Method of preventing heavy gauge strip steel from being scratched among finishing mill racks

A finishing mill and thick-gauge technology, applied in the field of metallurgical industry control, can solve problems such as scratches, achieve the effects of improving the pass rate, avoiding scratches, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

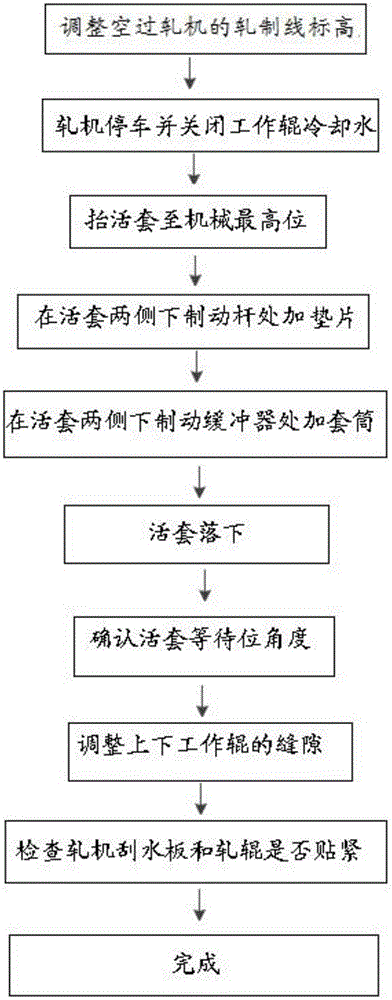

[0041] Embodiment 1: as figure 1 As shown, the embodiment 1 of the present application avoids the method that the thick-gauge steel strip is scratched between the finishing mill stands and comprises the following steps:

[0042] Step S1: Before rolling the thick-gauge strip steel, select the roll diameter of the lower work roll of the empty rolling mill to be 630 mm, so that the elevation of the rolling line of the empty rolling mill is a positive elevation; The line elevation is +5mm.

