Method for producing variational format/constant format ultra-thin hot-rolled strip steel by using semi-headless technique

A hot-rolled strip, semi-endless technology, applied in the field of rolling ultra-thin hot-rolled strip, can solve the unmentioned problems, achieve increased productivity, reduce the number of tail throwing and strip threading, improve stability and The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

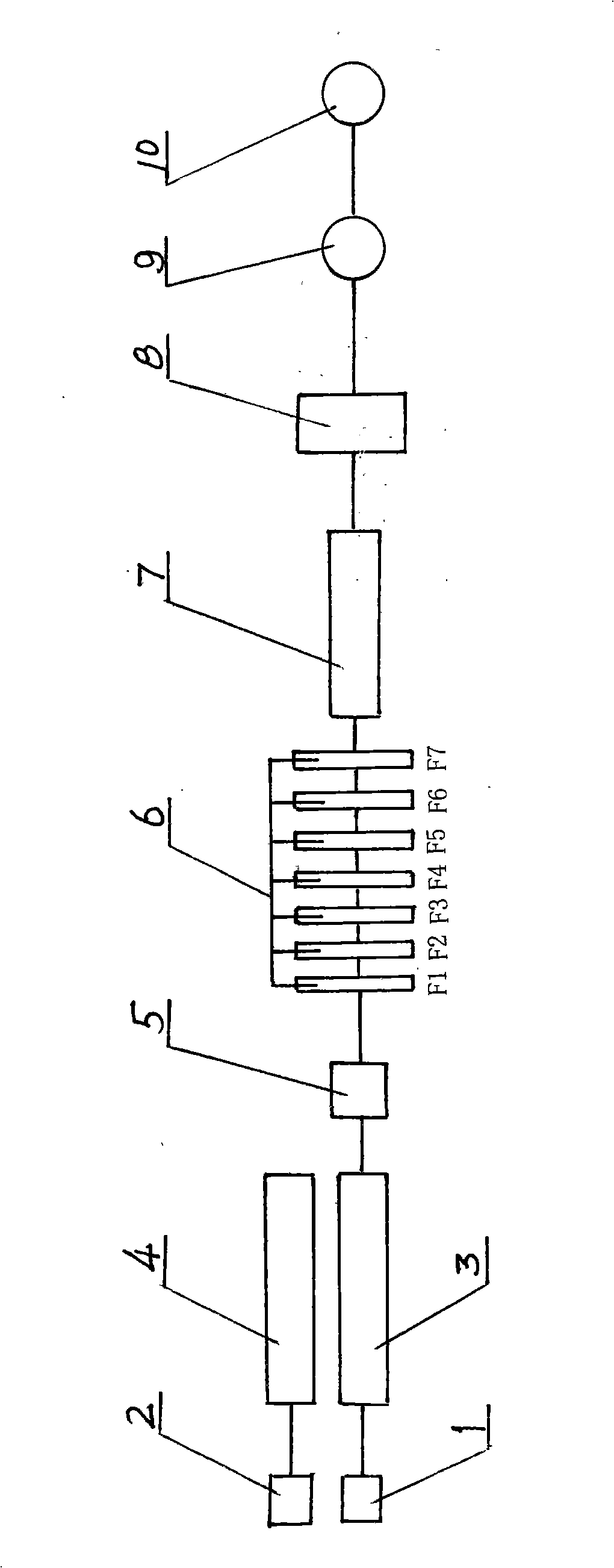

[0027] Embodiment 1: multiple batches of variable specification rolling

[0028] Adopt all three semi-endless variable-size rolling modes, that is, one semi-endless long billet is cut into three finished rolls, the thickness of the finished roll 1 is different from the thickness of the finished roll 2 and the finished roll 3, and the thickness sequence of each finished roll It is 1.8mm~1.6mm~1.6mm, and the width of the finished roll is 1229~1231mm.

[0029] Pour the molten iron from the blast furnace into a 100t oxygen top-bottom compound blowing converter and add scrap steel into the converter for conventional smelting. The molten steel is sent to the LF furnace for refining, and the refined molten steel is sent to the first continuous casting machine 1 and the second continuous casting machine 2 for completion The casting work of refined molten steel becomes continuous casting slab (ie slab). Electromagnetic Vibration Mold Control (EMBR) technology is used to ensure the qua...

Embodiment 2

[0039] Embodiment 2: Multiple batches of constant specification rolling

[0040] All three semi-endless constant specification rolling modes are adopted, that is, one semi-endless long billet is cut into three finished coils, the thickness specifications of each finished coil are in the order of 1.4mm~1.4mm~1.4mm, and the width of the finished coil is 1259~ 1261mm. This semi-endless constant-gauge rolling mode can also be used to roll constant-gauge hot-rolled strip steel with a thickness of 1.2mm, 1.6mm, or 1.8mm, and the width can be controlled within the range of 900-1600mm.

[0041] Pour the molten iron from the blast furnace into a 100t oxygen top-bottom compound blowing converter and add scrap steel into the converter for conventional smelting. The molten steel is sent to the LF furnace for refining, and the refined molten steel is sent to the first continuous casting machine 1 and the second continuous casting machine 2 for completion The casting work of refining molten ...

Embodiment 3

[0047] Embodiment 3: multiple batches of variable specification rolling

[0048] All four semi-endless variable specification rolling modes are adopted, that is, one semi-endless long billet is cut into four finished coils, and the thickness specifications of each finished coil are in the order of 1.3mm~1.2mm~1.0mm~1.0mm, and each finished coil The width is between 1259-1263mm (the width can also be controlled within the range of 900-1600mm), and the thickness distribution is: finished roll 1 is 1.3mm, finished roll 2 is 1.2mm, finished roll 3 is 1.0mm, and finished roll 4 is 1.0 mm.

[0049] Pour the molten iron from the blast furnace into a 100t oxygen top-bottom compound blowing converter and add scrap steel into the converter for conventional smelting. The molten steel from the furnace is sent to the LF furnace for refining. The refined molten steel is completed by the first continuous casting machine 1 and the second continuous casting machine 2 The casting work of refin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com