Freestone type peach pitting device

A kind of nuclear device, peach technology, applied in the field of de-pitting device for peaches, which can solve the problems of hand injury and work intensity, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below will combine specific embodiment and appended Figure 1-7 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

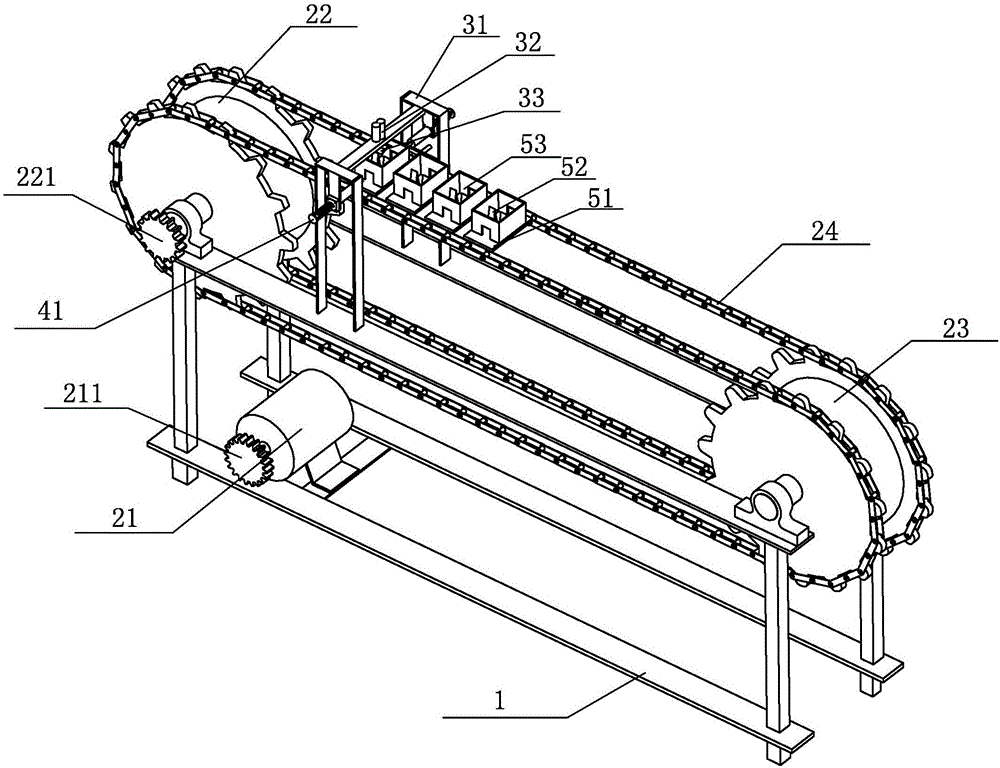

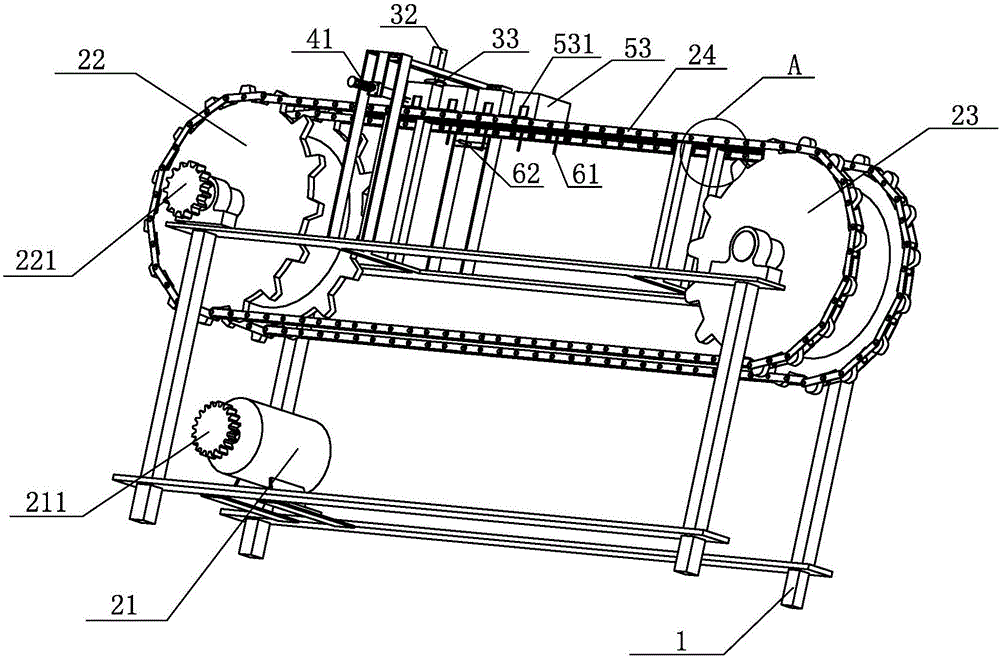

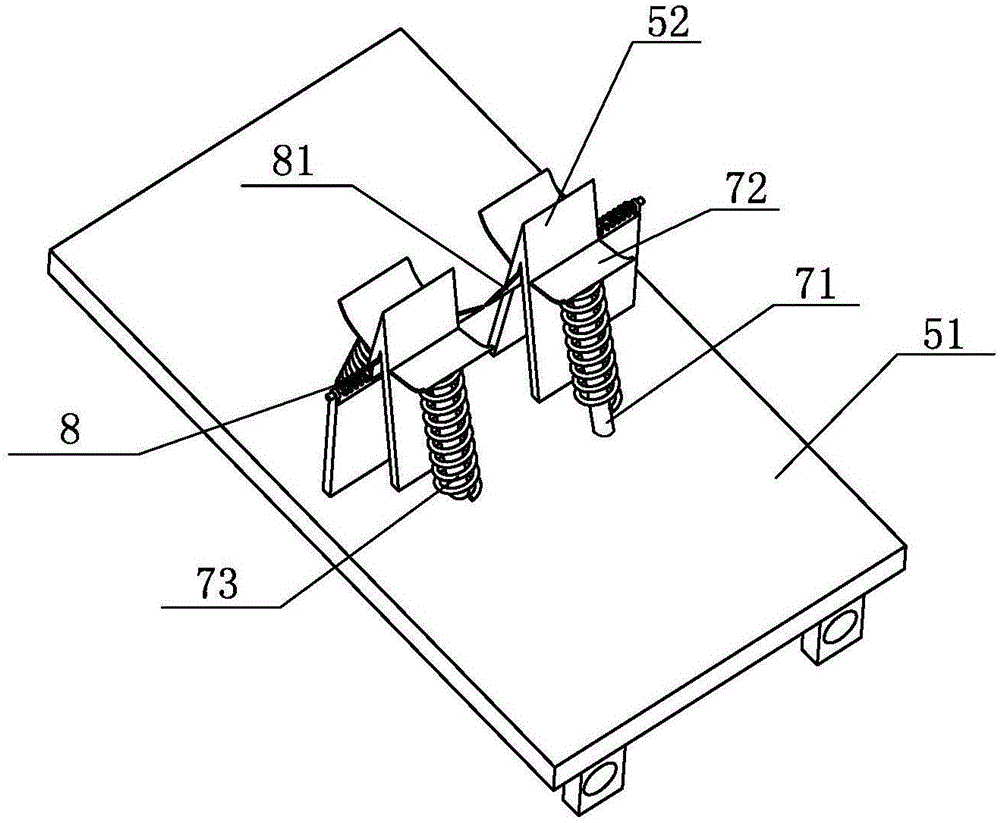

[0028] The invention provides a kind of off-pit peach pitting device (such as figure 1 shown), the device includes a complete machine support 1, a transmission mechanism, a valve opening mechanism and a control circuit board (in order to keep the drawings clear, the control circuit board is drawn in the accompanying drawings), and the transmission mechanism and the valve opening mechanism are located on the whole On the machine support 1, the transmission mechanism includes a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com