Lifting type gas stove

A gas stove, lift-type technology, applied in the field of stoves, can solve the problems of affecting users' cleaning of stoves, complex structure, and high product manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

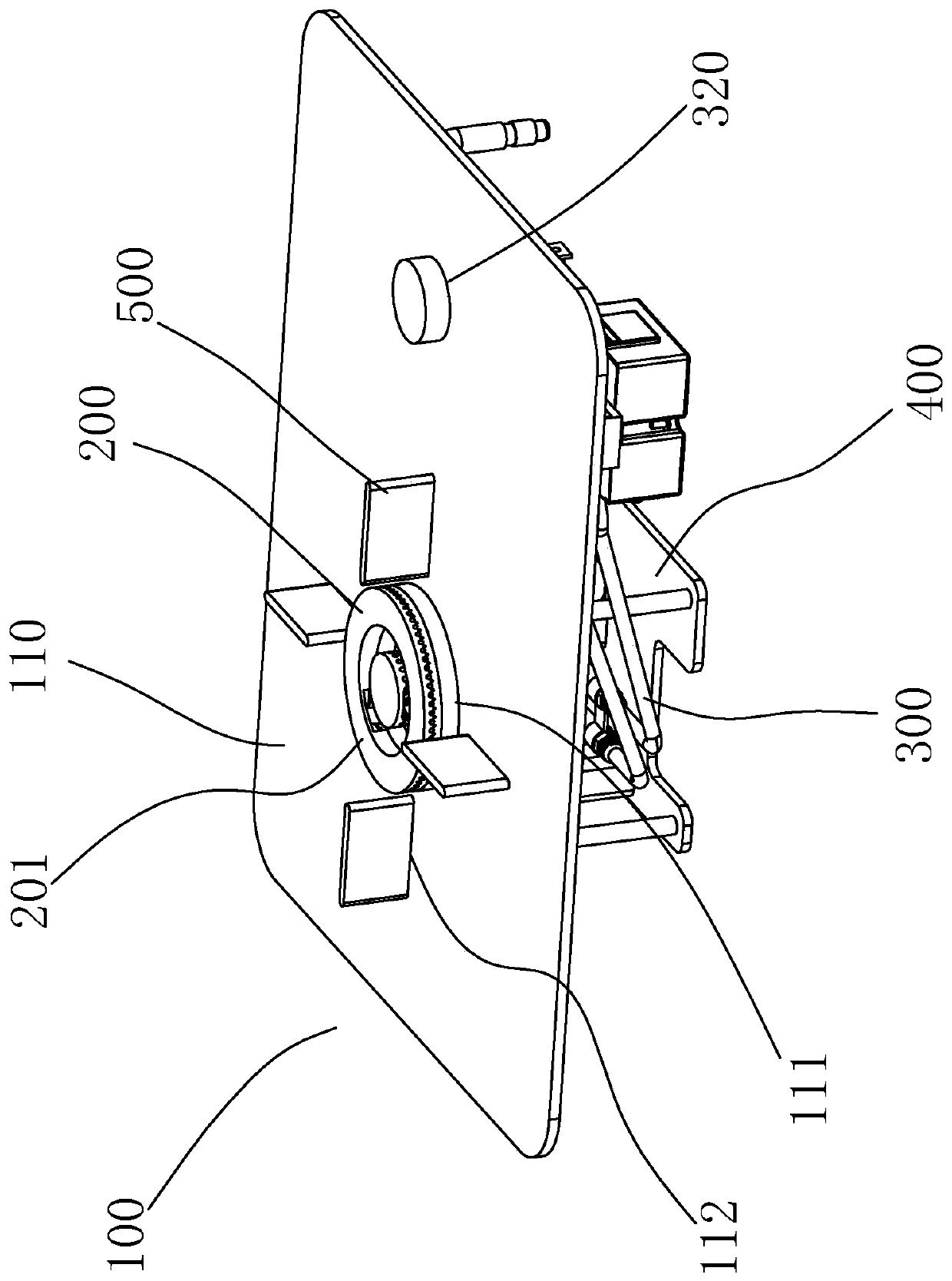

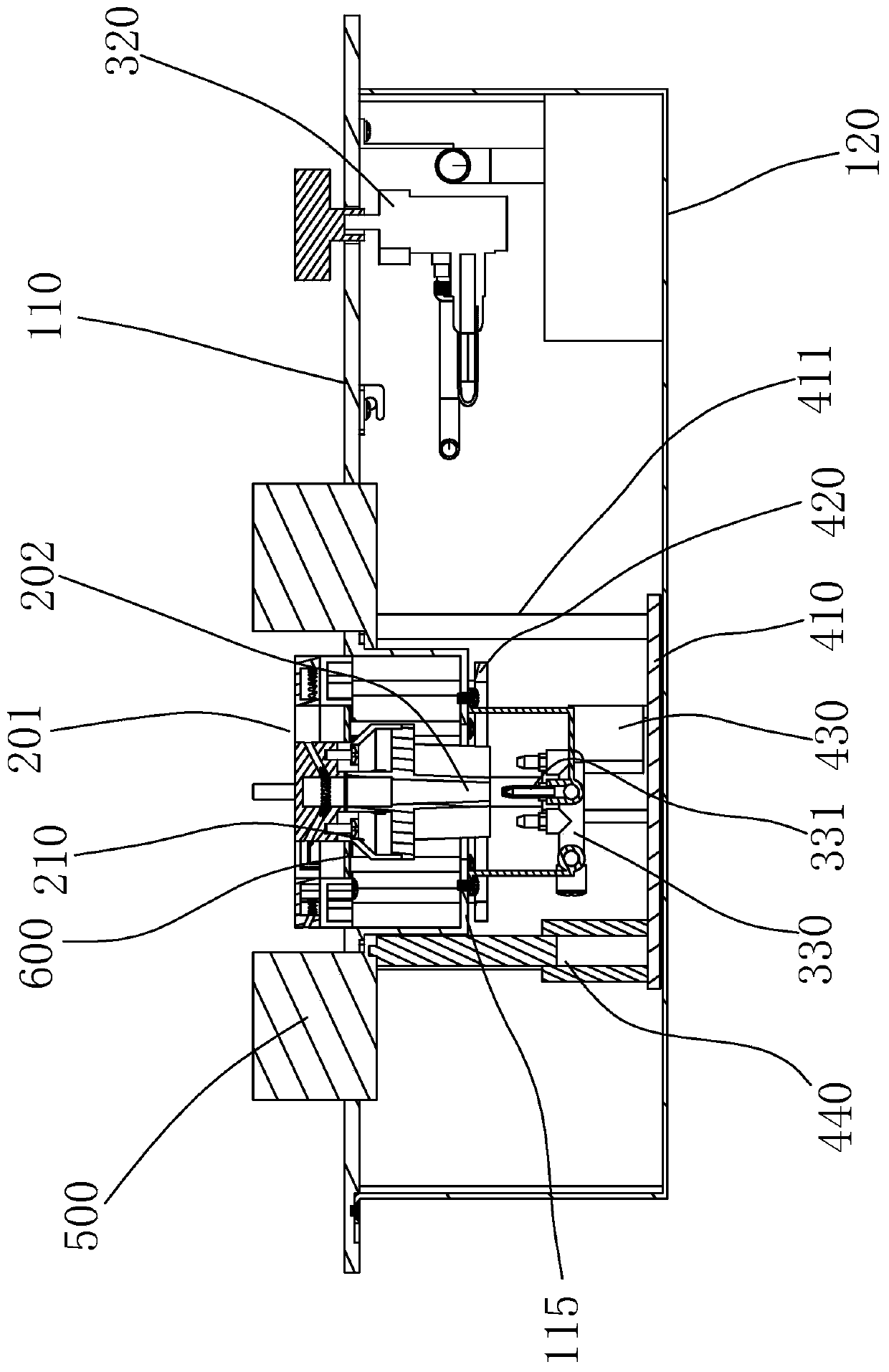

[0041] refer to Figure 1 ~ Figure 3 , a lift-type gas cooker, including a cooker body 100, the cooker body 100 includes a panel 110, a bottom case 120, a burner 200, a gas supply system 300 and a lifting device 400 are arranged inside the cooker body 100, the panel 110 is also provided with a stove frame 500 .

[0042] The panel 110 is provided with a furnace head through hole 111 and a furnace frame through hole 112 .

[0043] The gas supply system 300 is fixed in the stove body, the gas supply system 300 includes an air intake pipe 310, a switch assembly 320, and an air supply assembly 330, and the air supply assembly 330 includes a nozzle 331, and the injection direction of the nozzle 331 is up.

[0044] The lifting device 400 includes a base plate 410, a bracket 420, a drive mechanism 430, and a rack drive mechanism 440. The base plate 410 is fixed on the back of the panel 110 through a plurality of installation rods 411. The drive mechanism 430 includes a push rod moto...

