Polyphase permanent magnet motor with leakage reactance adjustable structure

A permanent magnet motor, a technology for adjusting the structure, applied in the synchronous motor with a static armature and a rotating magnet, the shape/pattern/structure of the magnetic circuit, the shape/pattern/structure of the winding conductor, etc. Low torque density, complex process and other problems, to achieve the effect of high air gap magnetic density, high torque density and power density, and low temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

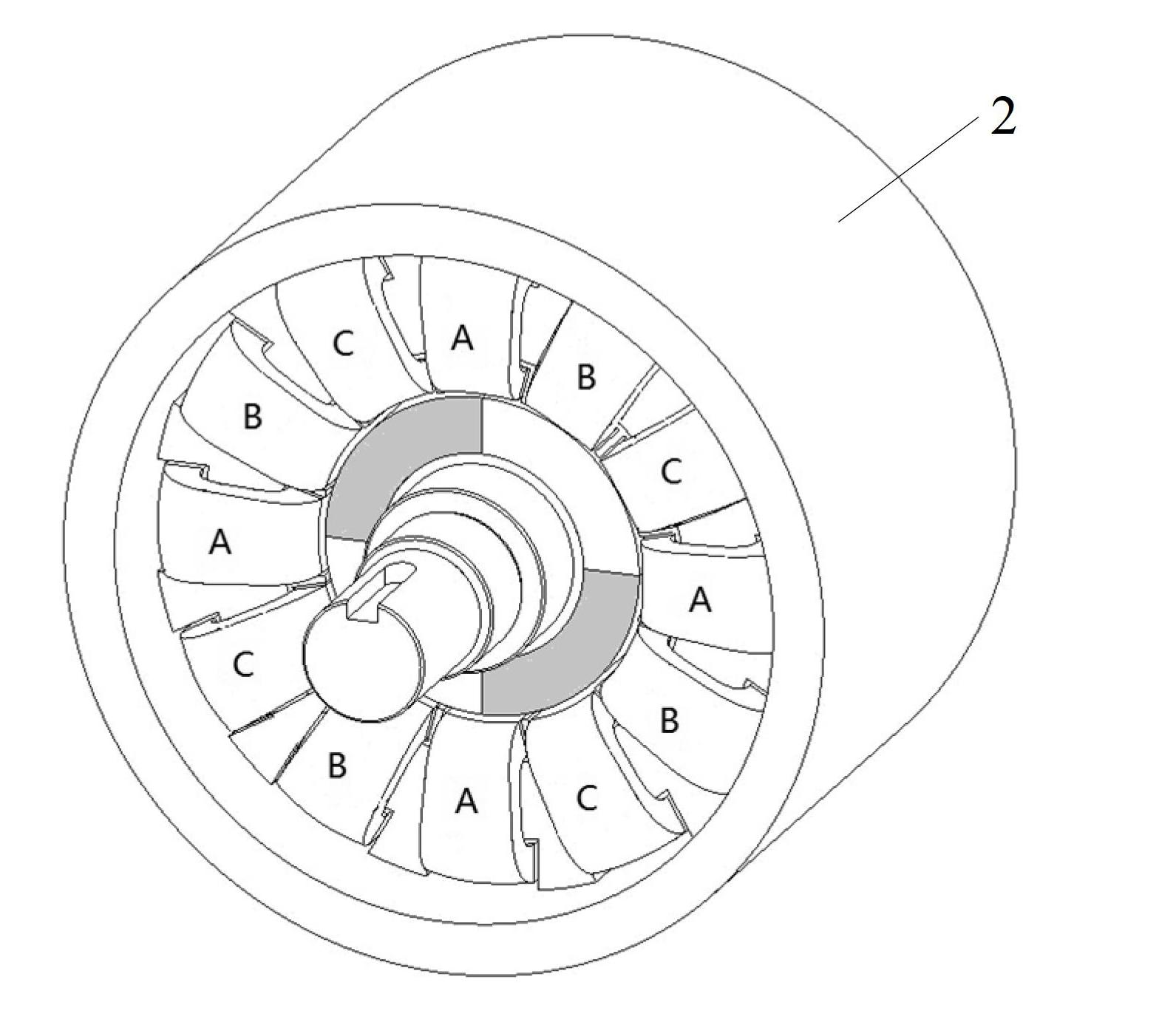

[0022] Specific implementation mode one, see Figures 1 to 5This embodiment will be described. A multi-phase permanent magnet motor with adjustable leakage reactance described in this embodiment is a cylindrical rotary motor, which includes a stator and a rotor, an air gap between the rotor and the stator, and the stator includes a stator core 1, a stator winding And the casing 2, the stator also includes a coil bobbin 3, the stator core is circular, the inner surface of the stator core is smooth, and the outer surface of the stator core is opened in the axial direction, and the through slot is the stator core Slot 1-1, there are km core slots evenly distributed along the circumference on the outer surface of the stator core, a coil frame 3 is installed on the inner wall of the stator core, and the coil frame consists of a thin-walled tube 3-1 and km thin partitions 3- 2, where k is a natural number and m is the phase number of the stator winding. The thin partitions 3-2 are...

