Double-zero foil blank 8079 alloy head and tail quality control method

A quality control method and double-zero foil technology, applied in manufacturing tools, furnaces, heat treatment equipment, etc., can solve problems such as scratches, and achieve the effects of improving quality, reducing production costs, and reducing rework loss and burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

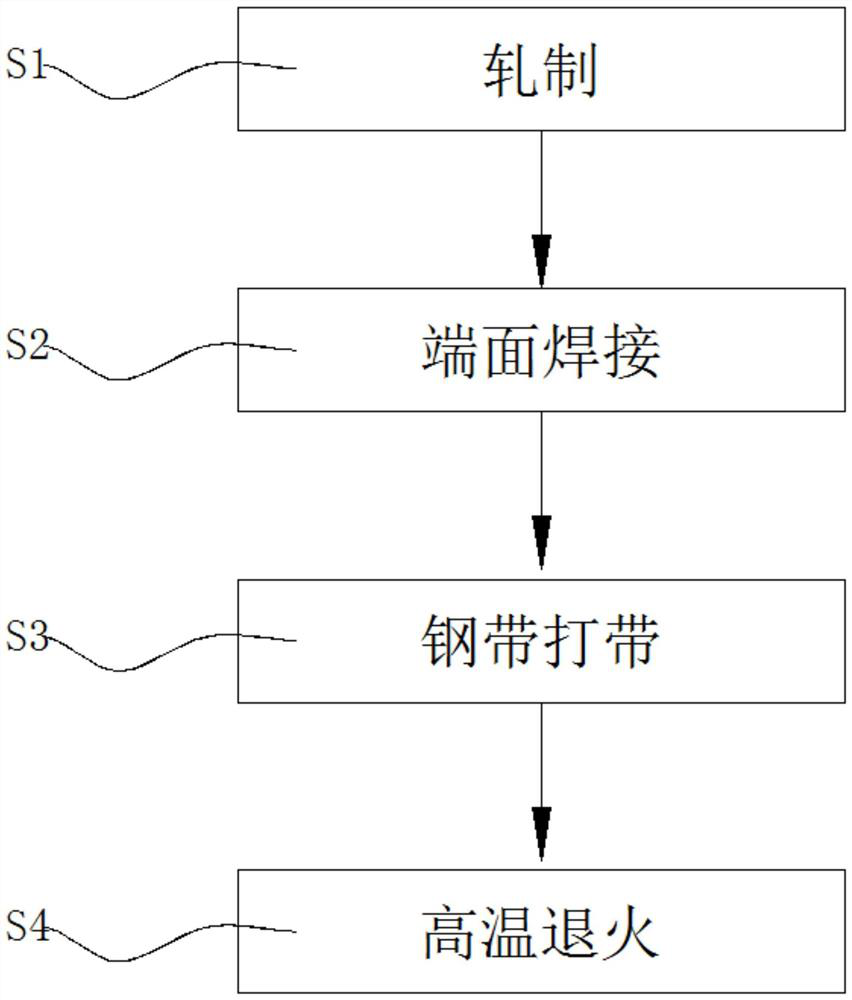

[0033] Specific implementation mode one: please refer to Figure 1-6 , the present invention provides a technical solution: a method for controlling the quality of the head and tail of a double zero-foil blank 8079 alloy, comprising the following steps:

