Patents

Literature

66results about How to "Normal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

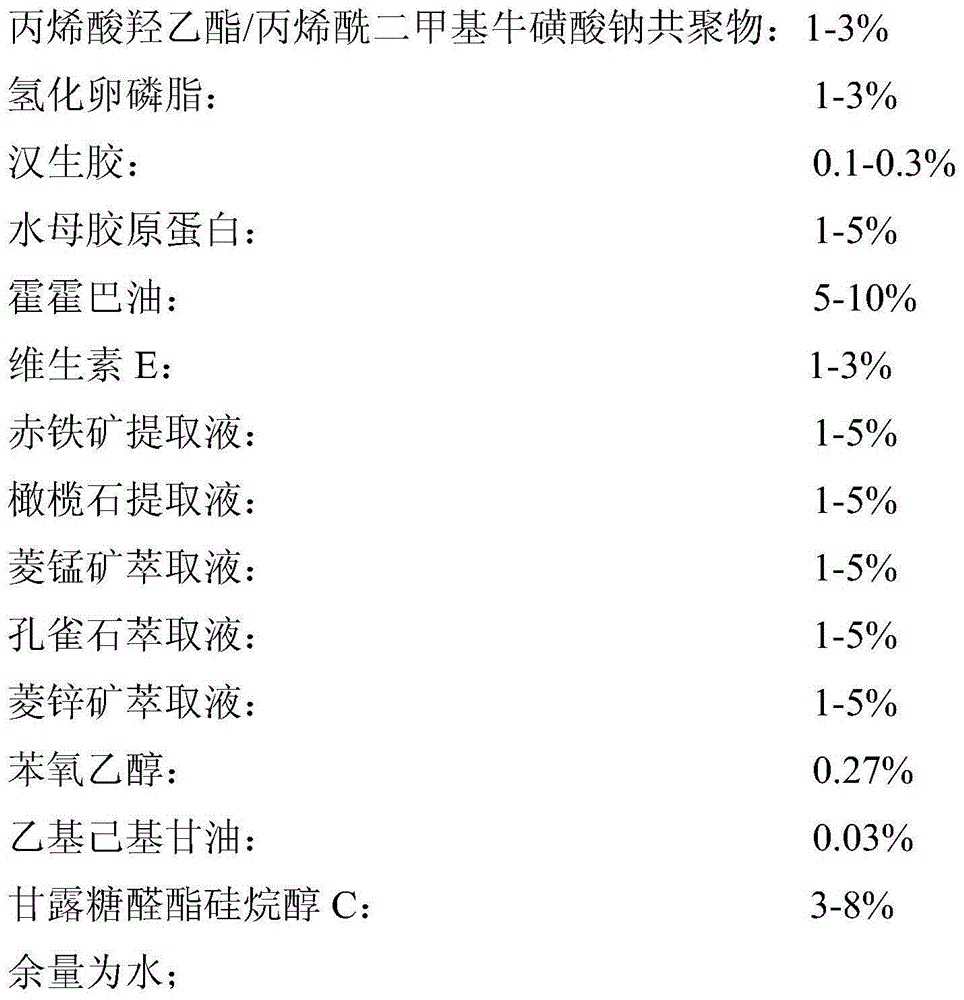

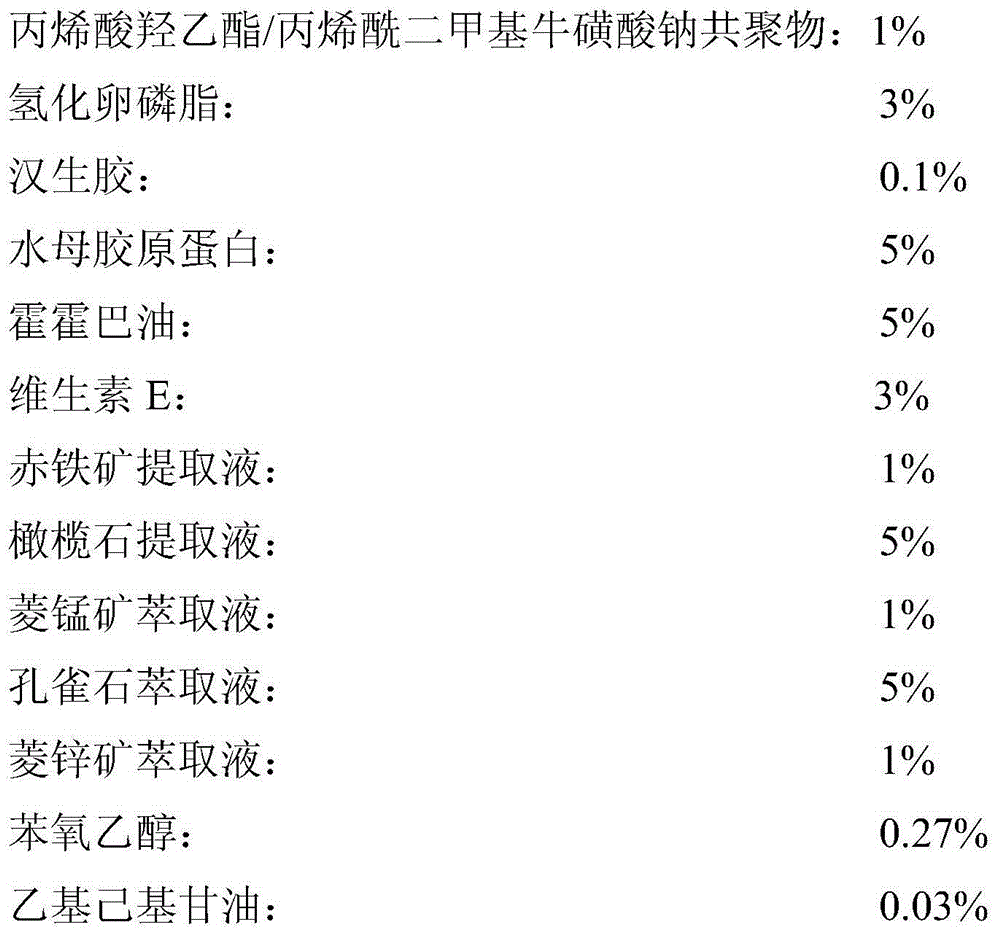

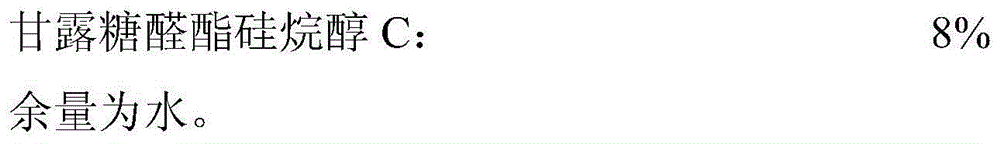

Skin comprehensive anti-aging water condensation and preparation method thereof

ActiveCN104784071ADelay agingPromote proliferation and divisionCosmetic preparationsToilet preparationsTrace elementJojoba oil

The invention discloses a skin comprehensive anti-aging water condensation and a preparation method thereof. The water condensation is prepared from a hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, hydrogenated lecithin, xanthan gum, jellyfish collagen, jojoba oil, vitamin E, a hematite extraction liquid, an olivine extraction liquid, a rhodochrosite extraction liquid, a malachite extraction liquid, a smithsonite extraction liquid, phenoxyethanol, ethylhexylglycerin, algisium C and water. The anti-aging water condensation has the main effective components being the liquid ore extracts rich in various trace elements. The anti-aging water condensation can prolong the life of cells and delay skin aging, and is a comprehensive nursing type product which can comprehensively deal with the skin aging problem.

Owner:广州丽丰化妆品制造有限公司

Flexible stretchable biosensor and preparation method thereof

InactiveCN109381182ASimple structureNormal structureDiagnostic recording/measuringSensorsTransmission channelEngineering

The invention provides a flexible stretchable biosensor. The flexible stretchable biosensor has the advantages that the structure is simple, multiple working electrodes and multiple signal transmission channels are designed on a flexible film substrate, and it can be ensured that after one electrode goes wrong, other electrodes can work normally, thereby improving the safety of the biosensor, improving the accuracy of signal measurement and reducing the measurement error. The invention further provides a preparation method of the flexible stretchable biosensor, which has the advantages that the tensile property of the biosensor can be enhanced, and the conformability between the flexible stretchable biosensor and a measured object can be improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

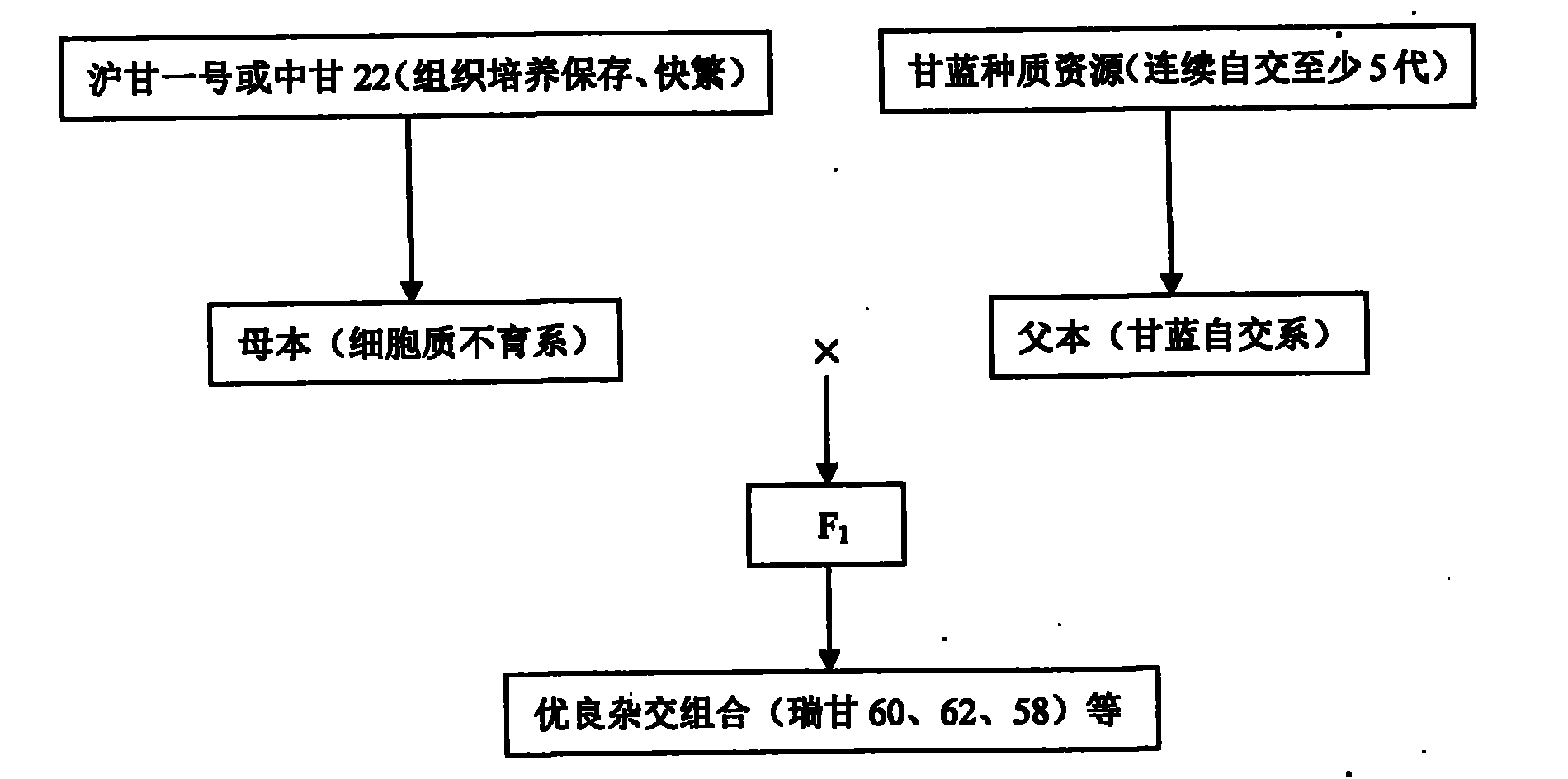

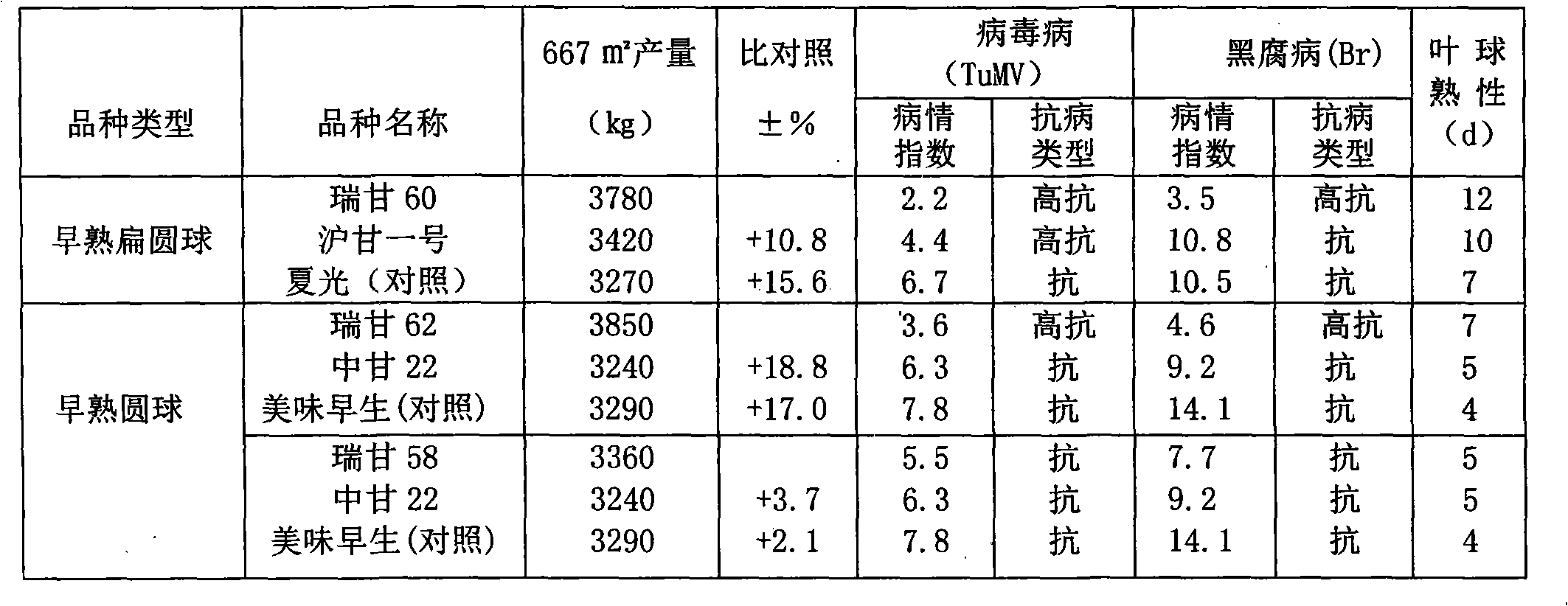

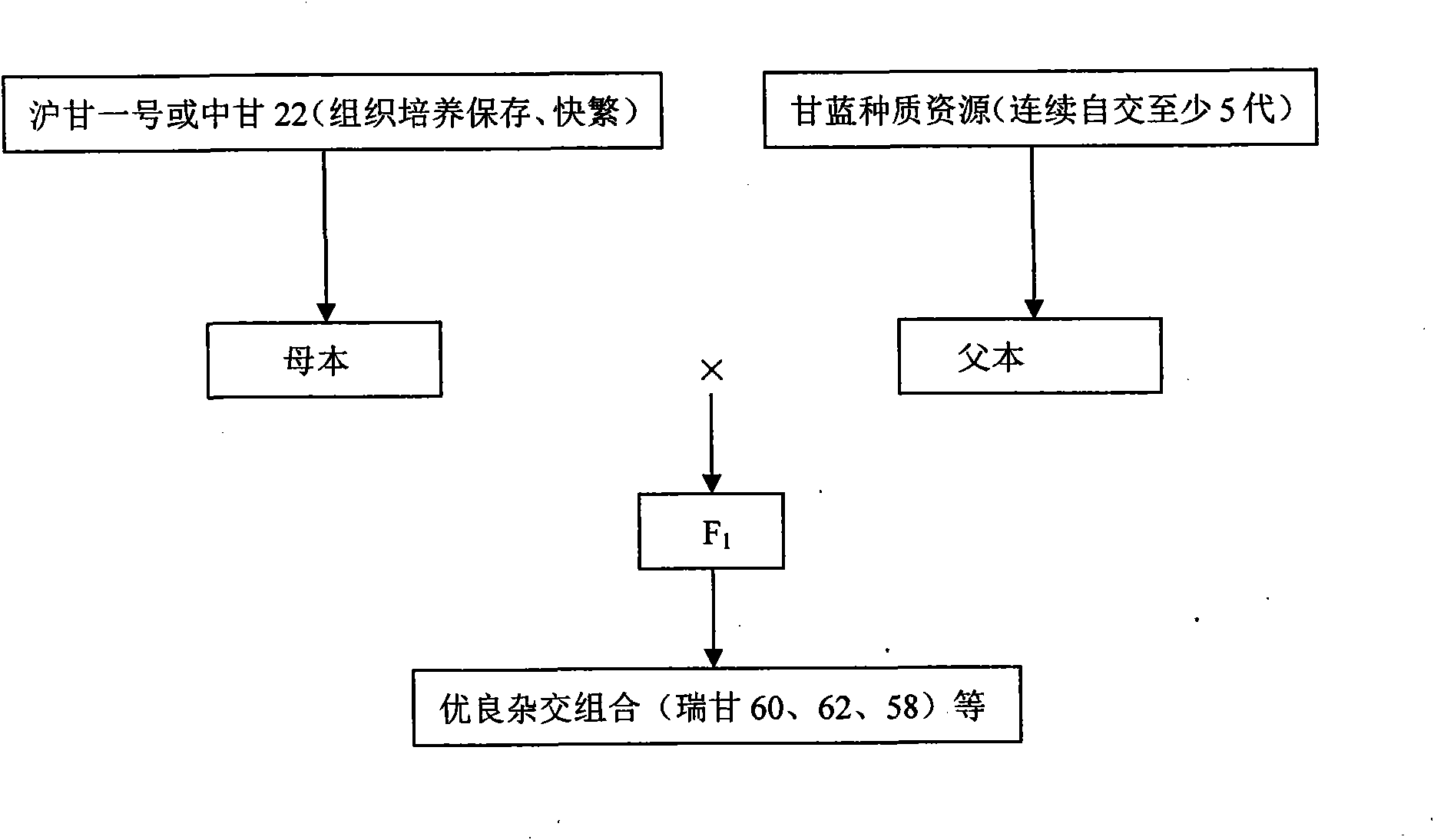

Simplified breeding method for preparing hybrid cabbage by using cytoplasmic male sterile lines

ActiveCN101803564APromote steady developmentNormal developmentPlant genotype modificationHeterosisPollen

The invention relates to a breeding method of hybrid cabbage, in particular to a simplified breeding method for preparing hybrid cabbage by using cytoplasmic male sterile lines, which belongs to the technical field of plant culture. The invention directly adopts the cabbage varieties of Zhonggan No.22 and Hugan No.2 prepared by cytoplasmic male sterile lines sold in the market as maternal plants, and adopts cabbage inbred lines (with the same ball shape as the maternal plants, the same type of leaf ball mature performance as the maternal plants and stable botanical characters) as pollen suppliers for preparing good coenospecies. The invention has the advantages that when the advantages of using the cytoplasmic male sterile lines for preparing the cabbage coenospecies are maintained, good cabbage inbred lines do not need to be used as recurrent parents for fifth to seventh generation backcrossing and transformation with male sterilant materials, the labor is saved, the cost is saved, the breeding time is greatly shortened, and in addition, the hybrid vigour parts of the original varieties can be maintained into the new hybrid varieties.

