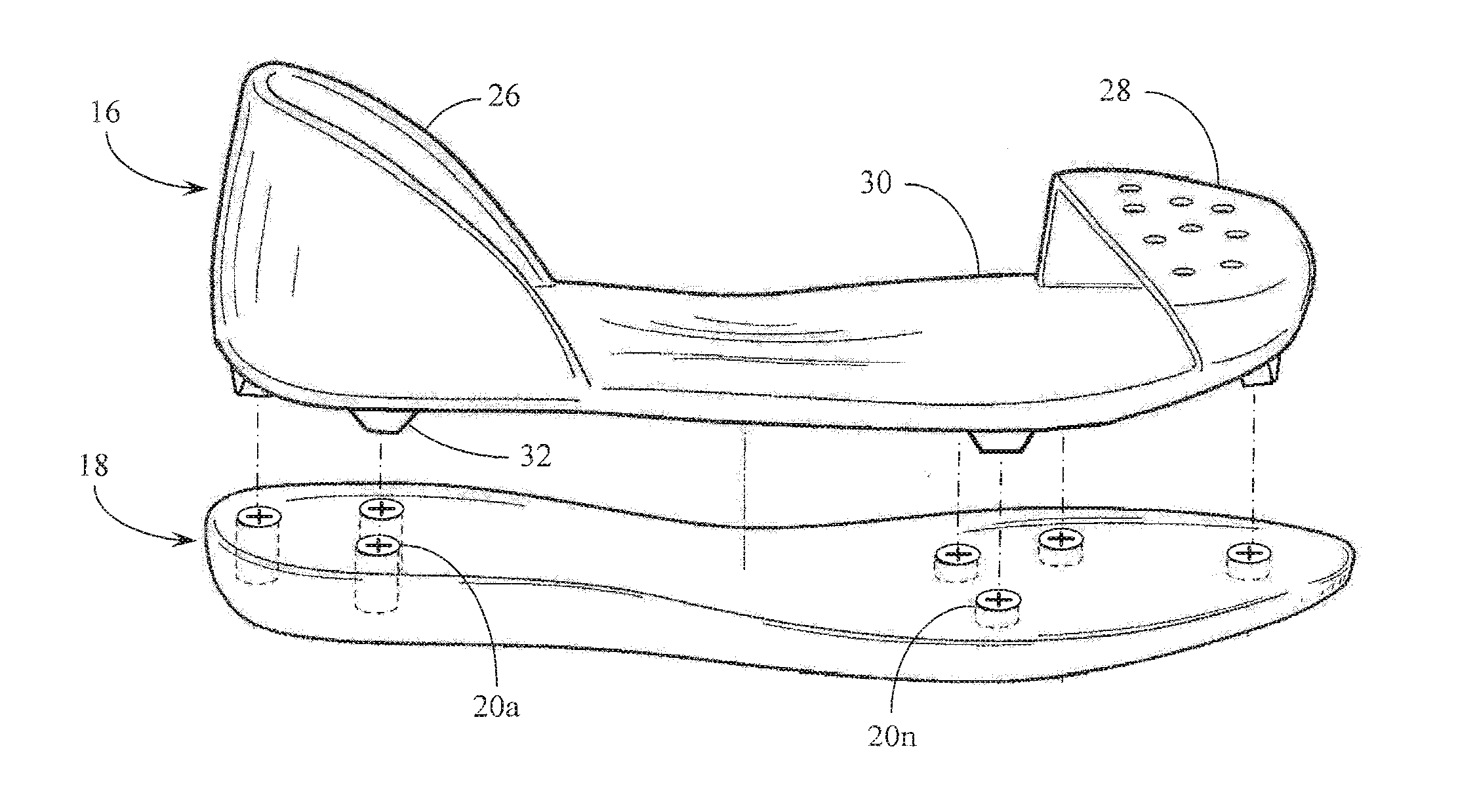

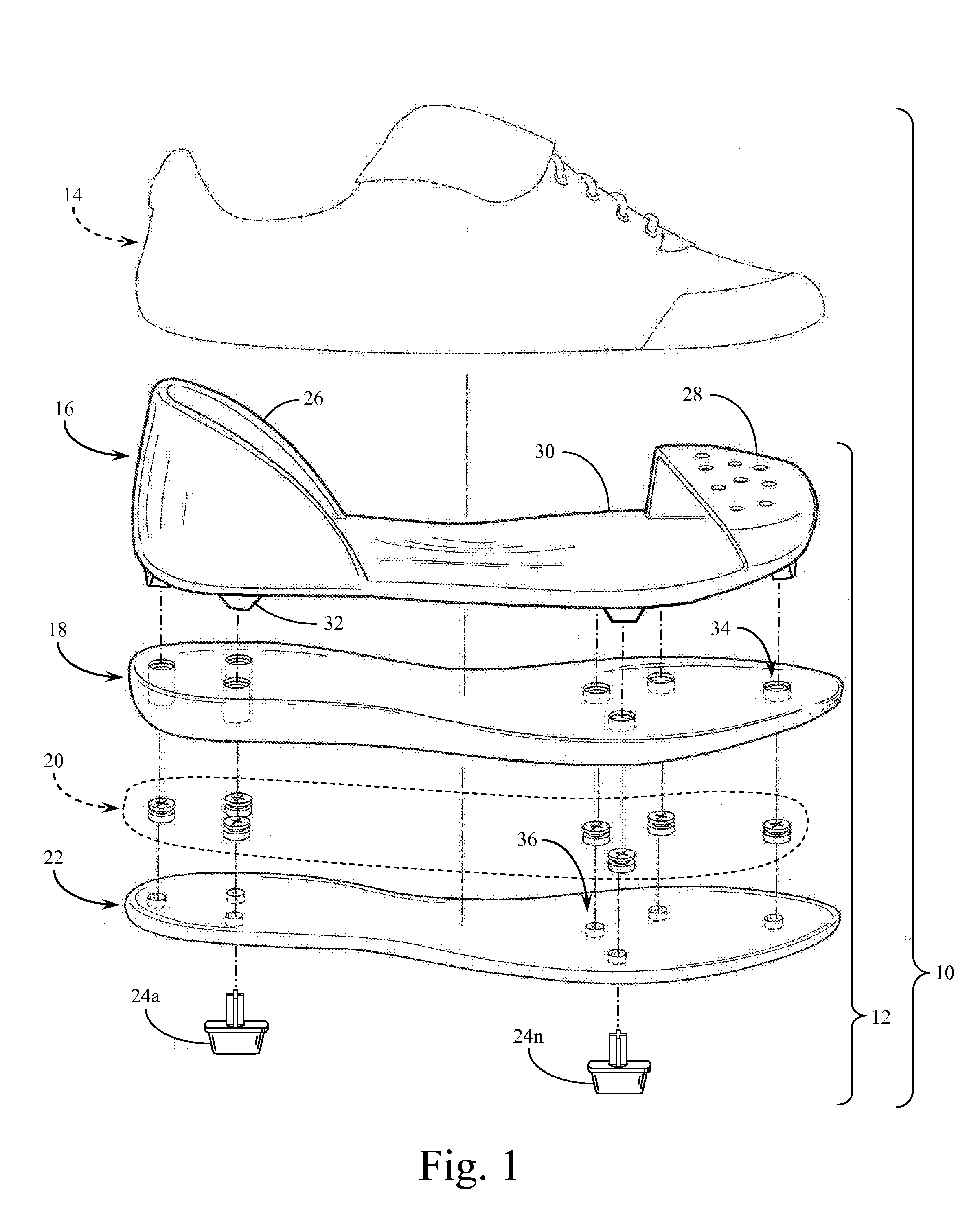

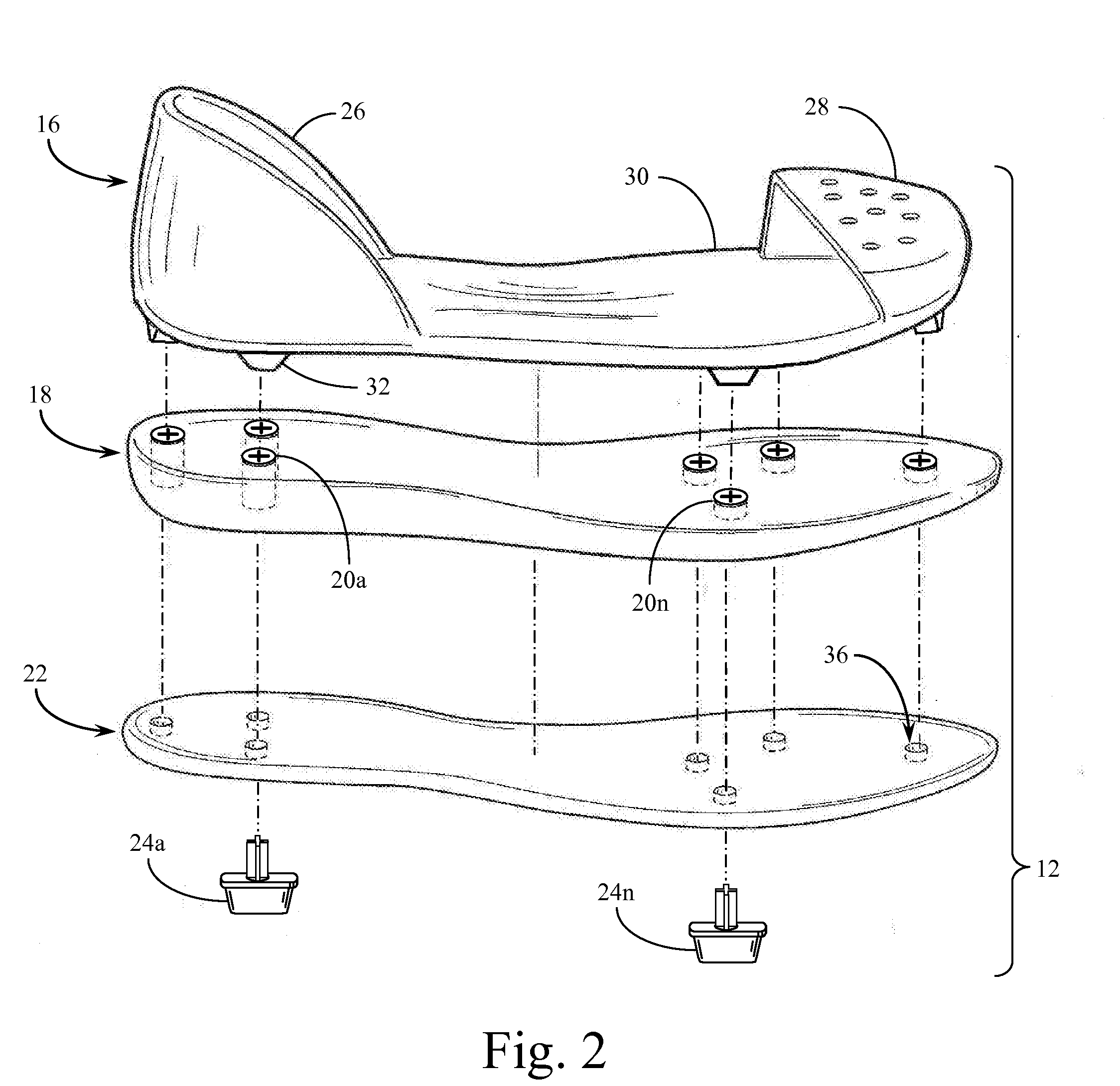

[0014]The CSI unit fills the inner space adjacent to the topside surface of the sole. The insole cradle unit includes a sock lined plastic layer encompassing a

heel cup, arch support and

toe protector having cleats / spikes attached, affixed or receptacle means for said cleats / spikes. The sock liner comprises a compressibly resilient foam layer having top and bottom surfaces sized and shaped for

insertion into the footwear and for supporting the foot. The sole (mid / out) attenuates reaction forces and absorbs energy as the footwear contacts the surface. The midsole forms the middle layer of the

cushion sole and may be composed of resilient foam material, such as

polyurethane, or similar or combination of materials. The cleats / spikes are provided at the bottom of the sole for ground engaged traction. The CSI shoe structure reduces manufacturing cost and simplifies manufacturing processes.

