Damping pantograph for rail transit trains

A technology for pantographs and trains, which is applied in the field of rail transit, and can solve the problems of high manpower consumption, reduced service life of carbon skateboards, pantograph-catenary accidents, etc., and achieves the goal of improving service life and safety factor, increasing fatigue life, and reducing abnormal wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

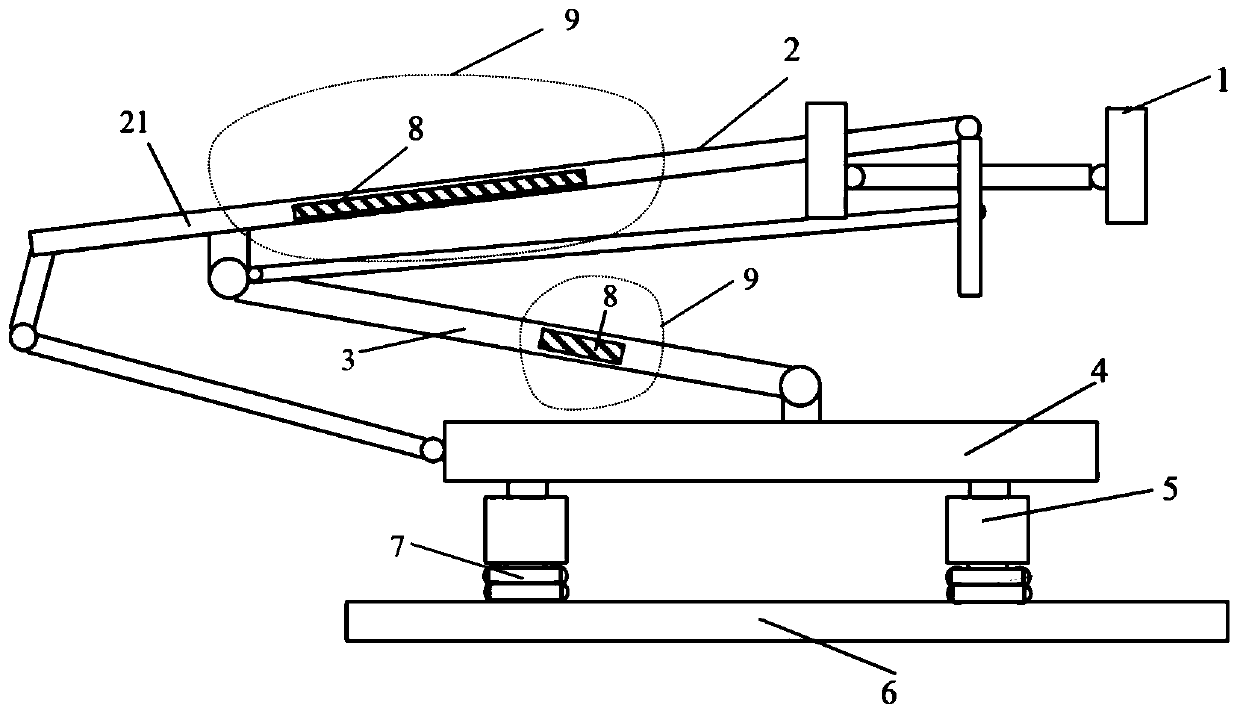

[0037] Such as figure 1 As shown, this embodiment provides a damping pantograph for rail transit trains. Although the structure of the pantograph varies according to different pantograph structural designs and the driving environment conditions of the locomotive, the basic structure Both include carbon skid plate 1 , upper frame 2 , lower arm 3 , pantograph base frame 4 , insulation 5 and roof mounting base 6 . In this embodiment, a resonant vibration force damping unit 8 and a vibration isolation unit 7 are also provided on the pantograph. The upper frame 2 is composed of the upper beam 21 and the cross beam. The upper beam 21, the cross beam and the lower arm 3 are all beam structures of the pantograph, which is also one of the parts that generate the most serious resonance response. The upper beam 21 and the crossbeam are mostly hollow tubes, and the lower arm 3 has both hollow tubes and other profiles. The upper beam 21, crossbeam and lower arm 3 in this embodiment all ad...