Owner:YUNNAN SINONG VEGETABLES SEED

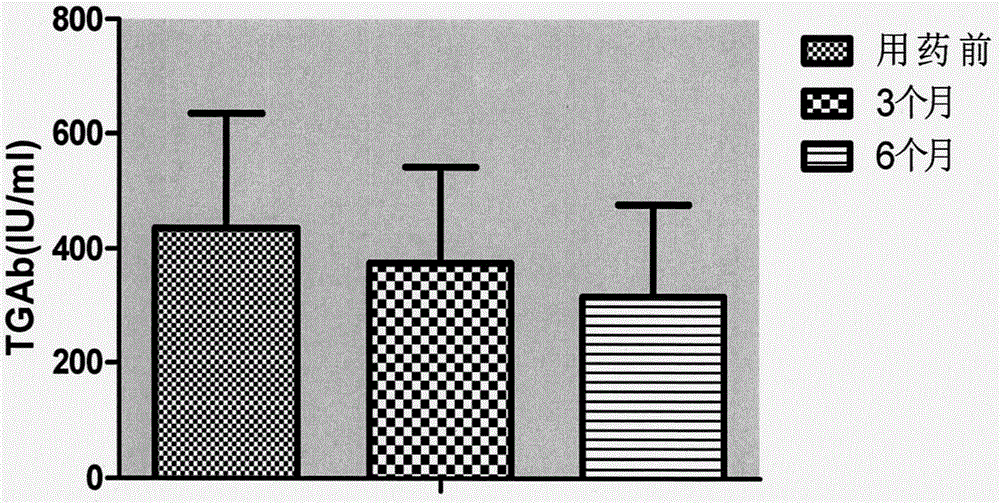

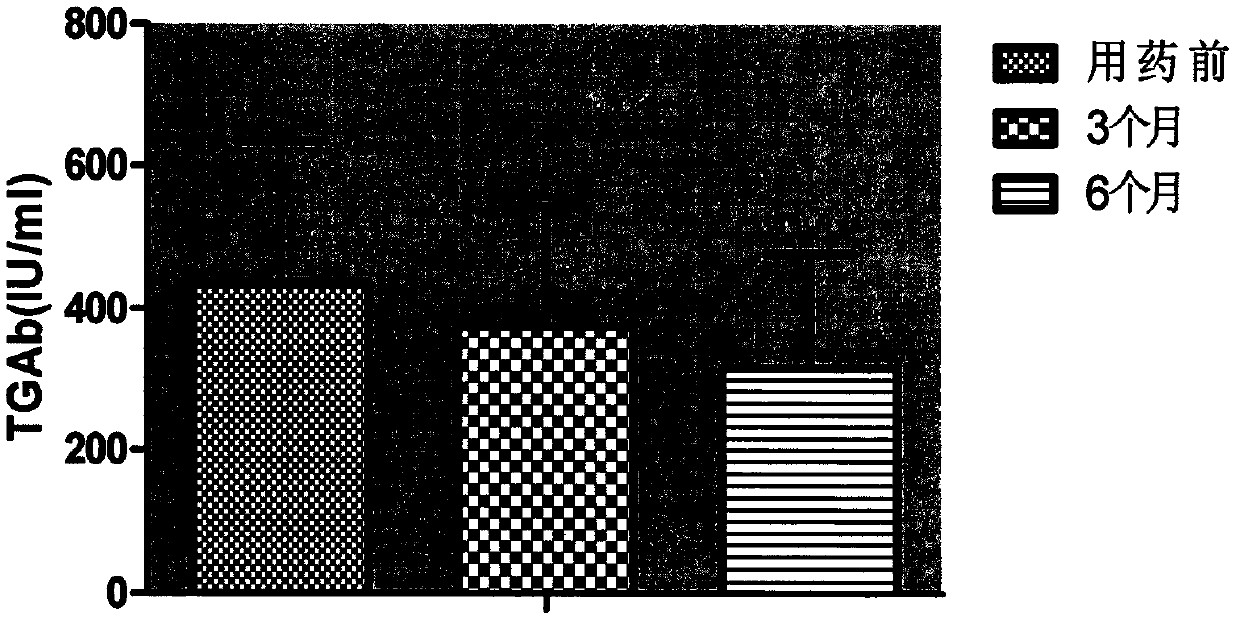

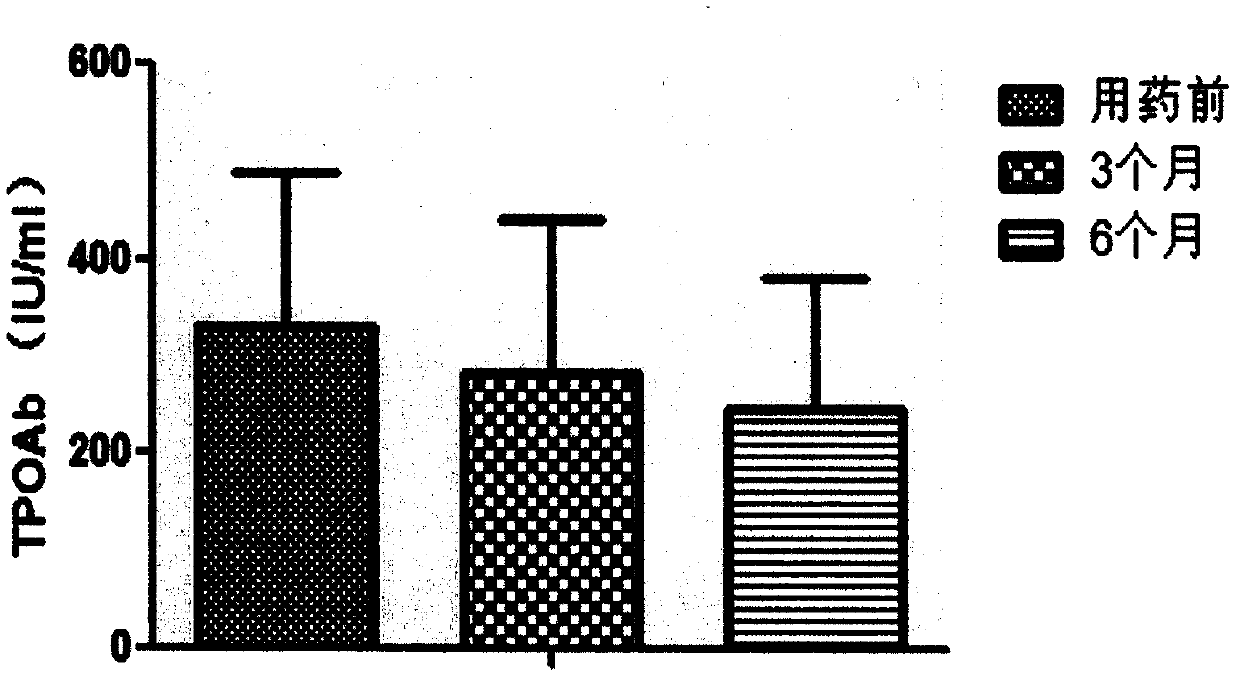

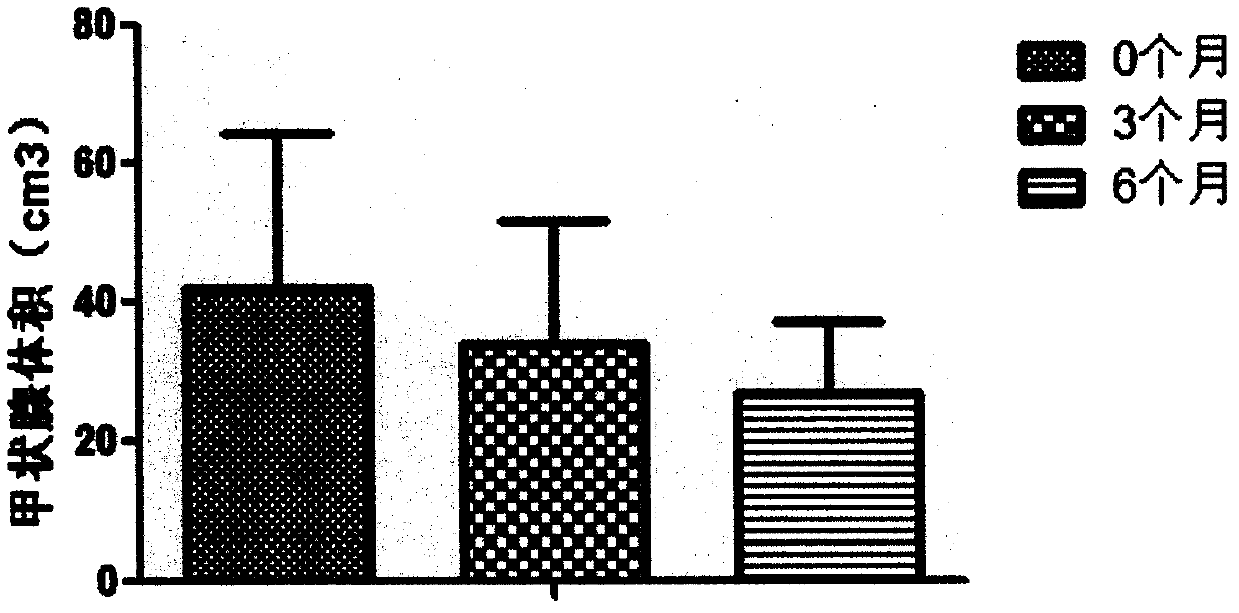

Pharmaceutical composition for treating Hashimoto's thyroiditis and preparation method thereof

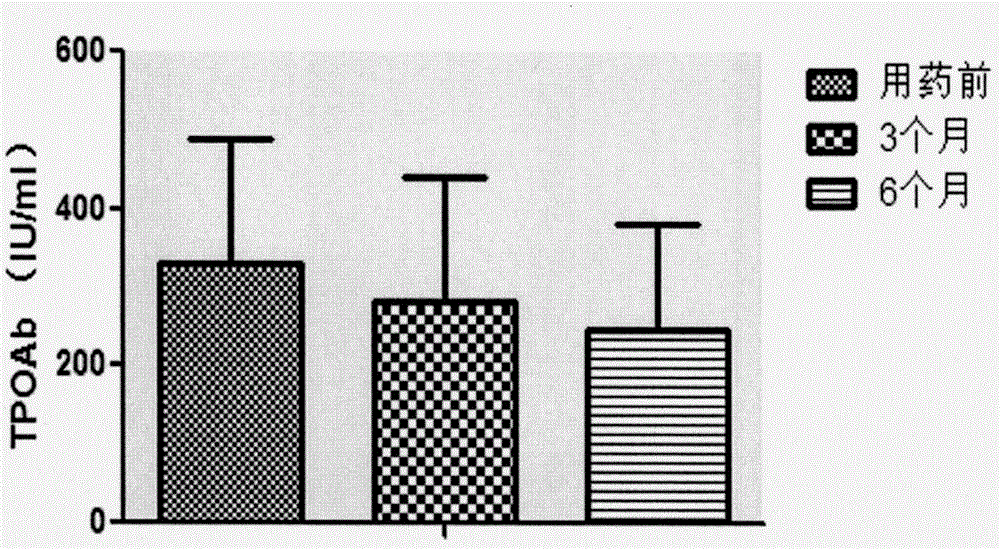

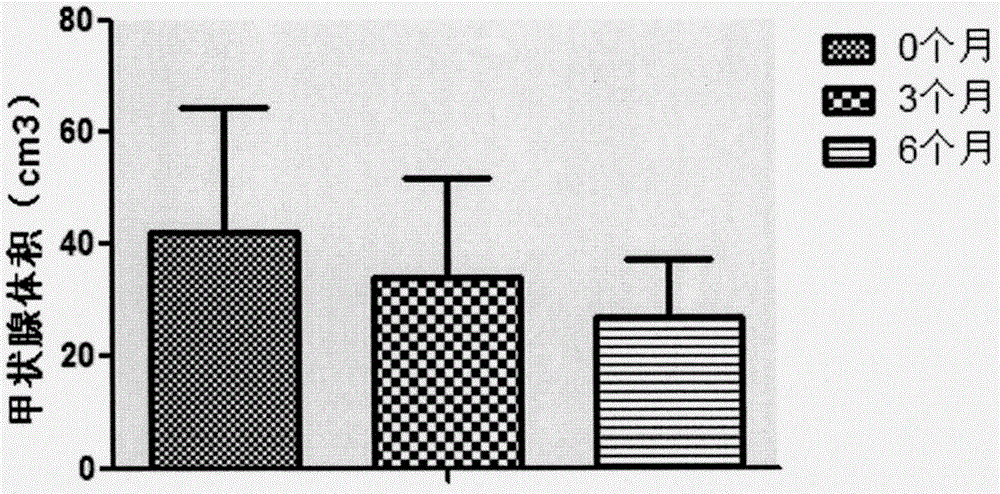

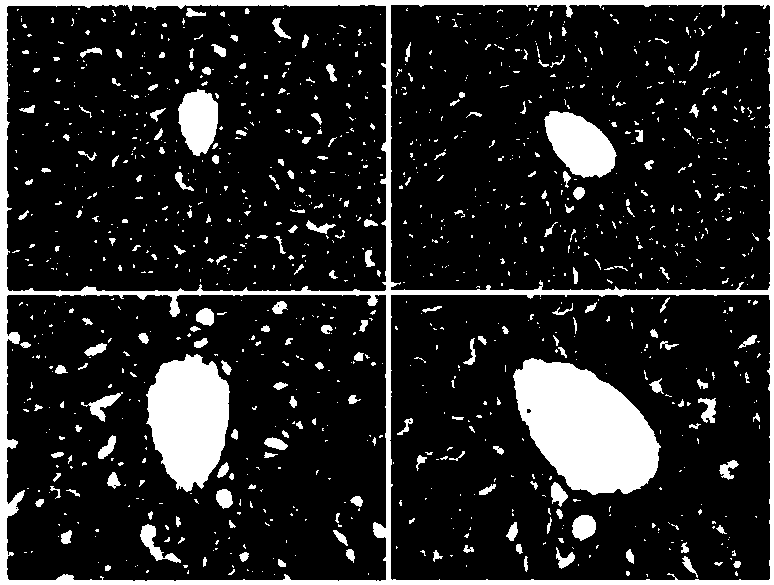

ActiveCN106421633ASymptoms improvedReduce volumePill deliveryGranular deliveryClinical studyInflammatory infiltration

The invention relates to a pharmaceutical composition for treating Hashimoto's thyroiditis and a preparation method thereof. The pharmaceutical composition is composed of bupleurum, radix curcumae, prunella vulgaris, rhizoma Dioscoreae Nipponicae, thunberg fritillary bulb, radix scrophulariae, edible tulip, astragalus, dark plum and other components, and can be made into granules, capsules, tablets or pills by the conventional pharmaceutical processes. The pharmaceutical composition has the effects of soothing liver-qi stagnation, reducing phlegm, removing stasis, and softening hardness to dissipate stagnation, and applies to patients with Hashimoto's thyroiditis and thyroid nodules. Clinical studies have shown that the pharmaceutical composition can significantly improve the symptoms of Hashimoto's thyroiditis, reduce the thyroid volume and isthmus thickness, and reduce the level of TgAb and TPOAb, and the total effective rate is 97.22%. In addition, for patients with thyroid nodules, nodules can be significantly reduced or even disappeare, no significant adverse reactions are presented in the course of treatment. Experimental studies have shown that the pharmaceutical composition reduces the level of TgAb and TPOAb, and reduces inflammatory infiltration and thyroid follicular damage.

Owner:BEIJING UNIV OF CHINESE MEDICINE

Organ preserving liquid

PendingCN109769797APrevent subsequent damageEnsure stabilityDead animal preservationVascular endotheliumLiver transplantation

The invention provides a method for maintaining the survival and / or function of vascular endothelial cells in the in vitro preservation process and used preserving fluid. The method and the preservingfluid are suitable for storing various organs. The in vitro liver can survive to exceed 24h during the preservation by the organ preserving liquid and in the mechanical filling process; the liver microcirculation structure is complete; no obvious damage exists; the choleresis function is good; the liver synthesis and metabolism functions are good; the in vitro preservation time of the liver is greatly prolonged; the postoperative survival rate of later-period liver transplantation patients is improved.

Owner:HEFEI HUAQI BIOLOGICAL ENG CO LTD

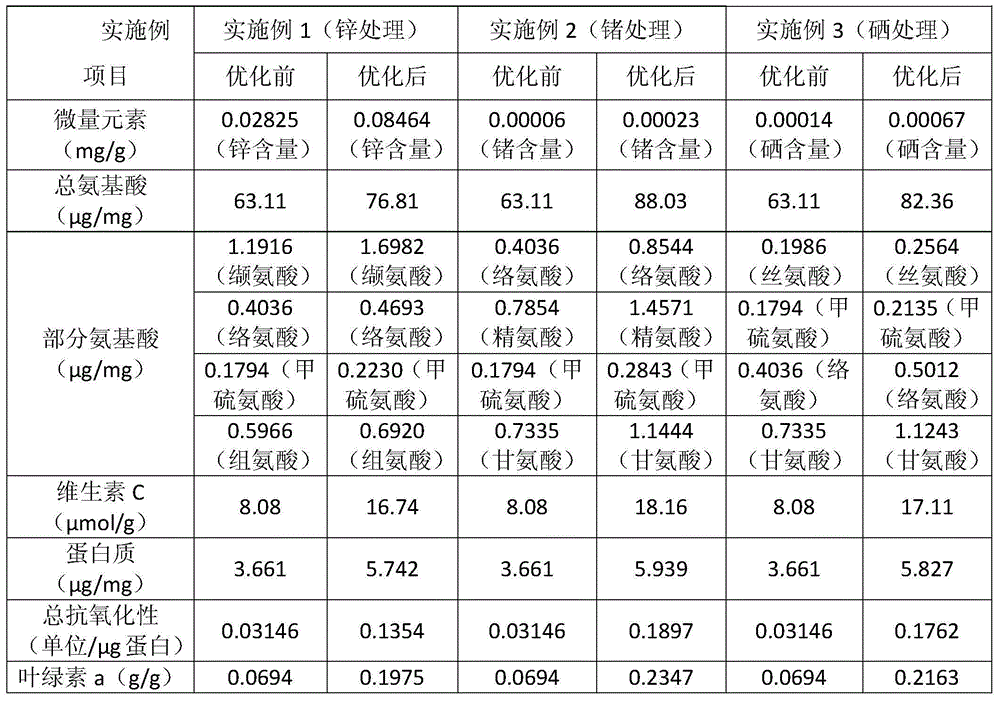

Microelement culture solution and method for increasing microelements of pea sprouts with same

InactiveCN104557200AAchieve the effect of medicine and food at the same timeIncreased total antioxidant capacitySeed and root treatmentCultivating equipmentsSulfateField pea

The invention discloses a microelement culture solution and a method for increasing microelements of pea sprouts with the same. The microelement culture solution is a solution containing one or more of 0.3-0.6 mg / L of zinc sulfate, 300-500 mg / L of organic selenium and 200-400 mg / L of germanium dioxide. The method for increasing the microelements of the pea sprouts comprises steps as follows: firstly, pea seeds are soaked in the microelement culture solution and then cultured, and the microelement culture solution is sprayed once every 12-24 h during culture. Compared with the prior art, the microelement culture solution and the method have the advantages as follows: the microelements of the cultured pea sprouts are high in enrichment degree, the microelement culture solution can also promote growth of the pea sprouts, production is not limited by seasons, the production cycle is short, the cost is low, the benefit is high, and the pea sprouts are natural and pollution-free.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Feed additive for protecting intestinal health of hybrid snakehead fish and preparation method of feed additive

ActiveCN105639191APromote growth and developmentNormal structureAnimal feeding stuffAccessory food factorsFood additiveAnimal science

The invention discloses a feed additive for protecting intestinal health of a hybrid snakehead fish and a preparation method of the feed additive. The feed additive comprises the following components, by weight part: 25-35 parts of copper-loading montmorillonite, 20-30 parts of mannan oligosaccharide, 15-20 parts of bacillus licheniformis, 10-15 parts of glutamine dipeptide, 7-12 parts of tributyrin, 5-10 parts of origanum vulgare essential oil, and 4-8 parts of yeast nucleic acid. The method comprises: pulverizing the solid raw materials above, sieving the obtained materials through a sieve with 120-140 mesh, mixing the obtained materials with tributyrin and origanum vulgare essential oil to enable a coefficient of variation of the obtained mixture to be no more than 5%, and obtaining the feed additive. The feed additive can promote intestinal growth and development of the hybrid snakehead fish, ensures a normal intestinal structure and function, and optimizes intestinal flora of the hybrid snakehead fish. A normal intestinal micro-ecological environment is ensured, and the ability of digesting and absorbing nutritive substances of the hybrid snakehead fish is improved.

