Vertical tension-free movable sleeve

A tension-free, looper technology, used in feeding devices, positioning devices, storage devices, etc., can solve the problems of easy scratches on the surface of steel plates, easy scratches on the surface, and easy breakage of strips, so as to reduce scratches and scratches. The effect of good protection against marks, plate shape and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

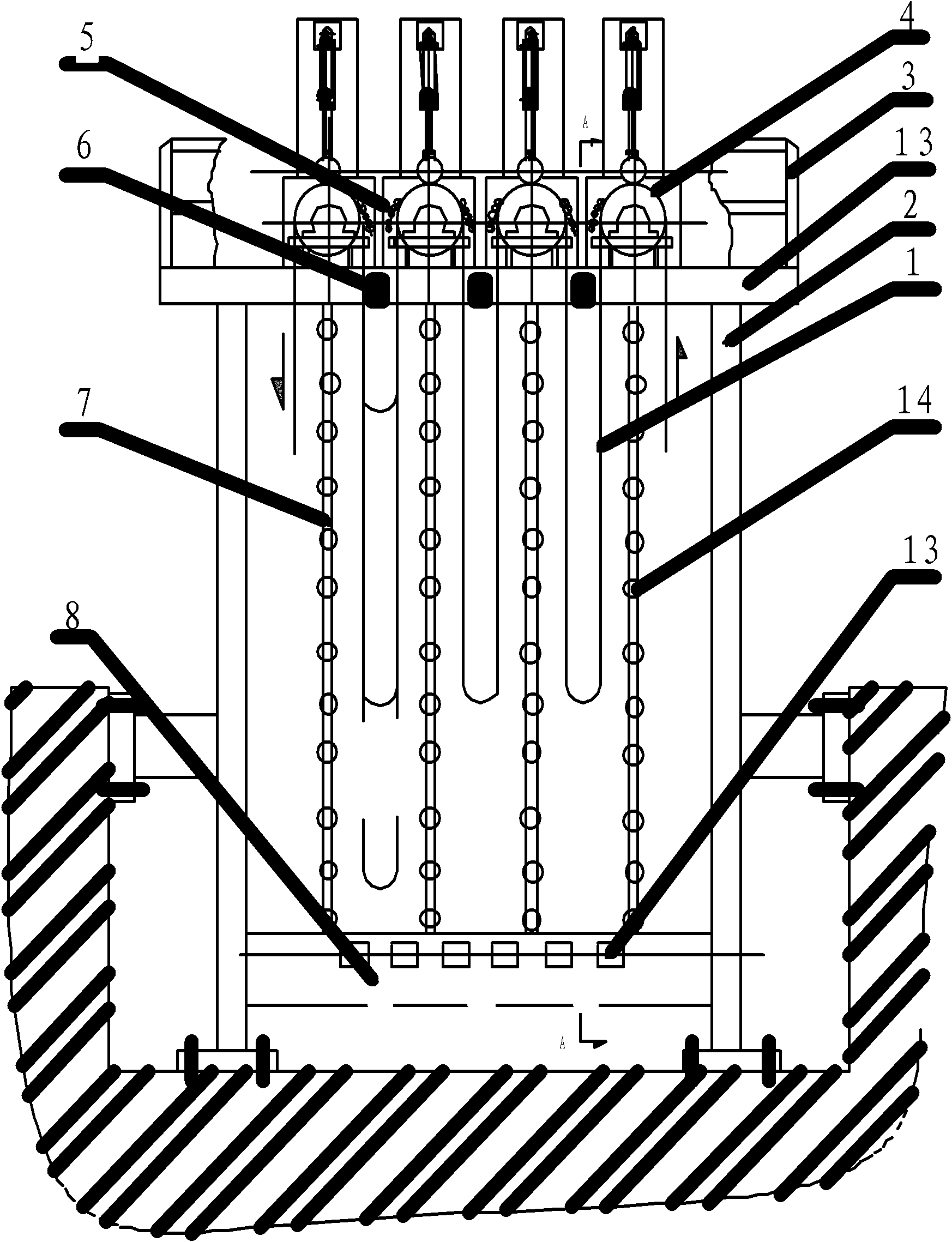

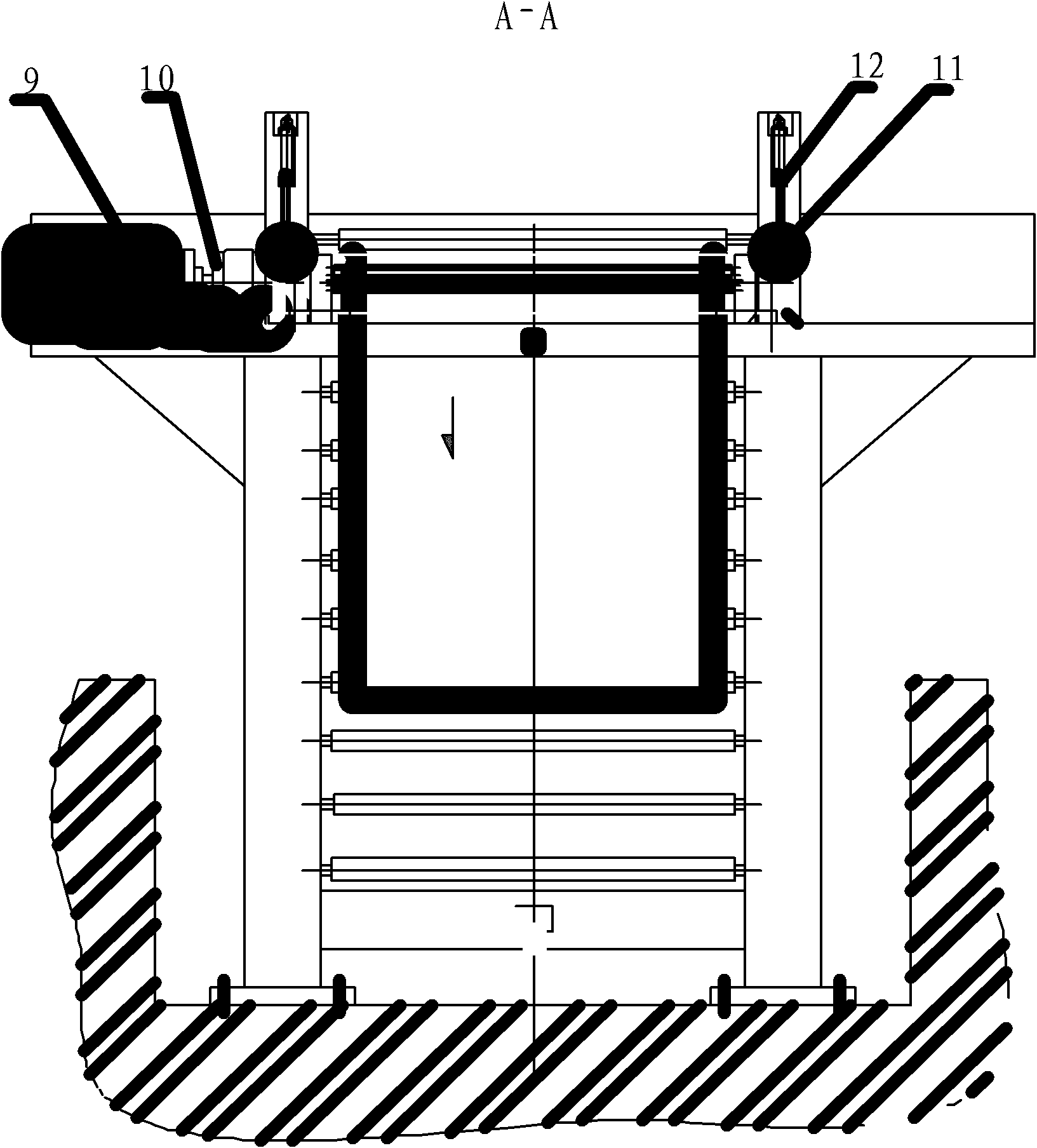