specific Embodiment approach 2

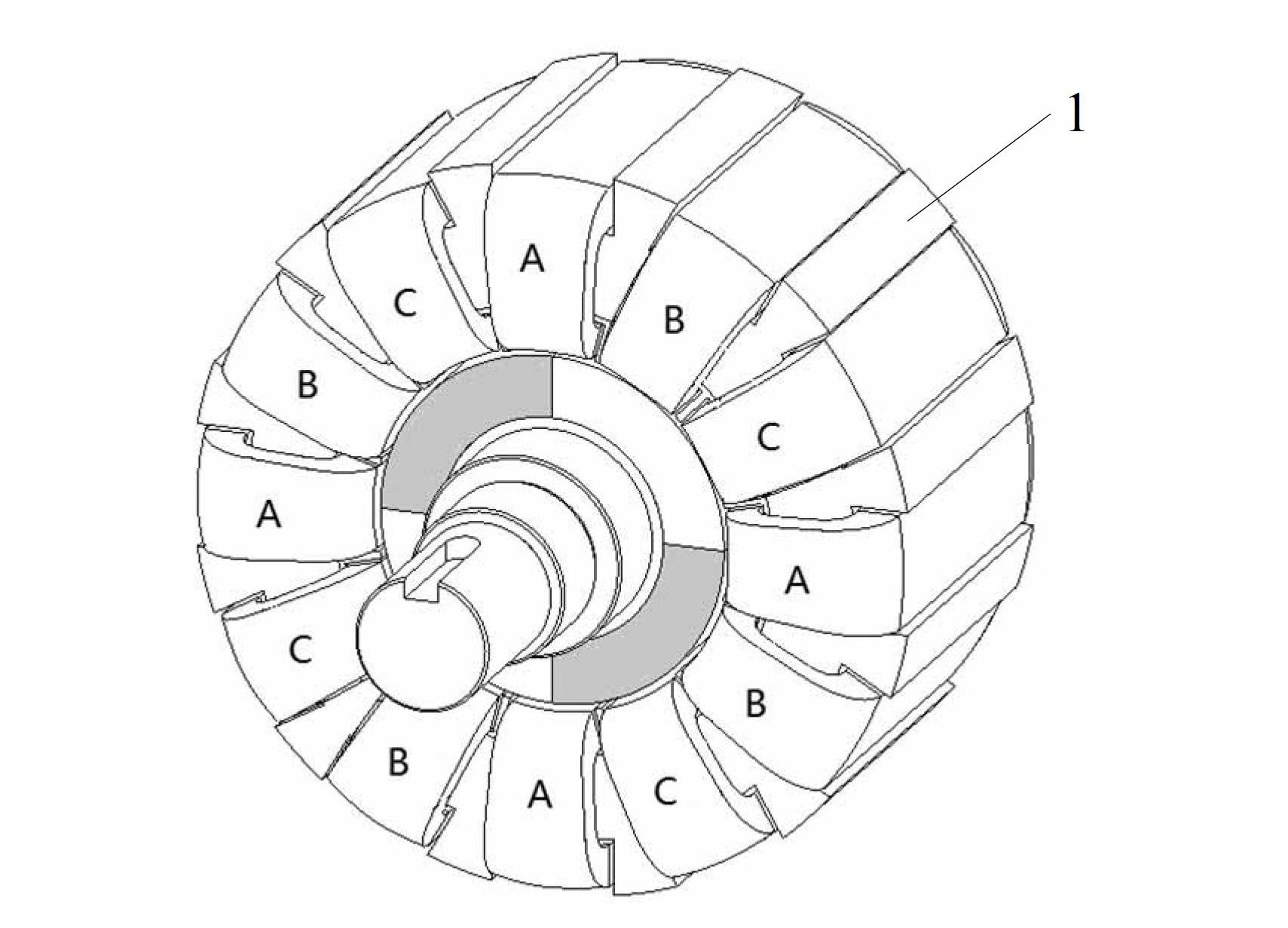

[0025] Specific implementation mode two, see Figure 6 and 7 The present embodiment is illustrated. The multi-phase permanent magnet motor with adjustable leakage reactance described in this embodiment is a cylindrical rotary motor, which includes a stator and a rotor. There is an air gap between the rotor and the stator. The stator includes a stator core 1, a stator winding and a motor. Shell 2, the stator also includes a coil bobbin 3, the stator core is circular, the inner surface of the stator core is smooth, and the outer surface of the stator core is axially opened with slots, and the slots are stator core slots 1 -1, there are km core slots evenly distributed along the circumference on the outer surface of the stator core, and the coil frame 3 is installed on the inner wall of the stator core, and the coil frame is composed of a thin-walled tube 3-1 and km thin partitions 3-2 , wherein, k is a natural number, m is the phase number of the stator winding, the thin parti...

