Brake shoe protector and railway vehicle brake system

A technology of protectors and brake shoes, which is applied in railway braking systems, railway car body parts, vehicle maintenance, etc., can solve the problems of high operation and maintenance costs of railway vehicles, reduce maintenance costs, slow down abnormal wear, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

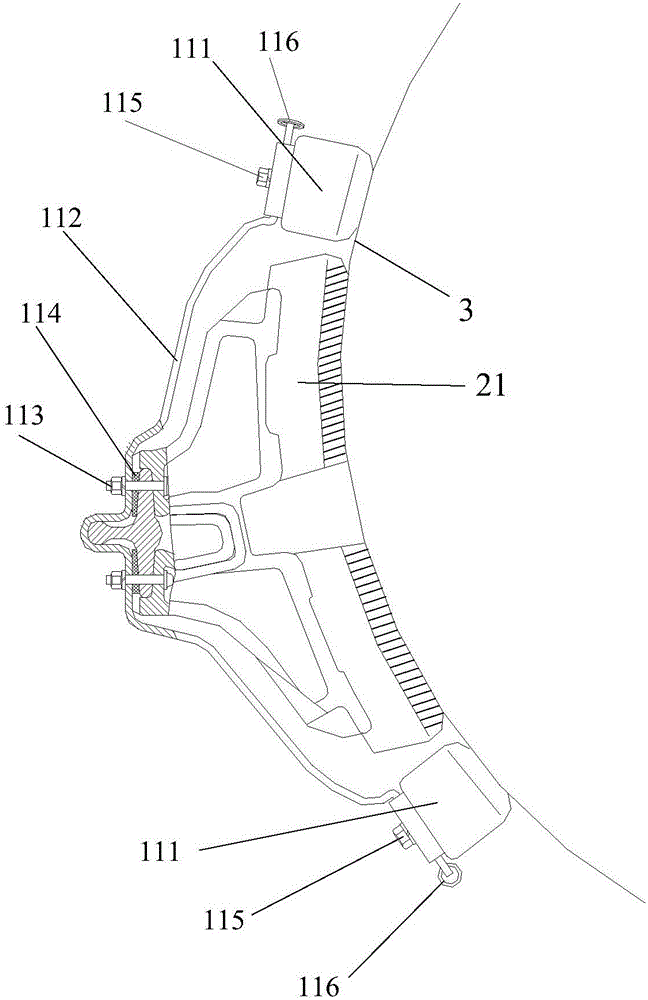

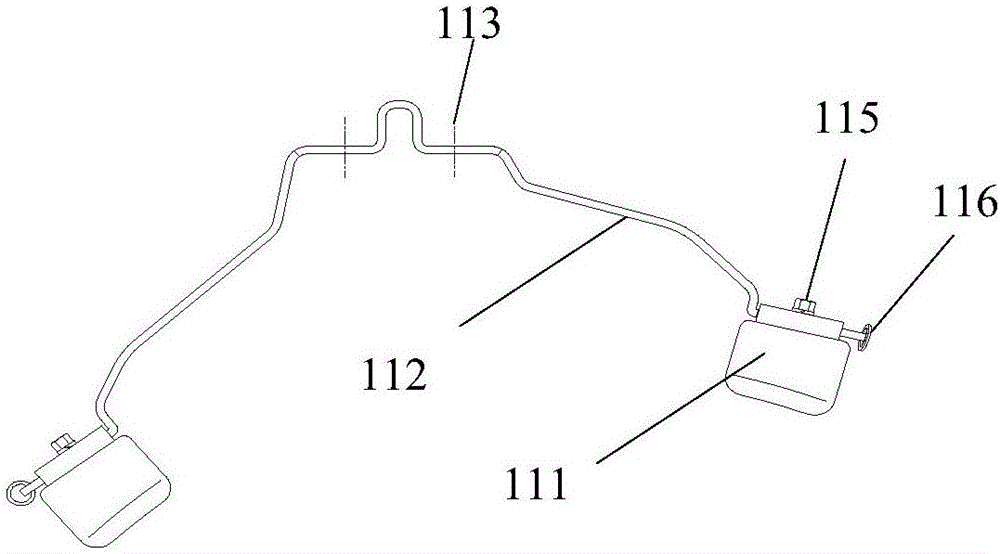

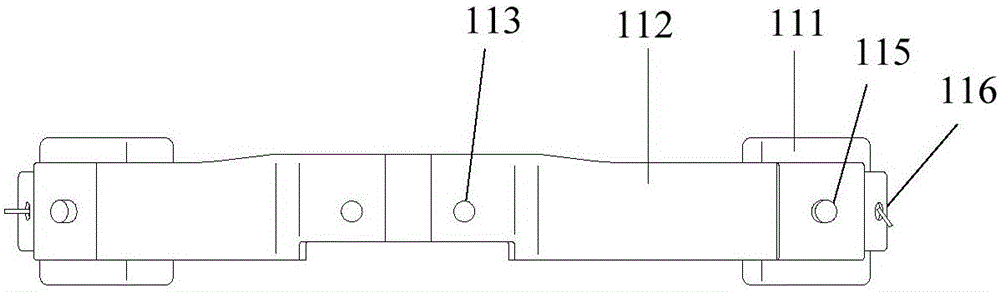

[0032] figure 1 It is a structural schematic diagram of Embodiment 1 of the brake shoe protector of the present invention, as figure 1 As shown, the brake shoe protector of this embodiment includes: two grinders 111 and a mounting plate 112 .

[0033] The mounting plate 112 is fixedly arranged on the back of the brake shoe 21, and the two ends of the mounting plate 112 extend beyond the upper and lower ends of the brake shoe 21. One end is fixed on the end of the mounting plate 112 , and the inner surface of each grinder 111 is in contact with the wheel tread 3 .

[0034] The grinder 111 is used to remove debris and foreign matter from the wheel tread 3 . Grinder 111 can adopt the same material as the working surface of brake shoe 21, which not only makes the grinder 111 good in wear resistance, long in life, but also lighter in weight, saves time and effort when replacing, and reduces labor intensity. The working surface of the brake shoe 21 refers to the surface that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com