Owner:GUANGDONG TONGWEI FEED

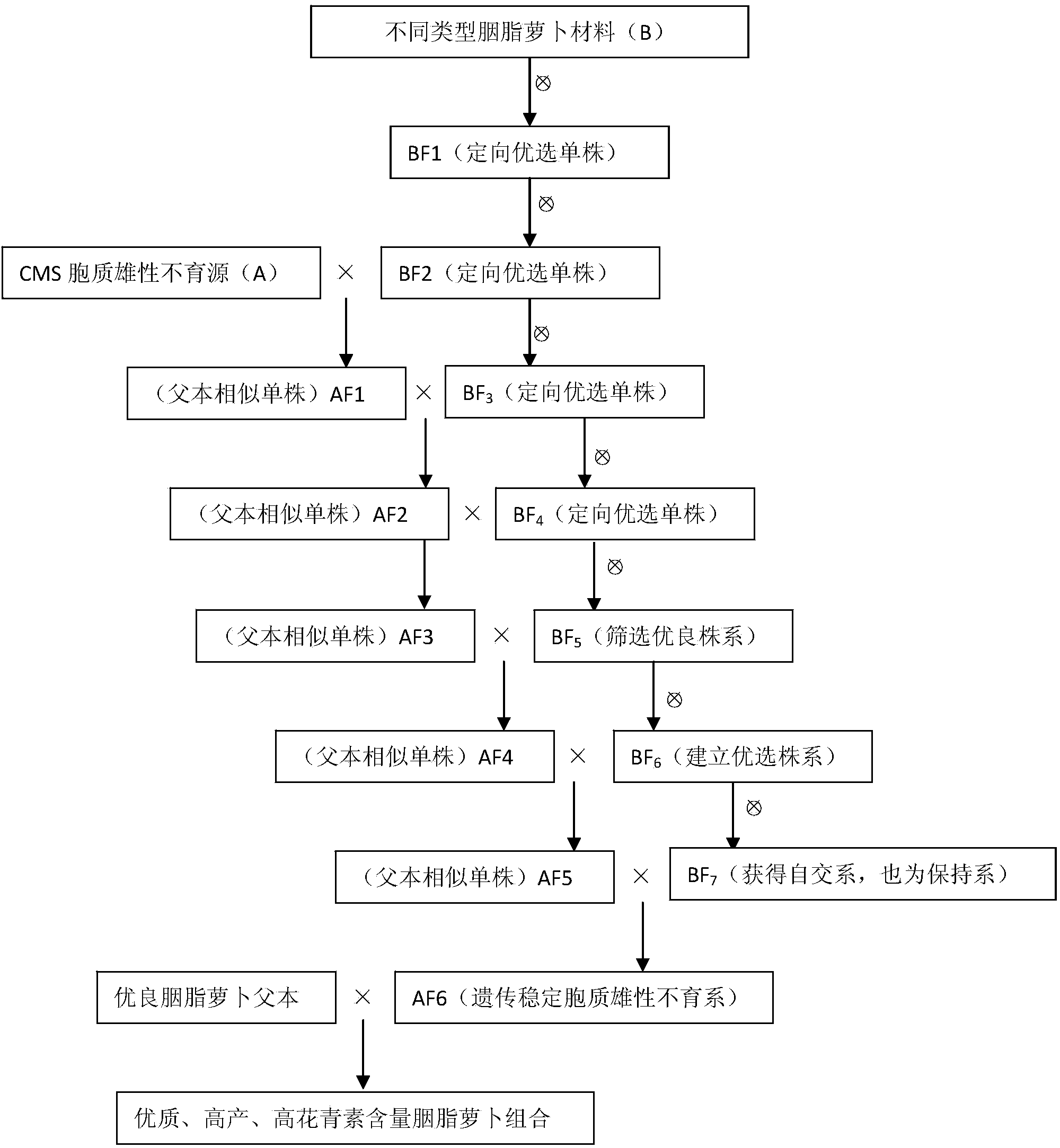

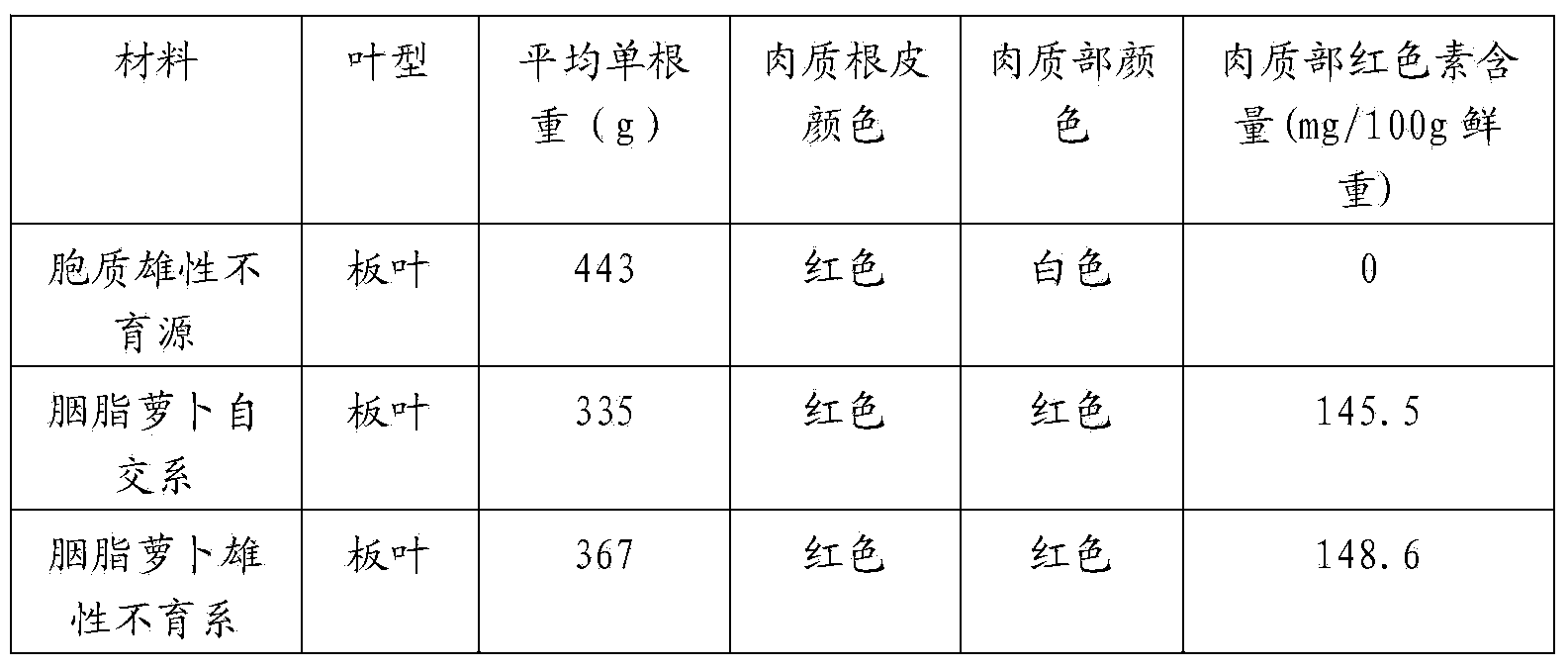

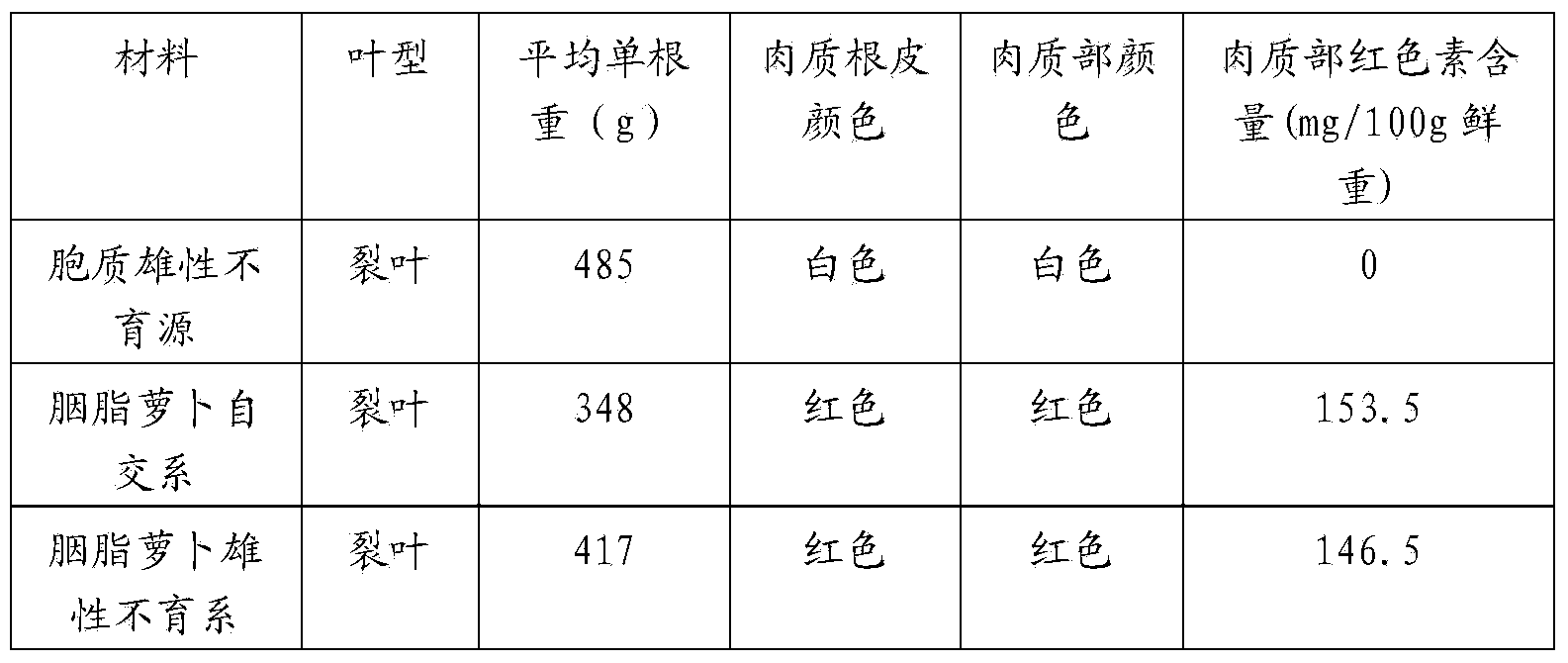

Breeding method for rapidly obtaining cytoplasm male sterility line and maintenance line of carmine radish

InactiveCN104160948AStable traitsImprove the coordination effectPlant genotype modificationInterspecific hybridizationSelfing

The invention discloses a breeding method for rapidly obtaining a cytoplasm male sterility line and a maintenance line of carmine radish. The method mainly comprises the following steps: selecting different types of carmine radish materials, performing first generation selfing, determining a selective breeding object, performing orientation selection on a single plant, and performing second generation selfing; performing orientation selection on the single plant for continuously selfing in a selfing offspring group, and performing orientation selection on the single plant according to the selective breeding object; selecting cytoplasm male sterility as a female parent, selecting the selected single plant as a male parent, performing interspecies cross, obtaining hybrid F1, thereby transferring CMS genes of the sterility to collard; continuously selfing and purifying the selfing offspring, and screening a sterile plant which is the closest to the selective breeding object of the male parent to serve as a female parent in a cytoplasm male sterility hybrid plant group, taking the screen single plant which is the closest to the selective breeding object in the selfing offspring as a male parent for continuously performing paired cross; and purifying the selfing offspring, transferring the male sterility, simultaneously performing paired cross on each generation, and selfing multiple generations to obtain the maintenance line and the male sterility line. According to the method, the labor and cost can be obviously reduced, and the breeding time is shortened.

Owner:单县秋歌农产品有限公司

Chondroitin sulfate production process

InactiveCN103497261AAvoid high temperature degradationHigh yieldEnvironmental resistanceThermal denaturation

The invention provides a chondroitin sulfate production process. A raw material is crushed to form particles with a diameter of 3-5mm, the particles are placed into an immersion pool, water which is 7-8 times as heavy as the raw material is added into the immersion pool for immersion, the particles are sent into a pulping machine to form a raw material pulp, the raw material pulp is sent into a reaction kettle, is heated and boils, then heat preservation is carried out for 10-15 minutes, and floating oil is taken out after temperature reduction to obtain collagen thermal denaturation liquid; a PH value of thermal denaturation liquid caustic soda is adjusted, bacterial enzymes are added, heat-preservation enzymolysis is carried out for 5-6 hours, the temperature is reduced to be the same as the temperature of cold water, then the temperature is raised to 70-75 DEG C, and heat-preservation is carried out for 10-15 minutes; materials after enzymolysis are clarified and filtered, and a wet-state chondroitin course product is obtained after alcohol precipitation, dehydration and alcohol removal; decoloration, concentration, alcohol precipitation and alcohol removal are carried out on the wet-state chondroitin course product, and a chondroitin fine product is obtained after drying. Mechanical physical degradation is carried out, the chondroitin is prevented from being degraded under a high temperature, the yield rate is improved, production cost is reduced, the yield is improved, the production efficiency is improved, the production is increased and the process is scientific and environmentally friendly.

Owner:河北三鑫实业集团有限公司

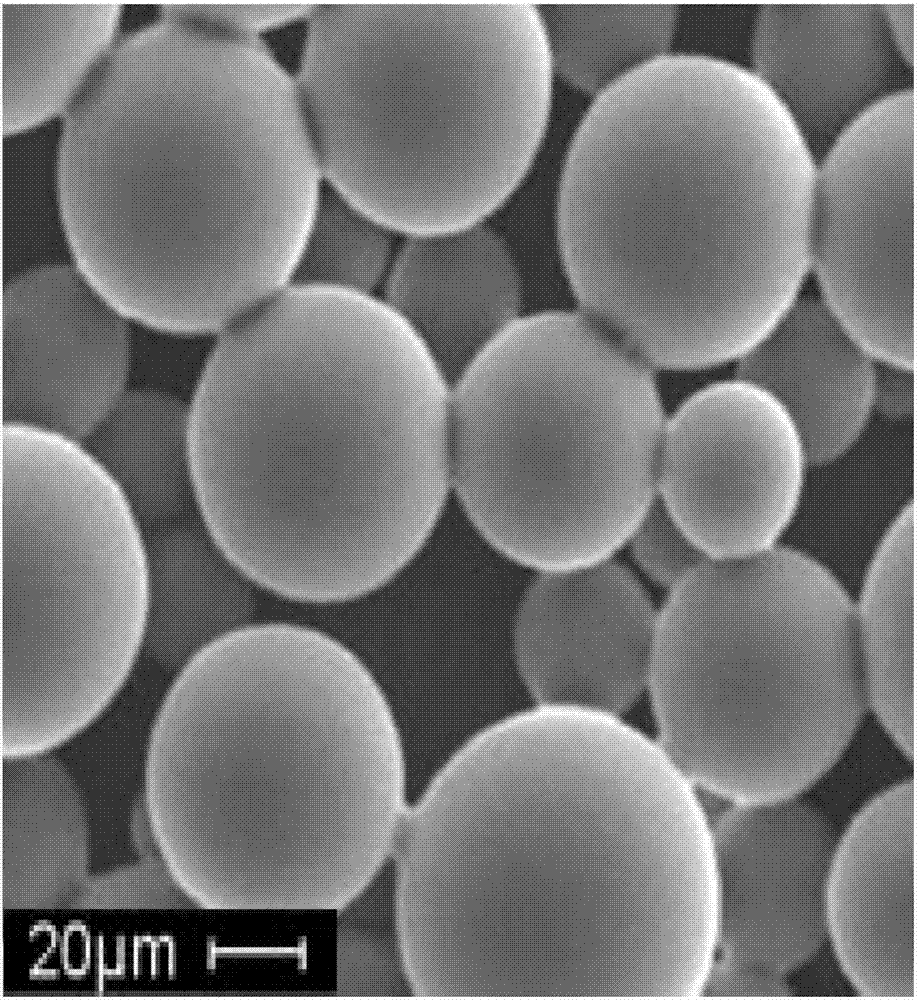

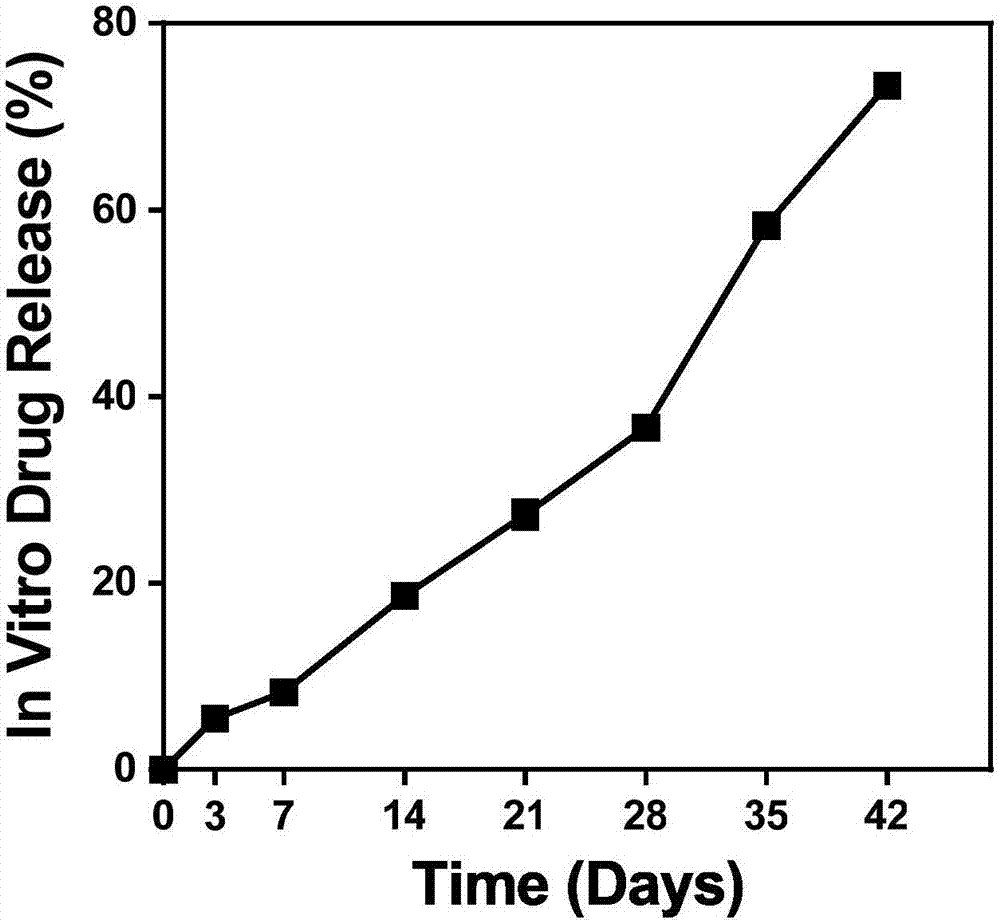

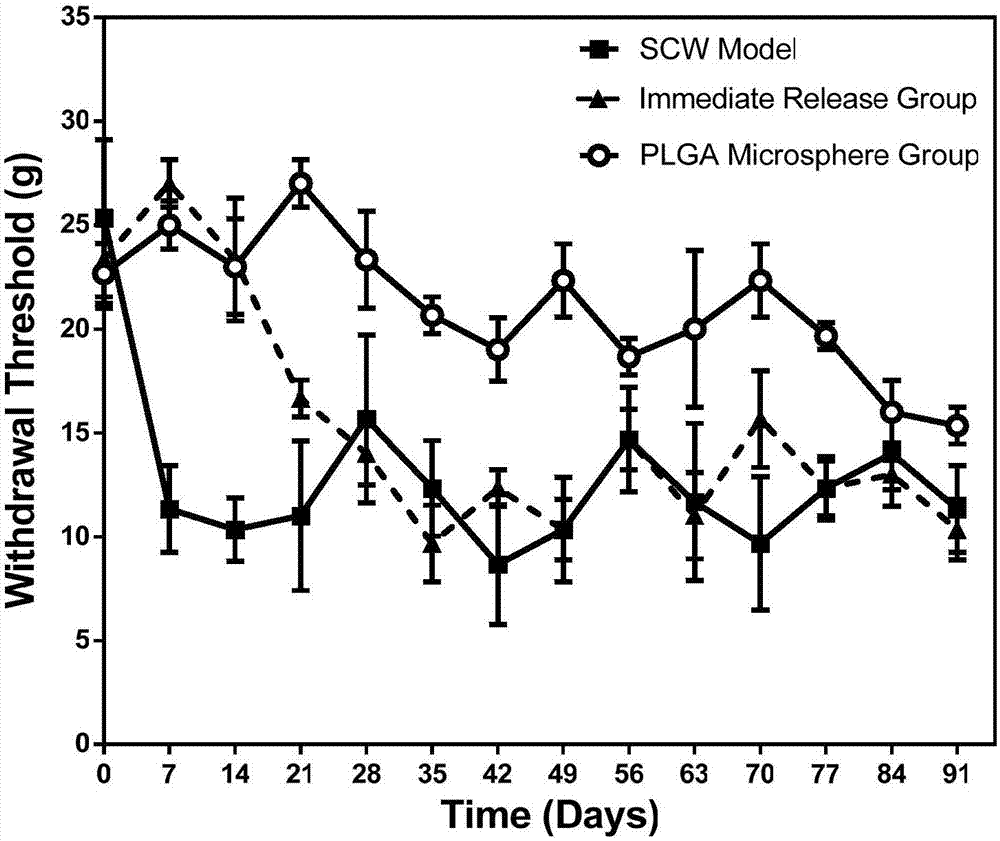

Injection containing triamcinolone acetonide and PLGA sustained release microspheres, preparation method of injection and application of injection to preparation of medicine for treating osteoarthritis pain