specific Embodiment approach 3

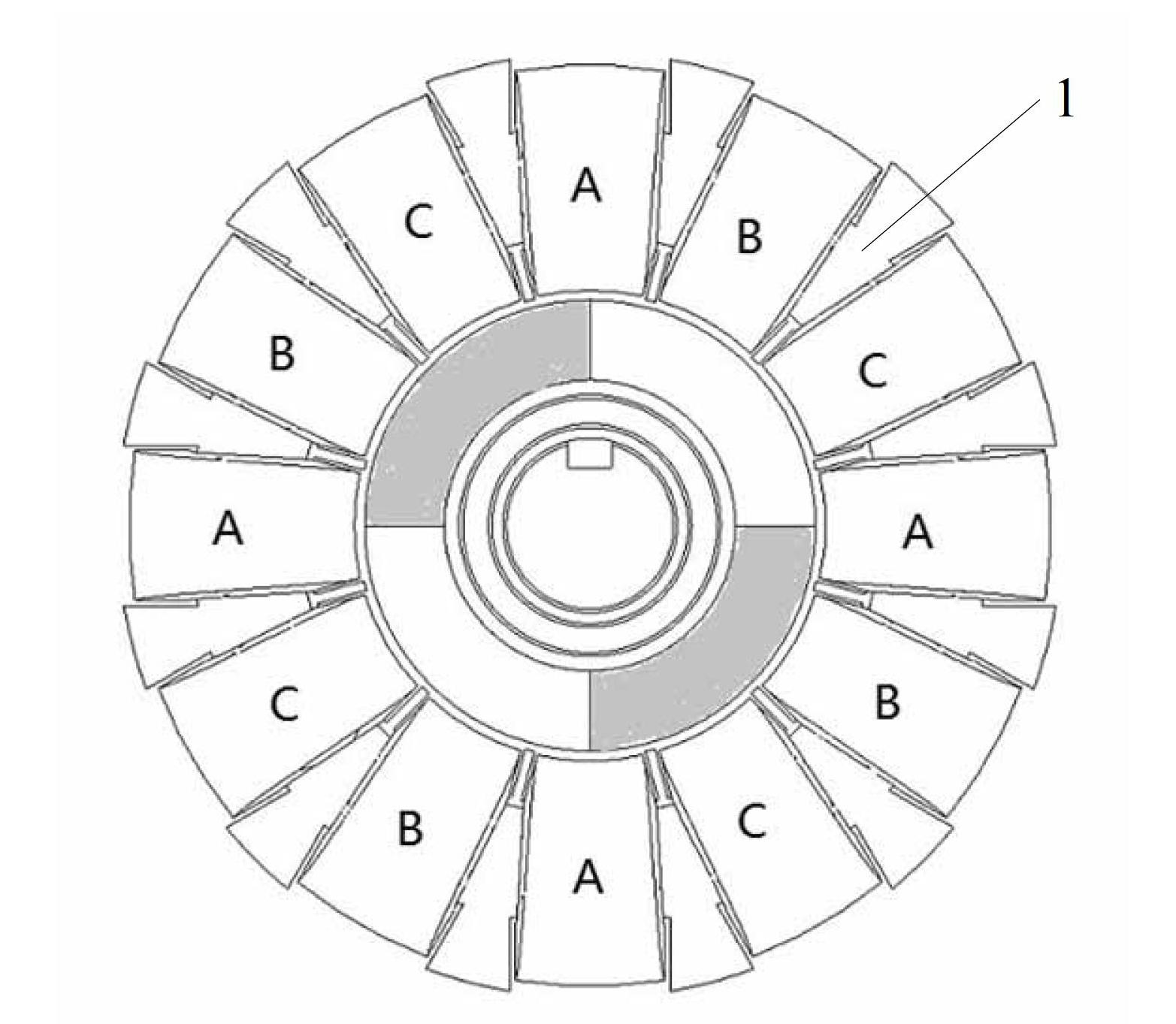

[0028] Specific implementation mode three, see Figure 7 , 8 , 9 and 10 illustrate this embodiment. The multi-phase permanent magnet motor with adjustable leakage reactance described in this embodiment is a cylindrical rotary motor, which includes a stator and a rotor. There is an air gap between the rotor and the stator. The stator includes a stator core 1, a stator winding and a motor. Shell 2, the stator also includes a coil bobbin 3, the stator core is circular, the inner surface of the stator core is smooth, and the outer surface of the stator core is axially opened with slots, and the slots are stator core slots 1 -1, there are 2km core slots evenly distributed along the circumference on the outer surface of the stator core, and the coil frame 3 is installed on the inner wall of the stator core, and the coil frame is composed of a thin-walled tube 3-1 and 2km thin partitions 3-2 , wherein, k is a natural number, m is the phase number of the stator winding, the thin par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com