Manufacturing method of brake drum

A manufacturing method and brake drum technology, applied in manufacturing tools, molding machines, casting and molding equipment, etc., can solve the problems of low rigidity, difficult flow of molding sand, laborious manual molding, etc., to reduce production energy consumption, and to achieve clear contours of castings. , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

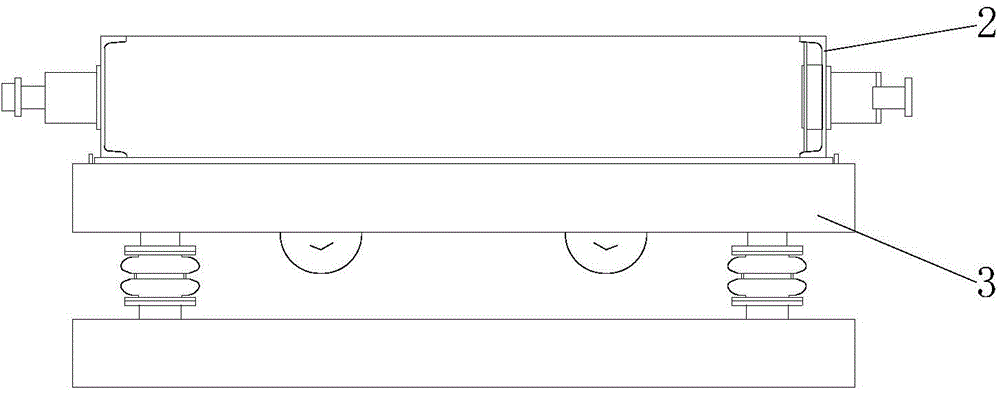

[0040] Such as Figures 1 to 7 As shown in one of the present invention, a brake drum manufacturing method of the present invention, the manufacturing method specifically includes the following steps:

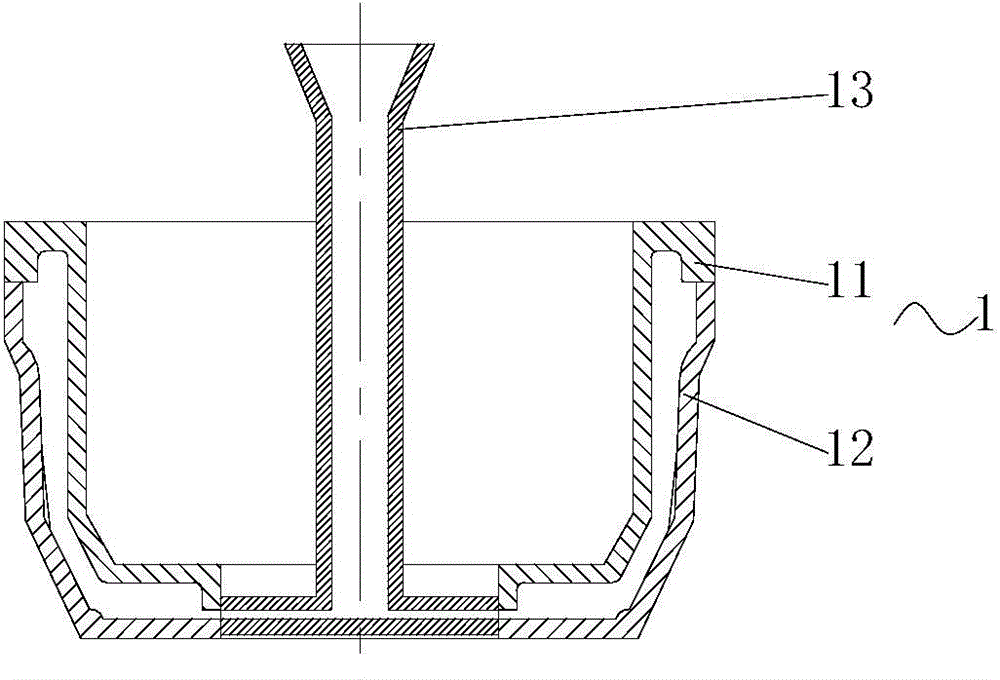

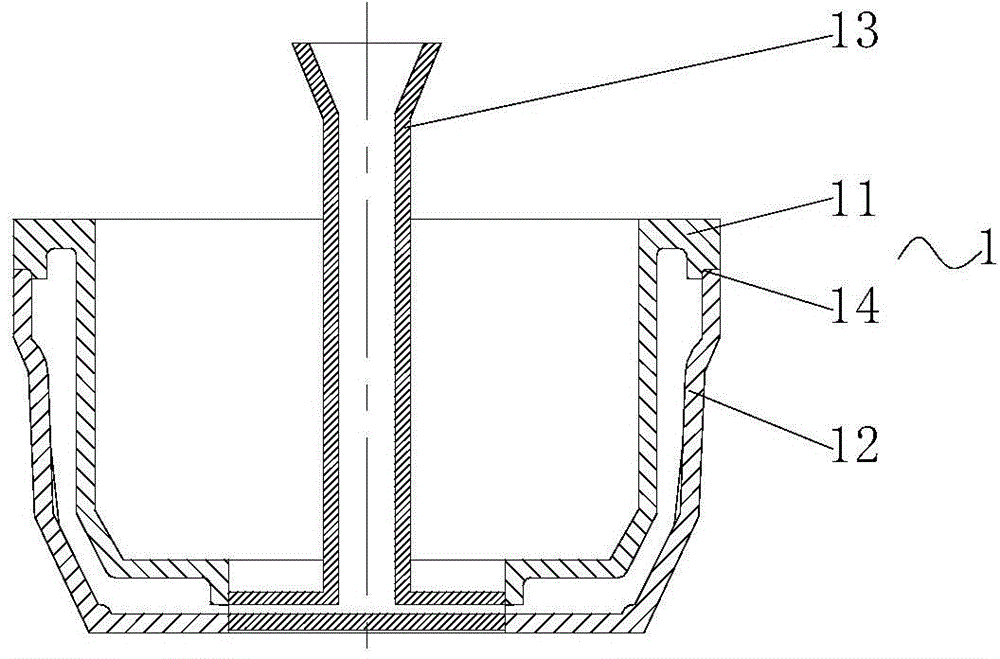

[0041] 1) On the core shooting machine, the upper mold shell type 11, the lower mold shell type 12 and the sprue cup shell type 13 are respectively manufactured with coated sand as raw materials, and then the upper mold shell type 11, the lower mold shell type 12 and the gate The cup shell mold 13 is assembled to form an integral film-coated sand shell mold 1, wherein a cavity for casting a brake drum is formed between the upper mold shell mold 11 and the lower mold shell mold 12, and the pouring inside the gate cup shell mold 13 The channel communicates with the above-mentioned cavity; figure 1 Among them, the assembling place of upper mold shell type 11 and lower mold shell type 12 adopts white glue bonding and sealing, as preferably, as figure 2 As shown, the assembly of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com