InactiveCN106983733AGood stabilityImprove drug stabilityOrganic active ingredientsAntipyreticMicrosphereOsteoarthritis

The invention provides injection containing triamcinolone acetonide and PLGA sustained release microspheres, a preparation method of the injection and application of the injection to the preparation of medicine for treating osteoarthritis pain. The injection comprises the triamcinolone acetonide, PLGA copolymer and hyaluronic acid, wherein the weight ratio of the PLGA to the triamcinolone acetonide is 100:(5-25); the weight ratio of the PLGA to the hyaluronic acid is 100:(5-15). The injection has the advantages that the medicine-loading sustained release microspheres are good in stability; the PLGA microspheres are used to wrap the triamcinolone acetonide, the medicine can be released in a sustained manner, medicine stability can be increased, and medicine hydrolysis can be reduced; the detection result of a reverse-phase hydrophobic high-performance liquid phase method shows that the quick release triamcinolone acetonide released in an aqueous solution in an in-vitro manner has evident degradation and absorption peaks and the triamcinolone acetonide wrapped in the microspheres is complete in structure and does not have evident degradation and absorption peaks; the hyaluronic acid has a synergistic effect, and due to the fact that hyaluronic acid improves knee joint viscosity, the clearance rate of the triamcinolone acetonide is further reduced, and acting time is prolonged.

Owner:江苏富泽药业有限公司

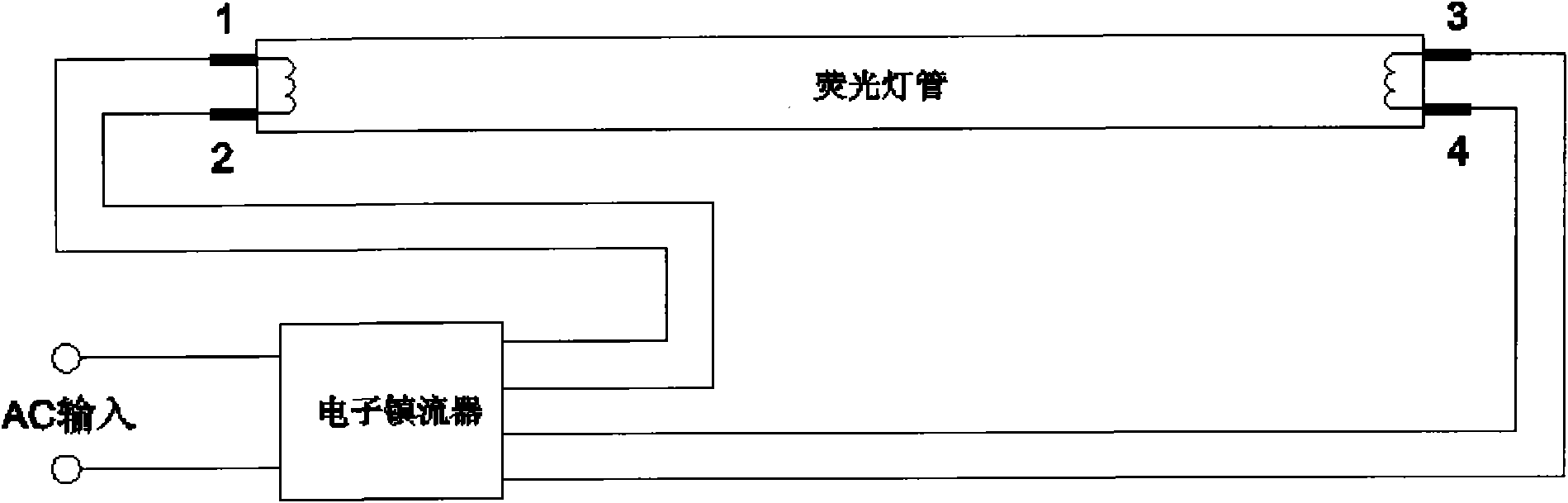

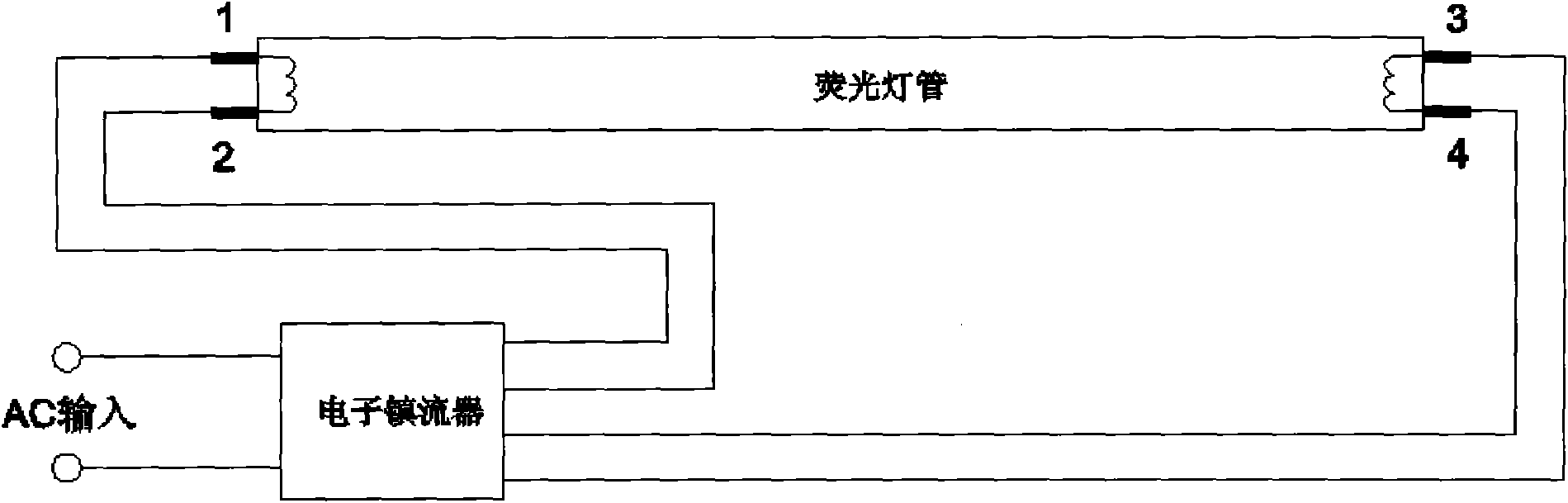

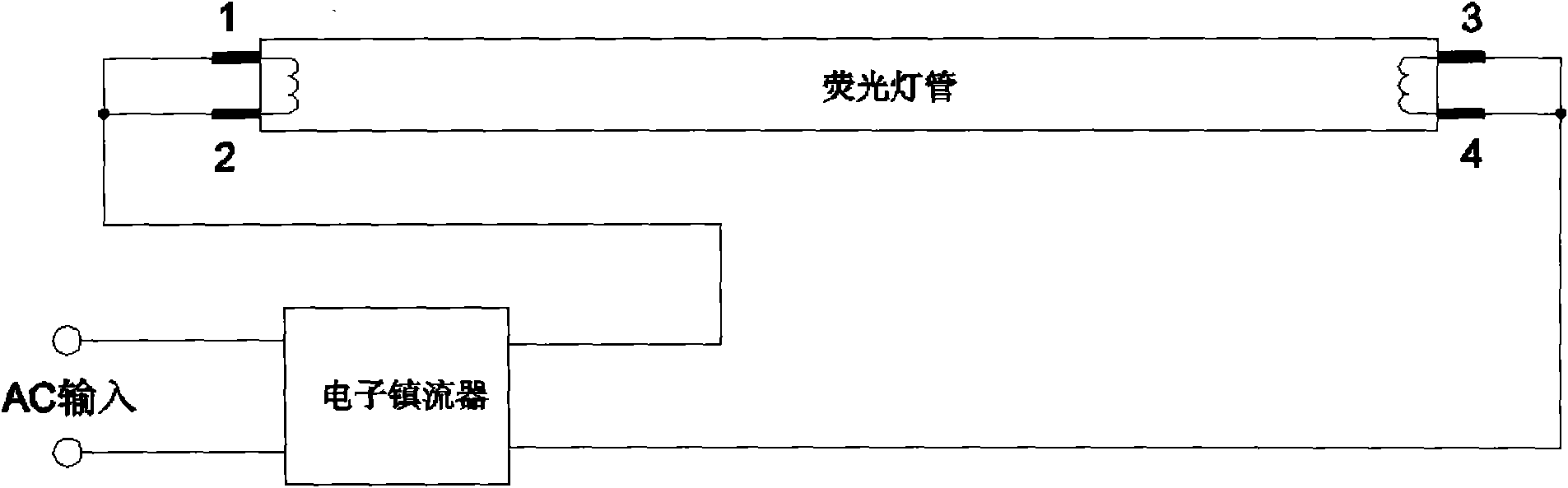

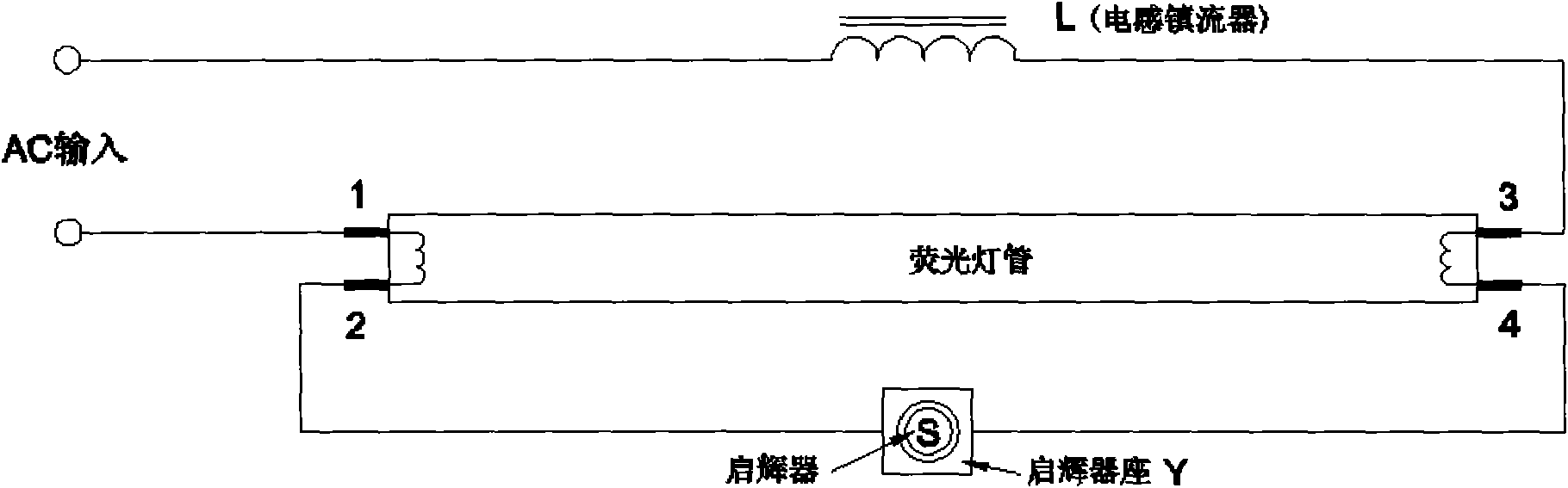

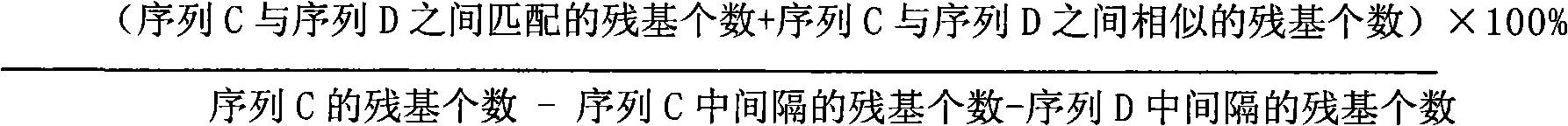

LED (light-emitting diode) fluorescent lamp and fluorescent lamp connecting circuit

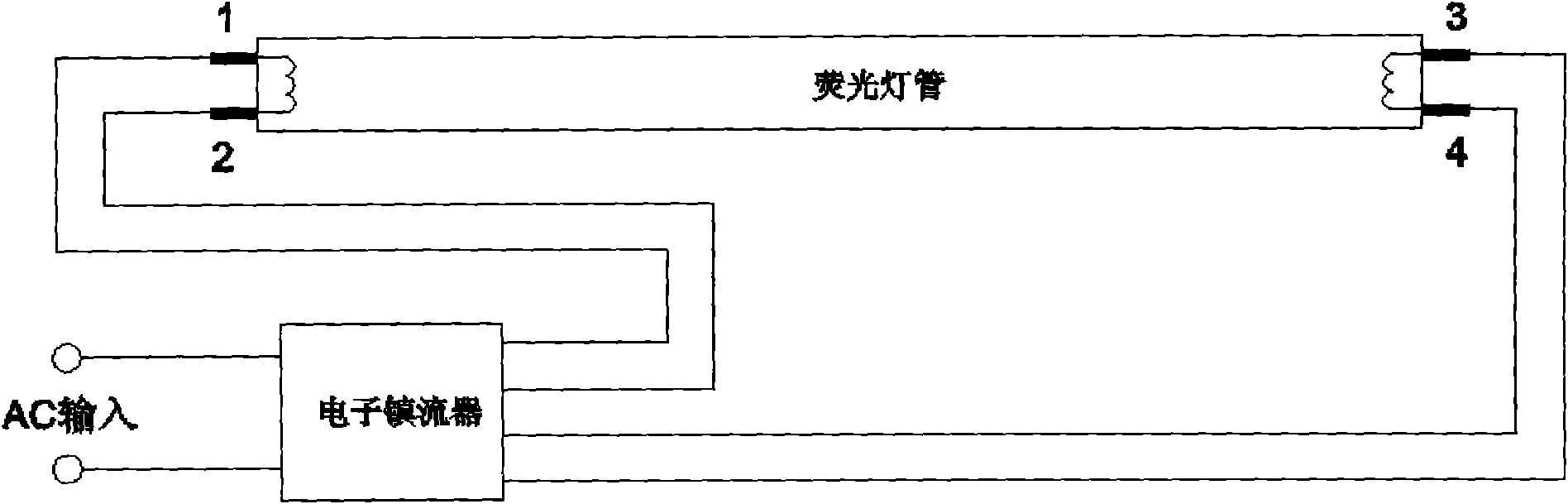

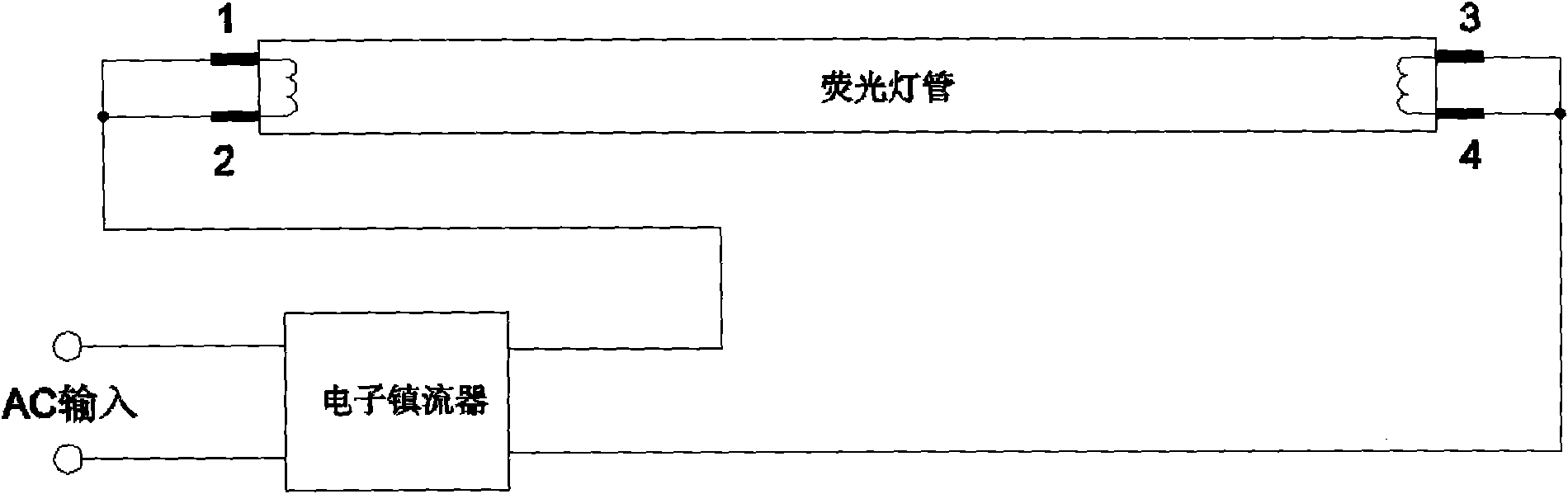

InactiveCN102155648ADoes not change the circuit structureNo change in structurePoint-like light sourceElectric circuit arrangementsEffect lightEngineering

The embodiment of the invention discloses an LED (light-emitting diode) fluorescent lamp and a fluorescent lamp connecting circuit. The LED fluorescent lamp comprises an LED fluorescent tube which comprises a first end closure and a second end closure; the two end closures respectively comprise two pins; a first inductance and a first bridge rectifier are connected in parallel between the two pins of the first end closure; a second inductance and a second bridge rectifier are connected in parallel between the two pins of the second end closure; output ends of the first bridge rectifier and the second bridge rectifier are connected in parallel with an LED lighting set; the LED lighting set comprises an LED light source group and a circuit for supplying a constant current or a constant voltage; a third inductance is connected in series between an input end of the LED lighting set and one pin of the second end closure; and a fourth inductance is connected in series between an output end of the LED lighting set and one pin of the first end closure. By adopting the LED fluorescent lamp and the fluorescent lamp connecting circuit, the LED fluorescent lamp can be directly used for replacing a fluorescent lamp under the condition that peripheral circuits of the traditional fluorescent lamp are not changed.