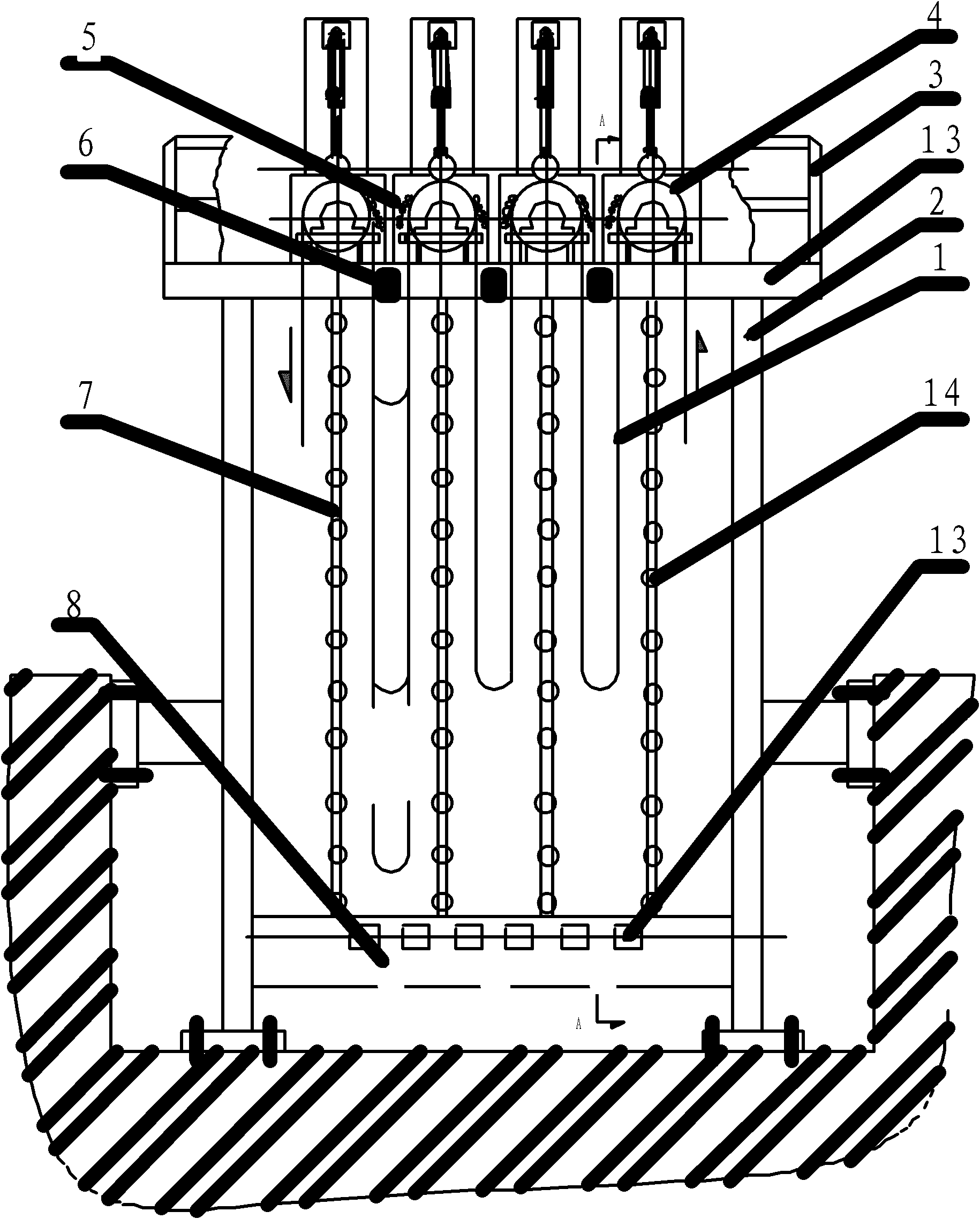

[0014] exist figure 1 , figure 2 Among them, in this embodiment, it is composed of frame 2 and pinch roller 4 installed on the top of frame 2. The top of frame 2 is made of steel structure, and guardrail 3 is installed around it for protection. The top and the bottom of the top are connected with isolation guards 7, and the guards are located under the pinch rollers 4, in the same direction as the pinch rolls, with the same number. Below the frame 2 along the direction of the isolation guard, a connecting crossbeam 13 is installed, where the connecting crossbeam 13 adopts a circular shape as much as possible to prevent the plate from being scratched when it sags.

[0015] The pinch roller 4 is composed of a lower roller and an upper roller, and the lower roller is driven by a driving force, which can be driven by a motor or a motor or any other power. Drooping gravity, each pinch roller has its own power, which can drive the lower roller of each pinch roller 4 separately, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com