Graphene/trimanganese tetraoxide composite nano lubricating additive and synthesis method thereof

A technology of trimanganese tetraoxide and lubricating additives, which is applied in the field of materials, can solve the problems of reducing the lubricating properties of graphene, the loss of carbon atoms in the layer, and performance degradation, etc., achieving excellent and stable lubricating properties, saving load process, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

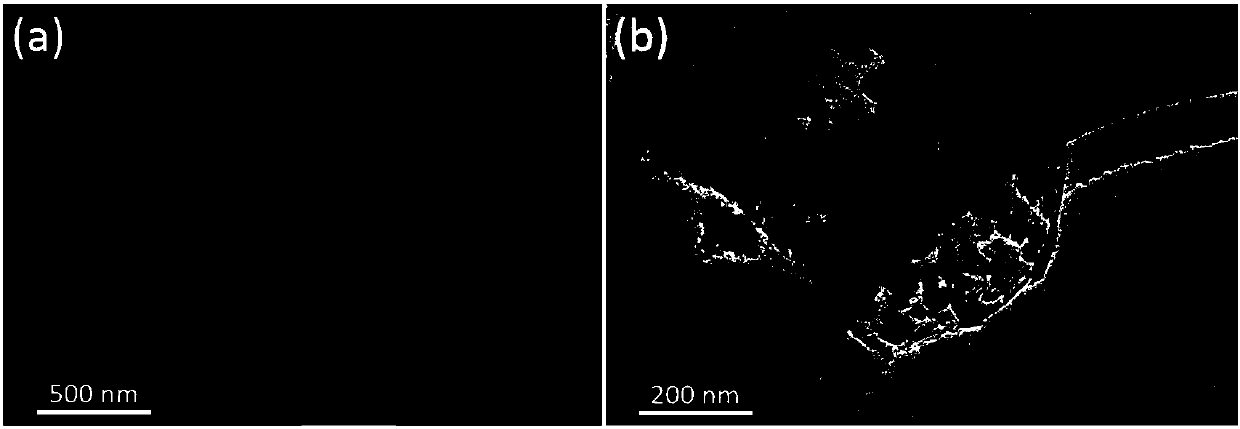

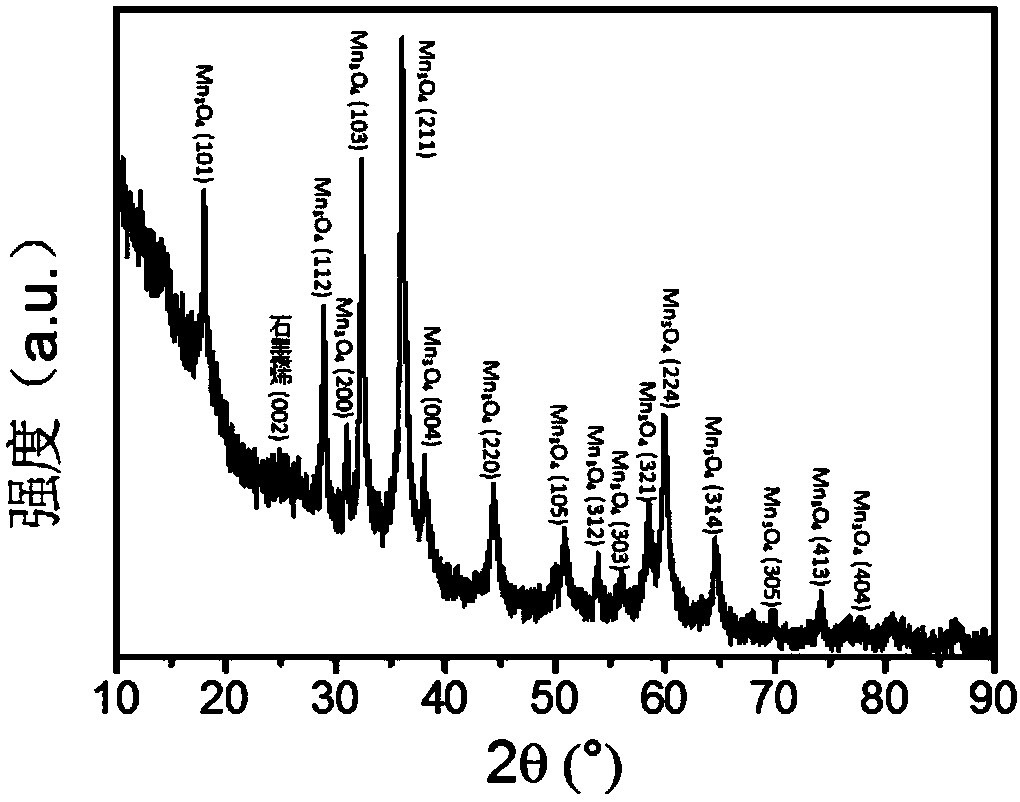

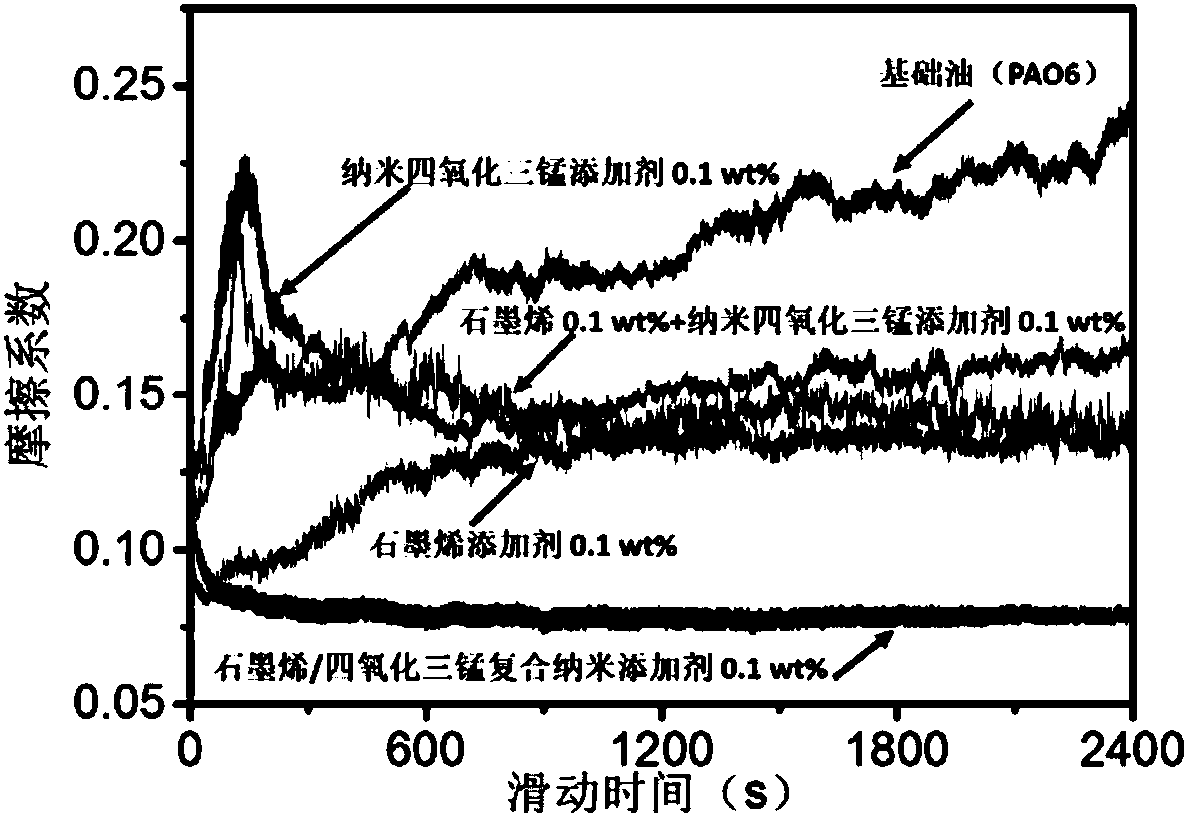

Image

Examples

Embodiment 1

[0057] (1) In an ice bath environment, mix 300g concentrated sulfuric acid and 35g potassium permanganate fully, then slowly add 10g graphite powder, after mixing evenly, raise the temperature to 50°C, and react for 1h to obtain graphite oxide and / or graphite oxide Mixture of alkenes;

[0058](2) Add 80 mL of 30% hydrogen peroxide to reduce the unreacted oxidant in the mixed solution, add 1 L of deionized water to dilute, and then maintain ultrasonic vibration for 1 hour to obtain the graphene oxide mixed solution;

[0059] (3) Under the action of magnetic stirring, slowly add potassium hydroxide solution (20wt%) directly to the graphene oxide mixed solution, adjust the mixed solution to be alkaline, and make its pH=9;

[0060] (4) filter out the solid precipitate in step (3) gained alkaline solution;

[0061] (5) Put the filtered solid precipitate into a blast drying oven, heat up to 170° C., and keep warm for 5 hours to obtain a graphene / manganese tetraoxide composite produ...

Embodiment 2

[0070] (1) In an ice bath environment, fully mix 300g concentrated sulfuric acid and 30g potassium permanganate, then slowly add 10g graphite powder, after mixing evenly, raise the temperature to 50°C for 1h to obtain graphite oxide and / or graphene oxide the mixture;

