Novel slide plate brick for automatic slag-retaining slide gate of converter and preparation method of slide plate brick

A sliding nozzle and automatic blocking technology, which is applied in the field of sliding bricks for the new type converter automatic slag blocking sliding nozzle and its preparation, can solve the problems of poor grasp of slag blocking timing, inability to prevent converter slag dropping, frequent parts replacement, etc., and achieve convenient The control of production cycle and tapping temperature, excellent thermal shock stability, and the effect of improving the life of the ladle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

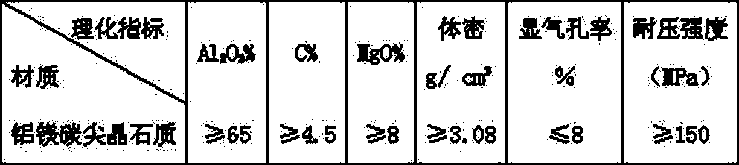

Method used

Image

Examples

Embodiment 1

[0037] A new method for preparing sliding bricks for automatic slag-retaining sliding nozzles of converters. The selected weight percentages are: 30% of tabular corundum with a particle diameter of 2-1mm, 33% of tabular corundum with a particle diameter of 1-0mm, and granules 6% of 98 magnesia with a diameter of 1-0mm, 8% of 325-mesh fused spinel, 4% of 180-mesh graphite, 4% of 1μm a-alumina powder, 1% of sintering agent, 5% of aluminum-silicon alloy powder and 4% resin, according to the mixing amount of 500 kg per machine, first turn on the automatic pressure-adjusting lifting type kneading machine, then put in the granular plate-shaped corundum and 98 magnesia, add the resin after 3 minutes, and after 8-10 minutes After mixing, put in fine powder materials such as fused spinel, graphite, a-alumina micropowder, sintering agent and aluminum-silicon alloy powder, stir for 8-10 minutes and then pressurize for 25 minutes. After the pressurization is completed, lift the roller out ...

Embodiment 2

[0039] A new method for preparing sliding bricks for automatic slag-retaining sliding nozzles of converters. The selected weight percentages are: 32% of tabular corundum with a particle diameter of 2-1mm, 28% of tabular corundum with a particle diameter of 1-0mm, and granules 7% of 98 magnesia with a diameter of 1-0mm, 10% of 325-mesh fused spinel, 5% of 180-mesh graphite, 6% of 1μm a-alumina powder, 2% of sintering agent, 6% of aluminum-silicon alloy powder and 5% resin, according to the mixing amount of 500 kg per machine, first turn on the automatic pressure-adjusting lifting type mixing machine, then put in the granular plate-shaped corundum and 98 magnesia, add the resin after 4 minutes, and after 8-10 minutes After mixing, put in fine powder materials such as fused spinel, graphite, a-alumina micropowder, sintering agent and aluminum-silicon alloy powder, stir for 8-10 minutes and then pressurize for 20 minutes. After the pressurization is completed, lift the roller out ...

Embodiment 3

[0041] A new method for preparing sliding bricks for automatic slag-retaining sliding nozzles of converters. The selected weight percentages are: 35% of tabular corundum with a particle diameter of 2-1mm, 30% of tabular corundum with a particle diameter of 1-0mm, and granules 8% of 98 magnesia with a diameter of 1-0mm, 11% of 325-mesh fused spinel, 5% of 180-mesh graphite, 5% of 1μm a-alumina powder, 1.5% of sintering agent, 7% of aluminum-silicon alloy powder and 4% resin, according to the mixing amount of 500 kg per machine, first turn on the automatic pressure-adjusting lifting type kneading machine, then put in the granular plate-shaped corundum and 98 magnesia, add the resin after 5 minutes, and after 8-10 minutes After mixing, put in fine powder materials such as fused spinel, graphite, a-alumina micropowder, sintering agent and aluminum-silicon alloy powder, stir for 8-10 minutes and then pressurize for 15 minutes. After the pressurization is completed, lift the roller o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com