Heating and uniform mixing device for production of circulation promotion and hair growth shampoo

A shampoo and mixing technology, which is applied in the field of shampoo, can solve the problems of poor heating effect of shampoo, inability to uniformly and quantitatively discharge materials, and lack of heating function, etc., to achieve good heating effect, fast mixing speed, and stirring efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

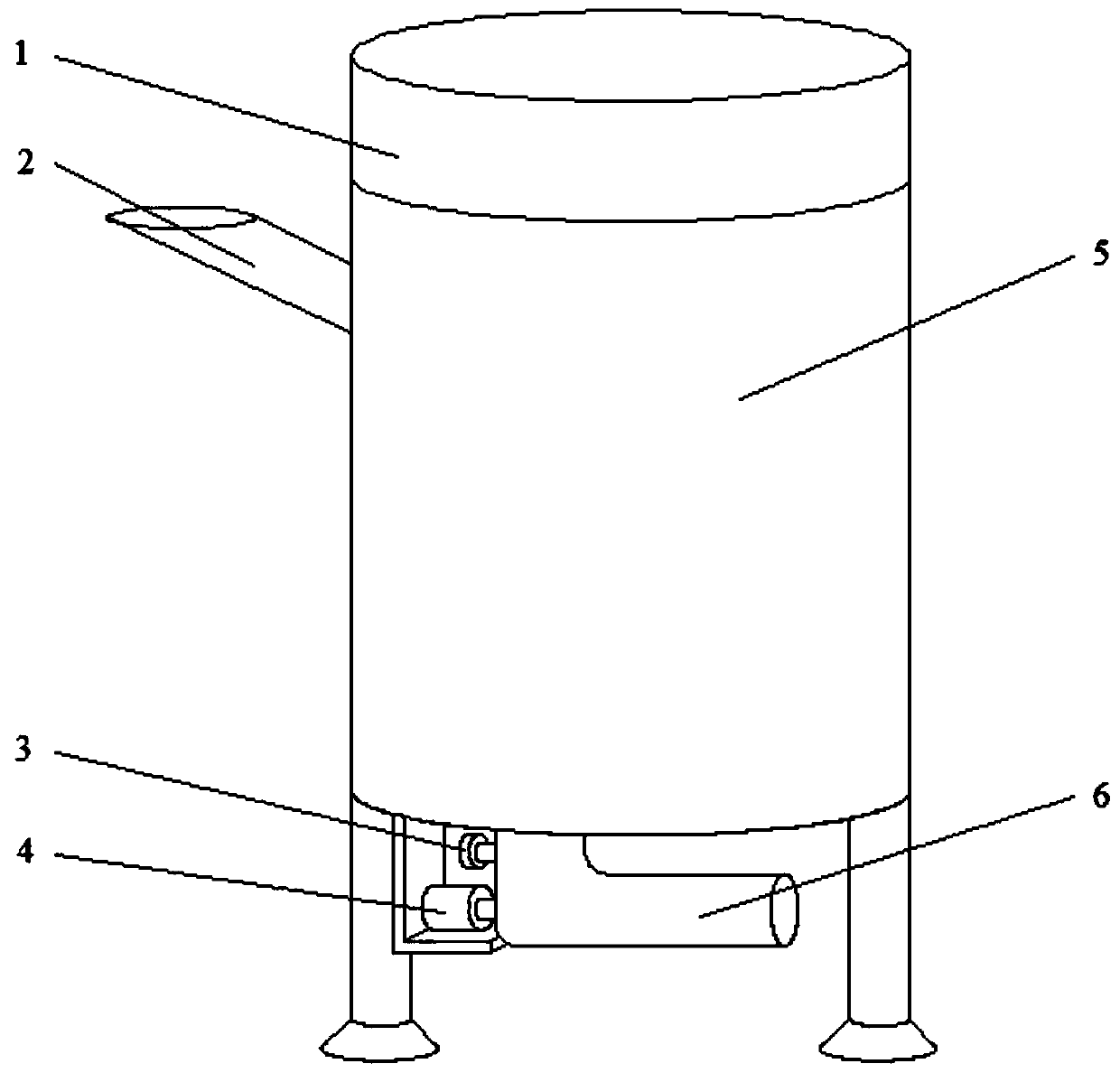

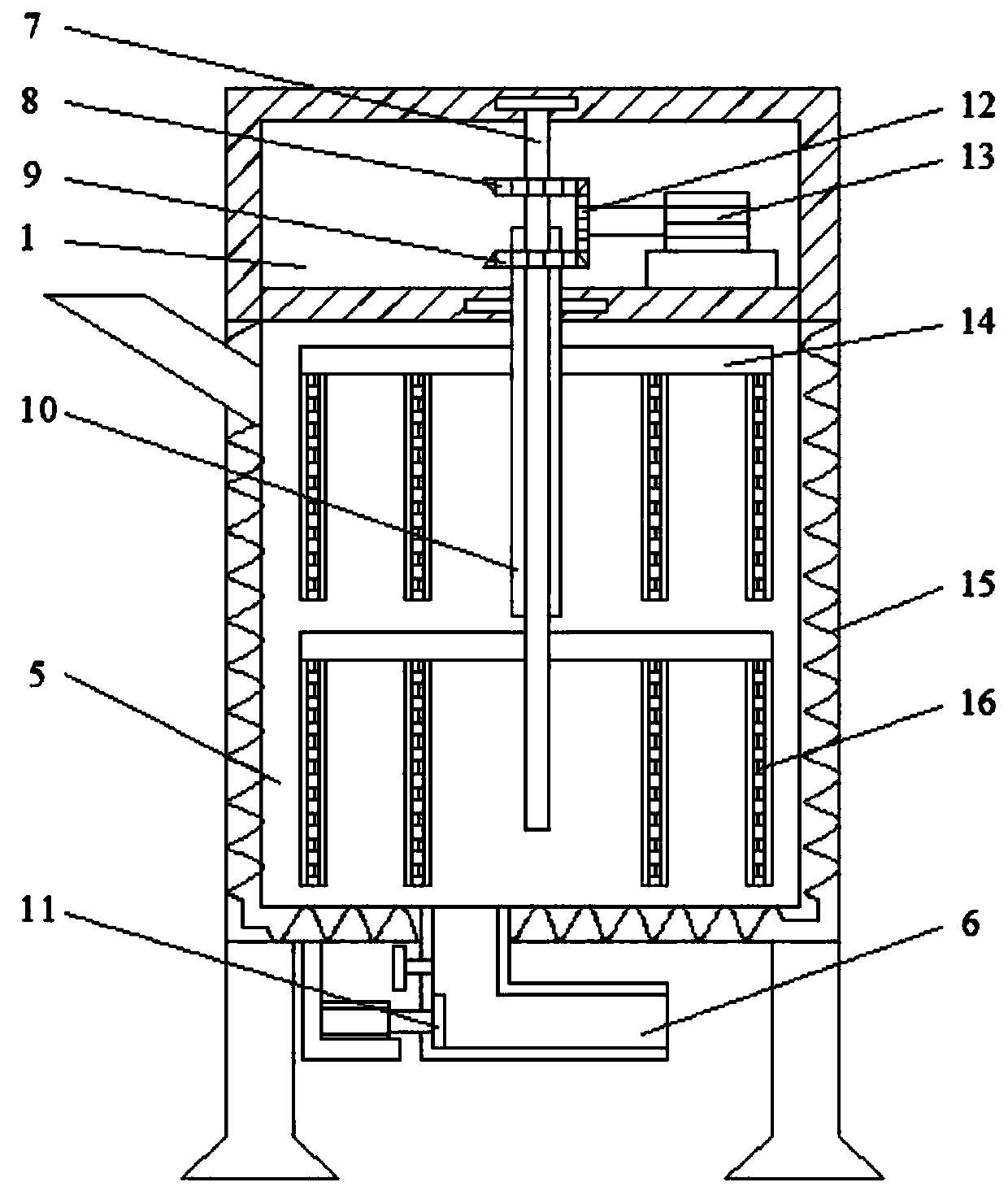

[0025] refer to Figure 1-2 , a heating and mixing device for promoting the circulation of hair growth shampoo production, comprising an equipment chamber 1 and a mixing chamber 5, the equipment chamber 1 is located at the top of the mixing chamber 5, and the internal stirring paddle 14 of the mixing chamber 5, the stirring paddle 14 is provided with two The stirring paddle 14 is provided with a transmission mechanism that drives the stirring paddle 14 to rotate, the inner wall of the mixing chamber 5 is inlaid with a heating wire 15, the vertical part of the stirring paddle 14 is inlaid with a heating rod 16, and the bottom of the mixing chamber 5 is connected with a Discharge pipe 6, electric telescopic rod 4 is installed on the side bottom of discharge pipe 6, and the telescopic end of electric telescopic rod 4 stretches into discharge pipe 6 inside and is welded with push plate 11.

