Half shaft for drive axle

A technology for drive axles and shafts, applied in axles, wheels, transportation and packaging, etc., can solve problems such as abnormal wear of iron filings, achieve the effects of reducing abnormal wear, improving performance, and reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

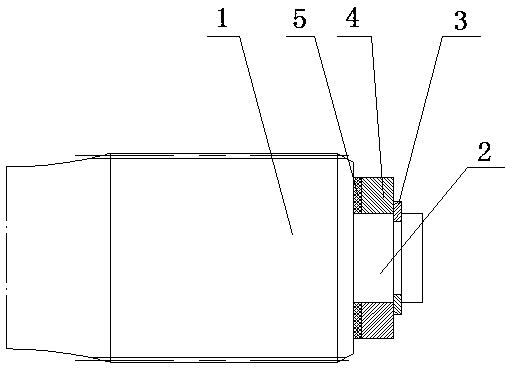

[0012] see figure 1 , The half shaft for the drive axle includes a half shaft body 1, the spline end of the half shaft body 1 is provided with a boss 2, and the boss 2 is provided with a ring of grooves, and the groove is sleeved with an elastic retaining ring for the shaft 3. A magnet 4 is provided on the boss 2 between the elastic retaining ring 3 for the shaft and the half shaft body 1, and an aluminum sheet 5 is provided on the boss 2 between the magnet 4 and the half shaft body 1.

[0013] see figure 1 When assembling, first install the aluminum sheet 5 on the boss 2, then install the magnet 4, and then install the shaft circlip 3, after the assembly is completed, insert the half shaft into the inter-wheel differential to match the half shaft gear .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com