of mixers, chemical/physical processes, mixers with rotating containers, etc., can solve the problems of long time and slow mixing speed, and achieve high work efficiency and fast mixing speed , full effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

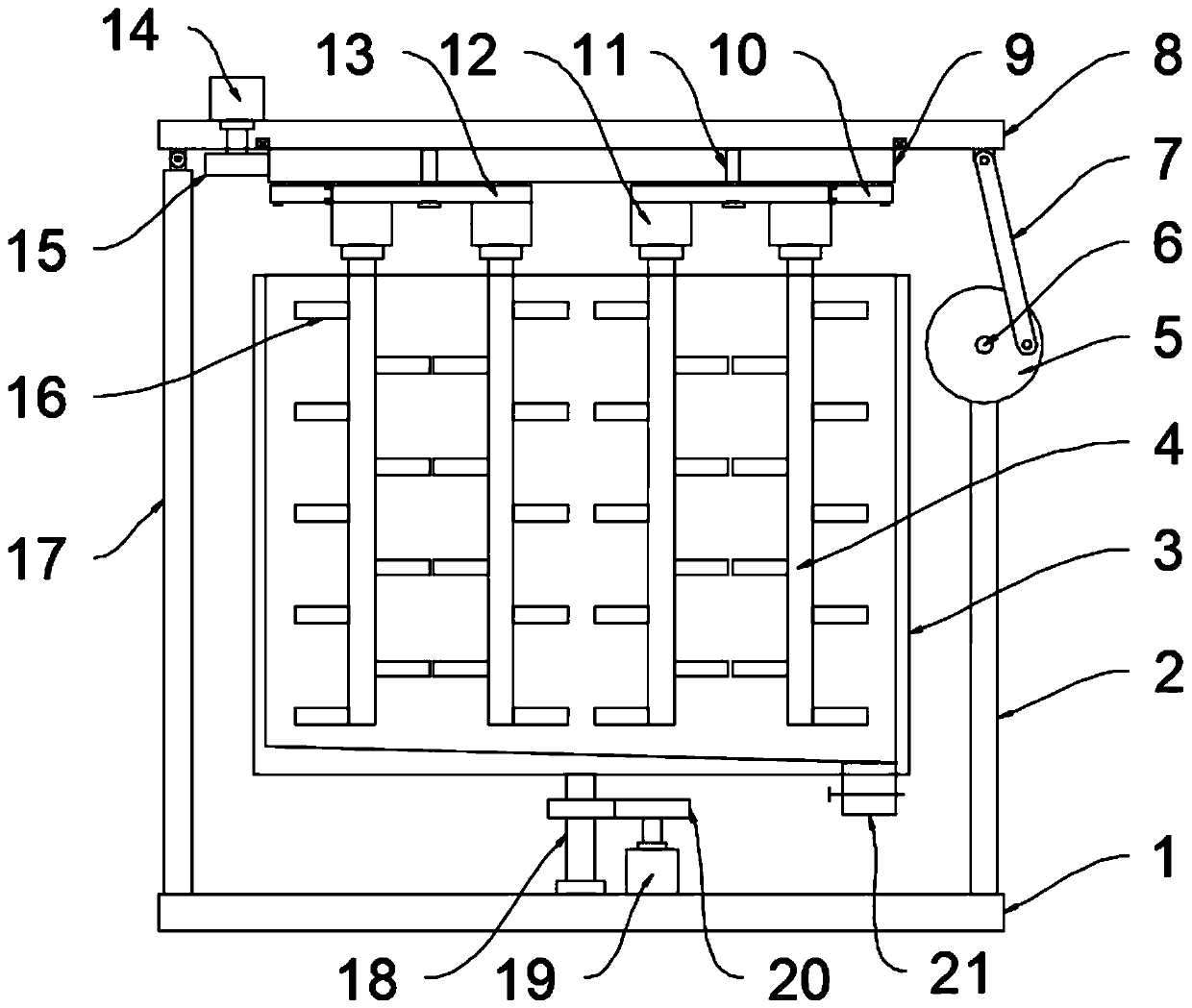

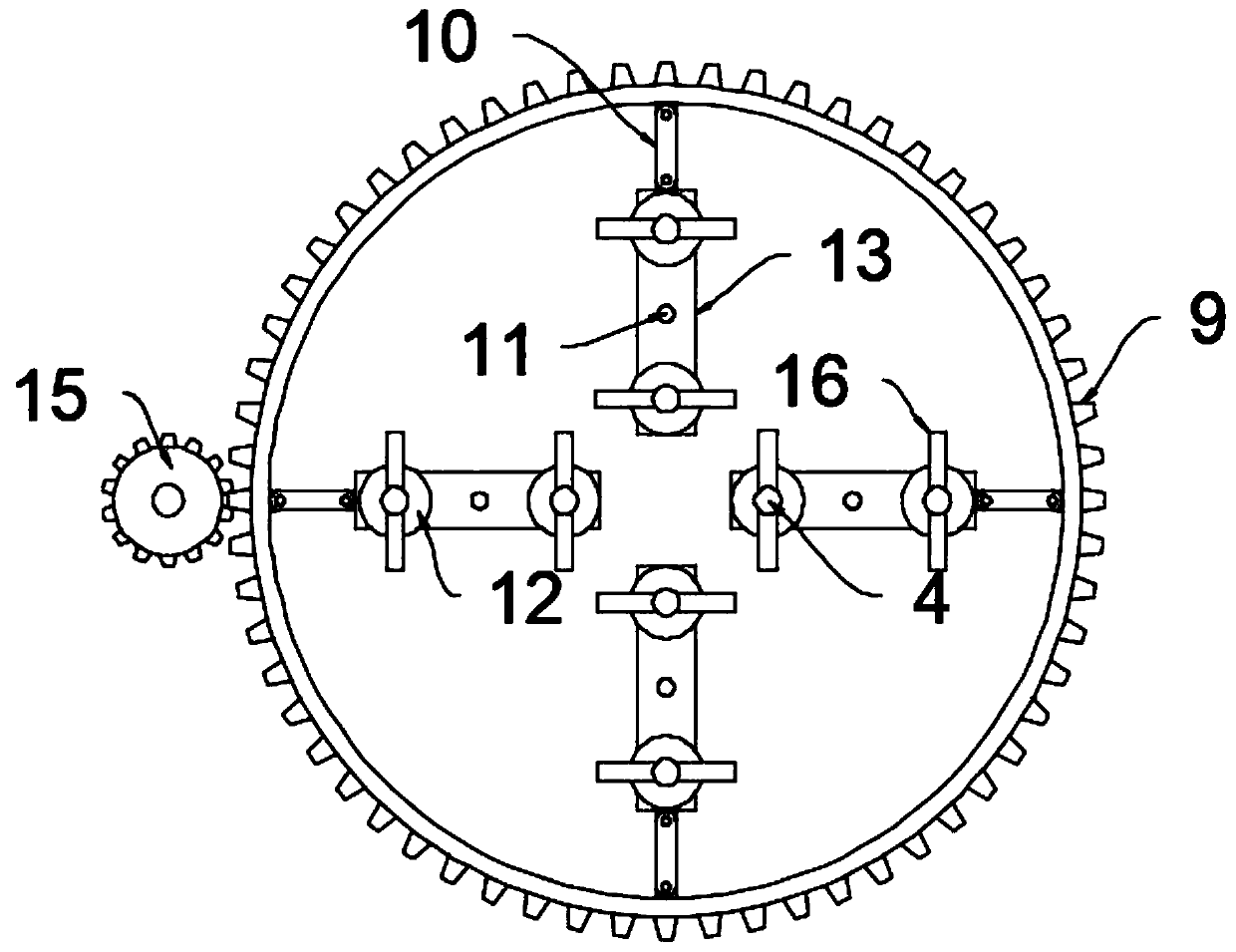

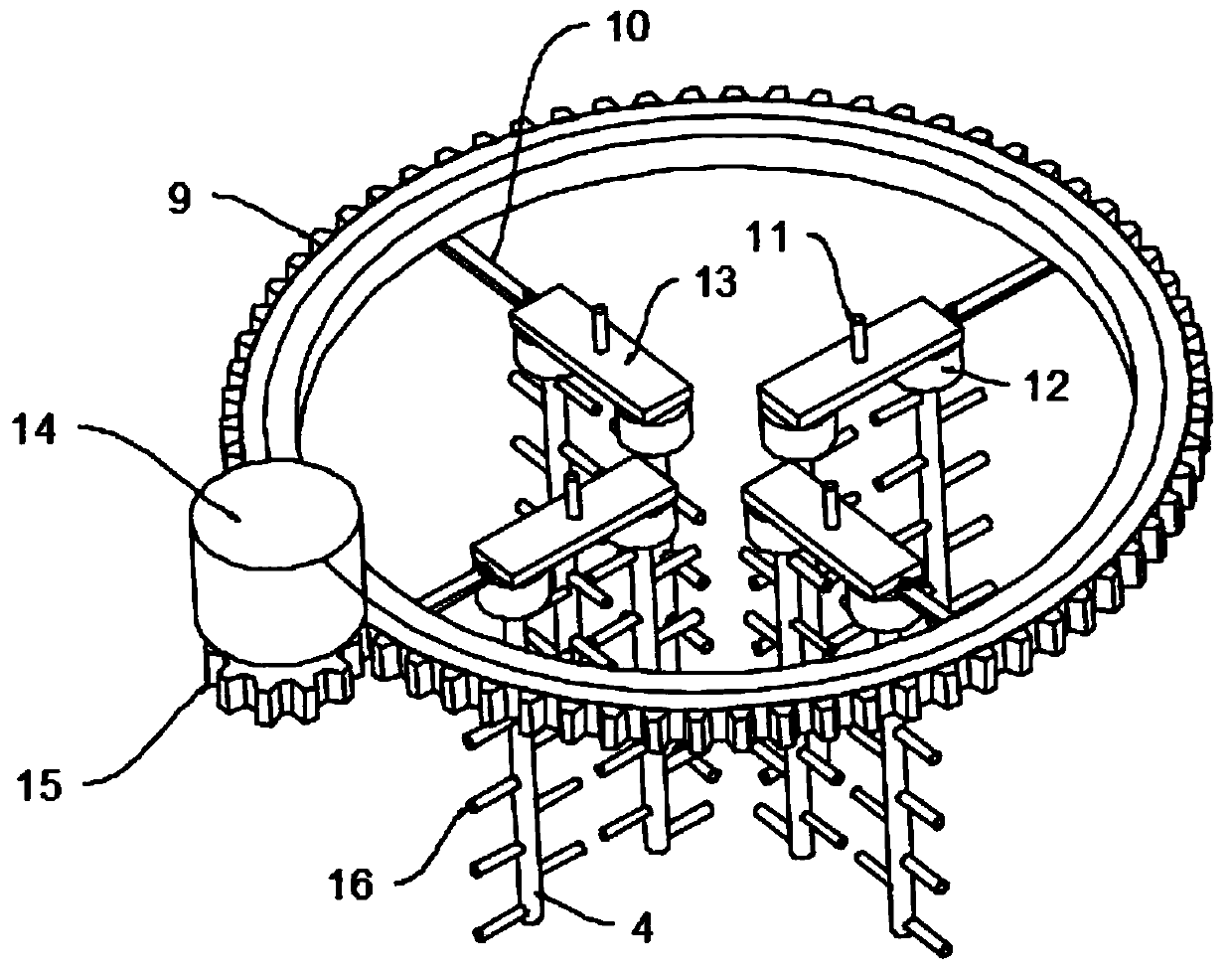

[0027] see Figure 1~3 , in an embodiment of the present invention, a kind of mixing equipment for biomass processing, comprising a bottom plate 1, a holding frame 3, a mounting plate 8 and a stirring unit, a holding frame 3 is installed above the bottom plate 1, the top of the holding frame 3 is open, and the holding One side of the bottom of the frame 3 is provided with a discharge port 21, and a valve is installed on the