Stator assembly of automotive engine or driving motor

A motor stator and stator assembly technology, which is applied in the manufacture of motor generators, electric components, electrical components, etc., can solve problems such as defects, insulation paint peeling off, component edge scratches, etc., so as to increase the service life, improve the slot full rate, The effect of improving power generation and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

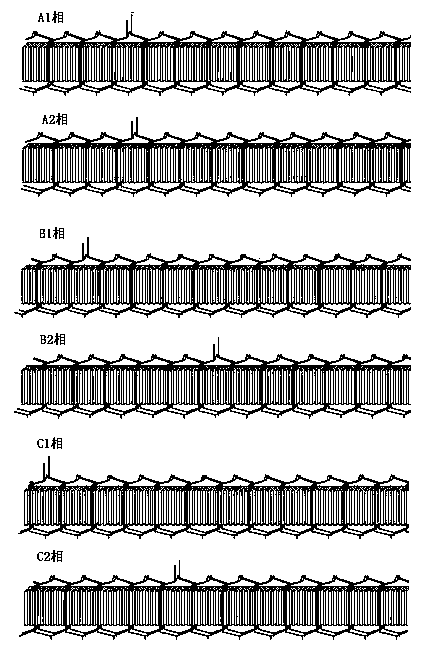

[0025] As shown in the figure, the stator assembly of the vehicle generator or drive motor includes a stator core 6 and a multi-phase winding. In this embodiment, the stator core 6 is 72 slots, 84 slots, 96 slots or 108 slots. Slotted stator core. The number of phases of the winding is six phases, respectively A1, A2, B1, B2, C1, C2 phases, see figure 1 .

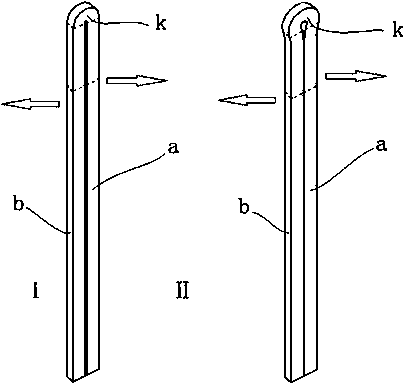

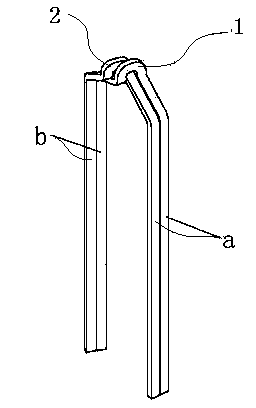

[0026] Each winding slot 8 of the stator core 6 has four layers of winding positions, and the winding of each phase consists of multiple sets of rectangular copper wire basic winding elements, a rectangular copper wire jumper connecting element 3 and a set of rectangular copper wires The basic winding element of the rectangular copper wire is composed of the basic winding element Ⅰ1 and the basic winding element Ⅱ2. After the middle parts of the two are twisted together, the two elements on the same side are attached side by side with straight sides. See Figure 4 , the straight sides a and b of the element on the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com