Developing composite material, preparation method and application thereof, implantable and interventional medical instrument and preparation method of implantable and interventional medical instrument

A composite material and medical device technology, which is applied in the field of vascular embolization device, vascular stent or occluder and their preparation and development of composite materials, can solve the problem that the development material cannot be developed well, and achieves the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] The imaging composite material, by weight percentage, is made of the following raw materials: 45% non-developing polymer, 50% radiopacity modifier and 5% surfactant. Wherein, the non-developing polymer is polycaprolactone (PCL), the radiopacity improving agent is iopromide, and the surfactant is glycerin.

[0102] The preparation method of developing composite material is as follows:

[0103] (1) According to the formula, weigh the prepared raw materials, blend them, crush them in a wall breaker, and stir them evenly; among them, the non-developing polymers can be granules, powders, or debris;

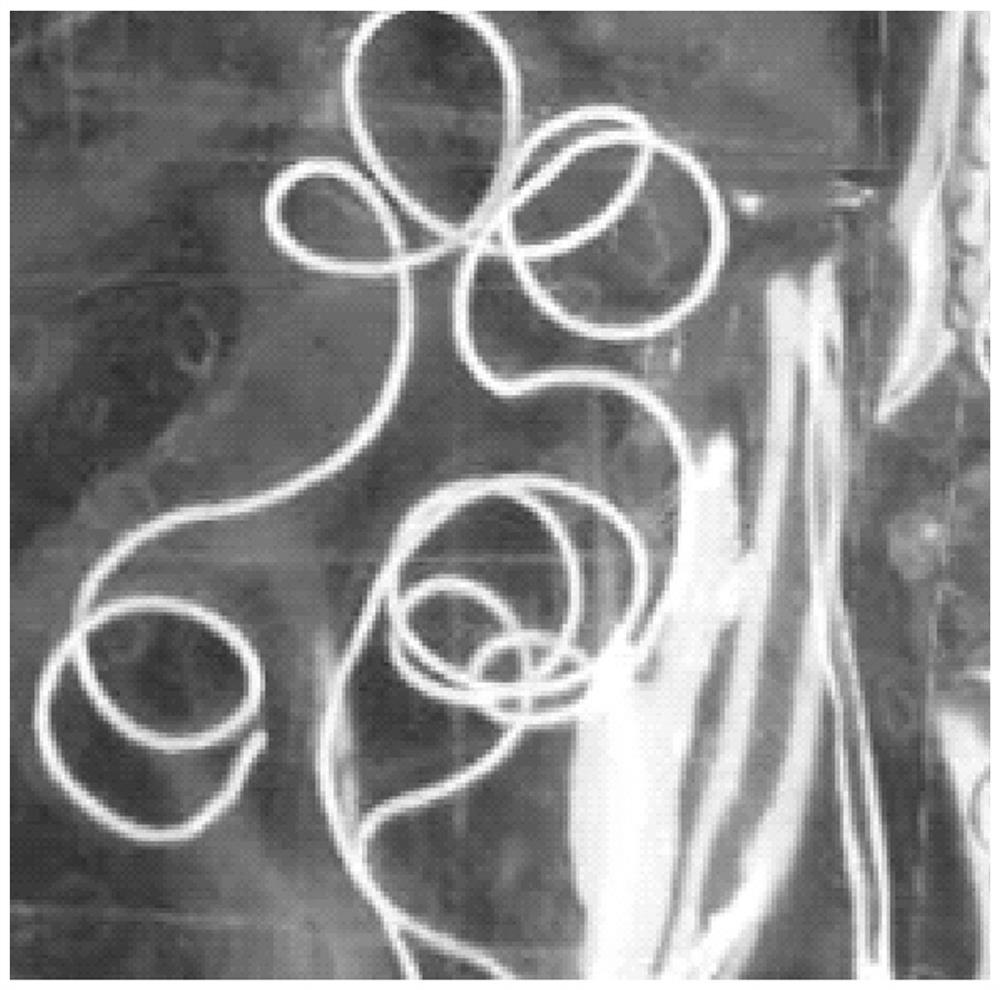

[0104] (2) Melting and stirring: melting and stirring devices such as figure 1 As shown, first put the raw materials in a heating container to preheat, melt and stir, let the materials mix thoroughly, until the mixture can pull out filaments, and can be used for normal extrusion after granulation;

[0105] (3) Extruded into filaments, the diameter of the filaments is 0.58±0.05...