discharge port 21. In this embodiment, the bottom of the inner cavity of the containing frame 3 is inclined to the side close to the discharge port 21, which is convenient for discharging and dressing. A mounting plate 8 connected to the bottom plate 1 through a connecting mechanism is installed above the frame 3, and a stirring unit for stirring the biomass raw materials in the containing frame 3 is installed on the mounting plate 8. In this embodiment, the containing frame 3 is rotated and installed On the bottom plate 1, a mounting column 18 is fixed on ...

Embodiment 2

[0030] see Figure 4The difference between this embodiment of the present invention and Embodiment 1 is that, in order to ensure the stability of the container frame 3 when it rotates, a plurality of support legs 22 are fixed at the bottom of the container frame 3, and the support legs 22 are slidably connected to the upper part of the bottom plate 1, In this embodiment, the upper part of the bottom plate 1 is provided with an annular sliding groove for supporting the sliding of the legs 22 .

[0031] The working principle of the present invention is: when working, the biomass raw material is added from the top of the dress frame 3, and then the third motor 19 is started, and the third motor 19 drives the installation column 18 to rotate through the gear pair 20, and the installation column 18 drives the dress frame 3 to rotate, The containing frame 3 drives the biomass raw material inside to rotate, and cooperates with the stirring unit to fully stir and mix the biomass raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com