Owner:刘昌贵

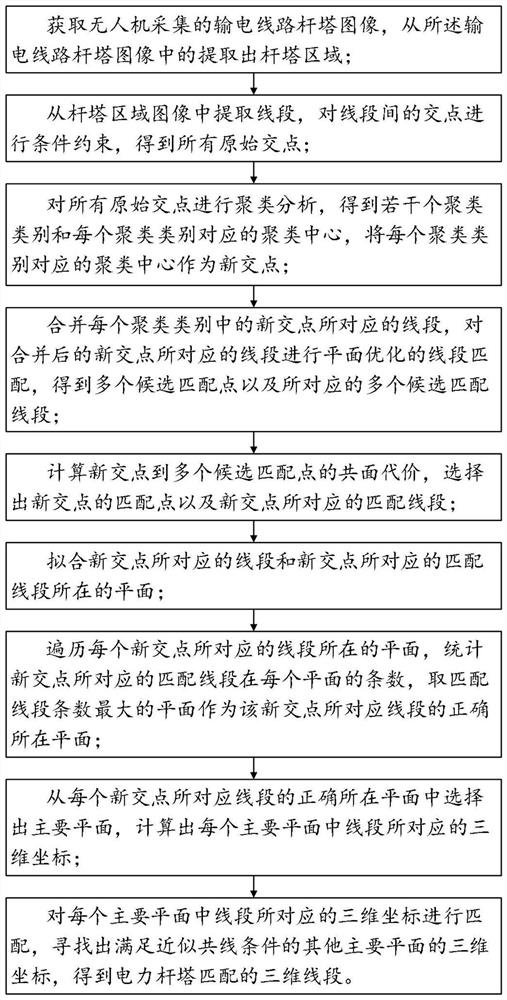

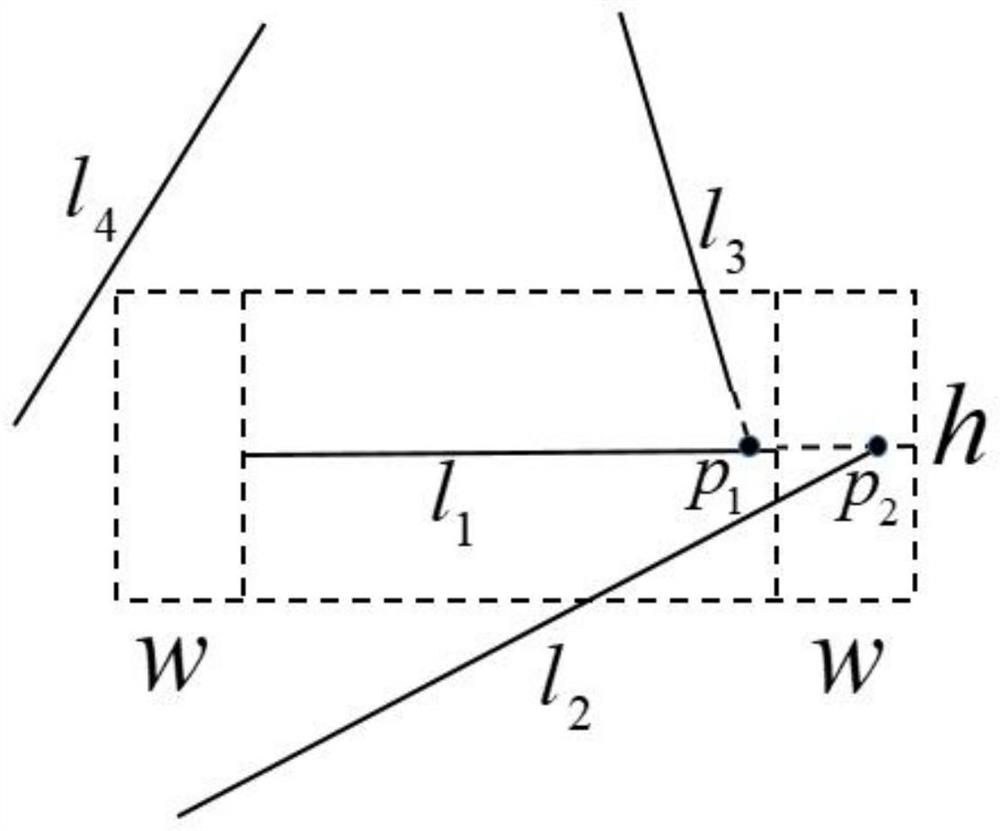

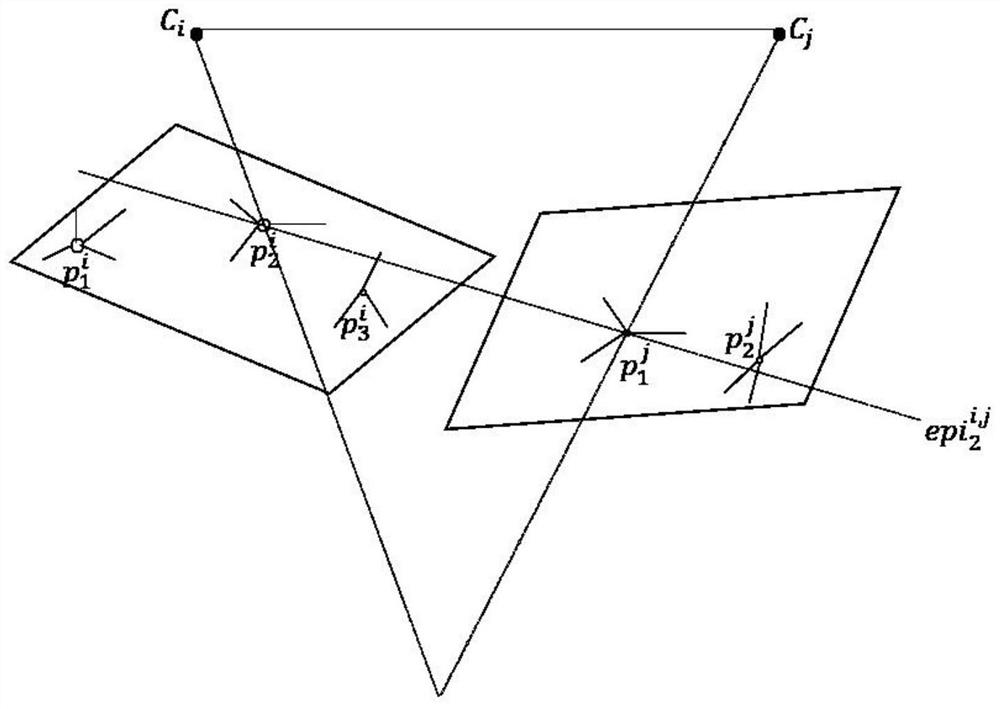

Power transmission line tower line segment matching method and equipment

ActiveCN111652163ANormal structureGuaranteed operational safetyImage analysisCharacter and pattern recognitionPower towerAlgorithm

The invention discloses a power transmission line tower line segment matching method and equipment. The method comprises the following steps: extracting a line segment from a tower region in a power transmission line tower image; performing conditional constraint on intersection points among the line segments to obtain original intersection points, clustering the original intersection points to obtain new intersection points, matching the line segments corresponding to the new intersection points based on a plane optimization and coplanar cost method, and selecting matching points of the new intersection points and matching line segments corresponding to the new intersection points; selecting the main planes from the planes by fitting the planes where the line segments are located, findingthe three-dimensional coordinates of other main planes meeting the approximately collinear condition according to the three-dimensional coordinates in the main planes, and therefore the three-dimensional line segments matched with the electric power tower are obtained. According to the method, a plurality of useless intersection points of the line segments are eliminated through a plane optimization and coplanar cost method, and finally, the three-dimensional line segment matching of the power tower is performed according to an approximate collinear condition, so that the line segment matching of the three-dimensional image of the power tower is realized in a large number of intersected line segments.

Owner:GUANGDONG POWER GRID CO LTD +1

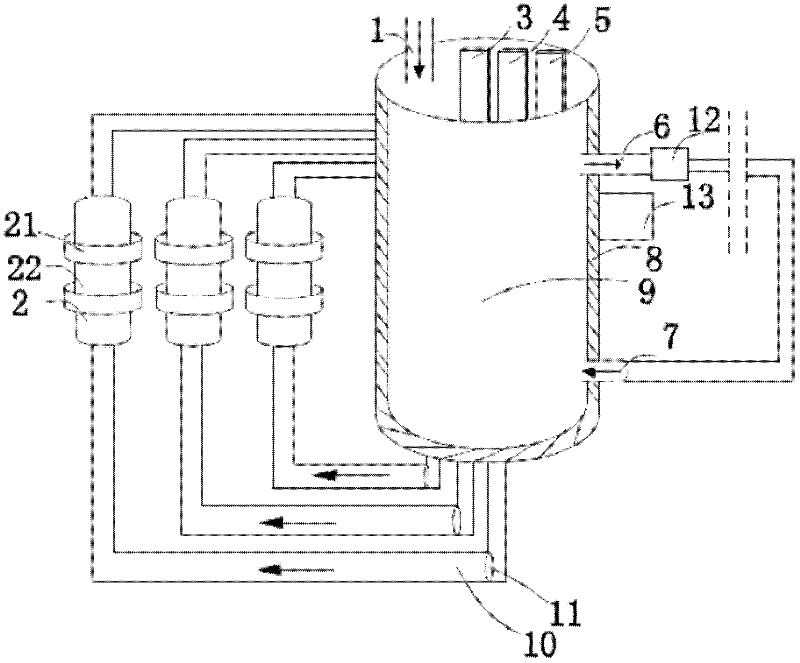

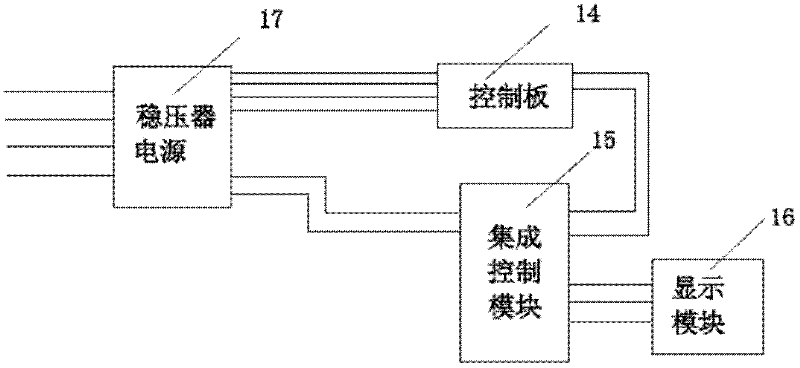

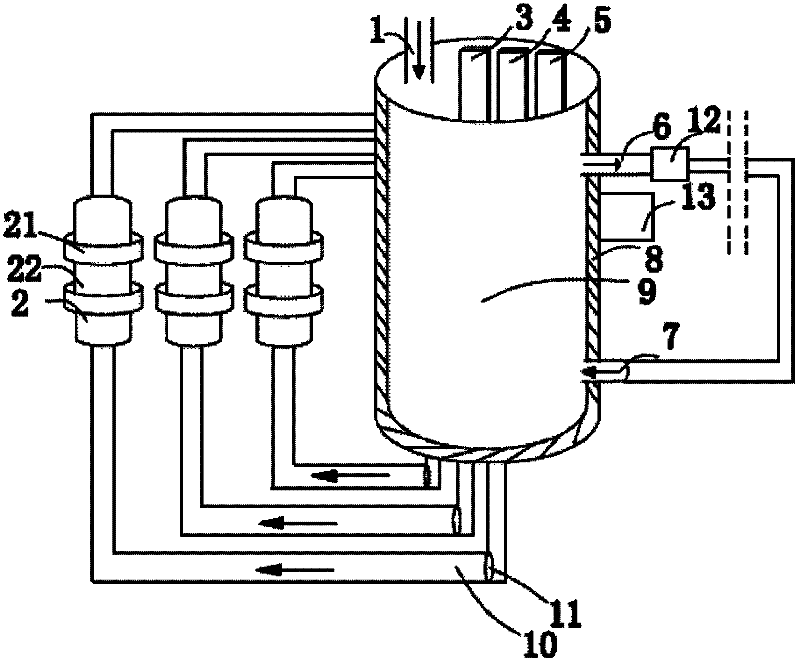

Variable-frequency electromagnetic heating device

InactiveCN102401420AAchieve separationEfficient use ofLighting and heating apparatusElectric heating systemEngineeringElectromagnetic heating

The invention discloses a variable-frequency electromagnetic heating device. The variable-frequency electromagnetic heating device comprises a hot water tank and a heating piece, and is characterized in that: a water inlet pipe, a water level detector, a pressure detector and a temperature detector are arranged at the upper end of the hot water tank; a water return pipe and a hot outlet pipe are arranged at the end on one side of the hot water tank; a hot water outlet pipe is connected with the heating piece; a heating device used for heating circulating water is connected out of the hot water tank through a diversion pipe; the heating device comprises a metal pipe and an electromagnetic induction heating coil; the electromagnetic induction heating coil is sleeved on the outer surface of the metal pipe; a diversion pump is arranged in the diversion pipe; and a control circuit for controlling the circulating water through the water level detector, the pressure detector, the temperature detector, the electromagnetic induction heating coil and the diversion pump is fixed to the hot water tank. The variable-frequency electromagnetic heating device performs circulation external heating on water, is safer in structure, reduces cost, prolongs service life, and achieves an energy-saving effect; and when a group of electromagnetic induction coils fail, other coils cannot be influenced, so that the system can be used normally and is convenient to use.

Owner:宁波高新区安立特电气科技有限公司

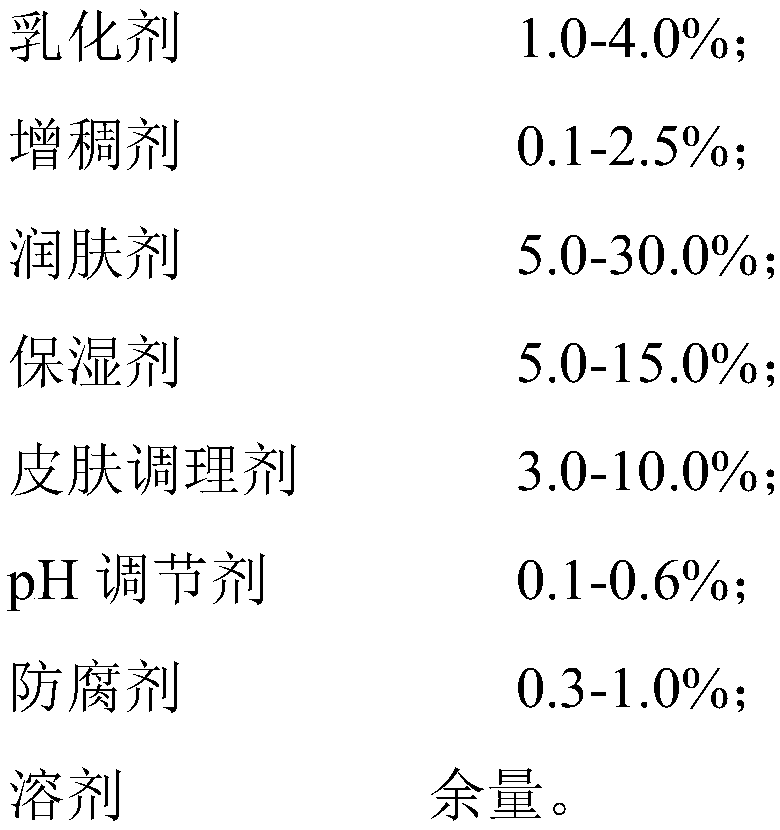

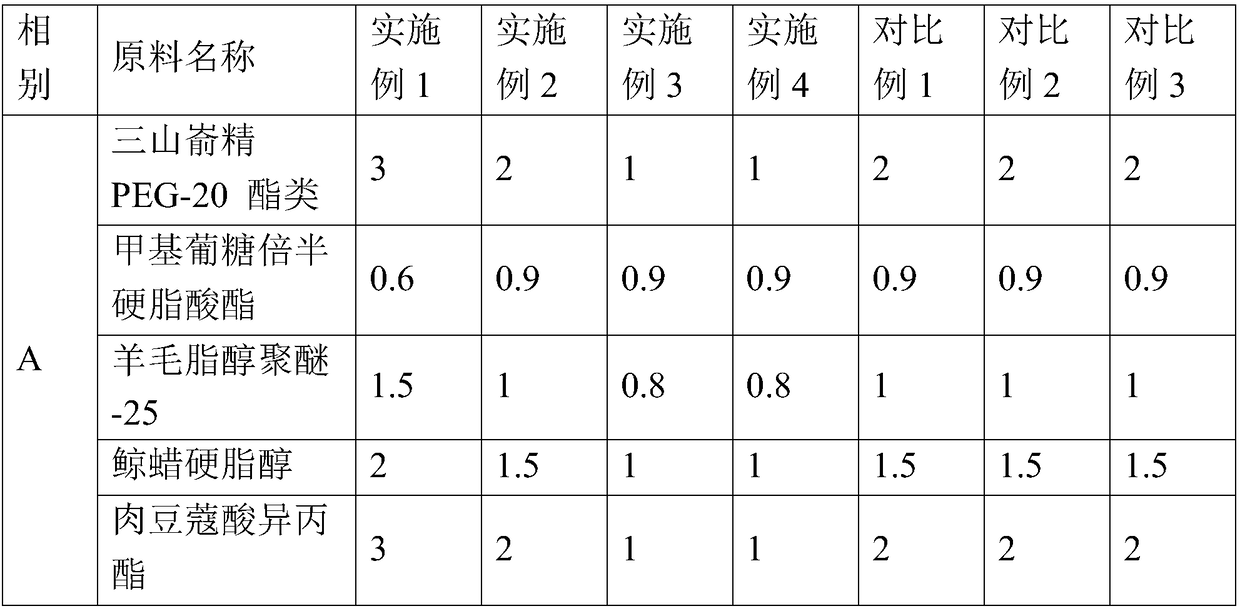

Anti-aging composition, cosmetics and preparation method thereof

InactiveCN108619075AKeep activePromote regenerationCosmetic preparationsToilet preparationsBiotechnologyNutrition

The invention provides an anti-aging composition which is characterized by comprising the following components in parts by weight: 1-5 parts of peony extract and 0.5-10 parts of stem cell culture solution. The above components are reasonably matched in a specific proportion to obtain the anti-aging composition; linoleic acid in the peony extract is converted into arachidonic acid in a human body and mutually cooperates with oligopeptides contained in the stem cell culture solution to form a normal cell structure, and maintain and regulate cell physiological functions and metabolic activities,so that skin cells keep active, and the skin cell regeneration is promoted, therefore, an anti-aging effect is effectively realized; in addition, in cooperation with antioxidant components and nutrients contained in the peony extract, the cell metabolism is regulated, the skin cell regeneration and the anti-oxidation are promoted, the four-effect combination of the nutrition components is provided, and the anti-aging effect is greatly improved.

Owner:BEIHAO STEM CELL & REGENERATIVE MEDICINE RES INST CO LTD

Protective lotion for anti-infrared radiation, anti-ultraviolet radiation, anti-dust and gas contamination

InactiveCN101554359ANormal structureIncreased ability to resist UVBCosmetic preparationsToilet preparationsDisinfectantChemistry

The invention relates to a protection lotion for anti-infrared radiation, anti-ultraviolet radiation, anti-dust and gas contamination, which comprises 0.5-4 of 18 ethanol, 1-10 of ring simethicone, 1-5 of triglyceryl caprylate / decanoate, 1-6 of stearate and stearic acid-glyceride, 1-5 of Isopropyl myristate, 1-8 of isopropyl palmitate, 0.01-0.1 of propylparaben, 0.01-0.2 of 2,6- -Di-tert-butyl-4-methylphenol, 2-15 of PROPANEDIOI, 5-20 of propanetriol, 0.05-0.4 of acrylic copolymer, 0.01-10 of heat shock protein active matter, 0.02-0.2 of methyl p-hydroxybenzoate, 40-60 of water, 0.2-0.5 of disinfectant, 0.01-0.1 of hyaluronic acid, 0.1-0.5 of essence, 0.1-3 of trolamine. The invention has prominent effects of anti-infrared, ultraviolet radiation and anti-dust and gas contamination and has good application prospect.