[0015]The sock liner is a very soft foam insert that adds plenty of comfort and relieves cleat / spike pressure with light

cushioning and shock absorption of the shoe. The foam lower layer has

compressibility sufficient to permit the layer to resiliently compress under the foot in response to pressure applied by the foot during periods of a

gait cycle when the footwear impacts the ground thereby absorbing shock and

cushioning the foot during

impact. The sock liner may further comprise an

open cell layer. The bottom surface of the upper layer is permanently bonded to the top surface of the lower layer for spacing the lower layer from the foot to reduce

heat transfer from the lower layer to the foot and insulate. The sock liner may include a

closed cell lower layer and a porous upper level permitting air to pass through to cool and dry the foot. The sock lined bonded plastic unit may be removable and replaceable. The CSI shoe improves stability, propulsion, sides-to-sides and gains maximum foot control. The cleat / spike insole has direct contact creating a natural

synergy with the athlete's foot.

[0016]The plastic cradle insole of the present invention provides support and is used for cleats / spikes attachment. The plastic insole cradle can be formed by injection molding a resin into a desired shape, including a receptacle. The receptacle is sized and dimensioned to receive a threaded or locking

system head of the shank (cleat component). The resin can be enhanced having a fibrous composition of nylon or glass. Arch support is placed beneath the medial region, and considerable weight may be saved, as conventional mid / out sole materials may be reduced or eliminated. The resistance to flex is important in the arch support region during the

gait cycle. In addition, the anterior of the support requires an increase of flexibility for toeing off.

[0017]Cleated athletic shoes typically include a sole having an upper extending upwardly from the sole and into which the foot of the athlete is positioned and secured in place. A conventional cleated athletic shoe usually includes a pattern of cleats in the rearfoot portion and in the

forefoot portion of the outsole. CSI spikes / cleats attach to the plastic insole with a screw, threaded shank head, shank lock

system and / or have a receptacle disposed on the exterior surface in the molding process. An engagement receptacle would have threads on the interior surface wall. Shoes with studs are designed for efficient, reliable attachment and disengagement. This allows the player to use the optimal stud for different

field conditions.

[0018]The sole of a typical athletic shoe accounts for 70% of the total shoe weight. Thus, to significantly reduce the total weight of a shoe, steps must be taken to reduce the weight of the sole. To achieve a sole which is lightweight, the components thereof must be structured from a

elimination concept to materials which are functionally efficient. The unisole structure of the present invention is lightweight, provides flexibility, rigidness and is easier to assemble than conventional midsole and outsoles. The unisole is attached to the upper by lasting and / or adhesives. In addition, the unisole reduces molding costs due to the fact that the midsole / outsole, or sole can be formed with one mold from a combined midsole / outsole material which eliminates the need for a separate outsole mold. By using one mold as compared to two molds, simultaneously reduces the thickness, cost and weight. As mentioned above, the unisole uses a combined midsole / outsole material to reduce the weight and increase the stability of the shoe. The stability is vital due to cleat pressure. The unisole and alternative components are molded from a compound comprising

cushioning foam (for example,

polyurethane or

ethyl vinyl acetate) and an abrasion resistant rubber. The EVA foam and compounds are available from

Eclipse Polymers Co. Ltd. EVA or

polyurethane are both capable of producing a suitable sole, however the primary requirements of the present invention are durability and stiffness value. The unisole is made by injection or form molding. The bottom surface may be molded with a plurality of

tread elements to increase the traction. A

tread element texturing may take the form of v-shaped flex groves, waffles, or other dimensional projections.

Login to View More

Login to View More  Login to View More

Login to View More