Embodiment 2

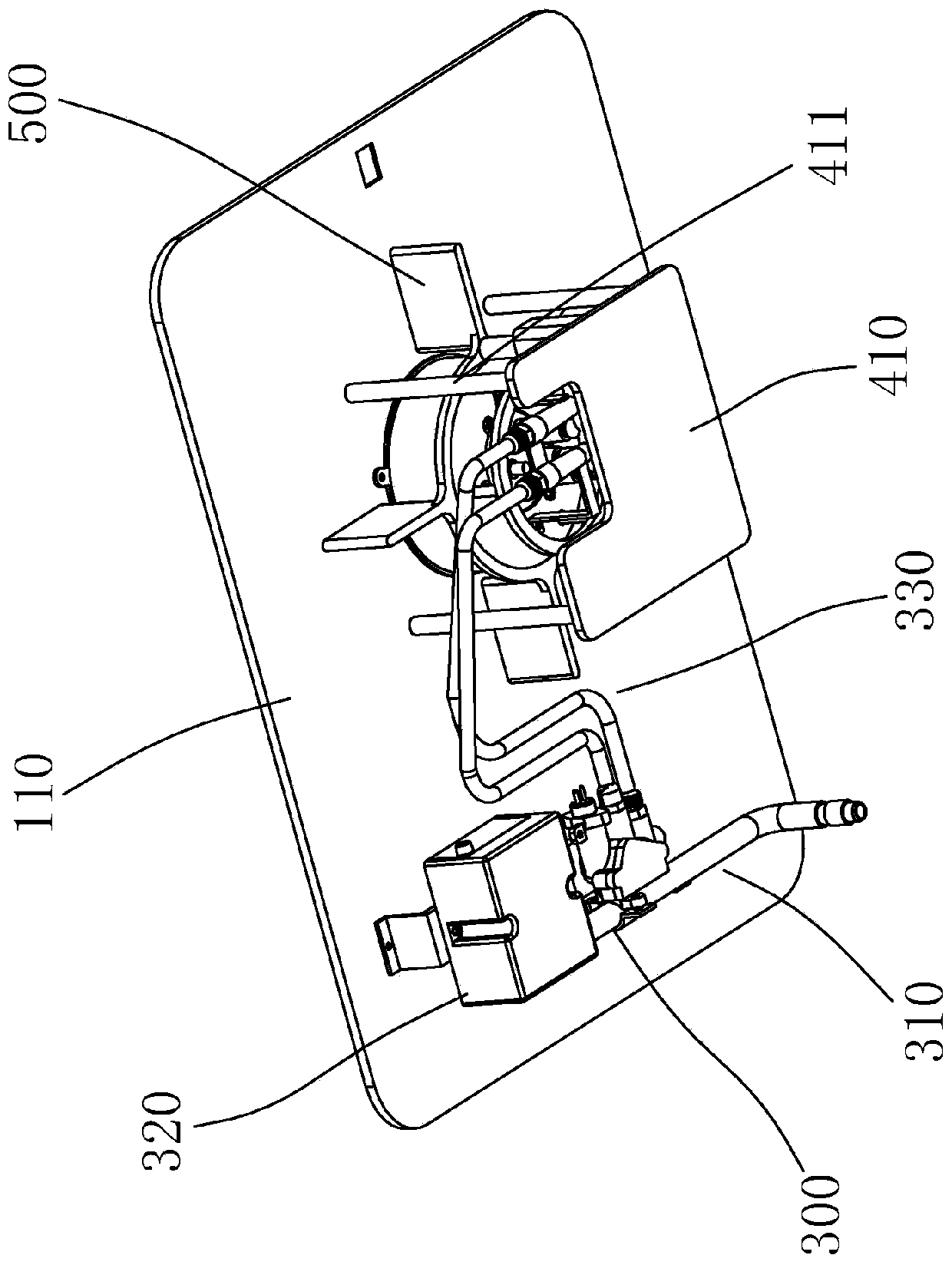

[0061] see Figure 1~3 as well as Figure 11 ~ Figure 13 , a lift-type gas cooker, including a cooker body 100, the cooker body 100 includes a panel 110, a bottom case 120, a burner 200, a gas supply system 300 and a lifting device 400 are arranged inside the cooker body 100, the panel 110 is also provided with a stove frame 500 .

[0062] The panel 110 is provided with a furnace head through hole 111 and a furnace frame through hole 112 .

[0063] The gas supply system 300 is fixed in the stove body, the gas supply system 300 includes an air intake pipe 310, a switch assembly 320, and an air supply assembly 330, and the air supply assembly 330 includes a nozzle 331, and the injection direction of the nozzle 331 is up.

[0064] The lifting device 400 includes a base plate 410, a bracket 420, a drive mechanism 430, and a rack drive mechanism 440. The base plate 410 is fixed on the back of the panel 110 through a plurality of mounting rods 411. The drive mechanism 430 include...

Embodiment 3

[0077] see figure 1 , Figure 14 , a lift-type gas cooker, including a cooker body 100, the cooker body 100 includes a panel 110, a bottom case 120, a burner 200, a gas supply system 300 and a lifting device 400 are arranged inside the cooker body 100, the panel 110 is also provided with a stove frame 500 .

[0078] The gas supply system 300 is fixed in the cooker body, the gas supply system 300 includes an air intake pipe 310, a switch assembly 320, and an air supply assembly 330, the air supply assembly 330 includes a nozzle 331, and the nozzle 331 is installed on the bottom On the side of the shell 120, the jetting direction of the nozzle 331 is horizontal to the right.

[0079] The panel 110 is provided with a furnace head through hole 111 and a furnace frame through hole 112 .

[0080] The burner 200 includes a burner head 201 and an ejector tube 202. The burner head 201 is located directly below the through hole 111 of the burner head. The burner 200 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com