Owner:王善有

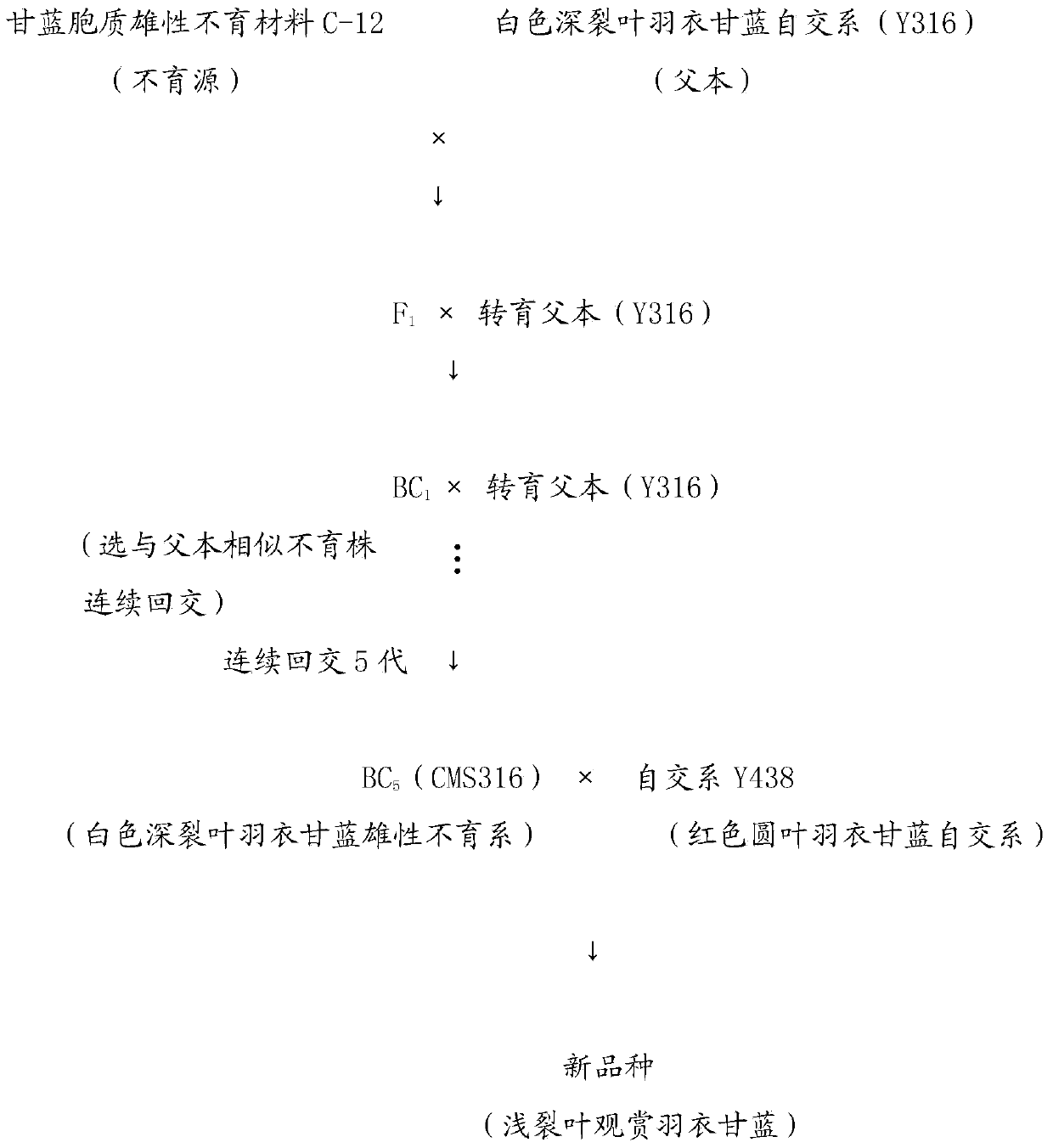

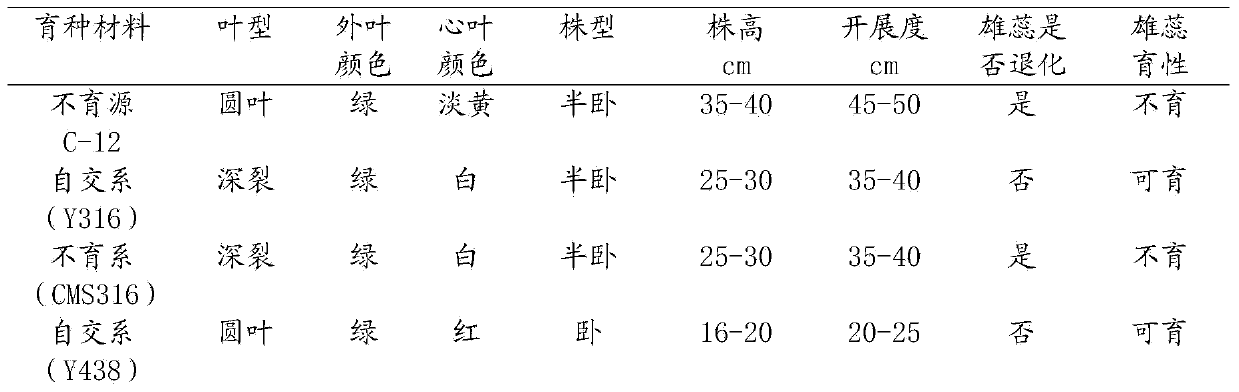

Breeding method of supersulcus-leaf Brassica oleracea var. acephala f. tricolor Hort.

ActiveCN103461104AEasy to change color in placeBright colorPlant genotype modificationBiotechnologyHybrid species

The invention discloses a breeding method of supersulcus-leaf Brassica oleracea var. acephala f. tricolor Hort., which comprises the following steps: carrying out inbred purification on collard species 'white peacock' to obtain white partite-leaf collard inbred line Y316, and hybridizing by using Y316 as a male parent and cabbage cytoplast male sterile material C-12 as a female parent; backcrossing with the original male parent by selecting an individual plant, which has the closest characters with the male parent, from filial generation as the female parent; repeating the second step, and continuously backcrossing to obtain white partite-leaf collard male sterile line CMS316; and carrying out inbred purification on the collard species 'red pigeon' to obtain red roundleaf collard inbred line Y438, and hybridizing by using Y438 as the male parent and the white partite-leaf collard male sterile line CMS316 as the female parent to obtain the supersulcus-leaf Brassica oleracea var. acephala f. tricolor Hort. hybrid. The new hybrid species obtained by the method disclosed by the invention has the advantages of high ornamental value, long ornamental period, cold resistance and disease resistance.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

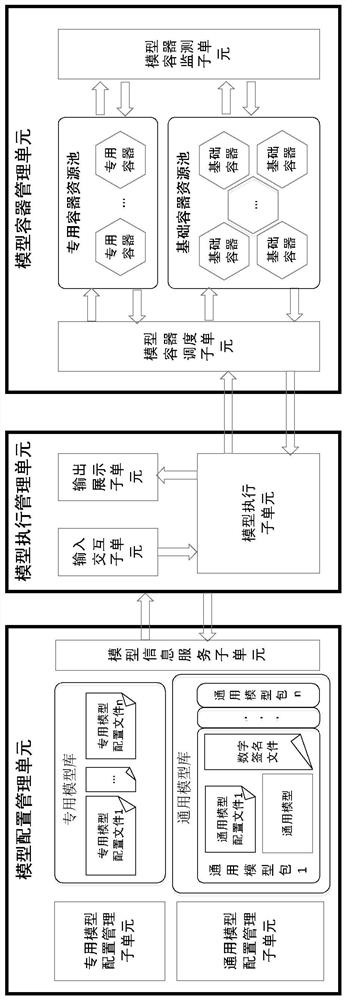

Data prediction system and method based on double-layer model structure

ActiveCN111752556AImprove reusabilityShorten the development cycleModel driven codeMarketingData predictionService system

The invention provides a data prediction system and method based on a double-layer model structure. The data prediction system comprises a model configuration management unit, a model execution management unit and a model container management unit. The model configuration management unit comprises a special model configuration management subunit, a general model configuration management subunit, ageneral model library, a special model library and a model information service subunit; the model container management unit comprises a model container scheduling subunit, a special container resource pool, a basic container resource pool and a model container monitoring subunit. The method has the following advantages: (1) through a double-layer model structure, the reuse degree of a general model can be greatly improved, so that the development period of a complex prediction model in each service system is shortened; and (2) normal, stable, safe and reliable operation of the double-layer model structure is ensured by adopting an isolated operation technical method of the container, and execution abnormity caused by conflict of execution of special models of different users is avoided.

Owner:自然资源部信息中心

Developing composite material, preparation method and application thereof, implantable and interventional medical instrument and preparation method of implantable and interventional medical instrument

PendingCN111760076ASuitable for extrusion molding processSimple manufacturing methodSurgeryComputational materials scienceSurface-active agentsReoperative surgery

The invention provides a developing composite material and a preparation method thereof. The composite material is prepared from the following raw materials in percentage by weight: 20%-80% of non-developing high-molecular polymer, 80%-20% of impermeability improver and 0-10% of surface active agent. When the composite material is prepared, a melting stirrer or an extruder is adopted for materialmixing or even mixing in a solvent, the solvent is removed, and then the composite material is granulated or extruded into wires or used for preparing medical instruments. Furthermore, the invention provides application of the composite material, an implantable and interventional medical instrument adopting the composite material and a preparation method of the instrument. The composite material is filamentous and also has a good developing effect, and the developing composite material which has a developer content exceeding 50% and is suitable for an extrusion process can be prepared by utilizing the method. The medical instrument prepared from the composite material has a good developing effect and is beneficial to intraoperative operation and postoperative follow-up visit.

Owner:BEIJING ADVANCED MEDICAL TECH

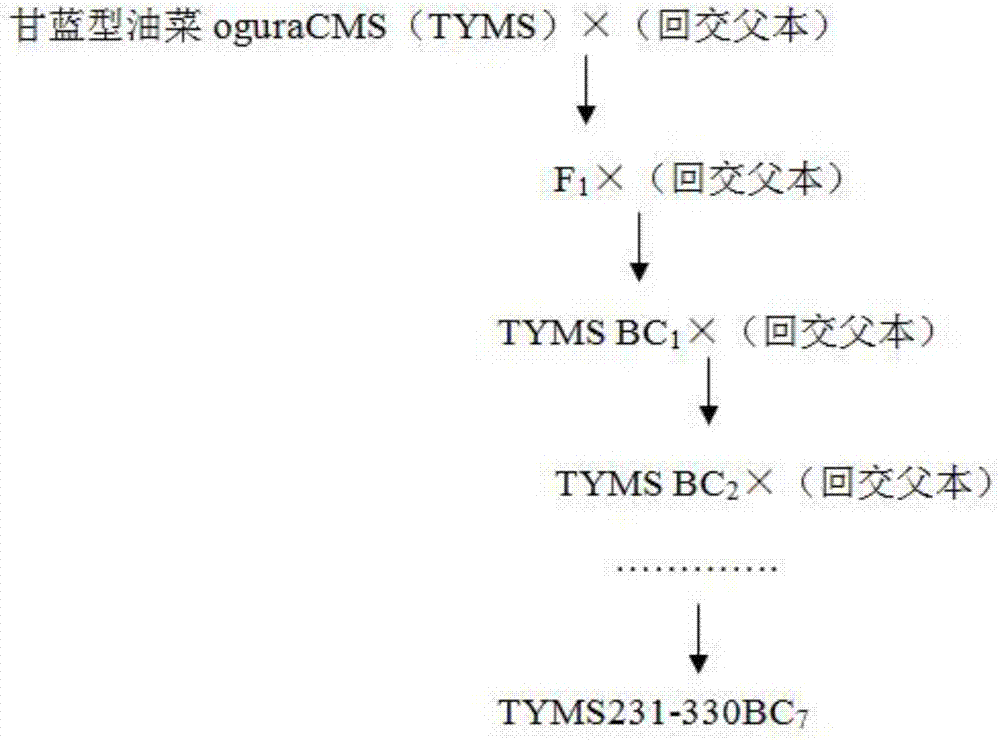

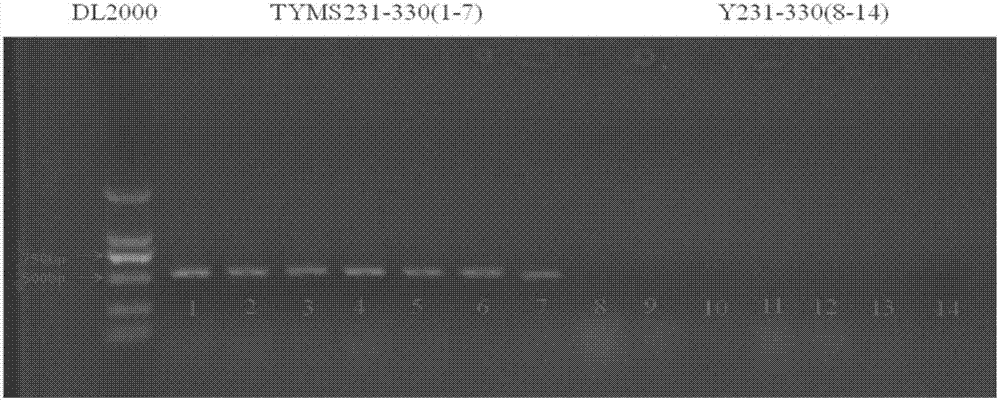

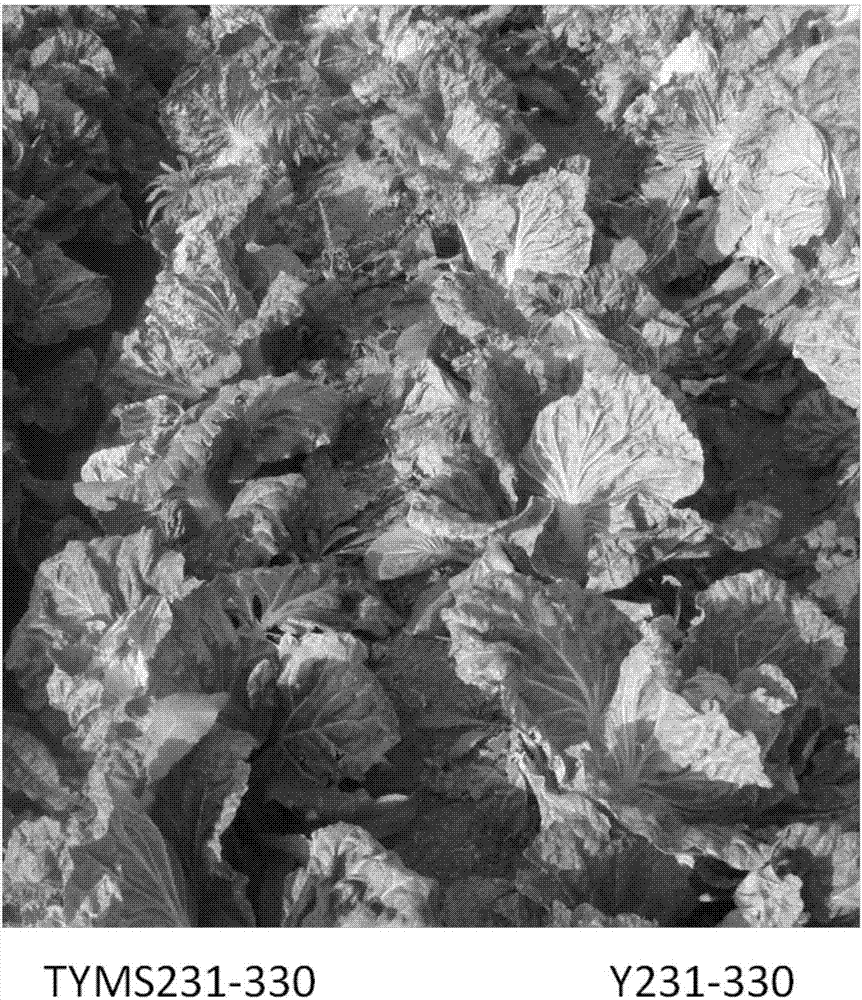

Breeding method of cytoplasmic male sterile early-maturing Chinese cabbage germplasm material

The invention discloses a breeding method of a cytoplasmic male sterile early-maturing Chinese cabbage germplasm material. The method comprises the steps of: with a brassica napus cytoplasmic male sterile material oguraCMS as a female parent and a Chinese cabbage precocious affinity early-maturing compatible line as a male parent, carrying out interspecific hybridization to obtain the first generation of bred seeds; and selecting superior individual plants with normal nectar but without aborted bud similar to the breeding male parent as the next round of backcross female parent, carrying out continuous seven generations of backcross breeding, carrying out field character selection to breed the cytoplasmic male sterile Chinese cabbage germplasm material TYMS231-330 which has stable sterility, and of which the sterile plant rate and the sterile degree reach 100% and the character is completely consistent with that of a corresponding maintainer line. According to the obtained sterile germplasm material TYMS231-330, the advantage of the male sterility of ogura cytoplasmic sterile source Chinese cabbage can be kept, the defects such as yellowing of plant leaves, nectary degradation and poor combining ability can be overcome, bees and the like can be attracted for normal pollination, the comprehensive resistance is high and the use value is high.

