Bush-tilting dynamic pressure bearing

A technology of dynamic pressure bearings and bearings, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of unstable load, inconvenient transportation and installation, and failure of fulcrum wear, so as to achieve stable and good support. The effect of lubrication bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The invention will be described in detail below in conjunction with specific embodiments.

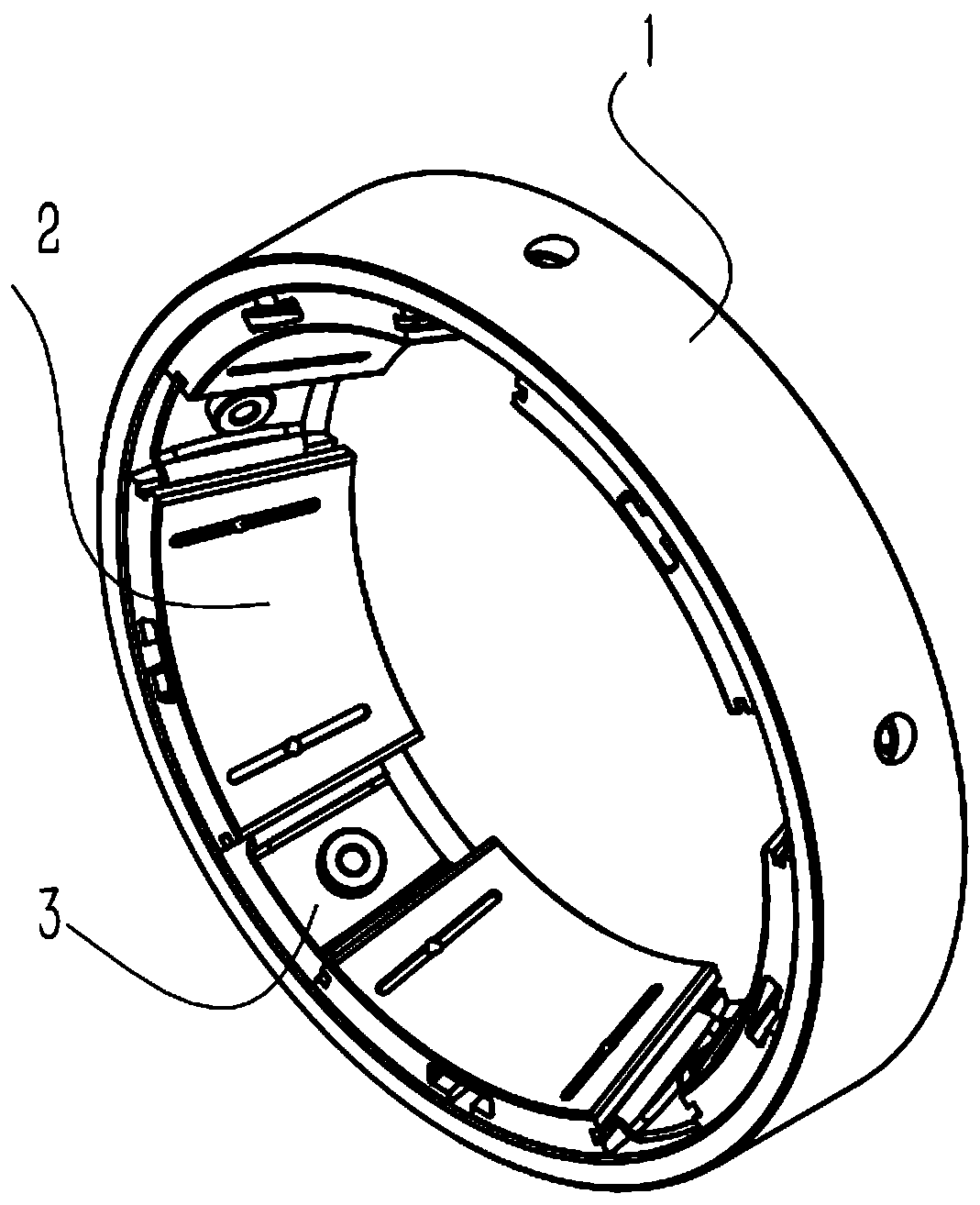

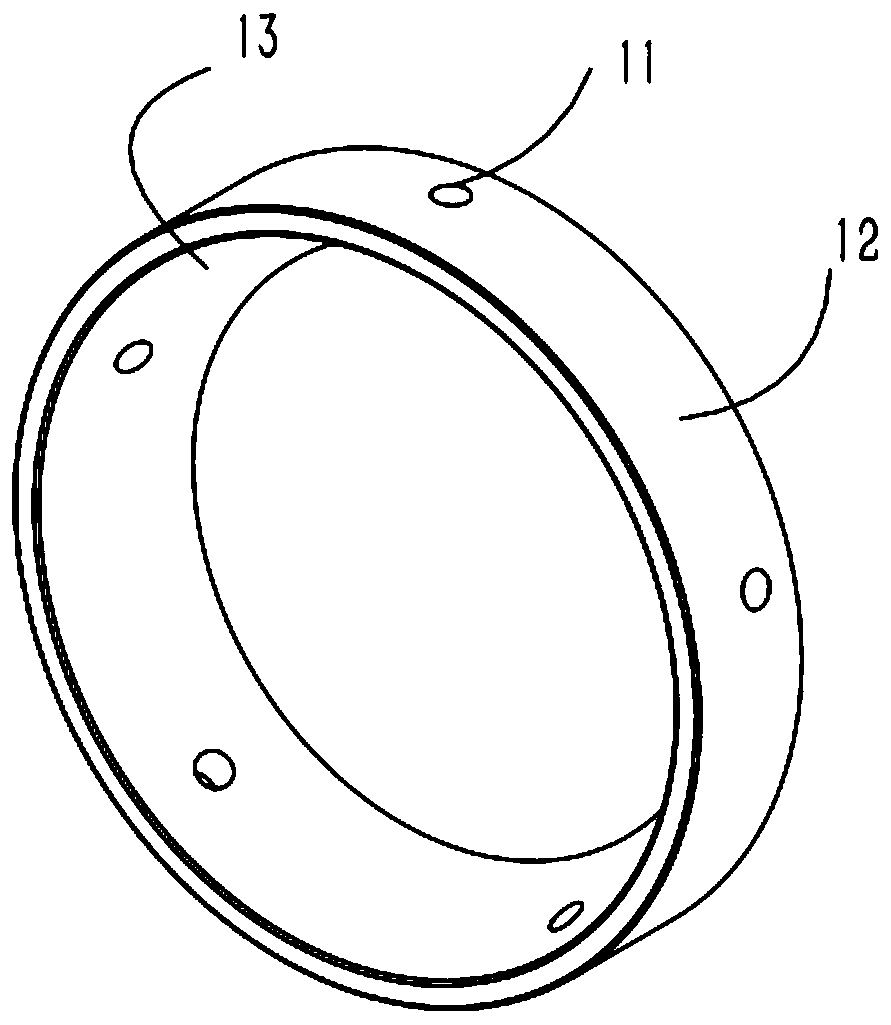

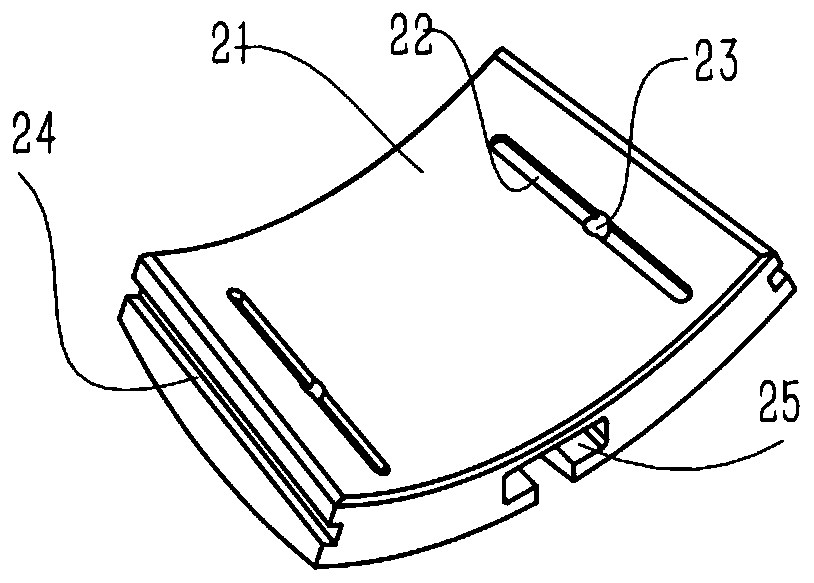

[0032] The tilting pad dynamic pressure bearing of this embodiment is as follows: figure 1 , figure 2 , image 3 , Figure 4 and Image 6 As shown, it includes a bearing outer ring 1 , a plurality of pads 2 and multiple sets of mounting components 3 , and multiple sets of mounting components 3 install a plurality of pads 2 on the annular inner surface 13 of the bearing outer ring 1 . The back surface 26 of the pad 2 and the inner surface 13 of the bearing outer ring 1 are spherical surfaces that match, and the centers of the two coincide with the axis of rotation of the installed main shaft 4, and the spherical surfaces of the two are in a non-working state through precision manufacturing When they are completely fitted together, the pads 2 are limited in the axial direction. The outer surface 12 of the bearing outer ring 1 is in the shape of a cylinder, which can be firmly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com