Embodiment 2

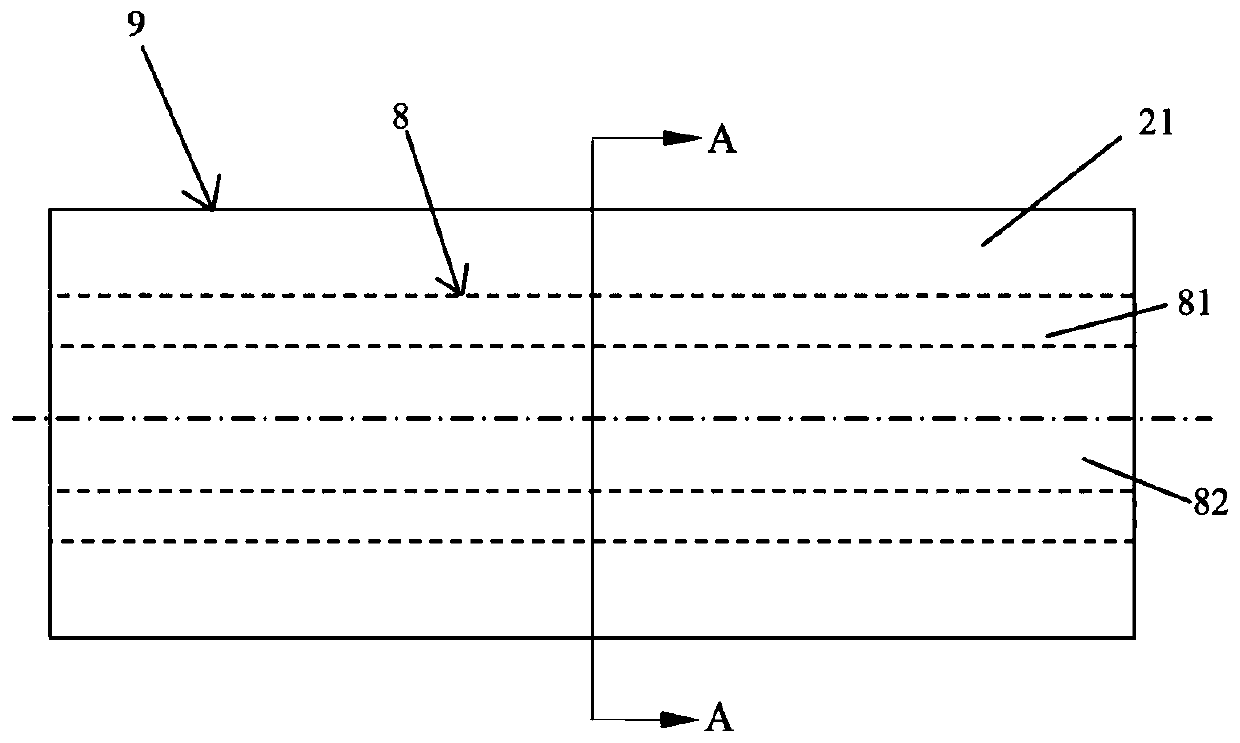

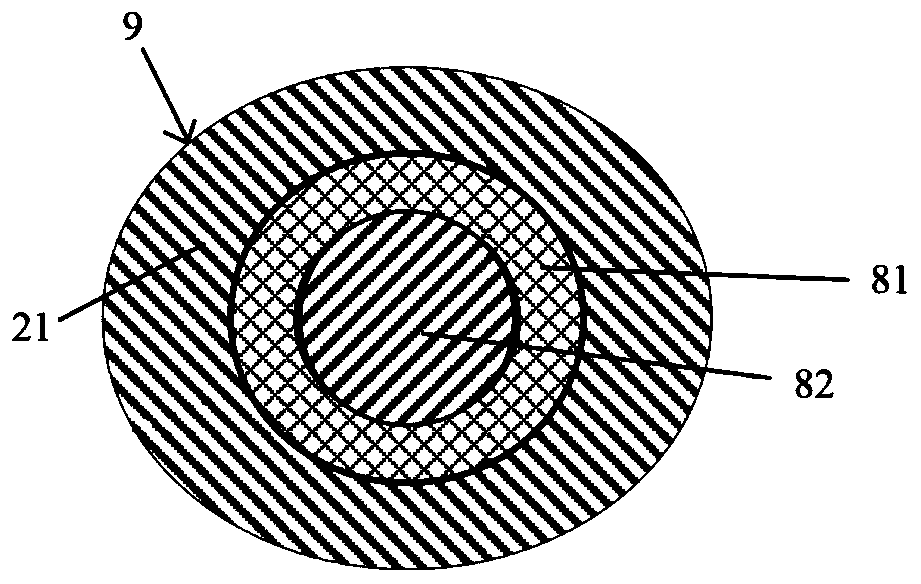

[0044] Such as Figure 5 with Image 6 As shown, the basic structure and principle of this embodiment are the same as the first example, the difference is that the harmonic dynamic damping unit 8 is arranged outside the beam structure instead of inside. The innermost layer of the harmonic vibration damping unit 8 is the elastic element layer 81 and is in close contact with the outer wall of the upper beam 21 , the cross beam or the lower arm 3 . Figure 5 Take the upper beam as an example. The elastic element layer 81 , the mass element layer 82 and the corresponding beam section together constitute the resonant damping beam 10 . The elastic element layer 81 and the mass element layer 82 are combined into one body by adhesive, vulcanization process or mechanical bonding. This design is applicable to any form of beams, including hollow tube beams and various profile beams with different cross-sections, such as Figure 7 The "T" shaped member shown, such as Figure 8 As sho...

Embodiment 3

[0047] Such as Figure 9 with Figure 10 As shown, the basic structure and principle of this embodiment are the same as those of the first example, the difference is that the harmonic dynamic damping unit 8 is composed of a multi-layer elastic element layer 81 and a multi-layer mass element layer 82, which is used to deal with multiple high vibration Amplitude situation. Figure 9 Take the harmonic dynamic damping unit 8 composed of two layers of elastic element layers 81 and two layers of mass element layers 82 in the upper beam 21 as an example. The elastic element layer 81 and the mass element layer 82 are arranged at intervals, the outermost layer is the elastic element layer 81 close to the inner wall of the cavity, and the innermost layer is the mass element layer 82 .

[0048] A plurality of elastic element layers 81 and a plurality of mass element layers 82 form one or more dynamic vibration absorbers with different resonant frequencies, and the resonant frequency ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com