Multihead stirrer

A stirrer and multi-head technology, which is applied to mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problems of excessive motor power, excessively long blade design, and increased linear speed, saving electric energy. , The effect of improving the stirring efficiency and speeding up the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

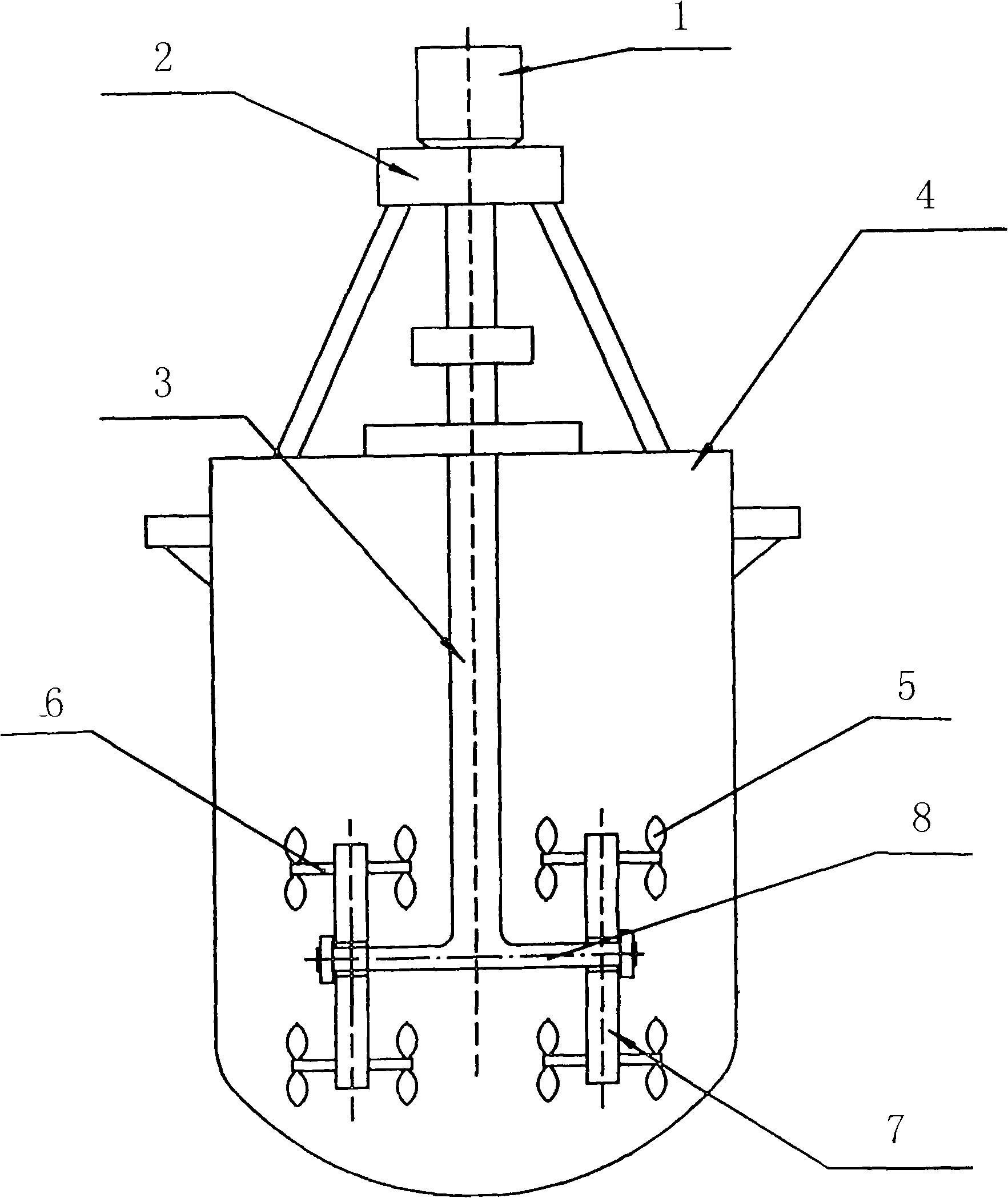

[0008] figure 1 It is a schematic diagram of the structure of the agitator installed in the reactor, which is the same as the prior art except that the structure of the multi-head agitating blades changes. Including motor 1, reducer 2, stirring shaft 3, a horizontal shaft 8 is fixed at the end of the stirring shaft 3, the two ends of the horizontal shaft 8 are symmetrically fixed with short shafts 7 parallel to each other, and the two ends of each short shaft 7 are symmetrically fixed Connecting shaft 6 is arranged, and the two ends of connecting shaft 6 are installed known technology mode and agitating blade 5 is installed, form multi-head agitating blade. The length of the blade can be in accordance with the known general size requirements.

[0009] The motor 1 drives the reducer 2 to rotate the stirring shaft 3, drives the multi-head stirring blades to rotate, and stirs the raw materials in the reaction kettle 4 to improve the stirring efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com