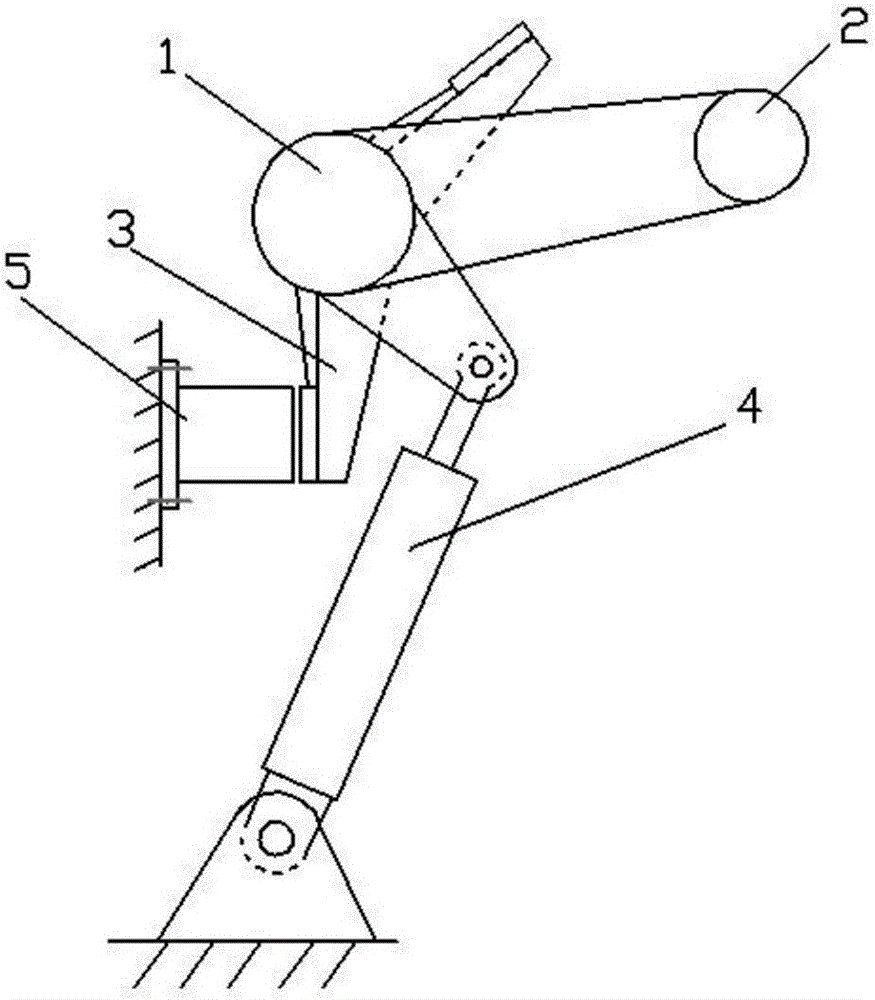

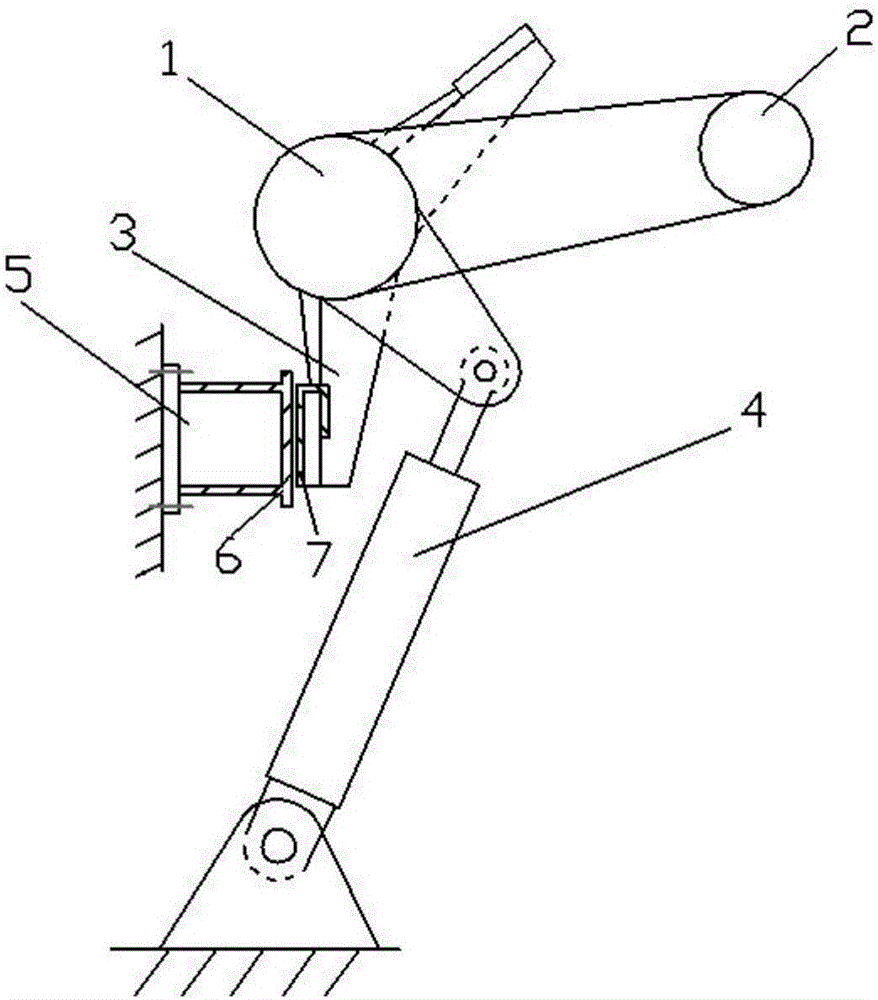

[0043] Step S2: After throwing steel from the final rolling stand of the finishing mill, stop the mill and turn off the cooling water of the work roll; lift the looper to the highest position of the machine, insert the safety pin of the looper, and install a A spacer with a thickness of 20mm, a steel sleeve is installed at one end of the brake buffer on both sides under the looper, a spacer or sleeve with the same thickness on each side, and the spacers on each side are located at Between th...

Embodiment 2

[0047] Embodiment 2: Step S1: Before rolling the thick-gauge steel strip, by moving the position of the lower work roll step pad (the lower step pad is located below the lower support roll, and the lower support roll is located below the lower work roll), so that the empty rolling mill The elevation of the rolling line is the positive elevation; the elevation of the guaranteed rolling line is +8mm.

[0048] Step S2: After throwing steel from the final rolling stand of the finishing mill, stop the mill and turn off the cooling water of the work roll; lift the looper to the highest position of the machine, insert the safety pin of the looper, and install a A gasket with a thickness of 30mm, a steel sleeve is installed at one end of the brake buffer on both sides under the looper, and a gasket or sleeve with the same thickness is installed on each side, and the gaskets on each side are located at the corresponding Between the side sleeve and the brake lever; pull out the safety p...

Embodiment 3

[0052] Embodiment 3: Step S1: Before rolling the thick-gauge steel strip, select the roll diameter of the lower work roll of the empty rolling mill to be 850mm, so that the elevation of the rolling line of the empty rolling mill is a positive elevation; After the machine, ensure that the elevation of the rolling line is +10mm.

[0053] Step S2: After throwing steel from the final rolling stand of the finishing mill, stop the mill and turn off the cooling water of the work roll; lift the looper to the highest position of the machine, insert the safety pin of the looper, and install a A spacer with a thickness of 40mm, a steel sleeve is installed at one end of the brake buffer on both sides under the looper, and a spacer or sleeve with the same thickness is placed on each side, and the spacers on each side are located at Between the sleeve and the brake lever on the corresponding side; pull out the safety pin of the looper, drop the looper, and confirm that the waiting position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com