Owner:河南省农业科学院园艺研究所

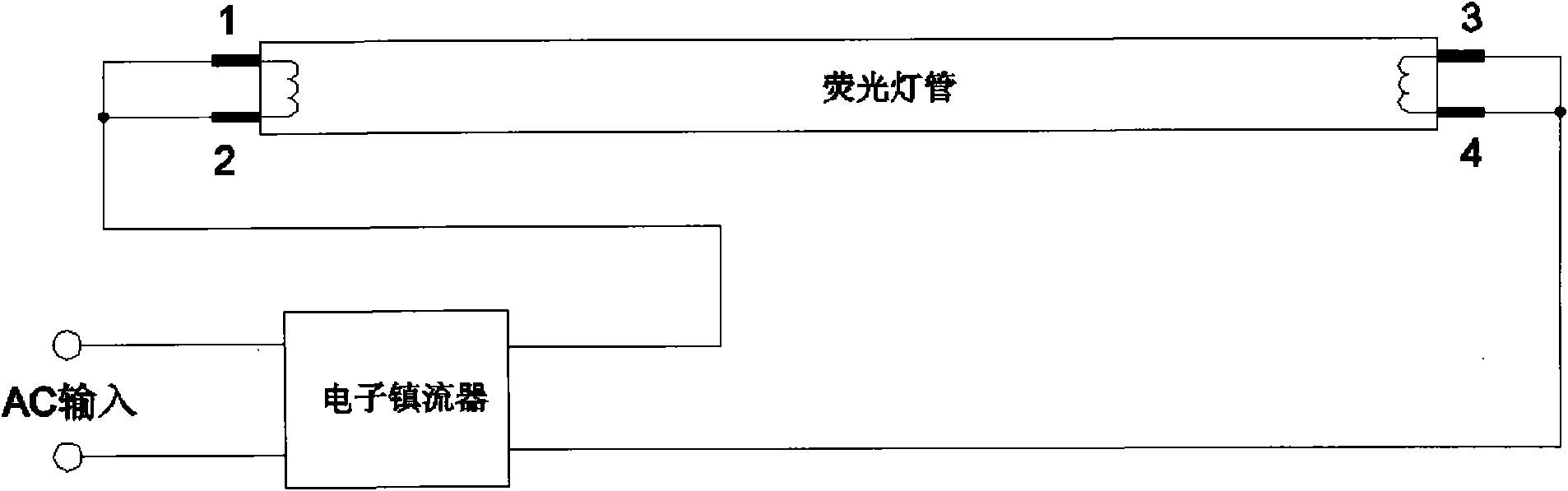

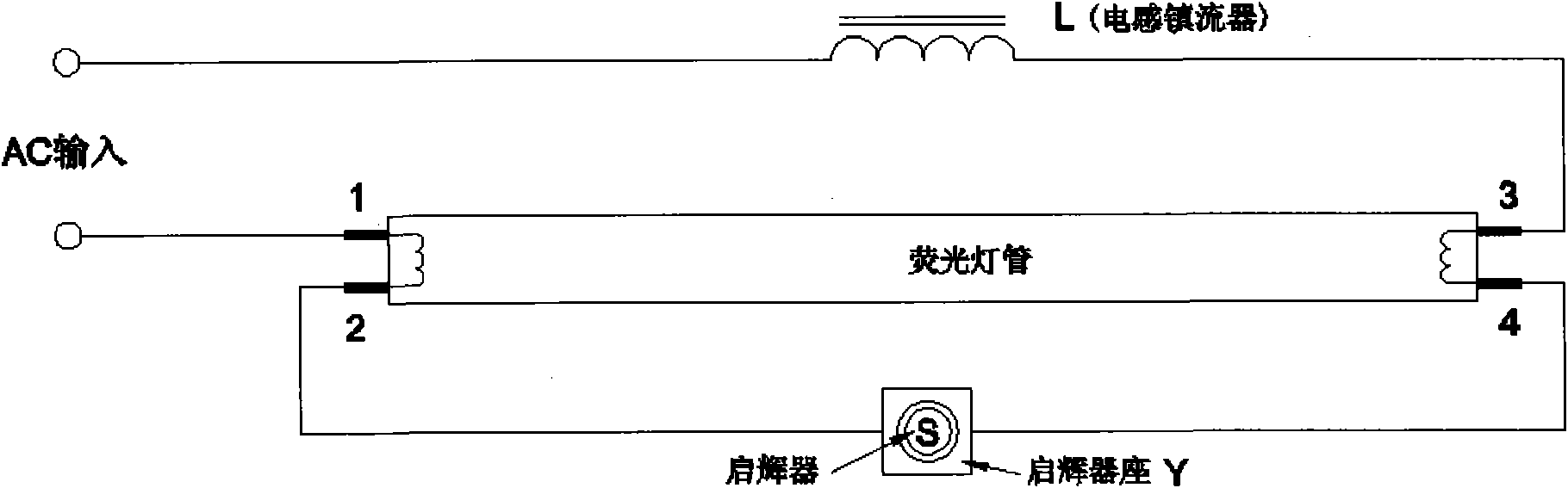

Light-emitting diode (LED) fluorescent lamp and connecting circuit thereof

InactiveCN102155641ADoes not change the circuit structureNo change in structurePoint-like light sourceElongate light sourcesPower flowEngineering

The embodiment of the invention discloses a light-emitting diode (LED) fluorescent lamp and a connecting circuit thereof. The LED fluorescent lamp comprises an LED fluorescent tube; the LED fluorescent tube comprises a first end cap and a second end cap, which comprise two pins respectively; a first inductor and a first bridge rectifier circuit are parallelly connected between the two pins of the first end cap; a second inductor and a second bridge rectifier circuit are parallelly connected between the two pins of the second end cap; a third inductor is serially connected between one pin of the first end cap and one pin of the second end cap; a forth inductor is serially connected between the other pin of the first end cap and the other pin of the second end cap; the output end of the first bridge rectifier circuit and the output end of the bridge rectifier circuit are parallelly connected with an LED lamp group which comprises an LED light source group and a circuit for supplying constant current and constant voltage. By the invention, the LED fluorescent lamp can be used for directly replacing a fluorescent lamp under the condition of no change of a peripheral circuit of the conventional fluorescent lamp.

Owner:刘昌贵

A kind of pharmaceutical composition for treating Hashimoto's thyroiditis and preparation method thereof

The invention relates to a pharmaceutical composition for treating Hashimoto's thyroiditis and a preparation method thereof. The pharmaceutical composition is composed of bupleurum, radix curcumae, prunella vulgaris, rhizoma Dioscoreae Nipponicae, thunberg fritillary bulb, radix scrophulariae, edible tulip, astragalus, dark plum and other components, and can be made into granules, capsules, tablets or pills by the conventional pharmaceutical processes. The pharmaceutical composition has the effects of soothing liver-qi stagnation, reducing phlegm, removing stasis, and softening hardness to dissipate stagnation, and applies to patients with Hashimoto's thyroiditis and thyroid nodules. Clinical studies have shown that the pharmaceutical composition can significantly improve the symptoms of Hashimoto's thyroiditis, reduce the thyroid volume and isthmus thickness, and reduce the level of TgAb and TPOAb, and the total effective rate is 97.22%. In addition, for patients with thyroid nodules, nodules can be significantly reduced or even disappeare, no significant adverse reactions are presented in the course of treatment. Experimental studies have shown that the pharmaceutical composition reduces the level of TgAb and TPOAb, and reduces inflammatory infiltration and thyroid follicular damage.

Owner:BEIJING UNIV OF CHINESE MEDICINE

Nursery pig feed containing chocolate powder

InactiveCN108552427AImprove palatabilityImprove immunityFood processingAnimal feeding stuffHybrid typeVitamin C

The present invention provides a nursery pig feed containing chocolate powder. The nursery pig feed containing the chocolate powder comprises the following components in parts by mass: 16-20 parts ofchocolate powder, 0.8-1.6 parts of a compound live micro-organism preparation, 24-32 parts of expanded soybeans, 14-18 parts of fermented soybean meal, 6-10 parts of alfalfa protein peptide powder, 6-10 parts of fish meal, 3-5 parts of calcium dihydrogen phosphate, 4-8 parts of calcium citrate, 2-5 parts of sodium chloride, 3-7 parts of compound trace elements, 3-7 parts of compound amino acids, 6-10 parts of choline, 0.1-0.3 part of multivitamin, 0.10-0.20 part of vitamin C, 3-6 parts of a compound acidifier, 5-8 parts of a growth promoting agent, 1-2 parts of a mixed type feed additive, and0.5-1.5 parts of an antioxidant. The nursery pig feed is strong in attracting ability and fast in energy supplement, also has intestinal bacteriostasis functions, and is the virtuous-circle environmental-friendly feed under trends of replacing and forbidding antibiotics.

Owner:河南农科牧业有限公司

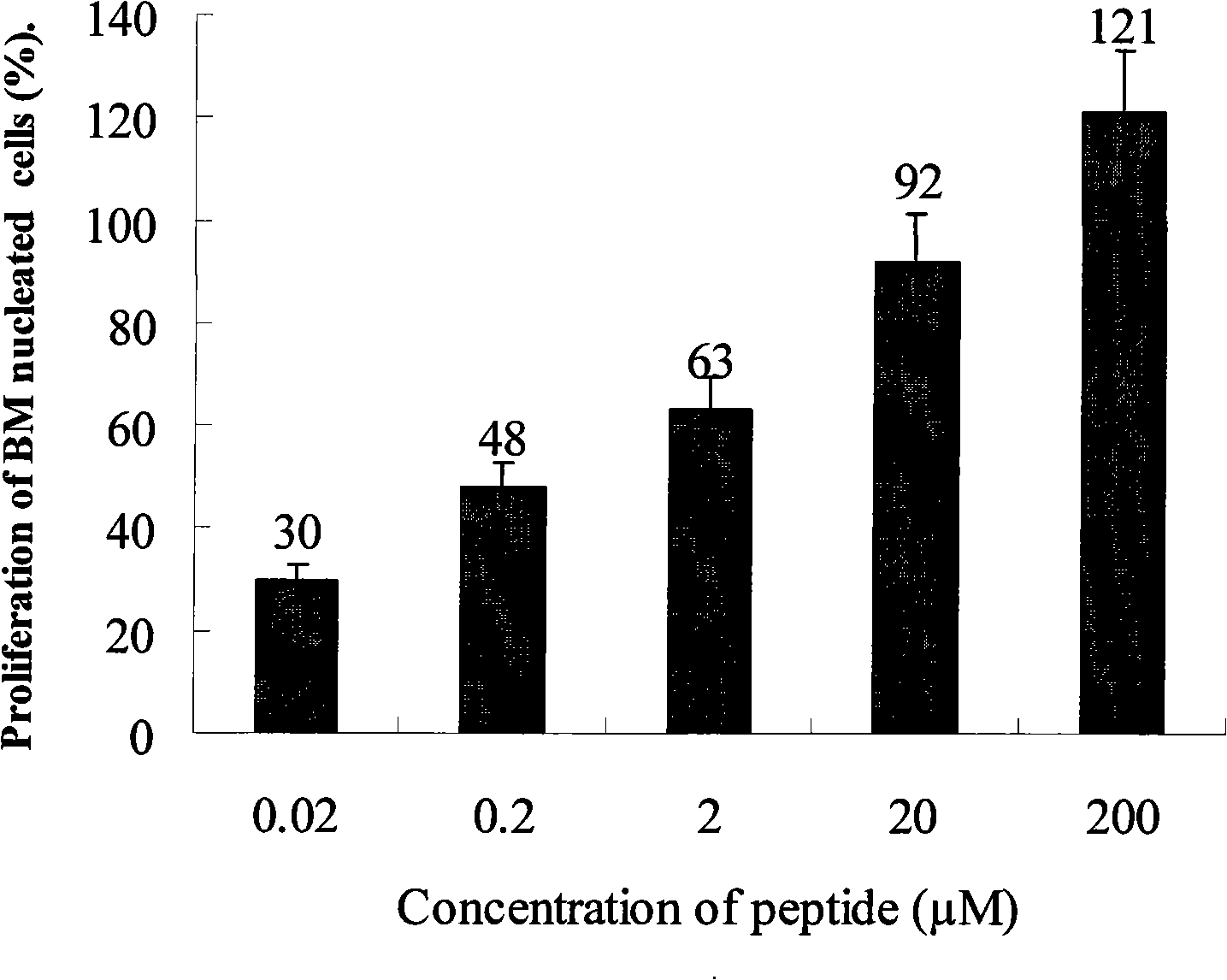

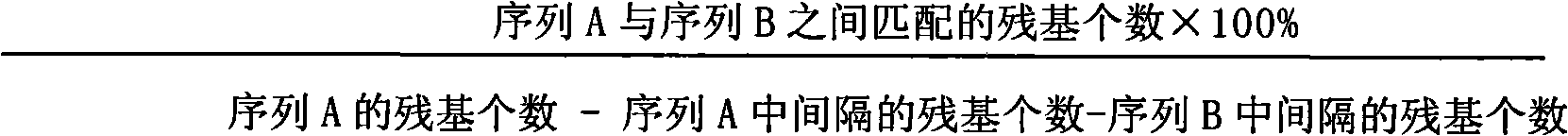

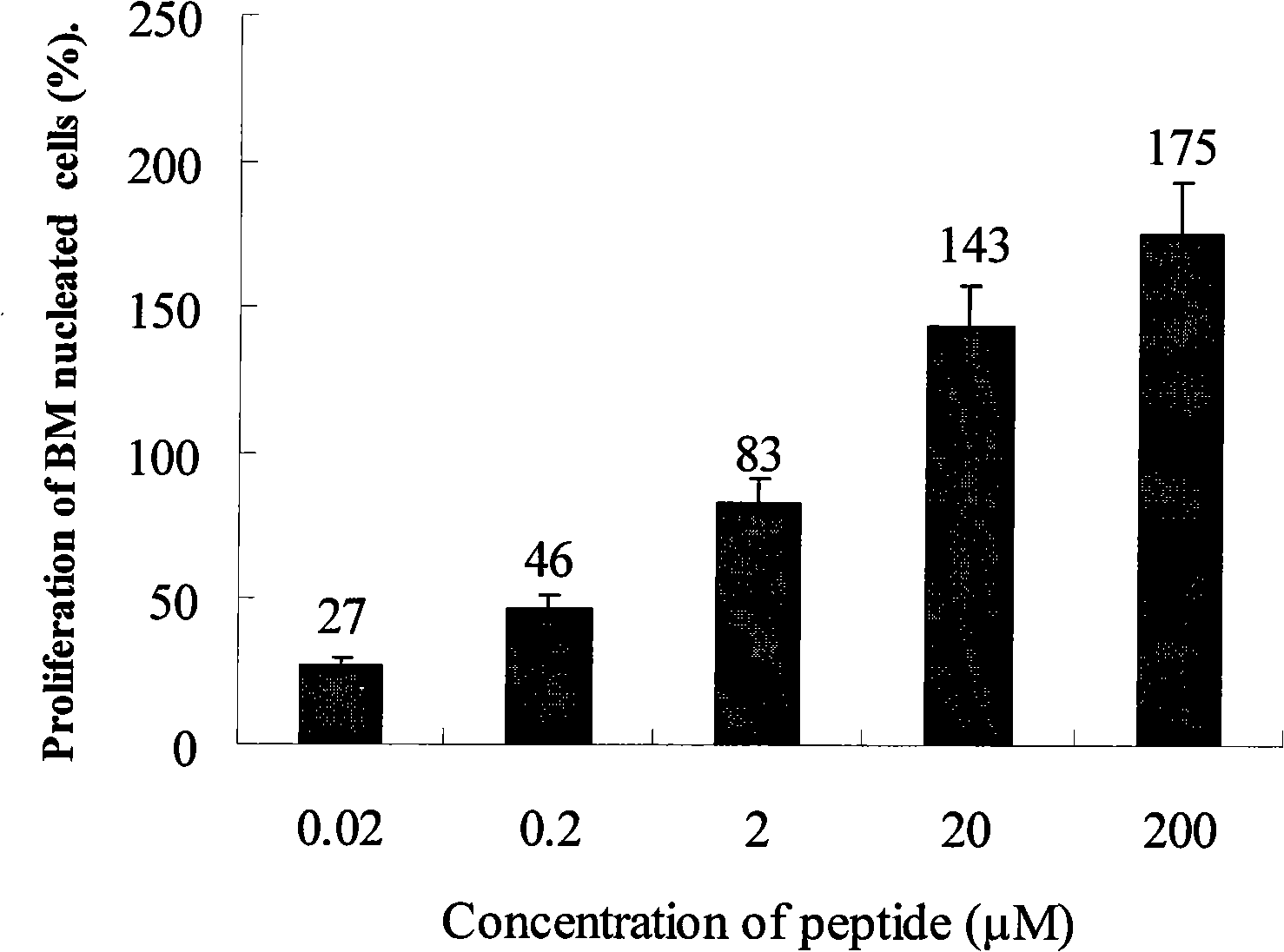

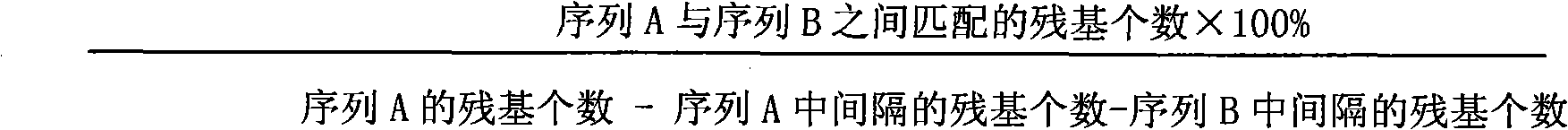

Peptide medicament series for accelerating medulla hematopoiesis cell proliferation

InactiveCN101270152APromote cell proliferationNormal cell structureOrganic active ingredientsSugar derivativesBone Marrow Blood-Forming CellPeptide analog

The present invention provides peptide drug series that can promote the proliferation of marrow hematopoietic cells. The main amino acid sequence of the short peptide fragments, analogs, derivants and variants of the short peptide of the peptide drug series is larger than or equal to 70 percent equal to and larger than or equal to 90 percent similar to the main amino acid sequence of the short peptide. The short peptide, nucleotides, short peptide fragments, short peptide analogs, short peptide derivants and short peptide variants are used for the preparation of drugs for treating manifold marrow hematopoietic cell defection diseases, congenital anaemia, aplastic anemia and various hemorrhagic anemia diseases and can be applied to the bone marrow transplantation of leukemia patients, etc., that is, the peptide drug of the present invention can treat pancytopenia caused by hemopoietic stem cell defects.

Owner:FUZHOU UNIVERSITY

Light-emitting diode (LED) fluorescent lamp and connecting circuit thereof

InactiveCN102155649ADoes not change the circuit structureNo change in structurePoint-like light sourceElongate light sourcesCapacitanceEngineering

The embodiment of the invention discloses a light-emitting diode (LED) fluorescent lamp and a connecting circuit thereof. The LED fluorescent lamp comprises an LED fluorescent tube; the LED fluorescent tube comprises a first end cap and a second end cap, which comprise two pins respectively; a first inductor and a first bridge rectifier circuit are parallelly connected between the two pins of thefirst end cap; a second inductor and a second bridge rectifier circuit are parallelly connected between the two pins of the second end cap; a first inductor is serially connected between one pin of the first end cap and one pin of the second end cap; a second inductor is serially connected between the other pin of the first end cap and the other pin of the second end cap; the output end of the first bridge rectifier circuit and the output end of the bridge rectifier circuit are parallelly connected with an LED lamp group which comprises an LED light source group and a circuit for supplying constant current and constant voltage. By the invention, the LED fluorescent lamp can be used for directly replacing a fluorescent lamp under the condition of no change of a peripheral circuit of the conventional fluorescent lamp.

Owner:刘昌贵

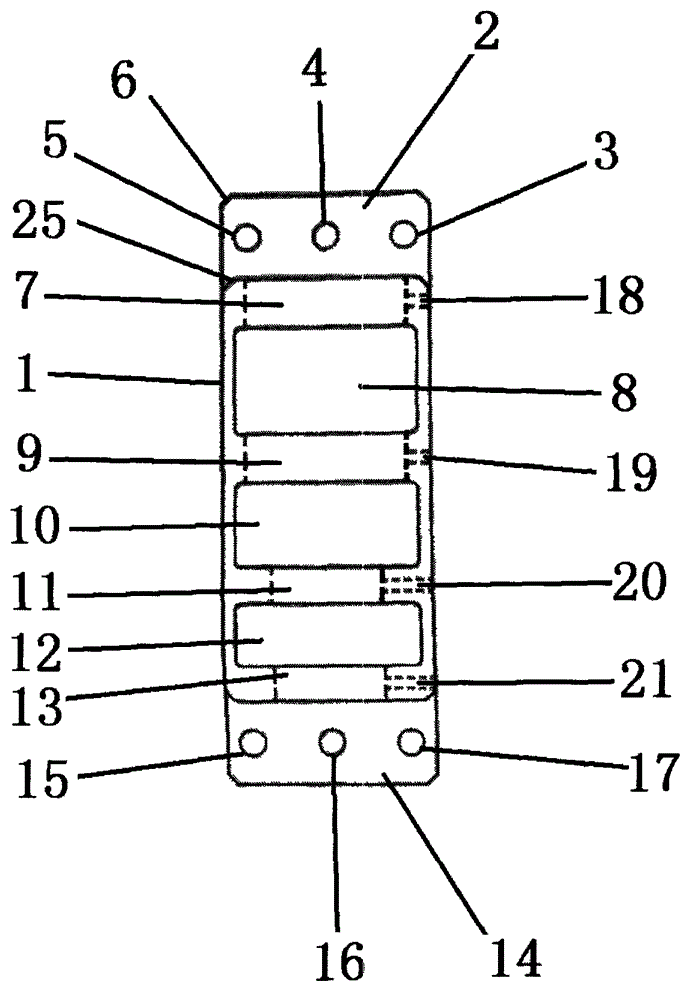

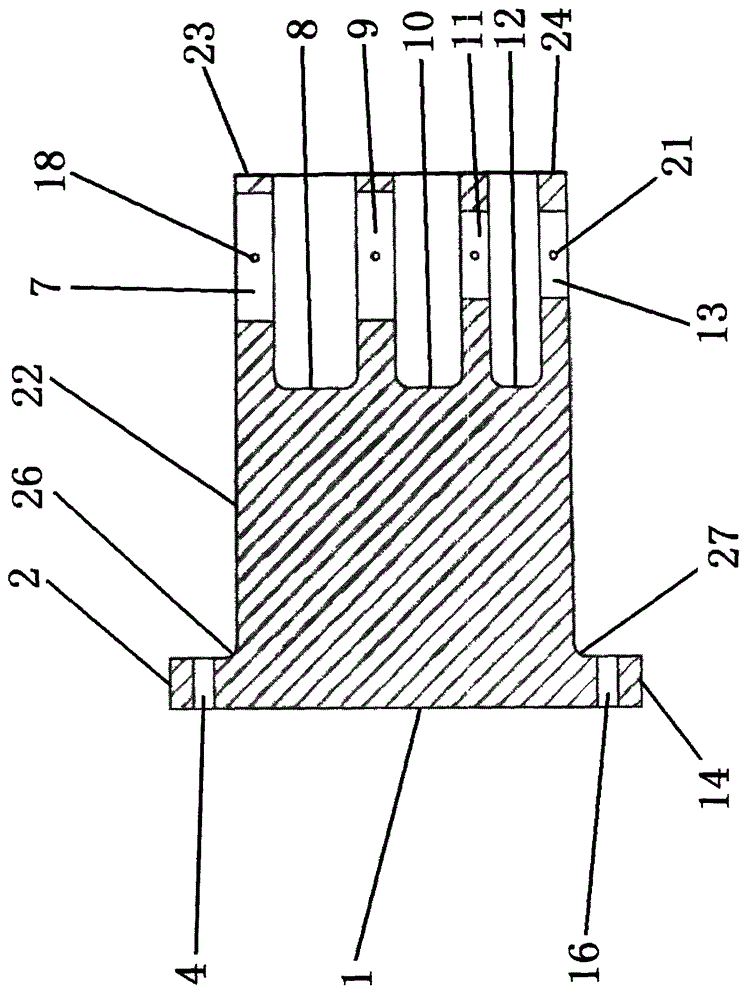

Dead axle seat of screw tap relief grinding machine

The invention discloses a dead axle seat of a screw tap relief grinding machine, comprising a metal seat which is a vertical metal block; the metal seat is formed by connecting an upper part, a middle part and a lower part; a first through hole, a second through hole and a third through hole are drilled in the front of the upper part of the metal seat from the right to the left; a fourth through hole, a fifth through hole and a sixth through hole are drilled in the front of the lower part of the metal seat front the left to the right; the upper part and the lower part of the metal seat are symmetric; the middle part of the front of the metal seat is provided with a metal board; an upper hole, a middle hole and a lower hole are dug backwards in the front of the metal board; the front part of the metal board is partitioned into four laminates, namely a first laminate, a second laminate, a third laminate and a fourth laminate; a first axle hole drilled in the first laminate, a second axle hole drilled in the second laminate, a third axle hole drilled in the third laminate and a fourth axle hole drilled in the fourth laminate are through holes and concentric circles; a first threaded hole, a second threaded hole, a third threaded hole and a fourth threaded hole are correspondingly drilled in the right surfaces of the first laminate, the second laminate, the third laminate and the fourth laminate; and the first axle hole, the upper hole, the second axle hole, the middle hole, the third axle hole and the lower hole are communicated with each other.