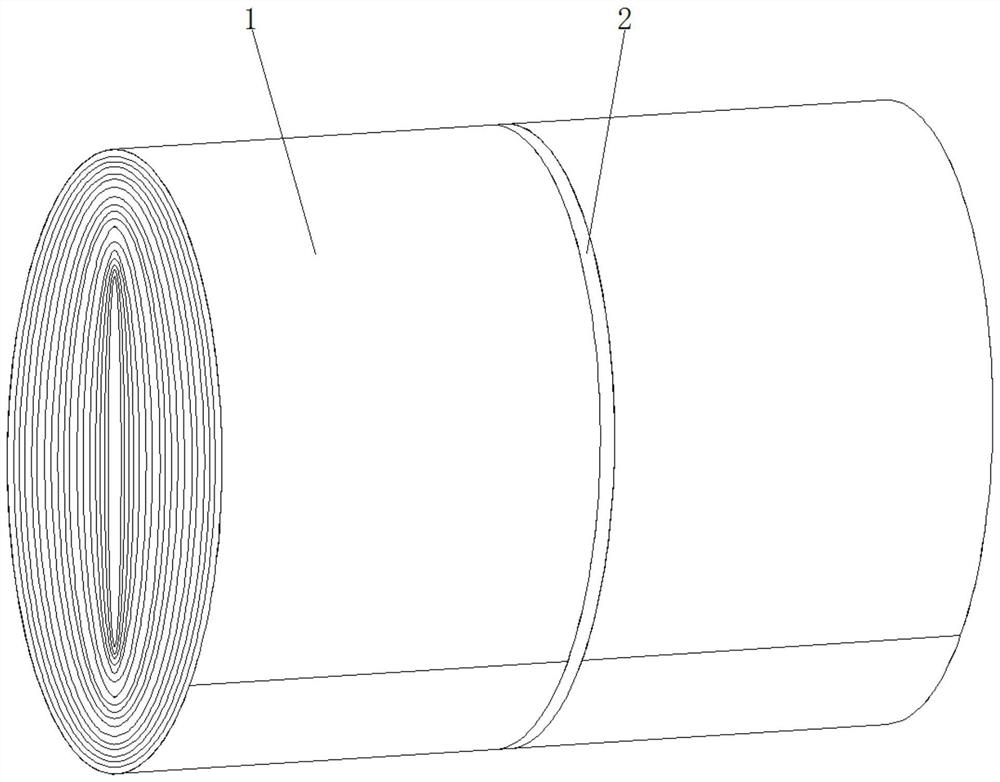

[0034] S1, rolling the aluminum alloy material into a thin plate with a thickness of 7-4.0mm, and winding the thin plate to form an aluminum alloy material coil 1;

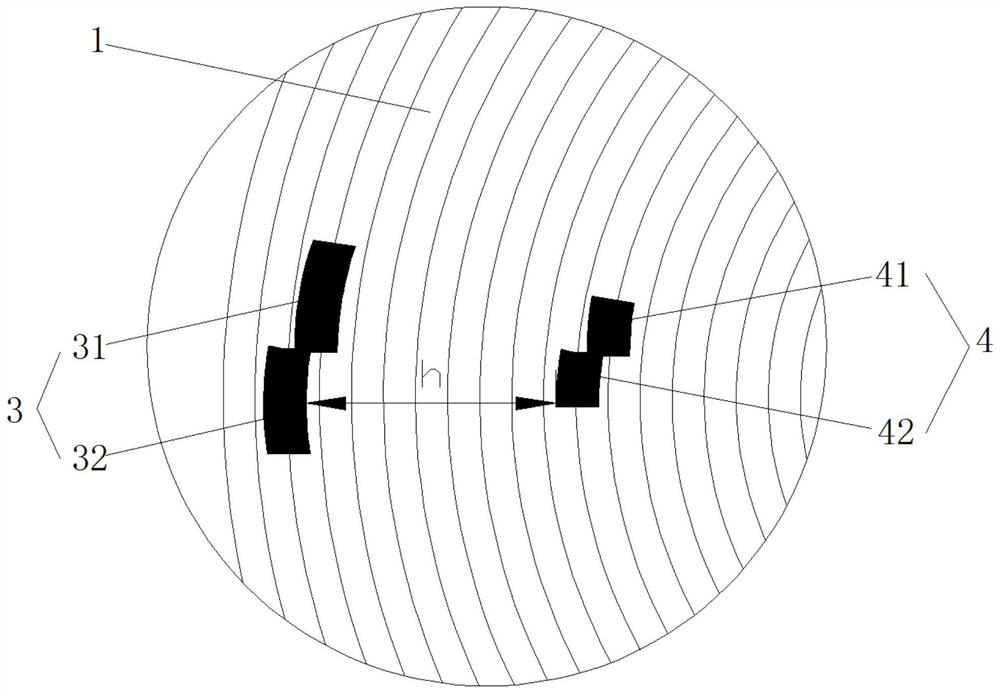

[0035] S2, spot welding the first electrode 3 and the second electrode 4 on the end surface of the aluminum alloy coil 1;

[0036] S3, making a steel strip 2 in the middle of the aluminum alloy coil 1;

[0037] S4, sending the aluminum alloy material roll 1 into an annealing furnace for high-temperature annealing treatment of finished products.

[0038] In step S1, when the aluminum alloy material coil 1 is finished, the aluminum alloy material coil 1 is supported by a trolley in advance. In step S2, the first welding rod 3 and the second welding rod 4 are clos...

specific Embodiment approach 2

[0040] Specific embodiment two: this embodiment is a further limitation of specific embodiment one, such as figure 2 As shown, the first welding rod 3 is made up of the first upper welding section 31 and the first lower welding section 32, the first upper welding section 31 and the first lower welding section 32 are mutually staggered, and the bottom end of the first upper welding section 31 is in line with the The top ends of the first lower welding section 32 are connected, and the welding sections connected in a staggered manner are arranged to avoid excessive weld seam of the aluminum alloy coil 1 and reduce the risk of tearing and breaking the strip during the next rolling pass.

specific Embodiment approach 3

[0041] Specific implementation mode three: this implementation mode is a further limitation of specific implementation mode two, such as figure 2 As shown, the second welding rod 4 is made up of the second upper welding section 41 and the second lower welding section 42, the second upper welding section 41 and the second lower welding section 42 are staggered from each other, and the bottom end of the second upper welding section 41 is in line with the The top ends of the second lower welding segments 42 are connected to each other.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com