Embodiment 21

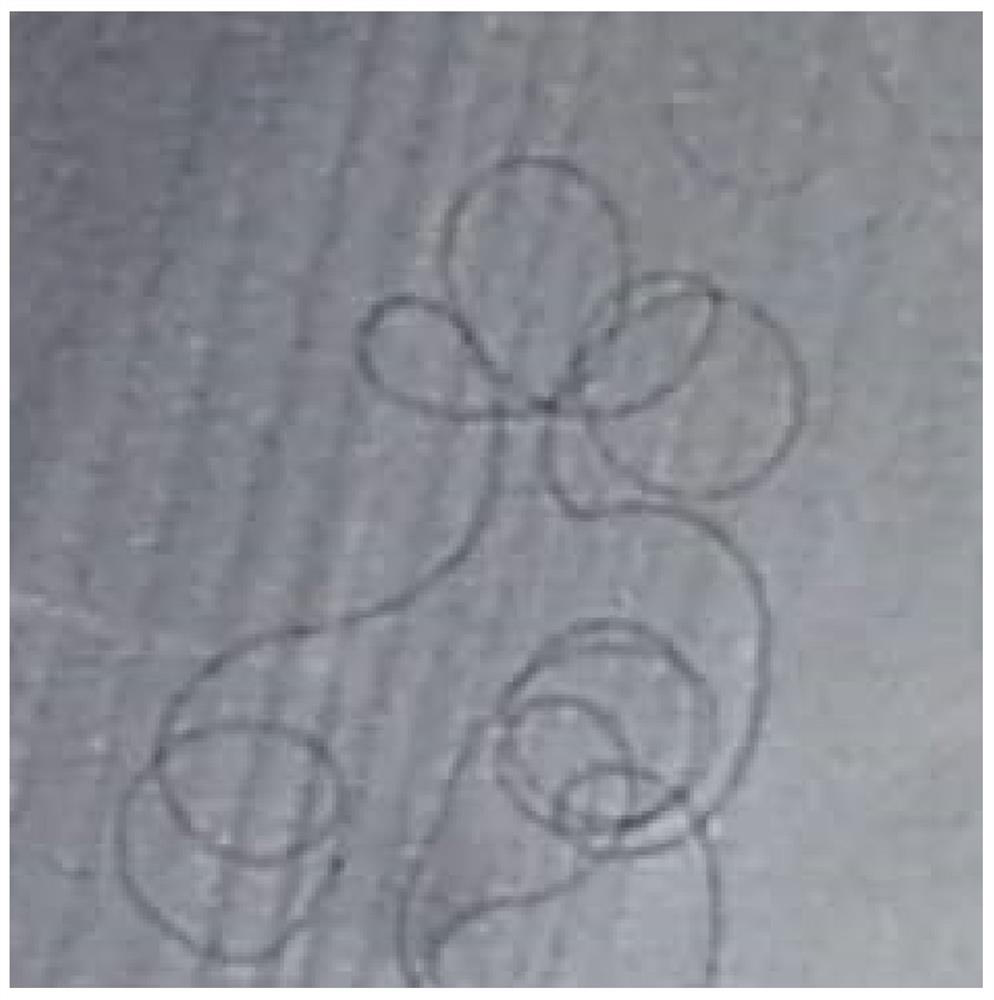

[0135] The difference from Example 1 is that the wire diameter is 0.7±0.05mm, and the structure and its developing effect are as follows: image 3 with 4 shown.

Embodiment 22

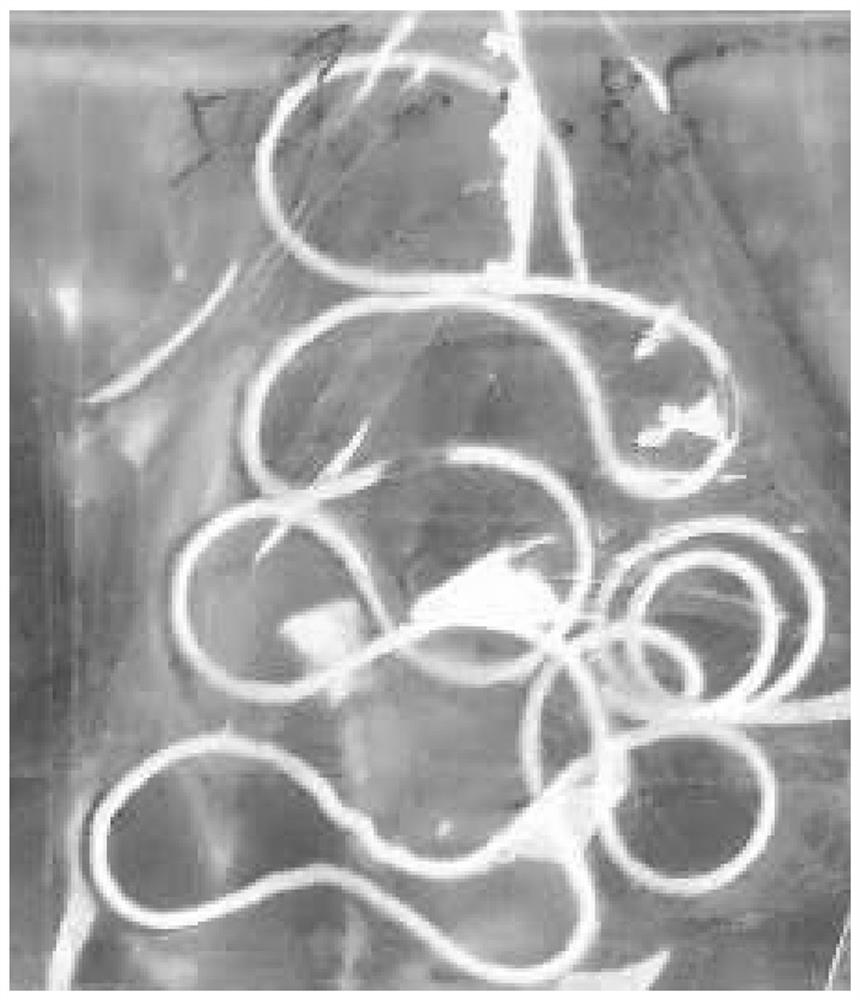

[0137] The difference from Example 1 is that the wire diameter is 0.85±0.05mm, and the structure and its developing effect are as follows: Figure 5 with 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com