Bushing, roller pin assembly and guide piston assembly

A technology of roller pins and bushings, which is applied in the direction of pump components, bearing components, engine components, etc., can solve the problem that the reliability, lubrication performance and service life of the guide piston components cannot adapt to the working conditions of the transmission parts, and the aggravation of the roller body and the bushing, etc. Roller pins and bushings are mechanically worn, and cannot meet the requirements of high-strength fuel injection pumps, etc., to achieve the effects of cooling effect, improved bearing capacity, simple structure, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

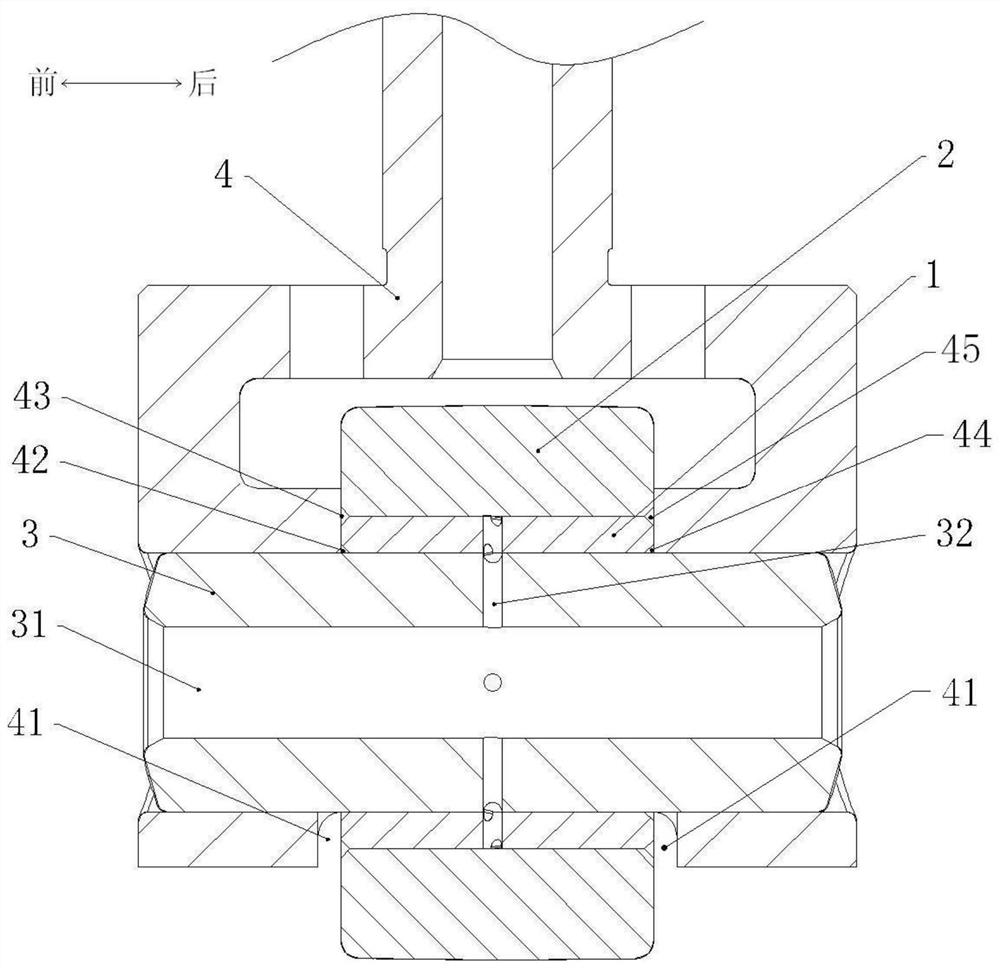

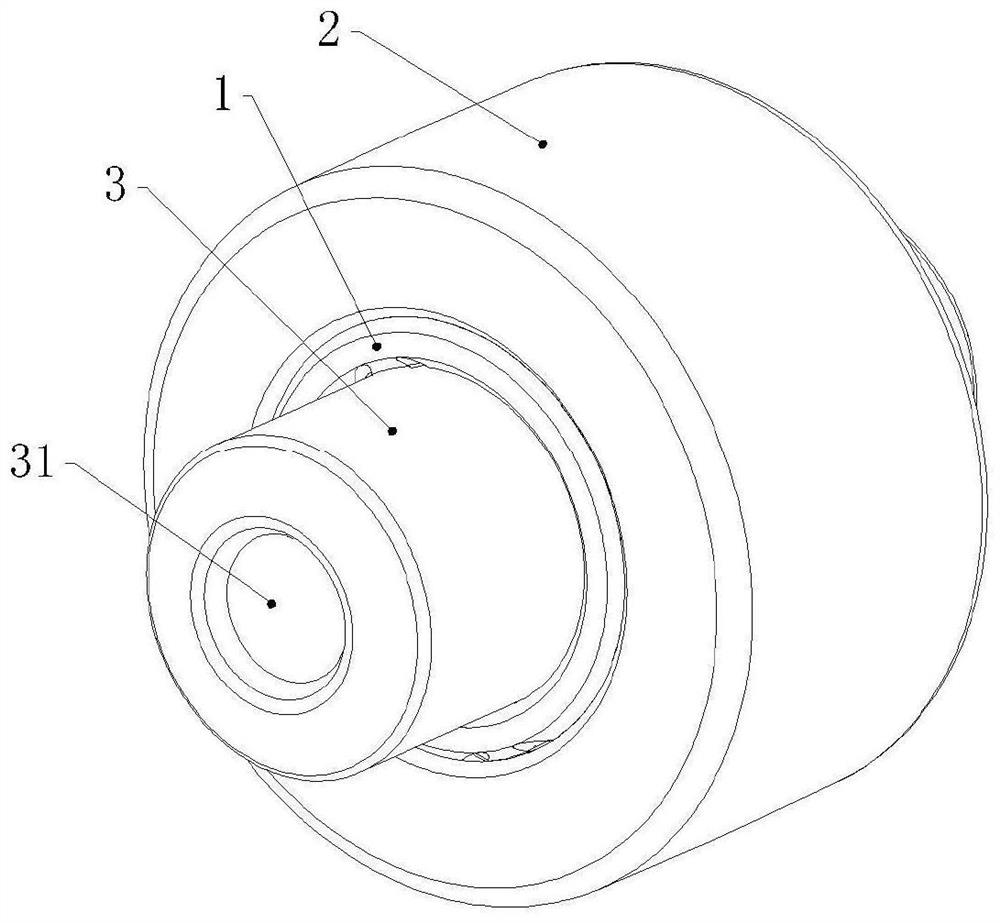

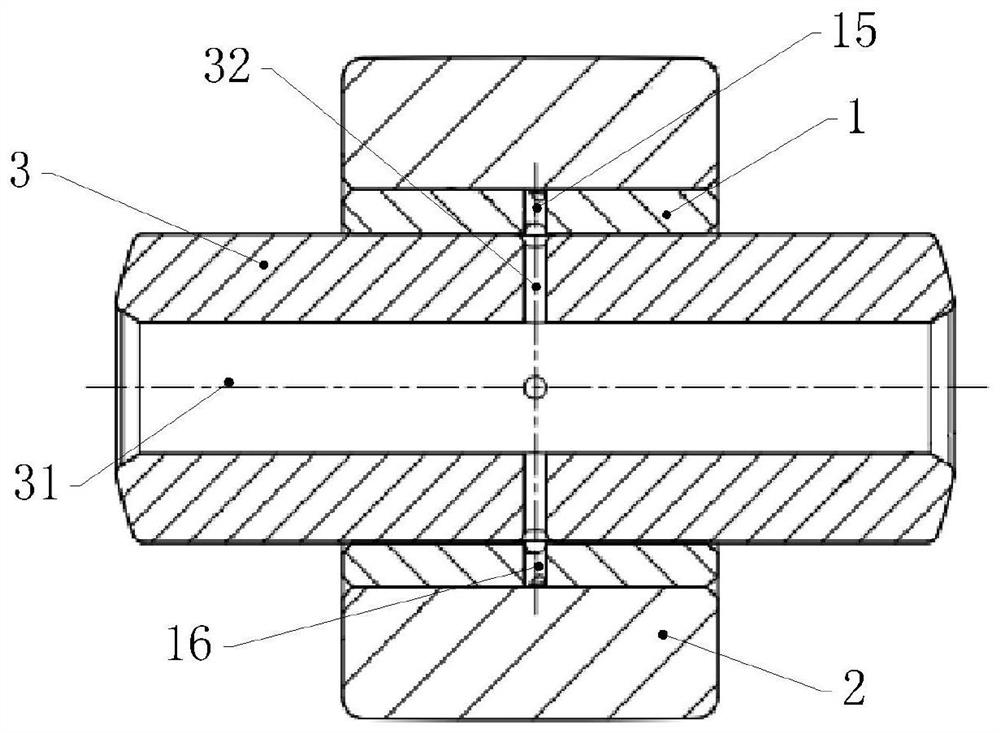

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as Figure 4-Figure 10 As shown, a bushing in this embodiment includes a cylindrical bushing body 1, the inner wall of the bushing body 1 is provided with an inner lubricating oil groove, and the outer wall of the bushing body 1 is provided with The outer lubricating oil groove, the bushing body 1 is also provided with a lubricating oil hole for connecting the inner lubricating oil groove and the outer lubricating oil groove, the inner lubricating oil groove and the outer lubricating oil groove are both axially penetrated forward and backward groove.

[0030] In this embodiment, the inner lubricating oil groove includes a first inner helical lubricating oil groove 11 and a second inner helical lubricating oil groove 12, and the outer lubricating oil groove includes a first outer helical lubricating oil groove 13 and a second outer helical lubricating oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com