Opening and closing system for oil path of linear compressor

A technology for linear compressors and closing systems, applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve problems such as noise, flow into oil circuits, overload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

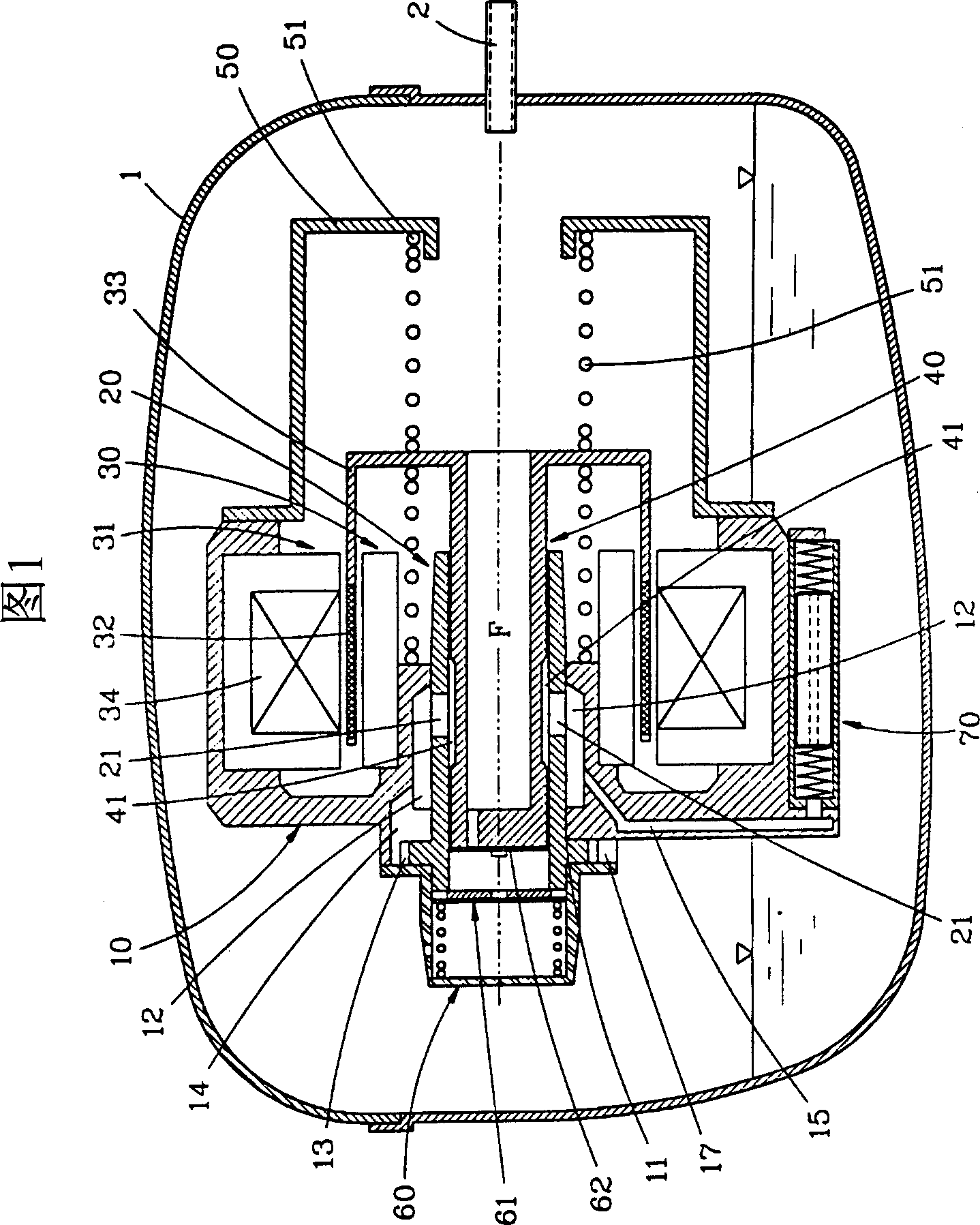

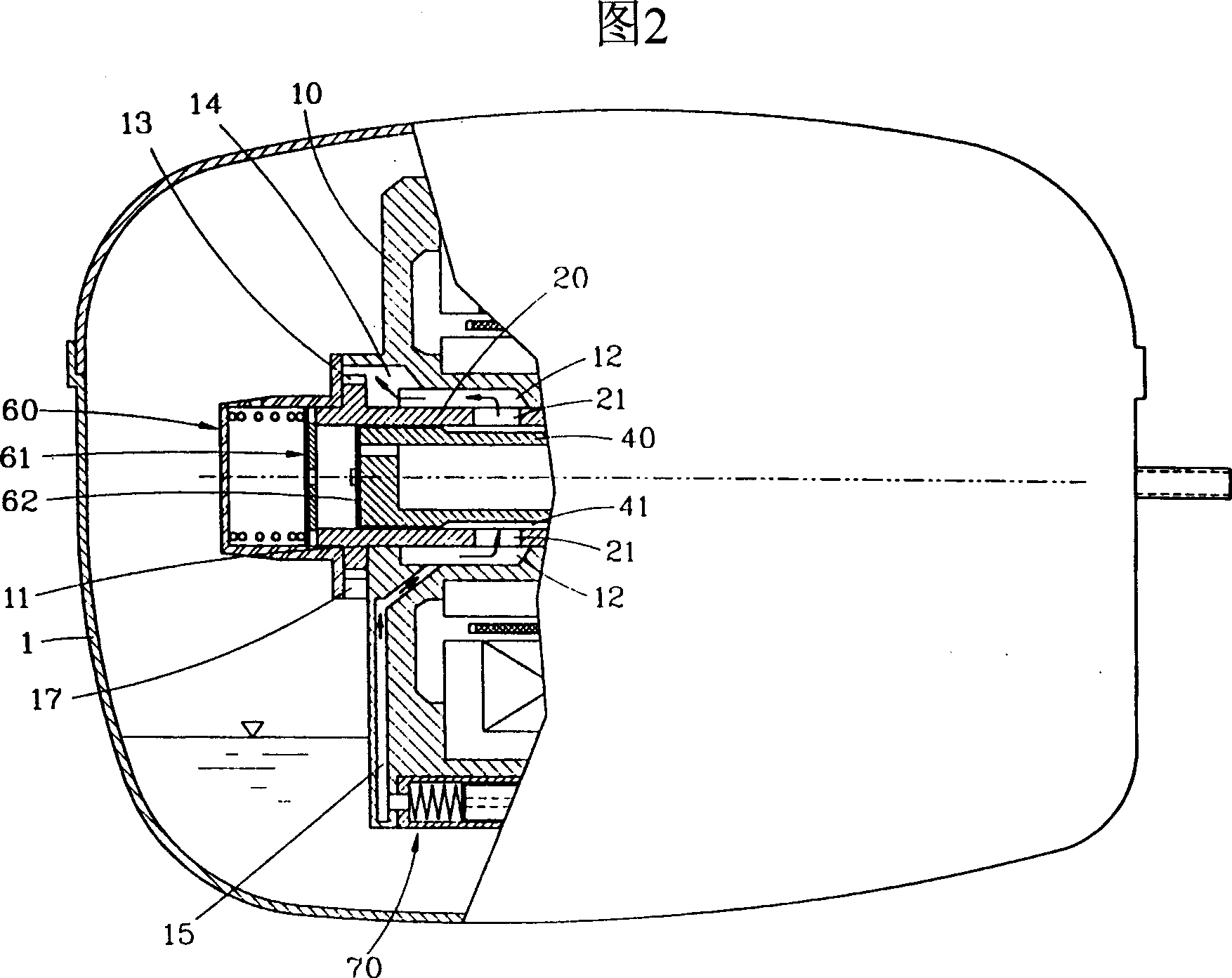

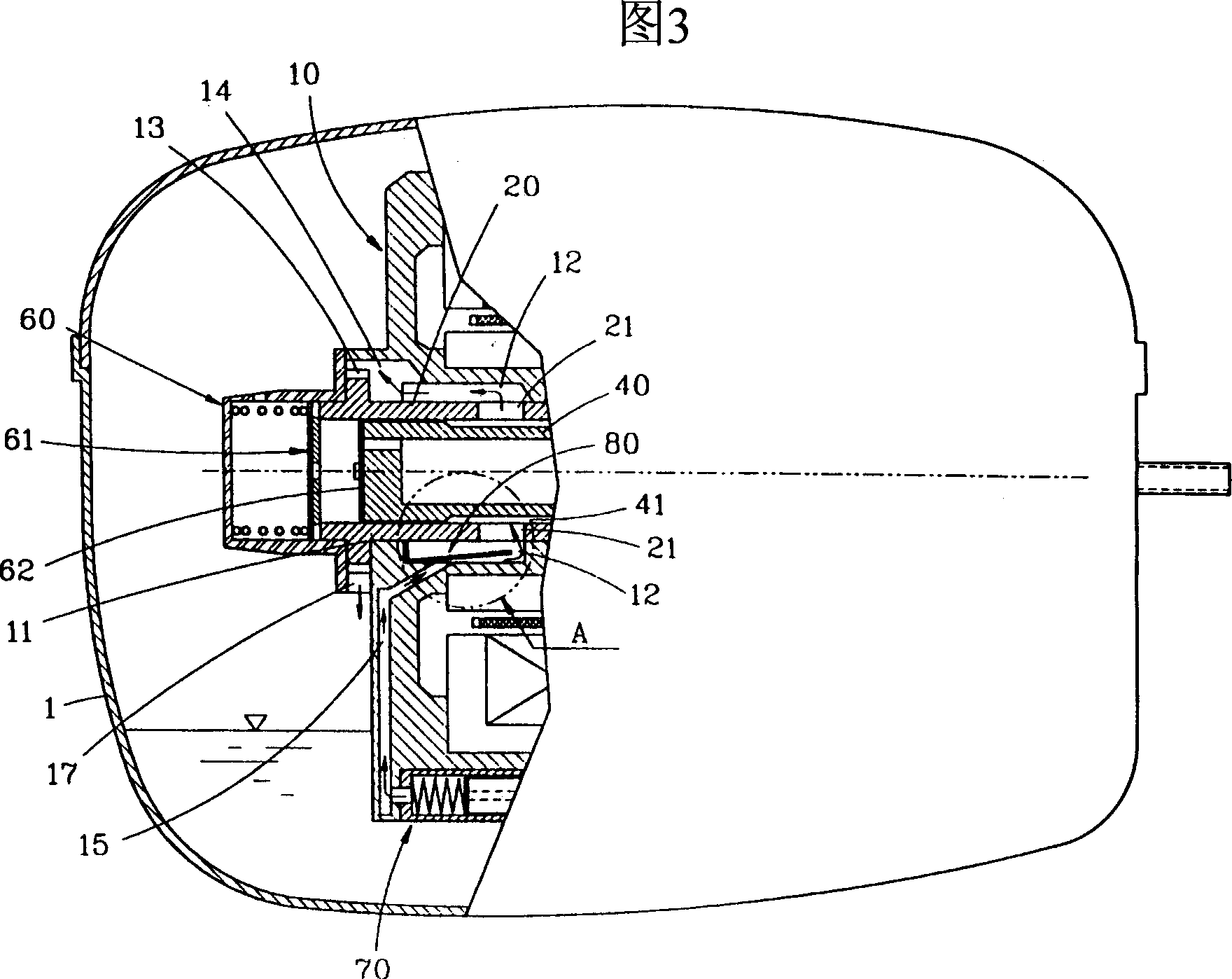

[0028] Referring now to the accompanying drawings, the oil passage opening and closing system of a linear compressor according to the present invention will be described in detail. Here, the same parts as in the prior art are denoted by the same reference numerals.

[0029] As shown in Figure 3, the oil circuit opening and closing system according to the linear compressor of the present invention comprises: a sealed container 1 full of oil at its bottom, a frame 10 arranged in the sealed container 1, a frame 10 inserted into the frame Cylinder 20 in the through hole 11 on a part of the frame, a piston 40 inserted into a part of the cylinder 20 and reciprocatingly driven by a motor, an exhaust cover 60 combined with one side of the cylinder 20 by covering the cylinder 20, and An oil feeder 70 arranged at the bottom of the frame 10 for pumping out oil.

[0030] In addition, the oil circuit opening and closing system of the linear compressor includes: a first oil groove 12 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com