Owner:PINGHU CITY SHANTE THREAD TOOL

Herbal female inflammation treatment preparation for repairing internal vaginal environment and preparation method of herbal female inflammation treatment preparation

InactiveCN107362310APromote recoveryPromote proliferationInorganic boron active ingredientsHydroxy compound active ingredientsSide effectAntibiotic Y

The invention provides a herbal female inflammation treatment preparation for repairing an internal vaginal environment, and belongs to the field of medicine preparations. The herbal female inflammation treatment preparation is made of the following raw materials in parts by weight: 50-80 parts of RADIX SOPHORAE FLAVESCENTIS, 15-40 parts of radix stemonae, 15-40 parts of fructus cnidii, 15-40 parts of hairyvein agrimony, 15-40 parts of Japanese beauty-berry leaves, 0.5-2.0 parts of alum, 0.1-2.0 parts of borneol, 0.5-2.0 parts of camphor, 1-15 parts of boric acid, 220-350 parts of glycerinum and 80-110 parts of gelatin. By adopting the herbal female inflammation treatment preparation, ecological balance in a vagina can be reconstructed, and inflammation can be controlled. Meanwhile, the herbal female inflammation treatment preparation is prepared from traditional Chinese herbal medicines, so that side effects and adverse effects of antibiotics can be effectively avoided.

Owner:贵州长生药业有限责任公司

Peptide medicaments for accelerating medulla hematopoiesis cell proliferation

InactiveCN101270151APromote proliferationNormal structureOrganic active ingredientsSugar derivativesHematopoietic cellMiddle medulla

The present invention provides a peptide drug that can promote the proliferation of marrow hematopoietic cells. The main amino acid sequence of the short peptide fragments, analogs, derivants and variants of the short peptide is larger than or equal to 70 percent, equal to and larger than or equal to 90 percent similar to the main amino acid sequence of the short peptide. The short peptide, nucleotides, short peptide fragments, short peptide analogs, short peptide derivants and short peptide variants are used for the preparation of drugs for treating manifold marrow hematopoietic cell defection diseases, congenital anaemia, aplastic anemia and various hemorrhagic anemia diseases and can be applied to the bone marrow transplantation of leukemia patients, etc., that is, the peptide drug of the present invention can treat pancytopenia caused by hemopoietic stem cell defects.

Owner:FUZHOU UNIV

Application of flavone compound or composition thereof to protection of red cell from injury

ActiveCN108210930ANormal structureNormal functionMaterial analysis by optical meansMammal material medical ingredientsFood additiveWhole blood product

The invention discloses application of a flavone compound and / or a composition containing the flavone compound to the protection and / or prevention of a red cell from an injury and to the maintenance of the quality of a blood product. According to the application, a human red blood cell can be effectively protected and even preventatively protected, and is enabled to be capable of resisting the damage of acidic, alkaline, osmotic pressure-abnormal, anoxic and peroxidated environments deviating from a normal physiological condition and a shear-stress injury caused under high-centrifugal-force washing action; the red cell is enabled to be capable of maintaining the normal structure and function of the red cell. The invention also discloses a method for protecting and / or preventatively protecting the red cell from being injured and maintaining the quality of the blood product. The method is simple in step and safe and convenient to operate; the used flavone compounds of hydroxysafflor yellow A and the like are a medicinal raw material and a food additive which are nationally approved for use; a complex radix angelicae sinensis injection is also a standard traditional Chinese medicinalset-prescription preparation nationally approved for use, and the application is safe and effective, and has a wide application prospect.

Owner:JINAN UNIVERSITY

Lactic acid compound bacteria and preparation of lycopene camel milk lozenge with assisted antihypertensive function

ActiveCN106259893AImprove gut floraImprove digestionMilk preparationBifidobacterium bifidumFilm-coated tablet

The invention discloses a lactic acid compound bacteria and preparation of lycopene camel milk lozenge with assisted antihypertensive function. According to the invention, lactobacillus casei, enterococcus faecium, lactobacillus bulgaricus, streptococcus thermophilus, lactobacillus rhamnosus, lactobacillus acidophilus, lactobacillus plantarum, diacetyl streptococcus and bifidobacterium bifidum are mixing and fermented according to the volume ratio of 2:1:4:2:1:4:2:1:0.5 so as to prepare the probiotics yogurt; camel milk grains and lycopene grains are prepared respectively by fermentation; a double-layer tablet is prepared according to the weight ratio of 1:1; the double-layer tablet is coated by a prepared film coating fluid; hot air with temperature of 30-40 DEG C is blown so that the weight of the double-layer tablet is increased by 2-3%; and then the tablet is dried and cured, thus preparing the lycopene camel milk lozenge. The prepared lycopene camel milk lozenge contains a large amount of probiotics and lactic acid bacteria, can improve the intestinal flora of the human body and improve the digestive function of the human body, has the liver protecting function, and has wide and applicable value.

Owner:天山牧歌投资管理有限公司

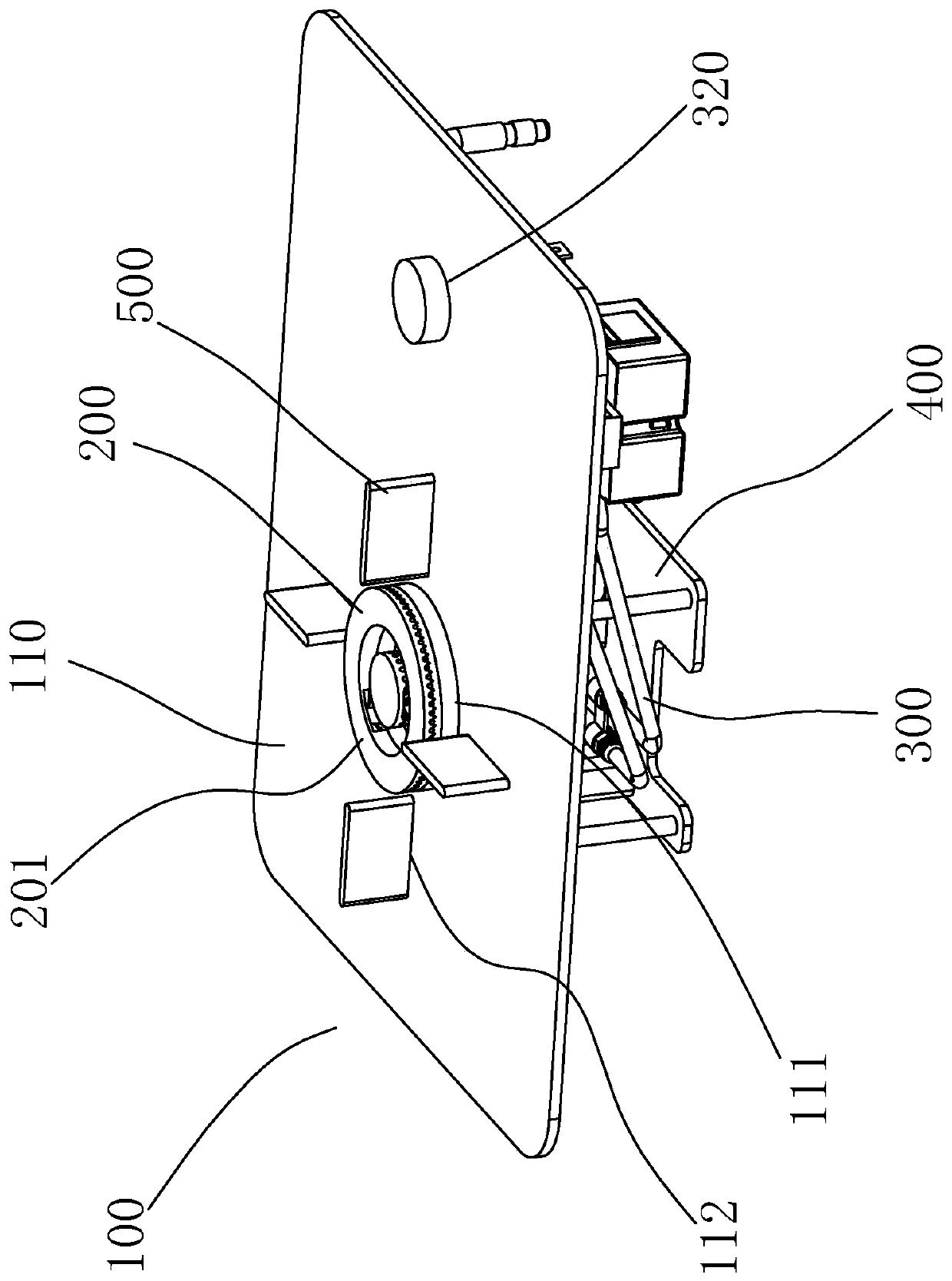

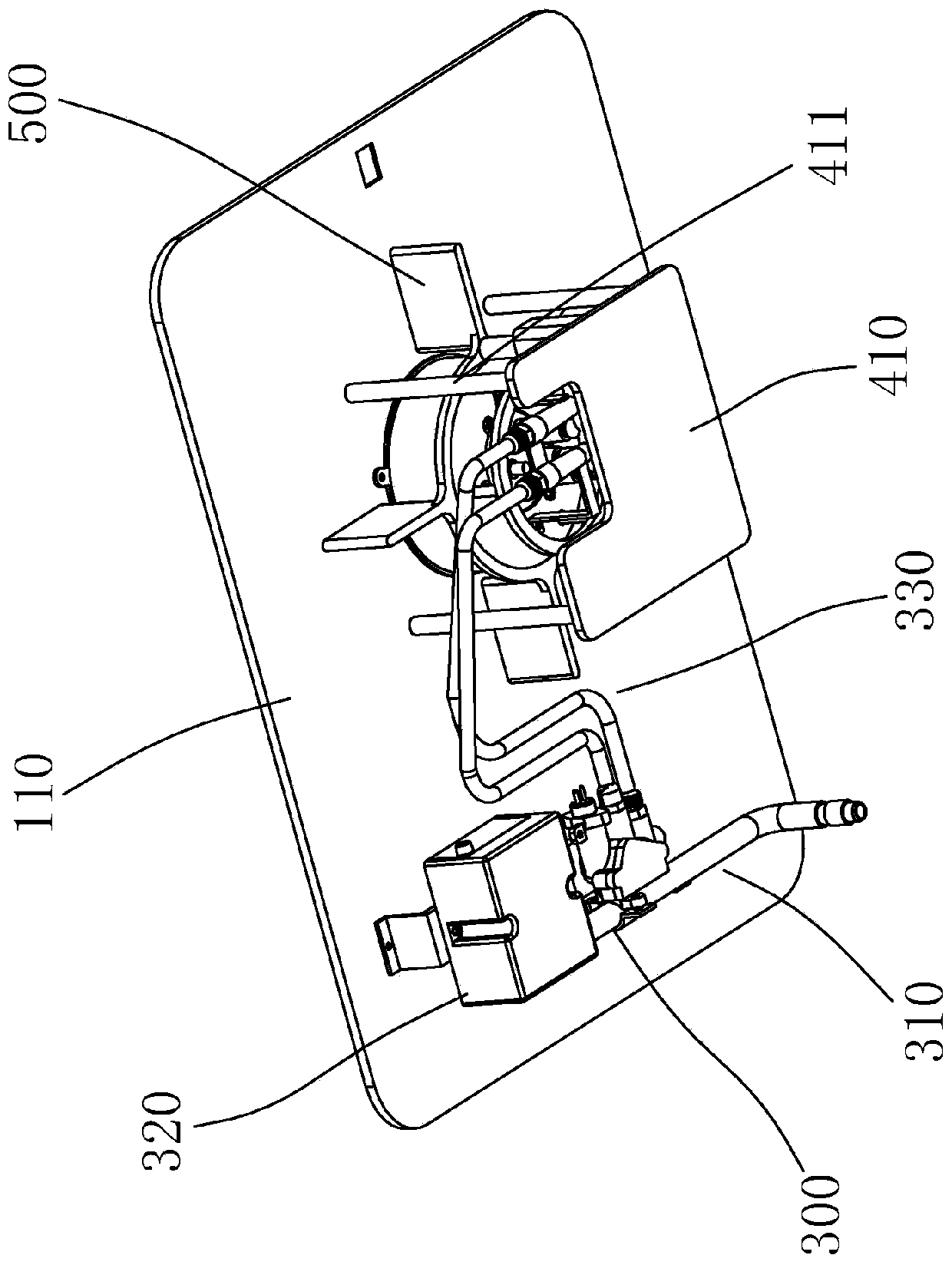

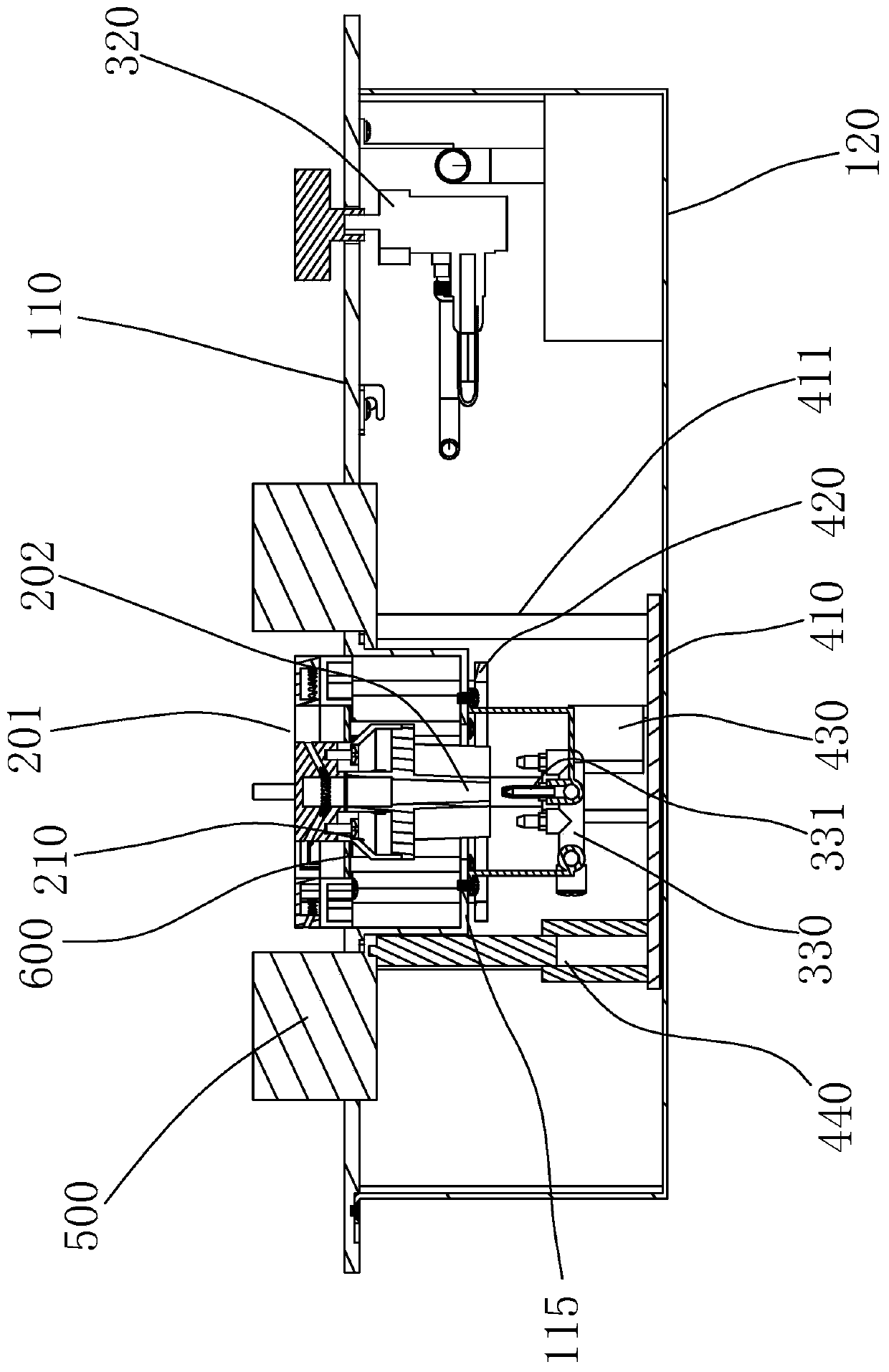

Lifting type gas stove

PendingCN110440302AGood planarization effectOptimize gas path designDomestic stoves or rangesLighting and heating apparatusSpray nozzleEngineering

The invention discloses a lifting type gas stove which comprises a stove body. The stove body comprises a panel; a combustor is arranged in the stove body; a lifting device and a nozzle are arranged in the stove body; a furnace end through hole is formed in the panel; the combustor comprises a furnace end and an injection pipe; the lifting device drives the combustor to lift up and down; the nozzle is fixed onto the stove body; the axial direction of the injection pipe is the vertical direction; the injection pipe comprises a gas inlet end; the nozzle directly faces the gas inlet end of the injection pipe; and when the combustor is lifted up to be in place, the nozzle faces the gas inlet end of the injection pipe; and a gap for air to enter is arranged between the gas inlet end and the nozzle. According to the lifting type gas stove provided by the invention, the lifting device is utilized for driving the combustor to lift up and down, so that the stove has a favorable plane effect; and meanwhile, a gas circuit design in the gas stove is optimized, so that the lifting type gas stove provided by the invention is simple, convenient and reasonable in structure, stable in gas supply, and convenient for product marketization.

Owner:GUANGDONG MACRO GAS APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com