Semi-independent suspension with inclined leaf springs

A semi-independent, leaf spring technology, applied in the direction of leaf springs, springs, springs/shock absorbers, etc., can solve the problem of poor reliability and load-carrying capacity of semi-independent leaf spring suspension, mutual influence of wheel jump on both sides, and maximum wheel rotation angle To achieve the effect of improving anti-rolling ability, improving wheel alignment parameters, and facilitating handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural principles and specific implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

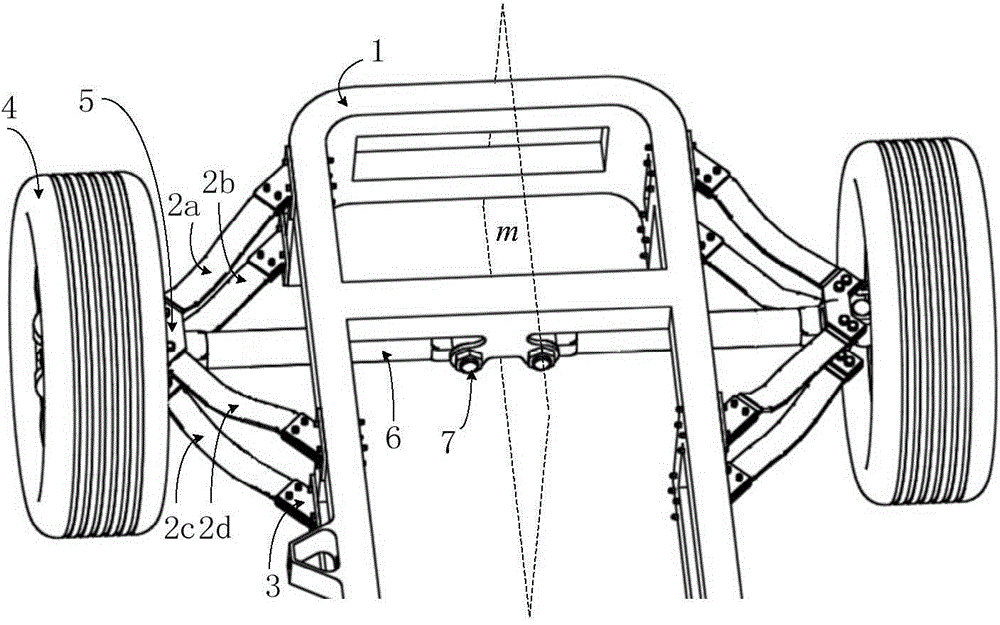

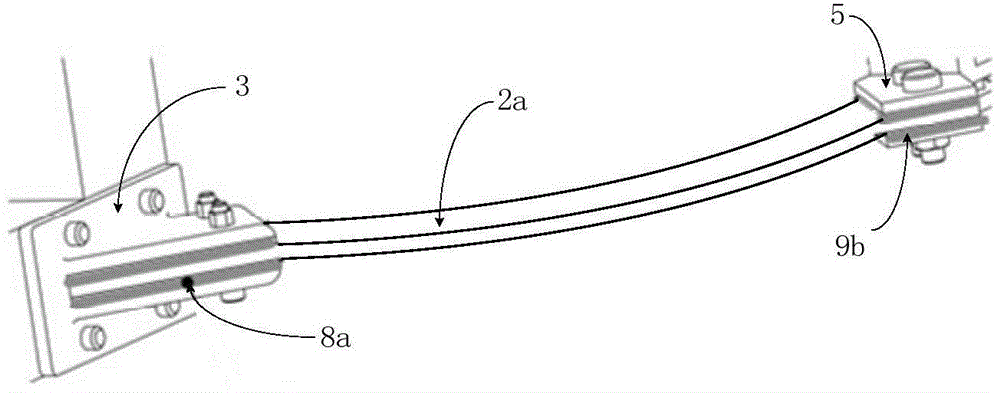

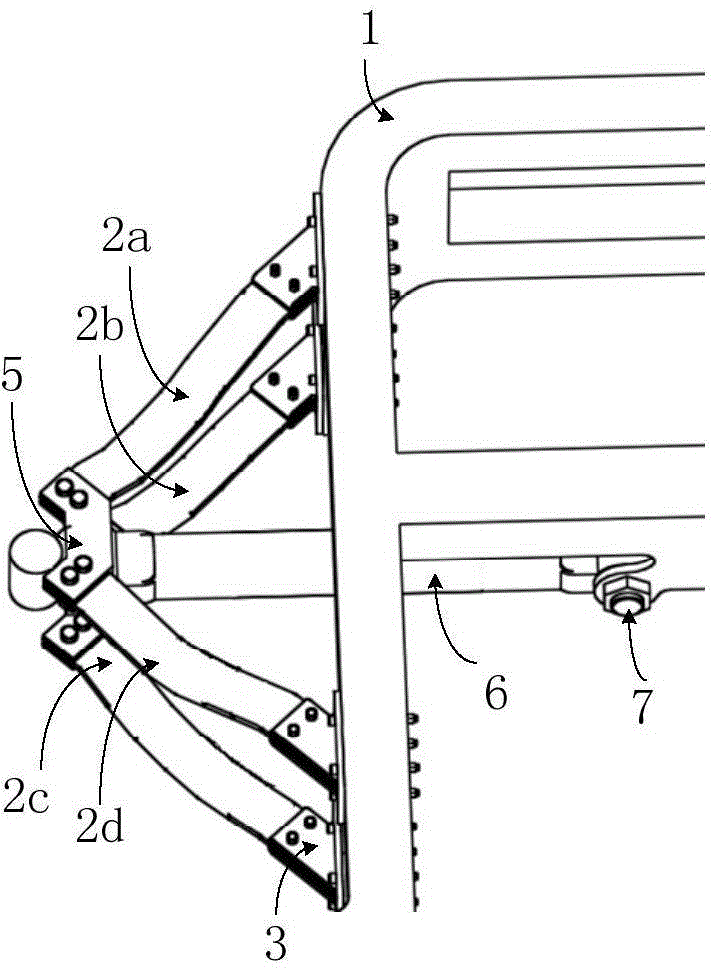

[0026] figure 1 It is an overall structure diagram of the present invention, and its overall structure is symmetrical about the m-plane (the m-plane is the longitudinal symmetrical center plane of the vehicle frame 1). Two semi-independent suspension devices, each semi-independent suspension device includes a leaf spring, an axle connecting member 5, a wheel 4 and a frame connecting member 3. One end of the half shaft 6 is connected to the vehicle frame 1 through the first 7 , and the other end is fixed to the axle connecting member 5 . The frame connecting member 3 is connected to the frame 1 by bolts, and the axle connecting member 5 is consolidated with the axle shaft 6; the leaf spring includes four inclined leaf springs, that is, the first inclined leaf spring 2a, the second inclined leaf spring Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com