High-environment-friendliness industrial material mixing equipment

An environmentally friendly, mixing technology, applied in mixers, shaker/oscillation/vibration mixers, mixers with rotary stirring devices, etc., can solve the problems of incomplete mixing and slow mixing speed, and achieve increased sealing , the effect of reducing the time of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

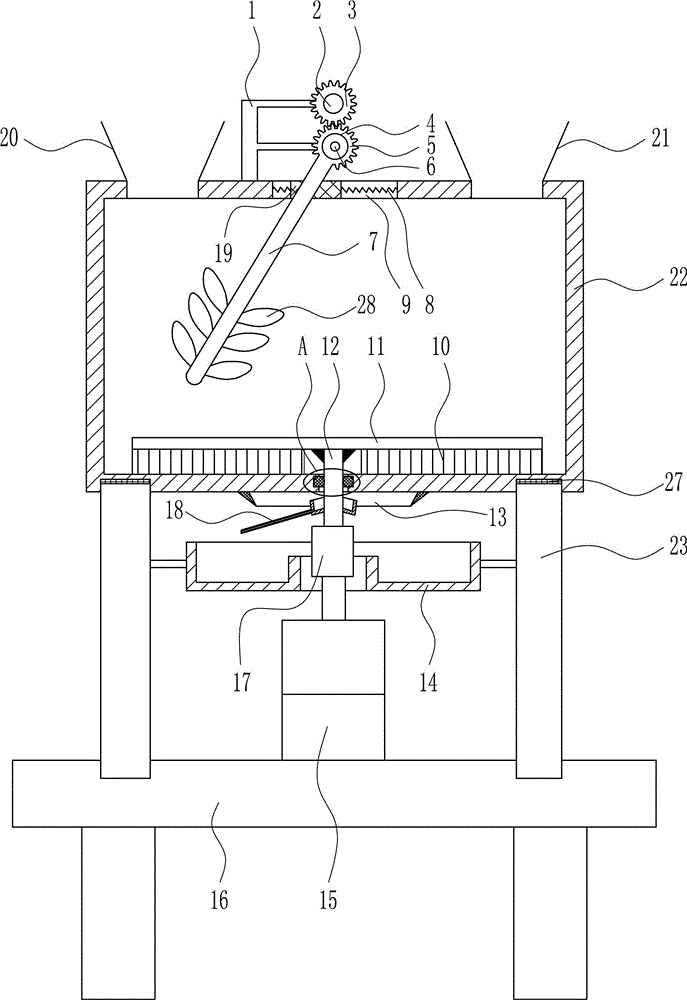

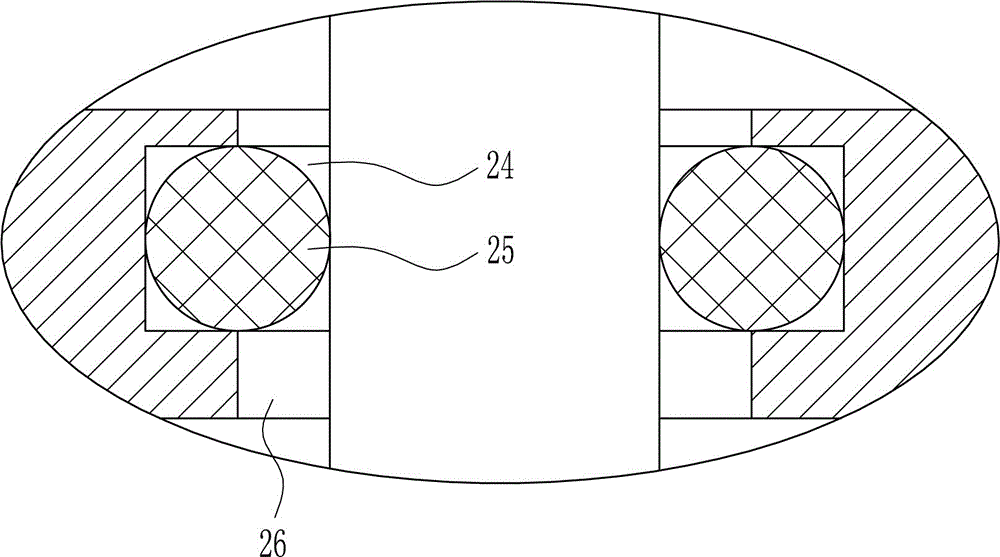

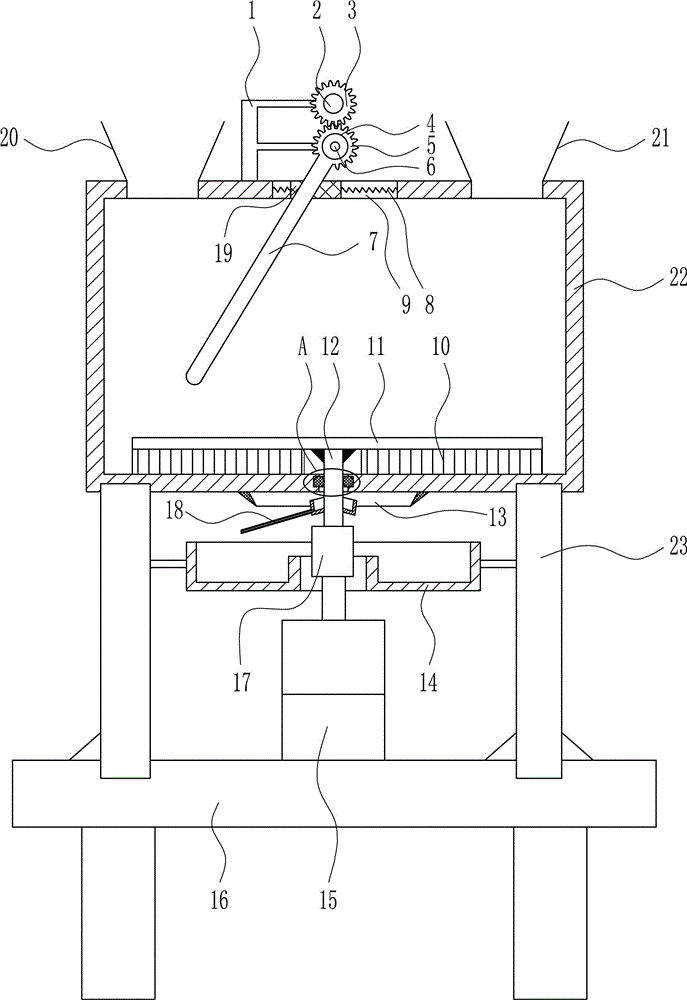

[0031] A high-environmental-friendly mixing equipment for industrial raw materials, such as Figure 1-5As shown, it includes a first bracket 1, a rotating motor 2, a first gear 3, a bearing seat 4, a second gear 5, a first rotating shaft 6, a swing lever 7, an elastic member 8, a brush 10, a fixed plate 11, a first Second rotating shaft 12, plastic basin 13, liquid receiving basin 14, geared motor 15, second bracket 16, coupling 17, liquid outlet pipe 18, first rubber pad 19, first feeding hopper 20, second feeding hopper 21. Mixing box 22, support rod 23, arc groove 24 and O-ring 25; the left and right sides of the top of the second support 16 are connected with support rods 23 by mortise joints, and the left support rod 23 and The support rod 23 on the right is connected with the liquid receiving basin 14 by means of adhesive connection, and the upper end of the support rod 23 is connected with the mixing box 22 by means of mortise joint, and a second through hole 26 and arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com