Gap-controllable mechanical sealing device based on hinge structure

A technology of mechanical sealing device and hinge structure, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of manual operation, poor safety and reliability, poor self-adaptive ability, etc., and achieve improved intelligence, simple structure, and reliability high control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

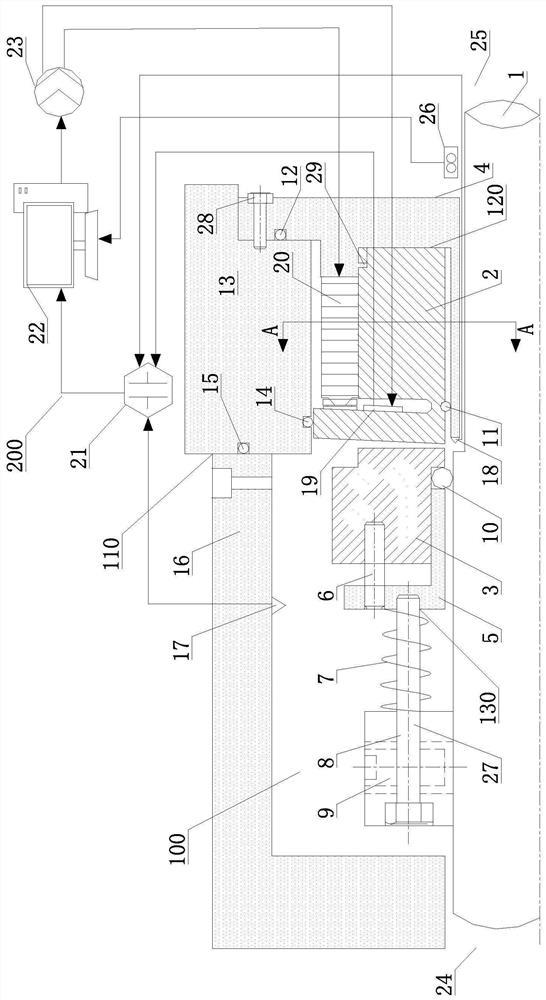

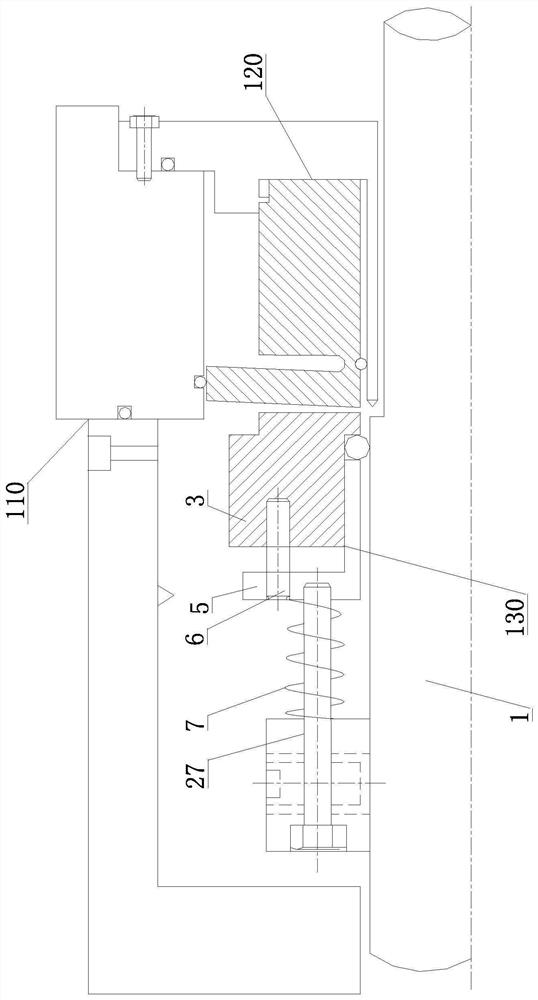

[0032] Embodiment 1 A mechanical seal device with controllable clearance based on a hinge structure according to the present invention includes a mechanical seal device 100 and an end face clearance regulating device 200;

[0033] The mechanical seal device 100 includes a housing assembly 110, a static ring assembly 120, a moving ring assembly 130 matched with the static ring assembly and used for sealing, and a rotating shaft 1 for driving the moving ring assembly to rotate in a circumferential direction; the housing assembly 110 has a gap Sleeve on the rotating shaft 1, and form an installation cavity between the housing assembly 110 and the rotating shaft 1; the static ring assembly 120 and the moving ring assembly 130 are arranged between the housing assembly 110 and the rotating shaft 1 In the installation cavity; the static ring assembly 120 is arranged on the low-pressure side 25 of the installation cavity, including the static ring seat 4, the static ring 2 sealed in th...

Embodiment 2

[0045] Embodiment 2 A method for controlling a gap-controllable mechanical seal device based on a hinge structure according to the present invention includes the following steps:

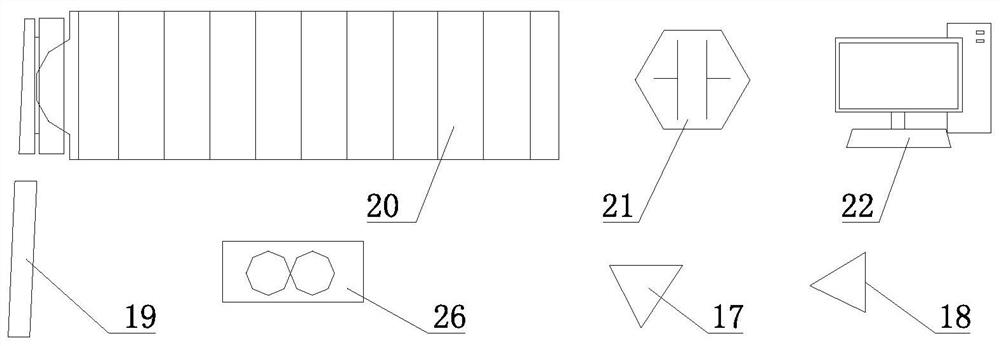

[0046] 1) The ultrasonic transducer 19 detects the thickness of the gap liquid film or the friction state through high-frequency ultrasonic waves; at the same time, the first thermocouple 17 and the second thermocouple 18 respectively measure the temperature in the installation cavity and at the outlet of the sealing gap;

[0047] 2) The signal conditioner 21 converts the ultrasonic signal measured by the ultrasonic transducer 19, the temperature signal measured by the first thermocouple and the second thermocouple into a digital signal recognizable by the microprocessor 22;

[0048] 3) The microprocessor 22 calculates the acquired digital signal and compares it with the standard database to obtain the corresponding sealing gap value;

[0049] 4) The microprocessor 22 outputs the corresponding curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com