[0026] In this embodiment, the transmission mechanism includes a first driven shaft 7, a s...

Embodiment 2

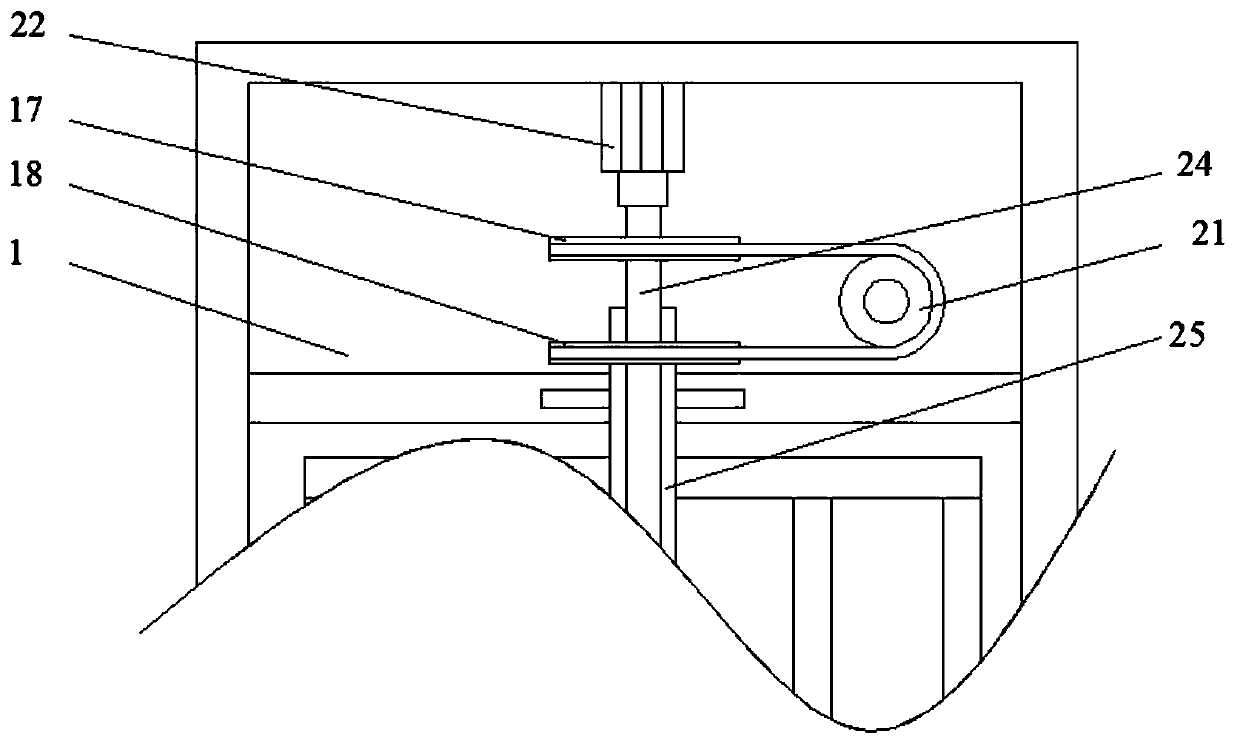

[0029] refer to Figure 3-4 The only difference between this embodiment and Embodiment 1 is that the transmission mechanism includes a second rotating motor 22, a driving shaft 24, a third driven shaft 25 and a belt 23, and the second rotating motor 22 is installed vertically on the top of the equipment room 1 In the middle of the middle part, the top of the output shaft of the second rotating electrical machine 22 is welded with a drive shaft 24, and the drive shaft 24 is welded with a drive wheel 17, and a support shaft 19 is welded on one side of the equipment room 1, and the two ends of the support shaft 19 are respectively connected to each other in rotation. The first driven wheel 20 and the second driven wheel 21, the third driven wheel 18 is welded on the third driven shaft 25, and the belt 23 connects the driving wheel 17, the first driven wheel 20, the second driven wheel 21 and the third driven wheel in turn. The driving wheel 18, the bottom end of the driving shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com