Method for dynamic adjustment of radial expansion force of uncoiler

A dynamic adjustment and uncoiler technology, applied in mechanical pressure/force control, non-electric variable control, control/regulation systems, etc., can solve problems such as tie rod breakage, inability to continuously change, restricting product yield, etc., to achieve smooth operation, Improve the quality pass rate and reduce the effect of scratch defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment.

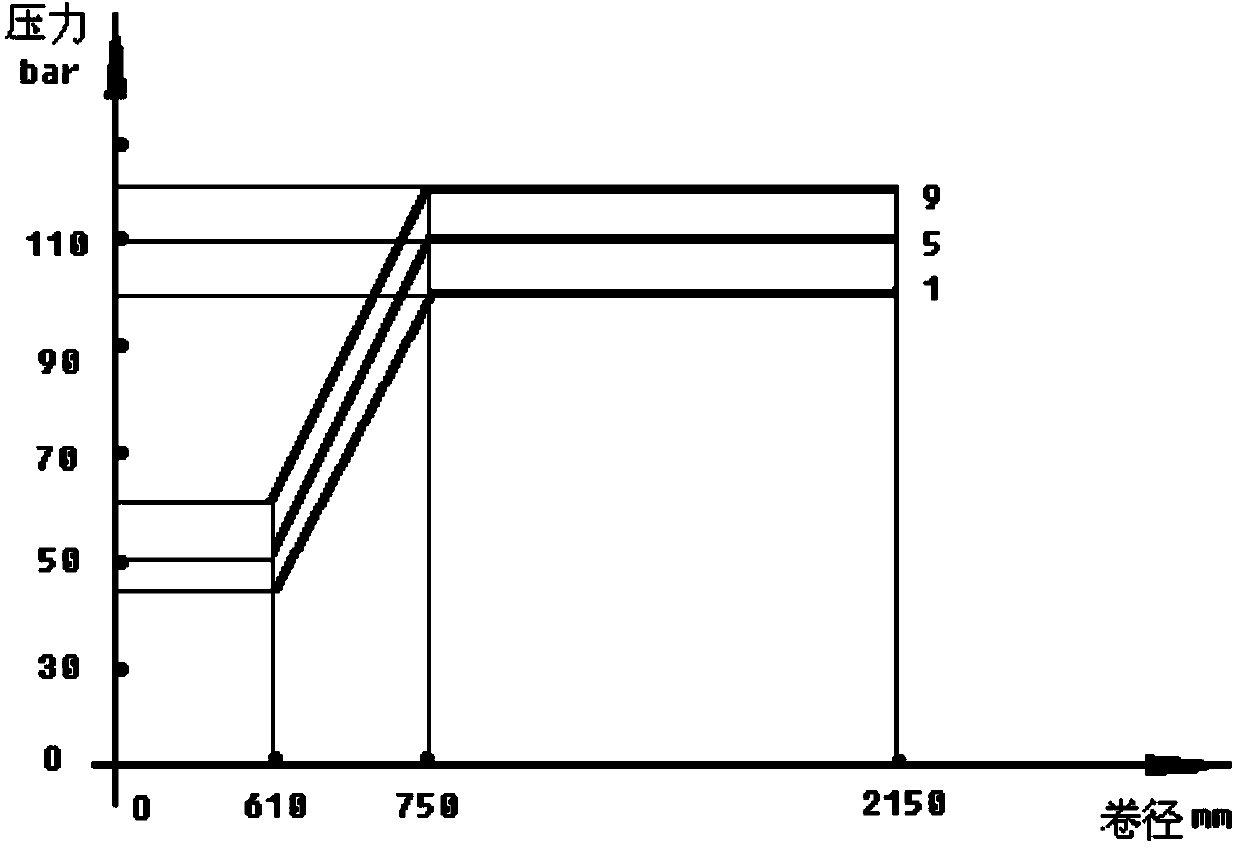

[0016] The method for dynamically adjusting the diameter expansion force of the uncoiler of the present invention mainly utilizes the original primary computer, secondary computer and unit PLC, and changes the manual pilot pressure reducing valve in the decompression circuit of the uncoiler reel expansion and contraction hydraulic system. It is a three-way proportional pressure reducing valve, and the proportional pressure reducing valve is used to control the tension force, so as to realize the dynamic change of the diameter expansion pressure with the change of the outer diameter of the steel coil. The specific method is:

[0017] 1. According to the previous coil diameter parameters and unit tension parameters, summarize and form the diameter expansion force, coil diameter and unit tension data curve, and compile the control relationship of each parameter into the unit PLC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com