Dead axle seat of screw tap relief grinding machine

A tap relief grinding and shaft fixing technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of structural relief grinding dislocation, low precision, and blade curling, etc., and achieve correct design, high precision, and sharp cutting edge sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

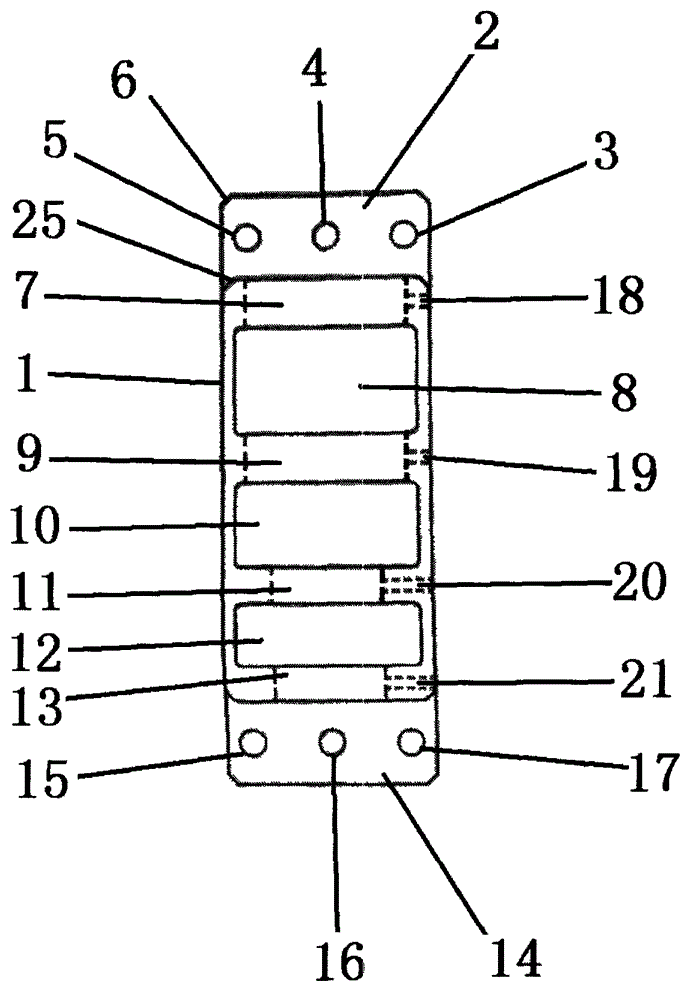

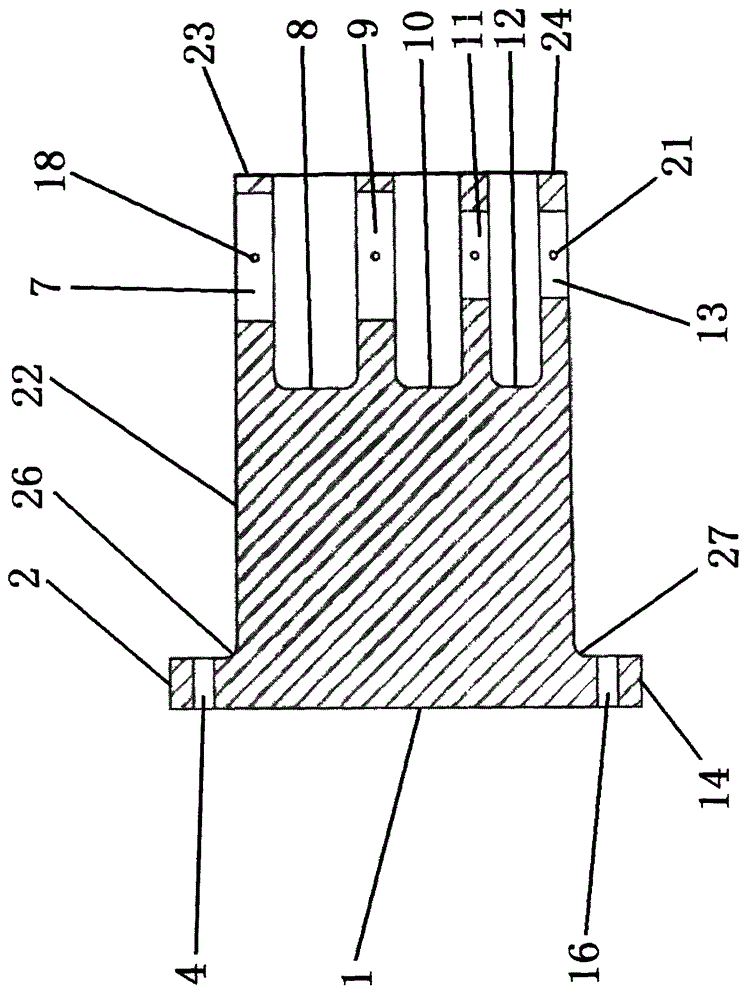

[0009]The fixed shaft seat of the tap shovel mill includes a metal seat, a metal plate and a hole. It is characterized in that the metal seat 1 is an upright metal block. The left and right lengths of the metal seat 1 are 100mm, and the upper and lower heights are 280mm. , the rear width is 30mm; the left, right, upper and lower four corners of the metal seat 1 are respectively turned into chamfers 6 of 45 degrees, and the chamfering distance is 5mm; the metal seat 1 has three parts: the upper part 2, the middle part and the lower part 14 Siamese composition; on the front surface of the upper part 2 of the metal seat 1, the first through hole 3, the second through hole 4, and the third through hole 5 are drilled in sequence from right to left, all from the front surface of the upper part 2 of the metal seat 1 Drill all the way to the back of the upper part 2 of the metal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com