[0071] (2) Add 80 mL of 30% hydrogen peroxide to reduce the unreacted oxidant in the mixed solution, add 5 L of deionized water to dilute, and then maintain ultrasonic vibration for 1 hour to obtain the graphene oxide mixed solution;

[0072] (3) Under the action of magnetic stirring, slowly add potassium hydroxide solid directly to the graphene oxide mixed solution, adjust the mixed solution to be alkaline, and make its pH=11;

[0073] (4) filter out the solid precipitate in step (3) gained alkaline solution;

[0074] (5) Put the filtered solid precipitate into a blast drying oven, heat up to 170° C., and keep warm for 5 hours to obtain a graphene / manganese tetraoxide composite product;

[0075] (6) Use 3L of...

Embodiment 3

[0078] (1) In an ice-bath environment, fully mix 300g of concentrated sulfuric acid and 35g of potassium permanganate, then slowly add 10g of graphite powder, after mixing evenly, heat up to 45°C and react for 1h to obtain graphite oxide and / or graphene oxide the mixture;

[0079] (2) Add 80 mL of 30% hydrogen peroxide to reduce the unreacted oxidant in the mixed solution, add 1 L of deionized water to dilute, and then maintain ultrasonic vibration for 1 hour to obtain the graphene oxide mixed solution;

[0080] (3) Under the action of magnetic stirring, slowly add potassium hydroxide solid directly to the graphene oxide mixed solution, adjust the mixed solution to be alkaline, and make its pH=11;

[0081] (4) filter out the solid precipitate in step (3) gained alkaline solution;

[0082] (5) Put the filtered solid precipitate into a blast drying oven, heat up to 100° C., and keep warm for 5 hours to obtain a graphene / manganese tetraoxide composite product;

[0083] (6) Use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com