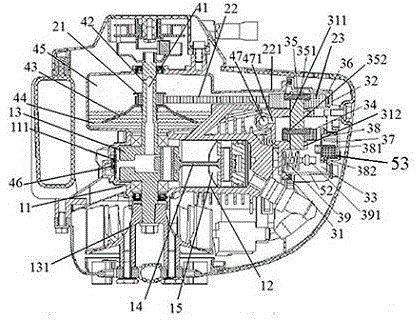

Four-stroke engine of vertical shaft OHC structure

A four-stroke engine, engine technology, applied in the direction of machine/engine, mechanical equipment, valve drive device, etc., to ensure separation and recovery, reduce abnormal consumption, and optimize engine emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

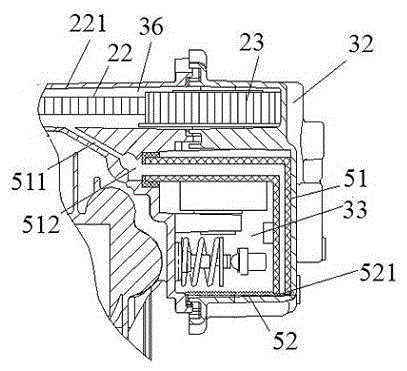

[0023] The lubricating oil pool collects the lubricating oil separated and settled from the valve train cavity and the respirator chamber; the lubricating oil separated and settled in the valve train cavity is directly collected into the lubricating oil pool below; Under the action of gravity, the oil flows into the lubricating oil sump from the return hole of the separator at the lower side of the separator.

[0024] The lubricating oil mist generating mechanism is arranged in such a way that the lubricating oil tank chamber is arranged above the engine main body, the engine output mechanism is arranged below the engine main body, the crankshaft is vertically supported on the crankcase and installed in the crankcase chamber, and the output end of the crankshaft extends downwards And it is connected with the engine output mechanism arranged under the main body of the engine, and the other end extends upwards through the lubricating oil tank chamber and the driving pulley, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com