Hot rolling oil composition and application thereof

A technology of composition and hot rolling oil, applied in lubricating composition, metal rolling, petroleum industry, etc., can solve problems such as no mention of anti-emulsifier, no mention of stainless steel hot rolling processing technology, etc.

Inactive Publication Date: 2018-01-26

CHINA PETROLEUM & CHEM CORP

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use of anti-emulsifiers is not mentioned in the formulas of these patent documents, nor is it mentioned that it is suitable for the processing technology of stainless steel hot rolling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

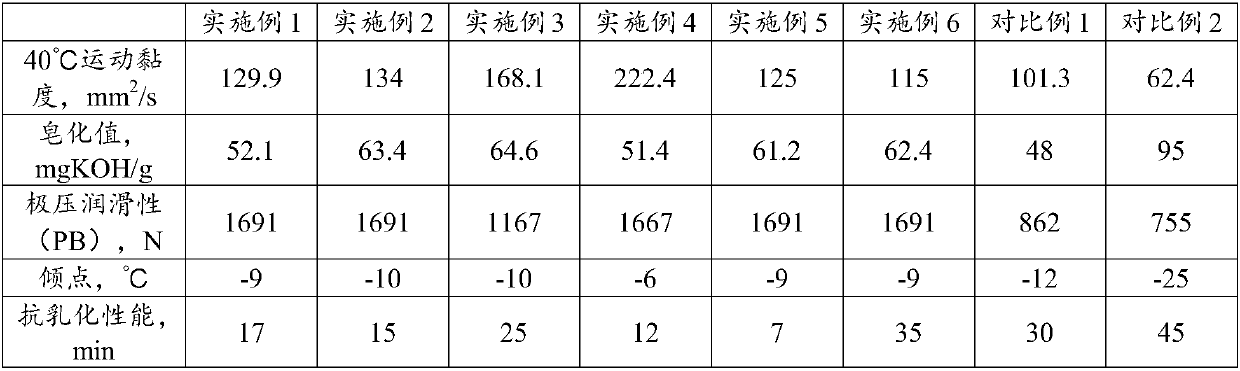

Embodiment 1~6

[0029] Heat component a) to 45-50°C, add the required amount of components b) and c)d) sequentially while stirring, and stir thoroughly. After 1.5 hours, stop heating and stir fully. After 0.5 hours, stop stirring. Filter and fill after standing for 1.5 hours.

Embodiment 1

[0031] components

Embodiment 2

[0033] components

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a hot rolled oil composition and application thereof. The hot rolled oil composition is composed of the following components in parts by weight: a) 40-80 parts of base oil; b)1-50 parts of an oily agent; c) 0.1-15 parts of an extreme pressure agent; and d) 0.01-1 part of a demulsifying agent. The hot rolled oil composition provided by the invention can better meet lubrication requirement of a hot rolling technology and can be used for lubrication during hot rolling of stainless steel.

Description

technical field [0001] The invention relates to a hot rolling oil composition and its application. Background technique [0002] In the hot rolling process of stainless steel plate, the scale is much less than that of ordinary steel, so the roll and the strip are in direct contact, and thermal adhesion is easy to occur on the roll surface in the front section of rough rolling and finishing rolling, which aggravates the uneven wear of the roll and leads to product failure. surface defects. Due to the strict requirements on the surface finish of the stainless steel plate, good lubrication is very necessary to prevent thermal adhesion of the roller surface. In hot rolling conditions, work rolls in contact with the strip and cooling water produce Fe 3 o 4 and Fe 2 o 3 Oxide with high hardness, which sticks to the surface of the roll, makes the roll produce a dark surface, that is, black skin. Black skin is the main cause of abnormal roll wear. After using hot rolling lubr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04B21B45/02C10N40/24C10N30/06

Inventor 杨兰王靖宇李谨张旭李晓阳张斌苏明兵

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com